ASTM F1037-05

(Test Method)Standard Test Method for Visual Rating of Appearance of Resilient Floors After In-Service Exposure to Foot Traffic

Standard Test Method for Visual Rating of Appearance of Resilient Floors After In-Service Exposure to Foot Traffic

SCOPE

1.1 This test method is intended to provide a numerical rating system for classification of resilient floors during the various stages of their wear life in relation to their condition, as perceived by a knowledgeable user.

This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.2 The values stated in inch-pound units are regarded as standard. The values given in parentheses are provided for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1037–05

Standard Test Method for

Visual Rating of Appearance of Resilient Floors After In-

1

Service Exposure to Foot Traffic

This standard is issued under the fixed designation F1037; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope by a panel of qualified observers under specified lighting

conditions in accordance with prescribed procedures.

1.1 This test method is intended to provide a numerical

rating system for classification of resilient floors during the

5. Apparatus

variousstagesoftheirwearlifeinrelationtotheircondition,as

5.1 Buffıng Machine, residential, equipped with single or

perceived by a knowledgeable user.

double brush (pad), soft fiber polishing brushes, and lamb’s

1.2 This standard does not purport to address all of the

wool pads. When equipped with polishing brushes, the unit

safety problems, if any, associated with its use. It is the

should deliver a nominal lineal velocity (loaded) of 1100 to

responsibility of the user of this standard to establish appro-

2

1400ft/min(eachbrush)andaDwellratioof190to210ft (17

priate safety and health practices and determine the applica-

2

to 19 m ) per min at a pressure of 0.40 to 0.50 psi. When

bility of regulatory limitations prior to use.

equipped with buffing pads, the unit shall deliver a nominal

1.3 The values stated in inch-pound units are regarded as

lineal velocity (loaded) of 1100 to 1400 lineal fpm (each pad)

standard. The values given in parentheses are provided for

2 2

and a Dwell ratio of 500 to 550 ft (45 to 50 m ) per min at a

information only.

pressure of 0.15 to 0.20 psi (see note).

2. Referenced Documents 5.2 Scrub Brush, approximately 2½by7 in. (63by178

1

2

mm) with nylon bristles approximately 1 ⁄4 in. (32 mm) long.

2.1 ASTM Standards:

1

5.3 Cellulose Sponge, approximate dry dimension 8by4 ⁄4

D1436 Test Methods for Application of Emulsion Floor

by1 in. (203by108 mm).

Polishes to Substrates for Testing Purposes

6. Reagent

3. Terminology

6.1 Cleaning Solution, shall be as recommended by the

3.1 Definitions of Terms Specific to This Standard:

flooring manufacturer and shall be prepared in sufficient

3.1.1 surface texture—surface imperfections such as deep

quantity in accordance with the manufacturer’s instructions.

scratches, indents, or changes in embossing texture.

NOTE 1—For flooring test specimens maintained with polish, the

4. Significance and Use

cleaning solution shall be capable of removing the polish.

4.1 Ratings are developed by subjective, comparative,

7. Sampling, Test Specimens, and Test Units

evaluation of exposed samples to original unexposed speci-

mens of those parameters experience has shown to be the most 7.1 Specimen size can vary as desired. A typical size panel

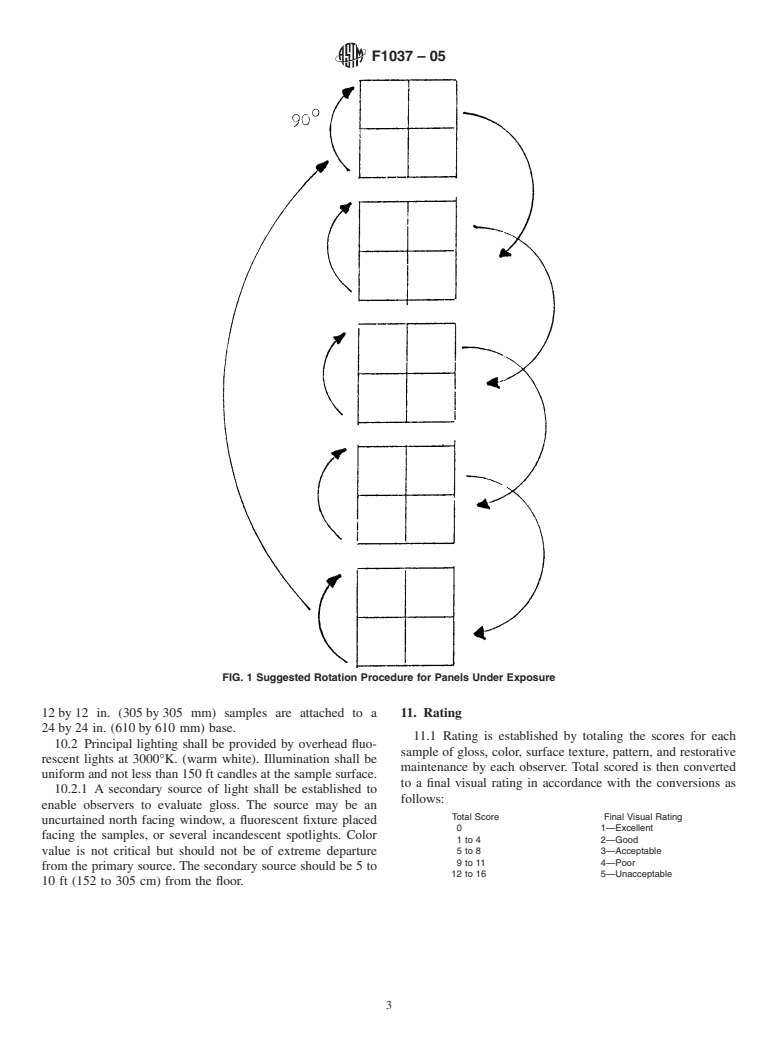

important in the consumers’ minds in evaluating the perfor- would be 24by24 in. (610by610 mm) and contain four

mance of a walking surface. These parameters are a change in 12by12 in. (305by305 mm) similar or different panels to be

gloss, color, surface texture, alterations to pattern and re- tested.Inaddition,acompanionspecimenmustberetainedand

storabilityofappearancewithnormalmaintenanceprocedures, stored in a location where its appearance will not be altered.

including the use of waxes, finishes, or buffing. Rating is done This specimen will be used for comparison purposes through-

out the test cycle. Each sample is to be cleaned in accordance

withthewashingprocedurein8.1.Thewaxingprocedureshall

1

ThistestmethodisunderthejurisdictionofASTMCommitteeF06onResilient

be followed on all resilient flooring samples designed to be

FloorCoveringsandisthedirectresponsibilityofSubcommitteeF06.30onPhysical

maintained with wax before each rating session. The original

Service Properties.

Current edition approved Nov. 1, 2005. Published November 2005. Originally

unexposed samples of these products shall be waxed also.

approved in 1987. Last previous edition approved in 2004 as F1037–04. DOI:

Those no-wax floors whose appearance, through exposure to

10.1520/F1037-05.

2 traffic,hasdeterioratedtoanoverallratingof“3”ormoreshall

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

be restored with either the waxing procedure (no samples

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

receive double-waxing) (see 8.2) or the buffing procedure (see

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F10

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.