ASTM D3000-95ae1

(Specification)Standard Specification for Polybutylene (PB) Plastic Pipe (SDR-PR) Based on Outside Diameter (Withdrawn 2003)

Standard Specification for Polybutylene (PB) Plastic Pipe (SDR-PR) Based on Outside Diameter (Withdrawn 2003)

SCOPE

1.1 This specification covers polybutylene (PB) pipe that is outside diameter controlled, made in standard thermoplastic pipe dimension ratios, and pressure rated for water (see Appendix). Included are criteria for classifying PB plastic pipe materials and PB plastic pipe, a system of nomenclature for PB plastic pipe, and requirements and methods of test for materials, workmanship, dimensions, sustained pressure, and burst pressure. Methods of marking are also given.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following safety hazards caveat pertains only to the test methods portion, Section 7, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

An American National Standard

e1

Designation: D 3000 – 95a

Standard Specification for

Polybutylene (PB) Plastic Pipe (SDR-PR) Based on Outside

Diameter

This standard is issued under the fixed designation D 3000; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Changes were made editorially in October 1999.

1. Scope moplastic Pipe and Fittings

D 2581 Specification for Polybutylene (PB) Plastics Mold-

1.1 This specification covers polybutylene (PB) pipe that is

ing and Extrusion Materials

outside diameter controlled, made in standard thermoplastic

D 2837 Test Method for Obtaining Hydrostatic Design

pipe dimension ratios, and pressure rated for water (see

Basis for Thermoplastic Pipe Materials

Appendix). Included are criteria for classifying PB plastic pipe

F 412 Terminology Relating to Plastic Piping Systems

materials and PB plastic pipe, a system of nomenclature for PB

2.2 NSF Standard:

plastic pipe, and requirements and methods of test for materi-

Standard No. 14 for Plastic Piping Components and Related

als, workmanship, dimensions, sustained pressure, and burst

Materials

pressure. Methods of marking are also given.

Standard No. 61 for Drinking Water Systems

1.2 The values stated in SI units are to be regarded as the

Components—Health Effects

standard. The values given in parentheses are for information

only.

3. Terminology

1.3 The following safety hazards caveat pertains only to the

3.1 Definitions—Definitions are in accordance with Termi-

test methods portion, Section 7, of this specification: This

nology F 412, and abbreviations are in accordance with Ter-

standard does not purport to address all of the safety concerns,

minologyD 1600,unlessotherwisespecified.Theabbreviation

if any, associated with its use. It is the responsibility of the user

for polybutylene plastic is PB.

of this standard to establish appropriate safety and health

3.2 Definitions of Terms Specific to This Standard:

practices and determine the applicability of regulatory limita-

3.2.1 hydrostatic design stress— the estimated maximum

tions prior to use.

tensile stress in the wall of the pipe in the circumferential

2. Referenced Documents orientation due to internal hydrostatic water pressure that can

be applied continuously with a high degree of certainty that

2.1 ASTM Standards:

failure of the pipe will not occur.

D 618 Practice for Conditioning Plastics and Electrical

2 3.2.2 pressure rating (PR)—the estimated maximum pres-

Insulating Materials for Testing

sure that water in the pipe can exert continuously with a high

D 1598 Test Method for Time-to-Failure of Plastic Pipe

3 degree of certainty that failure of the pipe will not occur.

Under Constant Internal Pressure

3.2.3 relation between standard dimension ratio, hydro-

D 1599 TestMethodforShort-TimeHydraulicFailurePres-

3 static design stress, and pressure rating—thefollowingexpres-

sure of Plastic Pipe, Tubing, and Fittings

sion, commonly known as the ISO equation, is used in this

D 1600 Terminology for Abbreviated Terms Relating to

specification to relate standard dimension ratio, hydrostatic

Plastics

design stress, and pressure rating:

D 1603 Test Method for Carbon Black in Olefin Plastics

D 2122 Test Method for Determining Dimensions of Ther- 2S/P 5 R 2 1, or 2S/P 5 D /t!2 1 (1)

~

O

where:

ThisspecificationisunderthejurisdictionofASTMCommitteeF-17onPlastic

Piping Systems and is the direct responsibility of Subcommittee F17.26 on Olefin

Based Pipe. Annual Book of ASTM Standards, Vol 08.02.

