ASTM A891/A891M-10(2015)

(Specification)Standard Specification for Precipitation Hardening Iron Base Superalloy Forgings for Turbine Rotor Disks and Wheels

Standard Specification for Precipitation Hardening Iron Base Superalloy Forgings for Turbine Rotor Disks and Wheels

ABSTRACT

This specification covers precipitation hardened iron base superalloy forgings which are primarily intended for use as turbine rotor disks and wheels. Two heat treatments are covered and selection will depend upon design, service conditions, mechanical properties, and elevated temperature characteristics. The material shall be made by vacuum melting followed by consumable electrode vacuum arc or electroslag remelting. The forgings shall undergo the following tests: tension test, hardness test, stress rupture test, and creep test. Also, the forgings shall be subjected to non-destructive examinations like ultrasonic examination and liquid penetrant examination. The forgings shall be uniform in quality and condition, clean, sound, and free of cracks, seams, laps, shrinkage, and other injurious imperfections.

SCOPE

1.1 This specification covers precipitation hardening iron base superalloy forgings which are primarily intended for use as turbine rotor disks and wheels.

1.2 Two heat treatments are covered. Selection will depend upon design, service conditions, mechanical properties, and elevated temperature characteristics.

1.3 All of the provisions of Specification A788/A788M, apply, except as amended herein.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A891/A891M −10(Reapproved 2015)

Standard Specification for

Precipitation Hardening Iron Base Superalloy Forgings for

Turbine Rotor Disks and Wheels

This standard is issued under the fixed designationA891/A891M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 Stress Rupture Test—Parameters for material fur-

nished in condition 2 of 7.3.3.

1.1 This specification covers precipitation hardening iron

3.1.3 Forging Drawing—Each forging shall be manufac-

base superalloy forgings which are primarily intended for use

tured in accordance with a drawing furnished by the purchaser

as turbine rotor disks and wheels.

showing the dimensions of the forging and the location of

1.2 Two heat treatments are covered. Selection will depend

mechanical test specimens.

upon design, service conditions, mechanical properties, and

3.1.4 Include the information specified in Specification

elevated temperature characteristics.

A788/A788M.

1.3 All of the provisions of Specification A788/A788M,

apply, except as amended herein.

4. Condition and Heat Treatment

1.4 The values stated in either SI units or inch-pound units

4.1 The forgings covered in this specification may be

are to be regarded separately as standard. The values stated in

ordered in two different solution treated and aged conditions:

each system may not be exact equivalents; therefore, each

4.1.1 Type 1:

system shall be used independently of the other. Combining

4.1.1.1 Solution anneal at 1650 6 25°F [900 6 14°C] for 2

values from the two systems may result in non-conformance

to5hat temperature liquid quench.

with the standard.

4.1.1.2 Precipitation harden at 1420 6 15°F [770 6 8°C]

for 16 h at temperature air cool; 1200 6 15°F [650 6 8°C] for

2. Referenced Documents

16 h at temperature air cool.

2.1 ASTM Standards:

4.1.2 Type 2:

A788/A788M Specification for Steel Forgings, General Re-

4.1.2.1 Solution anneal at 1800 6 25°F [980 6 14°C] for 2

quirements

to5hat temperature liquid quench.

E112 Test Methods for Determining Average Grain Size

4.1.2.2 Precipitation harden at 1420 6 15°F [770 6 8°C]

E139 Test Methods for Conducting Creep, Creep-Rupture,

for 16 h at temperature air cool; 1200 6 15°F [650 6 8°C] for

and Stress-Rupture Tests of Metallic Materials

16 h at temperature air cool.

E165/E165M Practice for Liquid Penetrant Examination for

General Industry

5. Manufacture

E292 Test Methods for Conducting Time-for-Rupture Notch

Tension Tests of Materials

5.1 The material shall be made by vacuum melting followed

by consumable electrode vacuum arc or electroslag remelting

3. Ordering Information

as agreed upon between producer and user.

3.1 Orders for material under this specification shall include

5.2 The forgings shall be upset forged so that the axis of the

the following:

disk corresponds with that of the ingot.

3.1.1 Condition—See Section 4.

6. Chemical Requirements

This specification is under the jurisdiction of Committee A01 on Steel,

6.1 Heat Analysis—Each heat shall be analyzed by the

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.06 on Steel Forgings and Billets.

manufacturer in accordance with Specification A788/A788M.

Current edition approved March 1, 2015. Published March 2015. Originally

The chemical composition shall conform to the requirements

approved in 1988. Last previous edition approved in 2010 as A891/A891M – 10.

specified in Table 1.

