ASTM C1019-14

(Test Method)Standard Test Method for Sampling and Testing Grout

Standard Test Method for Sampling and Testing Grout

SIGNIFICANCE AND USE

3.1 Grout used in masonry is a fluid mixture of cementitious materials and aggregate with a high water content for ease of placement.

3.1.1 During construction, grout is placed within or between absorptive masonry units. Excess water must be removed from grout specimens in order to provide compressive strength test results more nearly indicative of the grout strength in the wall. In this test method, molds are made from masonry units having the same absorption and moisture content characteristics as those being used in the construction.

3.2 This test method is used to either help select grout proportions by comparing test values or as a quality control test for uniformity of grout preparation during construction.

3.3 The physical exposure condition and curing of the grout are not exactly reproduced, but this test method does subject the grout specimens to absorption conditions similar to those experienced by grout in the wall.

Note 2: Test results of grout specimens taken from a wall should not be compared to test results obtained with this test method.

SCOPE

1.1 This test method covers procedures for both field and laboratory sampling and compression testing of grout used in masonry construction. Grout for masonry is specified under Specification C476.

Note 1: The testing agency performing this test method should be evaluated in accordance with Practice C1093.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1019 −14

StandardTest Method for

Sampling and Testing Grout

This standard is issued under the fixed designation C1019; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* C1611/C1611M Test Method for Slump Flow of Self-

Consolidating Concrete

1.1 This test method covers procedures for both field and

laboratory sampling and compression testing of grout used in

3. Significance and Use

masonry construction. Grout for masonry is specified under

Specification C476. 3.1 Groutusedinmasonryisafluidmixtureofcementitious

materials and aggregate with a high water content for ease of

NOTE 1—The testing agency performing this test method should be

placement.

evaluated in accordance with Practice C1093.

3.1.1 Duringconstruction,groutisplacedwithinorbetween

1.2 The values stated in inch-pound units are to be regarded

absorptive masonry units. Excess water must be removed from

as standard. The values given in parentheses are mathematical

grout specimens in order to provide compressive strength test

conversions to SI units that are provided for information only

results more nearly indicative of the grout strength in the wall.

and are not considered standard.

In this test method, molds are made from masonry units having

1.3 This standard does not purport to address all of the

the same absorption and moisture content characteristics as

safety concerns, if any, associated with its use. It is the

those being used in the construction.

responsibility of the user of this standard to establish appro-

3.2 This test method is used to either help select grout

priate safety and health practices and determine the applica-

proportionsbycomparingtestvaluesorasaqualitycontroltest

bility of regulatory limitations prior to use.

for uniformity of grout preparation during construction.

2. Referenced Documents

3.3 The physical exposure condition and curing of the grout

are not exactly reproduced, but this test method does subject

2.1 ASTM Standards:

the grout specimens to absorption conditions similar to those

C39/C39M Test Method for Compressive Strength of Cylin-

experienced by grout in the wall.

drical Concrete Specimens

C143/C143M Test Method for Slump of Hydraulic-Cement

NOTE 2—Test results of grout specimens taken from a wall should not

Concrete be compared to test results obtained with this test method.

C476 Specification for Grout for Masonry

4. Apparatus

C511 Specification for Mixing Rooms, Moist Cabinets,

Moist Rooms, and Water Storage Tanks Used in the

4.1 Maximum-Minimum Thermometer.

Testing of Hydraulic Cements and Concretes

4.2 Straightedge, a steel straightedge not less than 6 in.

C617 Practice for Capping Cylindrical Concrete Specimens

(152.4 mm) long and not less than ⁄16 in. (1.6 mm) in

C1064/C1064M Test Method for Temperature of Freshly

thickness.

Mixed Hydraulic-Cement Concrete

4.3 TampingRod,around,straight,steelrodwithadiameter

C1093 Practice for Accreditation of Testing Agencies for

3 1

Masonry of ⁄8 6 ⁄16 in. (10 6 2 mm) and a length of 12 6 4 inches.