Current edition approved Sept. 10, 1995. Published November 1995. Originally Available from the National Sanitation Foundation, P.O. Box 1468,AnnArbor,

published as D 3000 – 71. Last previous edition D 3000 – 95. MI 48106.

2 6

Annual Book of ASTM Standards, Vol 08.01. ISO R 161–1960, Pipes of Plastics Materials for the Transport of Fluids

Annual Book of ASTM Standards, Vol 08.04. (Outside Diameters and Nominal Pressures) Part 1, Metric Series.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

D 3000 – 95a

6. Requirements

S = hydrostatic design stress, Pa (or psi),

P = pressure rating, Pa (or psi),

6.1 Workmanship—The pipe shall be homogeneous

D = average outside diameter, mm (or in.),

O

throughout and free from visible cracks, holes, foreign inclu-

t = minimum wall thickness, mm (or in.), and

sions, or other defects. The pipe shall be as uniform as

R = standardthermoplasticpipedimensionratio(D /tfor

O

commercially practicable in color, opacity, density, and other

PB pipe).

physical properties.

3.2.4 standard thermoplastic pipe dimension ratio (SDR)—

6.2 Dimensions and Tolerances:

the standard thermoplastic pipe dimension ratio (SDR) is the

6.2.1 Outside Diameters—The outside diameters and toler-

ratio of pipe diameter to wall thickness. For PB pipe it is

ances shall be as shown in Table 1 when measured in

calculated by dividing the average outside diameter of the pipe

accordance with 7.4 and 7.4.1. Maximum and minimum

in millimetres or in inches by the minimum wall thickness in

(out-of-roundness) tolerances apply only to measurements

millimetres or in inches. If the wall thickness calculated by this

made on pipe prior to coiling, or as rounded by manufacturer’s

formula is less than 1.60 mm (0.062 in.), it shall be arbitrarily

recommended rounding tool.

increased to 1.60 mm. The SDR values shall be rounded to the

6.2.2 Wall Thicknesses—The wall thicknesses and toler-

nearest 0.5.

ances shall be as shown in Table 2 when measured in

3.2.5 standard thermoplastic pipe materials designation

accordance with 7.4 and 7.4.2.

code—the pipe materials designation code shall consist of the

6.2.3 Wall Thickness Range—Thewallthicknessrangeshall

abbreviation PB for the type of plastic, followed by theASTM

be within 12 % when measured in accordance with 7.4 and

type and grade in Arabic numerals and the hydrostatic design

7.4.3.

stress in units of 100 psi with any decimal figures dropped.

6.3 Carbon Black—The polybutylene pipe extrusion com-

Wherethehydrostaticdesignstresscodecontainslessthantwo

pound, Type II, Grade 1, Class C, shall contain at least 2 %

figures, a cipher shall be used before the number. Thus a

carbon black when tested in accordance with 7.5.

complete number code shall consist of two letters and four

6.4 Sustained Pressure—The pipe shall not fail, balloon,

figures for PB plastic pipe materials (see 5.2).

burst, or weep as defined in Test Method D 1598, at the test

pressures calculated to produce the specified fiber stress for

4. Pipe Classification

each specimen’s physical dimensions, when tested in accor-

dance with 7.6.

4.1 General—This specification covers PB pipe made from

6.5 Burst Pressure—The minimum burst pressure for PB

one PB plastic pipe material in four standard dimension ratios

plastic pipe shall be as calculated to produce the specified fiber

and four water pressure ratings.

stress for each specimen’s physical dimensions, when deter-

4.2 Standard Thermoplastic Pipe Dimension Ratios

mined in accordance with 7.7 and Table 3.

(SDR)—This specification covers PB pipe in four standard

dimensionratios,namely9,11,13.5,and17.Thesearereferred

7. Test Methods

to as SDR 9, SDR 11, SDR 13.5, and SDR 17, respectively.

The pressure rating is uniform for all nominal pipe sizes for a 7.1 Conditioning—Because of the crystalline transforma-

given PB pipe material and SDR (see Table X1.1). tion which takes place after polybutylene resins are cooled

from the melt, it is necessary to delay physical testing until 10

5. Materials days after pipe extrusion. During this 10-day period the pipe

shall be stored at temperatures between 4.4 and 37.8° C (40

5.1 General—Polybutylene plastics used to make pipe

and 100° F). The test specimen shall be taken after 8 days and

meeting the requirements of this specification are categorized

conditioned at 23 6 2° C (73.4 6 3.6° F) and 50 6 5%

by means of two criteria, namely (1) short-term strength tests,

relative humidity for not less than 40 h prior to test in

and(2)long-termtests.Sincethemaximumphysicalproperties

of the pipe are not developed until 10 days after extrusion,

burst testing must be delayed for this period.