DOI: 10.1520/A0891_A0891M-10R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.2 Product Analysis—The purchaser may obtain a product

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

analysis, representing each heat or multiple heat, in accordance

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. with the provisions of Specification A788/A788M.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A891/A891M−10 (2015)

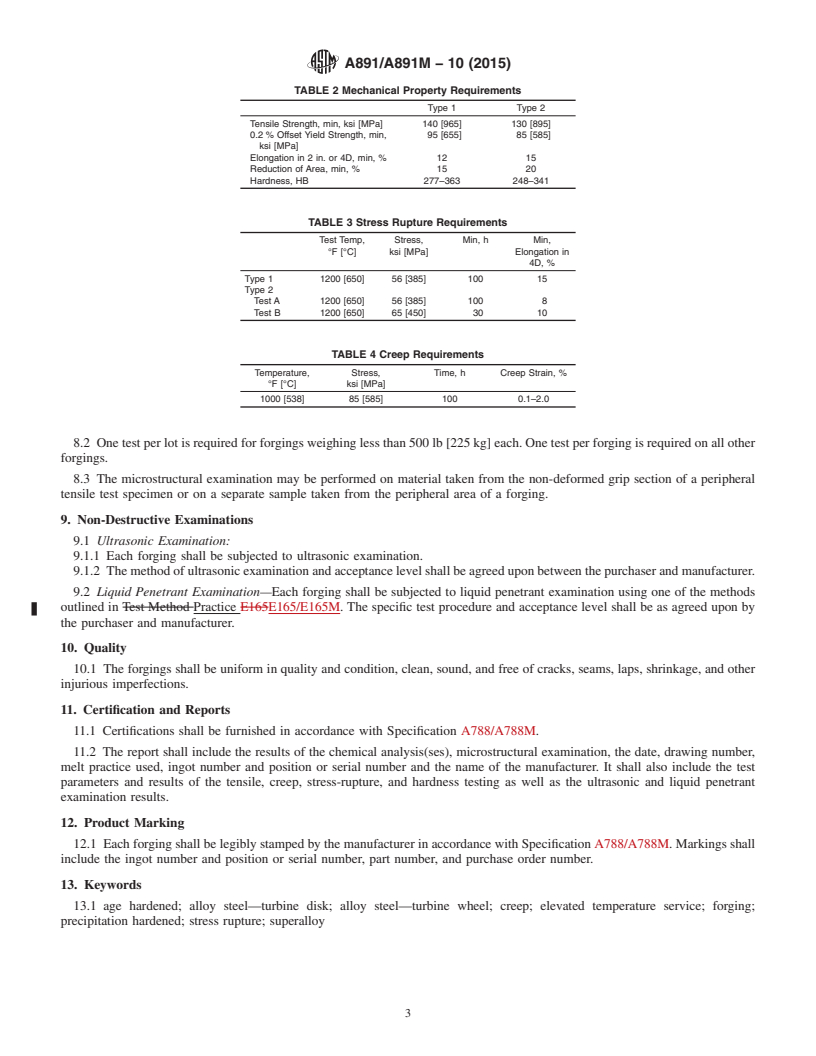

TABLE 1 Chemical Composition TABLE 3 Stress Rupture Requirements

Element Heat Analysis Range, Test Temp, Stress, Min, h Min,

Percentage °F [°C] ksi [MPa] Elongation in

4D, %

Carbon 0.05 max

Manganese 0.50 max Type 1 1200 [650] 56 [385] 100 15

Silicon 0.50 max Type 2

Test A 1200 [650] 56 [385] 100 8

Phosphorus 0.025 max

Sulfur 0.015 max Test B 1200 [650] 65 [450] 30 10

Chromium 13.50–16.00

Nickel 24.00–27.00

Molybdenum 1.00–1.50

TABLE 4 Creep Requirements

Titanium 1.90–2.35

Boron 0.003–0.010

Temperature, Stress, Time, h Creep Strain, %

°F [°C] ksi [MPa]

Vanadium 0.10–0.50

1000 [538] 85 [585] 100 0.1–2.0

Aluminum 0.35 max

Iron remainder

7. Mechanical Properties

7.5.2 For forgings weighing 500 to 2000 lb [225 to 900 kg]

7.1 The forgings shall conform to the mechanical property

one tension, stress rupture, and creep test, and two hardness

requirements specified in Table 2 after heat treatment as

tests shall be made on each forging.

prescribed in 4.1.

7.5.3 For forgings weighing over 2000 lb [900 kg] testing

7.2 Tension and Hardness—Tension and hardness testing

shall be performed as covered in Supplementary Requirement

shall be conducted in accordance with Specification A788/

S1.Inaddition,onetangentialtension,stressrupture,andcreep

A788M.

test shall be run on material taken from the forging hub.

7.3 Stress Rupture:

7.6 Test Location:

7.3.1 Combinationsmoothandnotchedbarspecimensusing

7.6.1 The tension, stress rupture, and creep specimens

0.252 in. [6.4 mm] diameter bars shall be tested to rupture in

covered in 7.5.1 and 7.5.2 shall be machined from tangential

accordancewithTestMethodsE292.Rupturemustoccurinthe

bars taken from the forging rim.

smooth section of each specimen.After 100 h, samples may be

7.6.2 Hardness tests shall be taken on both the rim and hub.

uploaded in 5-ksi [35-MPa] increments in 8 to 16 h intervals.

