ASTM B251-97

(Specification)Standard Specification for General Requirements for Wrought Seamless Copper and Copper-Alloy Tube

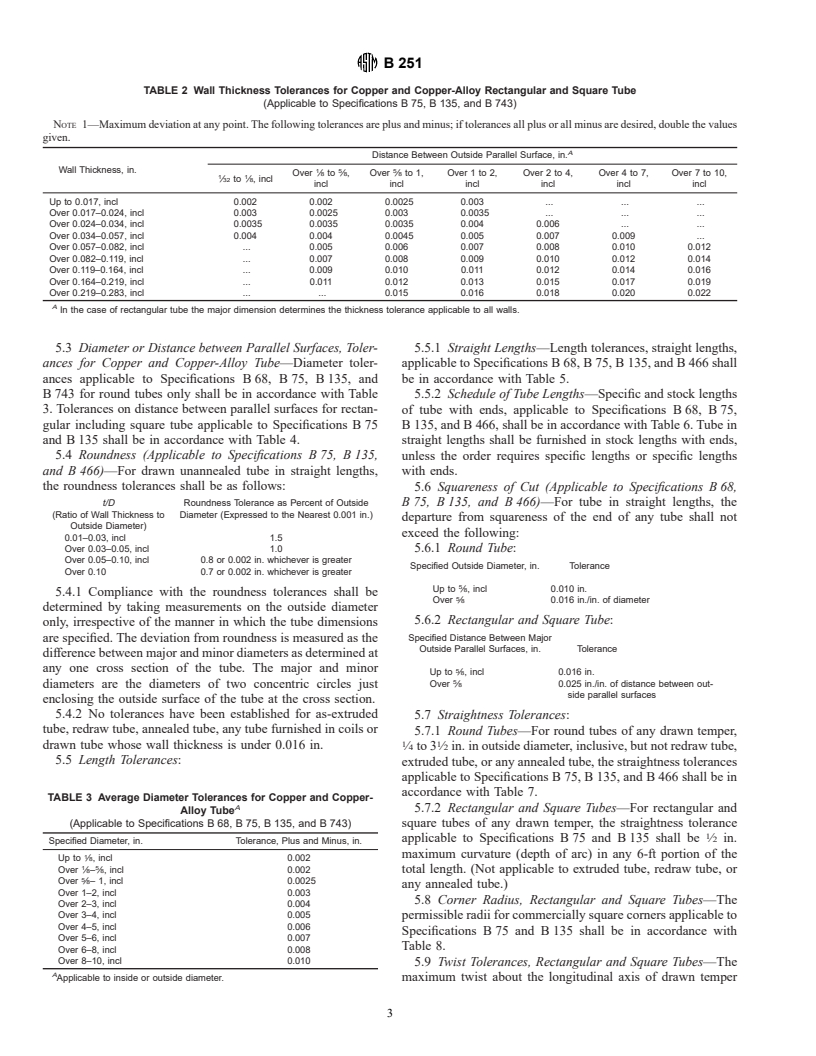

Standard Specification for General Requirements for Wrought Seamless Copper and Copper-Alloy Tube

SCOPE

1.1 This specification covers a group of general requirements common to several wrought product specifications. Unless otherwise specified in the purchase order, or in an individual specification, these general requirements shall apply to copper and copper-alloy tube supplied under Specifications B 68, B 75, B 135, B 466, and B 743.

Note 1-A complete metric companion to Specification B 251 has been developed-B 251M; therefore, no metric equivalents are presented in this specification.

General Information

Relations

Standards Content (Sample)

Designation: B 251 – 97

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

General Requirements for Wrought Seamless Copper and

1

Copper-Alloy Tube

This standard is issued under the fixed designation B 251; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

4

1. Scope E 3 Methods of Preparation of Metallographic Specimens

4

E 8 Test Methods for Tension Testing of Metallic Materials

1.1 This specification covers a group of general require-

E 18 Test Methods for Rockwell Hardness and Rockwell

ments common to several wrought product specifications.