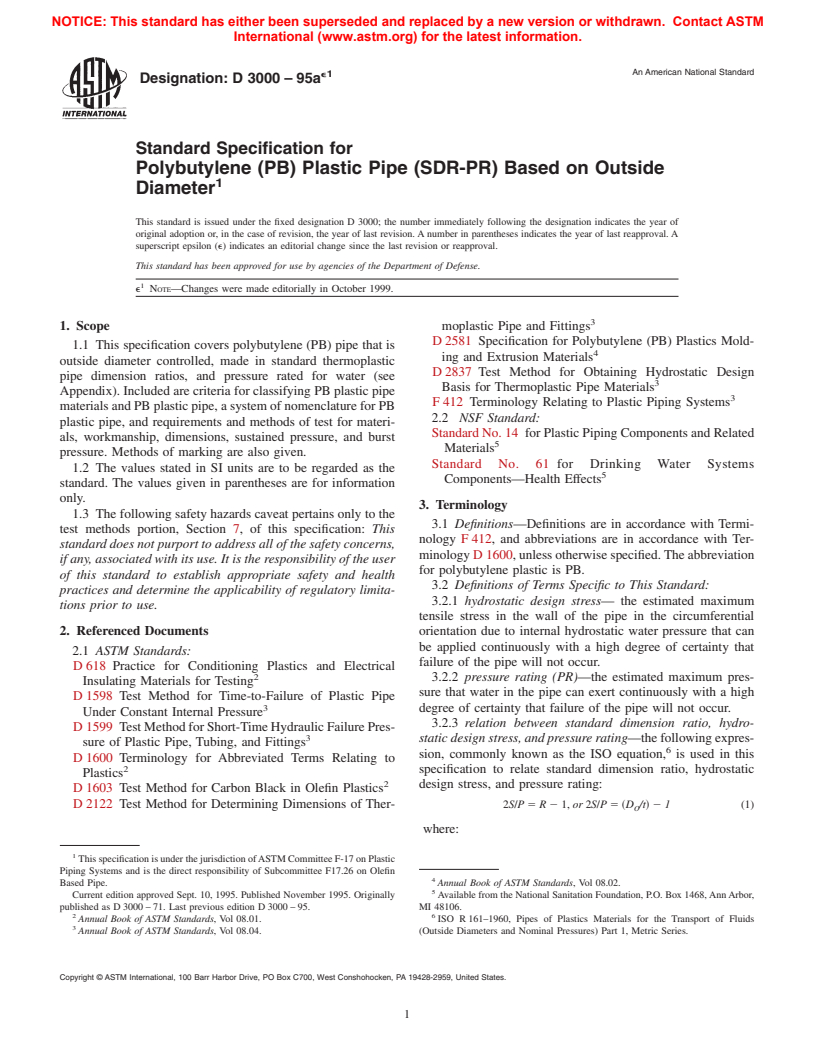

TABLE 1 Outside Diameters and Tolerances for PB Plastic Pipe

5.2 Basic Materials—This specification covers PB pipe

made from Type II, Grade 1 (PB) Plastic as defined in

Tolerances

Nominal Average

Specification D 2581.

For For Max and Min

Pipe Outside

Average, (Out-of-Round-

5.3 Hydrostatic Design Stress—This specification covers

Size, in. Diameter, in.

A

in. ness), in.

PB pipe made from PB plastics as defined by hydrostatic

⁄2 0.840 60.004 60.008

design stress developed on the basis of long-term tests (Ap-

⁄4 1.050 60.004 60.010

pendix).