7.3.2 Material

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A891/A891M − 10 A891/A891M − 10 (Reapproved 2015)

Standard Specification for

Precipitation Hardening Iron Base Superalloy Forgings for

Turbine Rotor Disks and Wheels

This standard is issued under the fixed designation A891/A891M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*Scope

1.1 This specification covers precipitation hardening iron base superalloy forgings which are primarily intended for use as

turbine rotor disks and wheels.

1.2 Two heat treatments are covered. Selection will depend upon design, service conditions, mechanical properties, and elevated

temperature characteristics.

1.3 All of the provisions of Specification A788/A788M, apply, except as amended herein.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

2. Referenced Documents

2.1 ASTM Standards:

A788/A788M Specification for Steel Forgings, General Requirements

E112 Test Methods for Determining Average Grain Size

E139 Test Methods for Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials

E165E165/E165M Practice for Liquid Penetrant Examination for General Industry

E292 Test Methods for Conducting Time-for-Rupture Notch Tension Tests of Materials

3. Ordering Information

3.1 Orders for material under this specification shall include the following:

3.1.1 Condition—See Section 4.

3.1.2 Stress Rupture Test—Parameters for material furnished in condition 2 of 7.3.3.

3.1.3 Forging Drawing—Each forging shall be manufactured in accordance with a drawing furnished by the purchaser showing

the dimensions of the forging and the location of mechanical test specimens.

3.1.4 Include the information specified in Specification A788/A788M.

4. Condition and Heat Treatment

4.1 The forgings covered in this specification may be ordered in two different solution treated and aged conditions:

4.1.1 Type 1:

4.1.1.1 Solution anneal at 1650 6 25°F [900 6 14°C] for 2 to 5 h at temperature liquid quench.

4.1.1.2 Precipitation harden at 1420 6 15°F [770 6 8°C] for 16 h at temperature air cool; 1200 6 15°F [650 6 8°C] for 16

h at temperature air cool.

4.1.2 Type 2:

4.1.2.1 Solution anneal at 1800 6 25°F [980 6 14°C] for 2 to 5 h at temperature liquid quench.

4.1.2.2 Precipitation harden at 1420 6 15°F [770 6 8°C] for 16 h at temperature air cool; 1200 6 15°F [650 6 8°C] for 16

h at temperature air cool.

This specification is under the jurisdiction of Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.06 on

Steel Forgings and Billets.

Current edition approved Nov. 1, 2010March 1, 2015. Published December 2010March 2015. Originally approved in 1988. Last previous edition approved in 20082010

as A891/A891M – 08.A891/A891M – 10. DOI: 10.1520/A0891_A0891M-10. 10.1520/A0891_A0891M-10R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A891/A891M − 10 (2015)

5. Manufacture

5.1 The material shall be made by vacuum melting followed by consumable electrode vacuum arc or electroslag remelting as

agreed upon between producer and user.

5.2 The forgings shall be upset forged so that the axis of the disk corresponds with that of the ingot.

6. Chemical Requirements

6.1 Heat Analysis—Each heat shall be analyzed by the manufacturer in accordance with Specification A788/A788M. The

chemical composition shall conform to the requirements specified in Table 1.

6.2 Product Analysis—The purchaser may obtain a product analysis, representing each heat or multiple heat, in accordance with

the provisions of Specification A788/A788M.

7. Mechanical Properties

7.1 The forgings shall conform to the mechanical property requirements specified in Table 2 after heat treatment as prescribed

in 4.1.

7.2 Tension and Hardness—Tension and hardness testing shall be conducted in accordance with Specification A788/A788M.

7.3 Stress Rupture:

7.3.1 Combination smooth and notched bar specimens using 0.252 in. [6.4 mm] diameter bars shall be tested to rupture in

accordance with Test Methods E292. Rupture must occur in the smooth section of each specimen. After 100 h, samples may be

uploaded in 5-ksi [35-MPa] increments in 8 to 16 h intervals.

7.3.2 Material supplied as Type 1 shall meet the stress rupture requirements specified in Table 3.

7.3.3 Material supplied as Type 2 shall meet the stress rupture requirements of either Test A or Test B of Table 3 as specified

by the purchaser.

7.4 Creep:

7.4.1 A creep test shall be performed in accordance with Test Methods E139 on a 0.252 in. [6.4 mm] diameter smooth bar.

7.4.2 The material shall meet the requirements specified in Table 4 after heat treatment as prescribed in 4.1.

7.5 Number of Tests—The testing frequency shall be as follows with a lot being defined as not more than 50 pieces of the same

part made from the same heat of material to the same forging parameters, forged within an 8 h period, and heat treated together:

7.5.1 For forgings weighing less than 500 lb [225 kg] each, one tension, stress rupture, and creep test shall be made on one

forging per lot. In addition, two hardness tests shall be made on each piece in the lot.

7.5.2 For forgings weighing 500 to 2000 lb [225 to 900 kg] one tension, stress rupture, and creep test, and two hardness tests

shall be made on each forging.

7.5.3 For forgings weighing over 2000 lb [900 kg] testing shall be performed as covered in Supplementary Requirement S1.

In addition,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.