ASTM B345/B345M-11

(Specification)Standard Specification for Aluminum and Aluminum-Alloy Seamless Pipe and Seamless Extruded Tube for Gas and Oil Transmission and Distribution Piping Systems (Withdrawn 2017)

Standard Specification for Aluminum and Aluminum-Alloy Seamless Pipe and Seamless Extruded Tube for Gas and Oil Transmission and Distribution Piping Systems (Withdrawn 2017)

ABSTRACT

This specification covers aluminum and aluminum-alloy seamless pipe and seamless extruded tube for gas and oil transmission and distribution piping systems. The pipe and tube shall be produced from hollow extrusion ingot (cast in hollow form or pierced) and shall be extruded by use of the die and mandrel method. The pipe and tube shall conform to the chemical composition requirements specified. The determination of chemical composition shall be made in accordance with suitable chemical (test methods E 34), or spectrochemical (test methods E 227, E 607, and E 1251) methods. Heat treatment for the production of T1 and T5-type tempers shall be in accordance with Practice B 807, and for the production of T4 and T6-type tempers, except as noted, shall be in accordance with practice B 918. Unless otherwise specified, alloys 6061, 6063, and 6351 may be solution heat treated and quenched at the extrusion press in accordance with practice B 807 for the production of T4 and T6-type tempers, as applicable. The material shall conform to the tensile property requirements specified. The tension tests shall be made in accordance with test methods B 557 and B 557M. Pipe and tube heat treated at the extrusion press shall conform to all requirements specified.

SCOPE

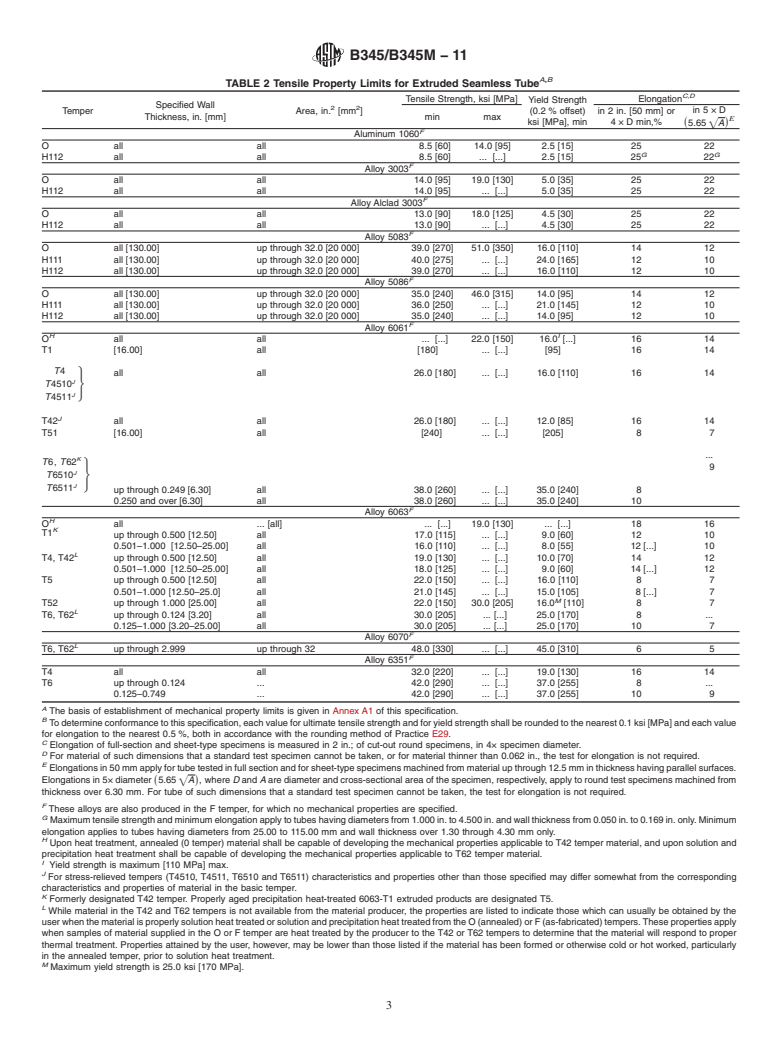

1.1 This specification covers seamless pipe and seamless extruded tube in the aluminum and aluminum alloys (Note 1) and tempers listed in Table 1 and Table 2, respectively. Seamless pipe and seamless tube are intended for use in applications involving internal pressure.

Note 1—Throughout this specification use of the term alloy in the general sense includes aluminum as well as aluminum alloy.

Note 2—For drawn seamless tubes, see Specifications B210 and B210M; for extruded tubes, Specifications B221 and B221M; for drawn seamless tubes for condensers and heat exchangers, Specifications B234 and B234M; for seamless pipe and seamless extruded tube, B241/B241M; for round welded tubes, Specification B313/B313M; for seamless condenser and heat exchanger tubes with integral fins, Specification ; for extruded structural pipe and tube, Specification B429/B429M; and for drawn tube for general purpose applications, Specification B483/B483M.

1.2 Alloy and temper designations are in accordance with ANSI H35.1 [H35.1M]. The equivalent Unified Numbering System alloy designations are those of Table 3 preceded by A9, for example, A93003 for aluminum alloy 3003 in accordance with Practice E527.