1 1.315 60.005 60.010

1 ⁄4 1.660 60.005 60.012

5.4 Compound—The PB plastic extrusion compound shall

1 ⁄2 1.900 60.006 60.012

meet the requirements of Type II, Grade 1, Class B, or Class C

2 2.375 60.006 60.012

as described in Specification D 2581. 2 ⁄2 2.875 60.007 60.015

3 3.500 60.008 60.015

5.5 Rework Material—Clean, rework material generated

4 4.500 60.009 60.015

from the manufacturer’s own pipe production, is capable of

6 6.625 60.011 60.035

being used by the same manufacturer, as long as the pipe A

Maximumandminimum(out-of-roundness)applyonlytomeasurementsmade

produced meets all the requirements of this specification. onpipeasextruded,orasroundedbymanufacturersrecommendedroundingtool.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

D 3000 – 95a

A

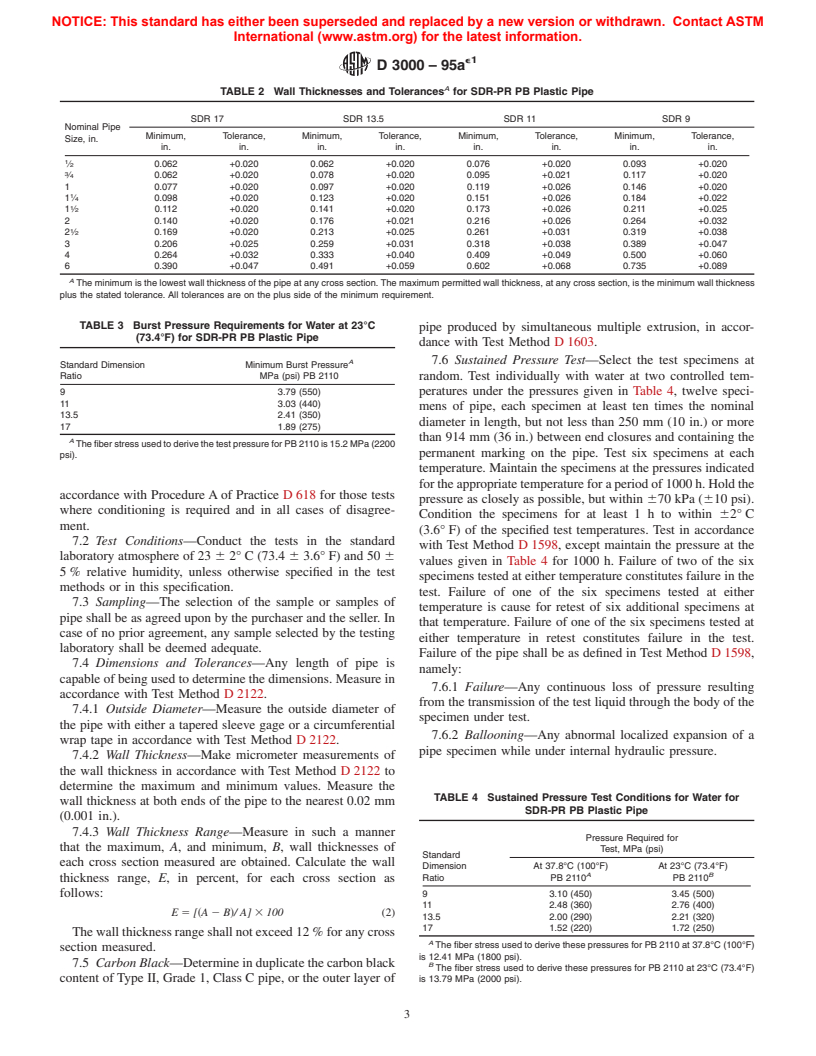

TABLE 2 Wall Thicknesses and Tolerances for SDR-PR PB Plastic Pipe

SDR 17 SDR 13.5 SDR 11 SDR 9

Nominal Pipe

Minimum, Tolerance, Minimum, Tolerance, Minimum, Tolerance, Minimum, Tolerance,

Size, in.

in. in. in. in. in. in. in. in.

⁄2 0.062 +0.020 0.062 +0.020 0.076 +0.020 0.093 +0.020

⁄4 0.062 +0.020 0.078 +0.020 0.095 +0.021 0.117 +0.020

1 0.077 +0.020 0.097 +0.020 0.119 +0.026 0.146 +0.020

1 ⁄4 0.098 +0.020 0.123 +0.020 0.151 +0.026 0.184 +0.022

1 ⁄2 0.112 +0.020 0.141 +0.020 0.173 +0.026 0.211 +0.025

2 0.140 +0.020 0.176 +0.021 0.216 +0.026 0.264 +0.032

2 ⁄2 0.169 +0.020 0.213 +0.025 0.261 +0.031 0.319 +0.038

3 0.206 +0.025 0.259 +0.031 0.318 +0.038 0.389 +0.047

4 0.264 +0.032 0.333 +0.040 0.409 +0.049 0.500 +0.060

6 0.390 +0.047 0.491 +0.059 0.602 +0.068 0.735 +0.089

A

Theminimumisthelowestwallthicknessofthepipeatanycrosssection.Themaximumpermittedwallthickness,atanycrosssection,istheminimumwallthickness

plus the stated tolerance. All tolerances are on the plus side of the minimum requirement.