4

Superficial Hardness of Metallic Materials

Unless otherwise specified in the purchase order, or in an

E 29 Practice for Using Significant Digits in Test Data to

individual specification, these general requirements shall apply

5

Determine Conformance with Specifications

to copper and copper-alloy tube supplied under Specifications

6

E 53 Test Methods for Chemical Analysis of Copper

B 68, B 75, B 135, B 466, and B 743.

E 55 Practice for Sampling Wrought Nonferrous Metals and

NOTE 1—A complete metric companion to Specification B 251 has 6

Alloys for Determination of Chemical Composition

been developed—B 251M; therefore, no metric equivalents are presented

E 62 Test Methods for Chemical Analysis of Copper and

in this specification.

6

Copper Alloys (Photometric Methods)

4

E 112 Test Methods for Determining Average Grain Size

2. Referenced Documents

E 478 Test Methods for Chemical Analysis of Copper

2.1 The following documents of the issue in effect on date

7

Alloys

of material purchase form a part of this specification to the

extent referenced herein:

3. Terminology

2.2 ASTM Standards:

3.1 Definitions:

B 68 Specification for Seamless Copper Tube, Bright An-

3.1.1 average diameter (for round tubes only)—the average

2

nealed

of the maximum and minimum outside diameters, or maximum

2

B 75 Specification for Seamless Copper Tube

2 and minimum inside diameters, whichever is applicable, as

B 135 Specification for Seamless Brass Tube

determined at any one cross section of the tube.

B 153 Test Method for Expansion (Pin Test) of Copper and

2 3.1.2 coil—a length of the product wound into a series of

Copper-Alloy Pipe and Tubing

connected turns. The unqualified term “coil” as applied to tube

B 154 Test Method for Mercurous Nitrate Test for Copper

2 usually refers to a bunched coil.

and Copper Alloys

3.1.2.1 bunched—a coil in which the turns are bunched and

B 170 Specification for Oxygen-Free Electrolytic Copper—

2 held together such that the cross section of the bunched turns

Refinery Shapes

is approximately circular.

B 193 Test Method for Resistivity of Electrical Conductor

3.1.2.2 double layer flat—a coil in which the product is

3

Materials

spirally wound into two connected disk-like layers such that

B 428 Test Method for Angle of Twist in Rectangular and

one layer is on top of the other. (Sometimes called “double

2

Square Copper and Copper Alloy Tube

layer pancake coil” or “double layer spirally wound coil.”)

B 466 Specification for Seamless Copper-Nickel Pipe and

3.1.2.3 level or traverse wound—a coil in which the turns

2

Tube

are wound into layers parallel to the axis of the coil such that

B 643 Specification for Copper-Beryllium Alloy Seamless

successive turns in a given layer are next to one another.

2

Tube

(Sometimes called “helical coil.”)

2

B 743 Specification for Seamless Copper Tube in Coils

3.1.2.4 level or traverse wound on a reel or spool—a coil in

which the turns are positioned into layers on a reel or spool

1

This specification is under the jurisdiction of ASTM Committee B-5 on Copper

parallel to the axis of the reel or spool such that successive

and Copper Alloys and is the direct responsibility of Subcommittee B05.04 on Pipe

and Tube.

Current edition approved Feb. 10, 1997. Published April 1997. Originally

published as B 251 – 51 T. Last previous edition B 251 – 93. 4

Annual Book of ASTM Standards, Vol 03.01.

2

Annual Book of ASTM Standards, Vol 02.01. 5

Annual Book of ASTM Standards, Vol 14.02.

3

Annual Book of ASTM Standards, Vol 02.03. 6

Annual Book of ASTM Standards, Vol 03.05.

7

Annual Book of ASTM Standards, Vol 03.06.

1

---------------------- Page: 1 ----------------------

B 251

turns in a given layer are next to one another. of sizes commercially known as Automotive and General

3.1.2.5 single layer flat—a coil in which the product is Service Tube.

spirally wound into a single disk-like layer. (Sometimes called 3.1.5.2 tube, seamless—a tube produced with a continuous

“pancake coil” or “single layer spirally wound coil

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.