1.3 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A2.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

TABLE 1 Tensile Property Limits for Extruded Seamless PipeA,B AlloyTemperPipe Size,

in.Strength, min, ksi [MPa]ElongationC,D TensileYield (0.2 % Offset)in 2 in. [50 mm] or 4×

Diameter, min, % in 5 × D

(5.65 ) 3003 H18 under 127.0 [185]24.0 [165] 4 4 H1121 and over14.0 [95] 5.0 [35]2522 6061 T6 under 138.0 [260] 35.0 [240] 8... 1 and over 38.0 [260]35.0 [240] 10E 9 6063 T6 all30.0 [205]25.0 [170] 8 7 6351 T5

T6 all

all38.0 [260]

42.0 [290]35.0 [240]

37.0 [255] 10E

10F 9

9

A The basis for establishment of mechanical property limits is given in Annex A1 of this specification.

B To determine conformance to this specification, each value for tensile strength and for yield strength shall be rounded to the nearest 0.1 ksi [MPa] and each value for elongation to the nearest 0.5 %, both in accordance with the rounding method of Practice E29.

C Elongation of full-section and sheet-type specimens is measured in 2 in.; of cut-out round specimens, 4× specimen diameter.

D...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B345/B345M −11

Standard Specification for

Aluminum and Aluminum-Alloy Seamless Pipe and

Seamless Extruded Tube for Gas and Oil Transmission and

1

Distribution Piping Systems

This standard is issued under the fixed designation B345/B345M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2.1 The following documents of the issue in effect on the

1.1 This specification covers seamless pipe and seamless

dateofmaterialpurchaseformapartofthisspecificationtothe

extruded tube in the aluminum and aluminum alloys (Note 1)

extent referenced herein:

and tempers listed in Table 1 and Table 2, respectively.

Seamless pipe and seamless tube are intended for use in 2.2 ASTM Standards:

B210Specification for Aluminum and Aluminum-Alloy

applications involving internal pressure.

2

Drawn Seamless Tubes

NOTE 1—Throughout this specification use of the term alloy in the

B210MSpecification for Aluminum and Aluminum-Alloy

general sense includes aluminum as well as aluminum alloy.

2

Drawn Seamless Tubes (Metric)

NOTE 2—For drawn seamless tubes, see Specifications B210 and

B221Specification forAluminum andAluminum-Alloy Ex-

B210M; for extruded tubes, Specifications B221 and B221M; for drawn 2

truded Bars, Rods, Wire, Profiles, and Tubes

seamless tubes for condensers and heat exchangers, Specifications B234

B221MSpecification for Aluminum and Aluminum-Alloy

andB234M;forseamlesspipeandseamlessextrudedtube,B241/B241M;

2

Extruded Bars, Rods, Wire, Profiles, and Tubes (Metric)

for round welded tubes, Specification B313/B313M; for seamless con-

B234Specification for Aluminum and Aluminum-Alloy

denser and heat exchanger tubes with integral fins, Specification B404/

B404M; for extruded structural pipe and tube, Specification B429/

Drawn Seamless Tubes for Condensers and Heat Ex-

2

B429M; and for drawn tube for general purpose applications,

changers

Specification B483/B483M.

B234MSpecification for Aluminum and Aluminum-Alloy

Drawn Seamless Tubes for Condensers and Heat Ex-

1.2 Alloy and temper designations are in accordance with

2

changers (Metric)

ANSI H35.1 [H35.1M]. The equivalent Unified Numbering

B241/B241MSpecification for Aluminum and Aluminum-

SystemalloydesignationsarethoseofTable3precededbyA9,

2

Alloy Seamless Pipe and Seamless Extruded Tube

for example, A93003 for aluminum alloy 3003 in accordance

B313/B313MSpecification for Aluminum and Aluminum-

with Practice E527.

2

Alloy Round Welded Tubes

1.3 For acceptance criteria for inclusion of new aluminum

B404/B404MSpecification for Aluminum and Aluminum-

and aluminum alloys in this specification, see Annex A2. Alloy Seamless Condenser and Heat-Exchanger Tubes

3

with Integral Fins (Withdrawn 2006)

1.4 The values stated in either inch-pound units or SI units

B429/B429MSpecification for Aluminum-Alloy Extruded

are to be regarded separately as standard. Within the text, the

2

Structural Pipe and Tube

SI units are shown in brackets. The values stated in each

B483/B483MSpecification for Aluminum and Aluminum-

system are not exact equivalents; therefore, each system shall

Alloy Drawn Tube and Drawn Pipe for General Purpose

beusedindependentlyoftheother.Combiningvaluesfromthe 2

Applications

two systems may result in nonconformance with the specifi-

B557Test Methods for Tension Testing Wrought and Cast

2

cation.

Aluminum- and Magnesium-Alloy Products

B557MTest Methods forTensionTestingWrought and Cast

2

Aluminum- and Magnesium-Alloy Products (Metric)

1

B647Test Method for Indentation Hardness of Aluminum

This specification is under the jurisdiction ofASTM Committee B07 on Light

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on

Aluminum Alloy Wrought Products.

Current edition approved Aug. 1, 2011. Published August 2011. Originally

2

approved in 1959. Last previous edition approved in 2002 as B345/B345M–02 Annual Book of ASTM Standards, Vol 02.02.

3

which was withdrawn January 2011 and reinstated in August 2011. DOI: 10.1520/ The last approved version of this historical standard is referenced on

B0345_B0345M-11. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B345/B345M−11

A,B

TABLE 1 Tensile Property Limits for Extruded Seamless Pipe

C,D

Strength, min, ksi [MPa] Elongation

Pipe Size,

Alloy Temper

in 2 in. [50 mm] or 4× in 5×D

in.

Tensile Yield (0.2 % Offset)

Diameter, min, % 5.65 A

s d

œ

3003 H18 under 1 27.0 [185] 24.0 [165] 4 4

H112 1 and ove

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.