TABLE 3 Burst Pressure Requirements for Water at 23°C

pipe produced by simultaneous multiple extrusion, in accor-

(73.4°F) for SDR-PR PB Plastic Pipe

dance with Test Method D 1603.

A 7.6 Sustained Pressure Test—Select the test specimens at

Standard Dimension Minimum Burst Pressure

Ratio MPa (psi) PB 2110 random. Test individually with water at two controlled tem-

9 3.79 (550) peratures under the pressures given in Table 4, twelve speci-

11 3.03 (440)

mens of pipe, each specimen at least ten times the nominal

13.5 2.41 (350)

diameter in length, but not less than 250 mm (10 in.) or more

17 1.89 (275)

than 914 mm (36 in.) between end closures and containing the

A

ThefiberstressusedtoderivethetestpressureforPB2110is15.2MPa(2200

permanent marking on the pipe. Test six specimens at each

psi).

temperature. Maintain the specimens at the pressures indicated

fortheappropriatetemperatureforaperiodof1000h.Holdthe

accordance with Procedure A of Practice D 618 for those tests

pressure as closely as possible, but within 670 kPa (610 psi).

where conditioning is required and in all cases of disagree-

Condition the specimens for at least1hto within 62° C

ment.

(3.6° F) of the specified test temperatures. Test in accordance

7.2 Test Conditions—Conduct the tests in the standard

with Test Method D 1598, except maintain the pressure at the

laboratory atmosphere of 23 6 2° C (73.4 6 3.6° F) and 50 6

values given in Table 4 for 1000 h. Failure of two of the six

5 % relative humidity, unless otherwise specified in the test

specimens tested at either temperature constitutes failure in the

methods or in this specification.

test. Failure of one of the six specimens tested at either

7.3 Sampling—The selection of the sample or samples of

temperature is cause for retest of six additional specimens at

pipe shall be as agreed upon by the purchaser and the seller. In

that temperature. Failure of one of the six specimens tested at

case of no prior agreement, any sample selected by the testing

either temperature in retest constitutes failure in the test.

laboratory shall be deemed adequate.

Failure of the pipe shall be as defined in Test Method D 1598,

7.4 Dimensions and Tolerances—Any length of pipe is

namely:

capable of being used to determine the dimensions. Measure in

7.6.1 Failure—Any continuous loss of pressure resulting

accordance with Test Method D 2122.

from the transmission of the test liquid through the body of the

7.4.1 Outside Diameter—Measure the outside diameter of

specimen under test.

the pipe with either a tapered sleeve gage or a circumferential

7.6.2 Ballooning—Any abnormal localized expansion of a

wrap tape in accordance with Test Method D 2122.

pipe specimen while under internal hydraulic pressure.

7.4.2 Wall Thickness—Make micrometer measurements of

the wall thickness in accordance with Test Method D 2122 to

determine the maximum and minimum values. Measure the

TABLE 4 Sustained Pressure Test Conditions for Water for

wall thickness at both ends of the pipe to the nearest 0.02 mm

SDR-PR PB Plastic Pipe

(0.001 in.).

7.4.3 Wall Thickness Range—Measure in such a manner

Pressure Required for

that the maximum, A, and minimum, B, wall thicknesses of Test, MPa (psi)

Standard

each cross section measured are obtained. Calculate the wall

Dimension At 37.8°C (100°F) At 23°C (73.4°F)

A B

Ratio PB 2110 PB 2110

thickness range, E, in percent, for each cross section as

follows: 9 3.10 (450) 3.45 (500)

11 2.48 (360) 2.76 (400)

E 5 [~A 2 B!/A] 3 100 (2)

13.5 2.00 (290) 2.21 (320)

17 1.52 (220) 1.72 (250)

Thewallthicknessrangeshallnotexceed1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.