(300 6 100 millimetres). The rod shall have the tamping end

or both ends rounded to a hemispherical tip of the same

This test method is under the jurisdiction ofASTM Committee C12 on Mortars

diameter as the rod.

and Grouts for Unit Masonry and is the direct responsibility of Subcommittee

C12.02 on Research and Methods of Test.

4.4 Nonabsorbent Blocks and Spacers, nonabsorbent, rigid

Current edition approved Dec. 1, 2014. Published January 2015. Originally

squares and rectangles with side dimensions so as to achieve

approved in 1984. Last previous edition approved in 2013 as C1019 – 13. DOI:

the desired grout specimen side dimensions and of sufficient

10.1520/C1019-14.

quantity or thickness to yield the desired grout specimen

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

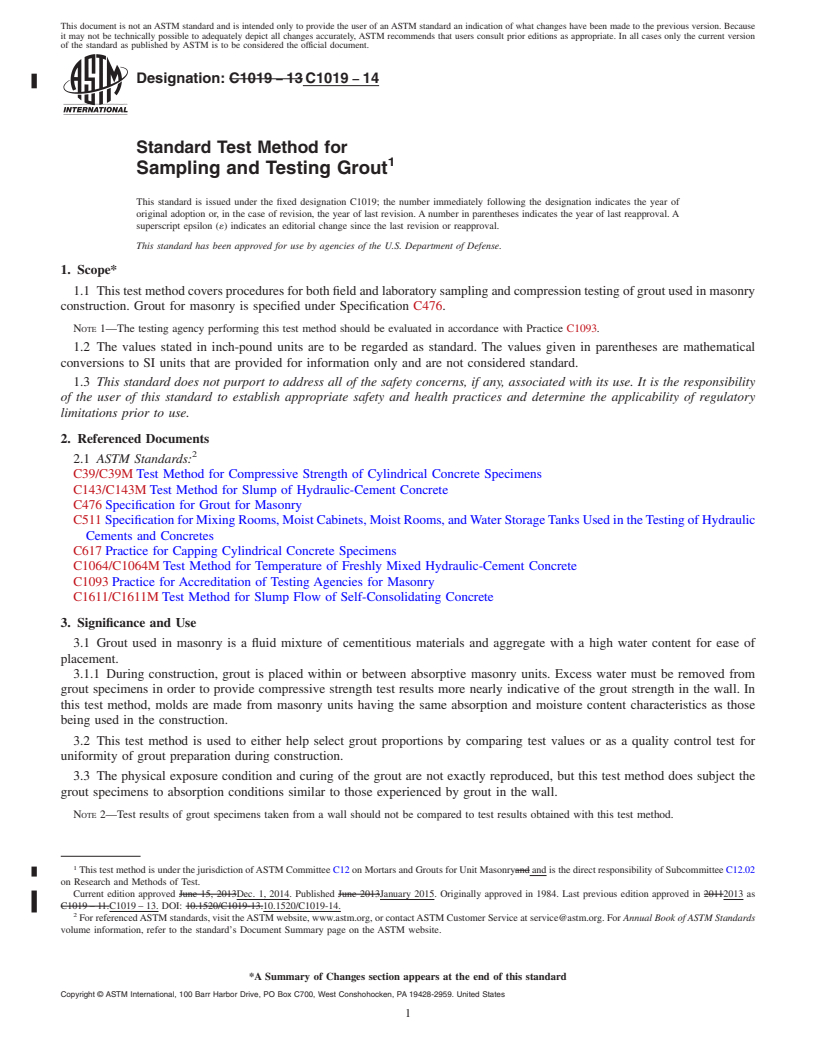

height, as shown in Fig. 1, Fig. 2, and Fig. 3.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. NOTE 3—Nonabsorbent blocks may be of plastic, wood, or other

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1019 − 14

6.1.3 Form a space with a square cross-section, 3 in. (76

mm) or larger on each side and twice as high as its width, by

stacking masonry units of the same type and moisture condi-

tion as those being used in the construction. The surface of the

unit in contact with the grout specimen shall not have been

previously used to mold specimens. Place nonabsorbent

blocks, cut to proper size and of the proper thickness or

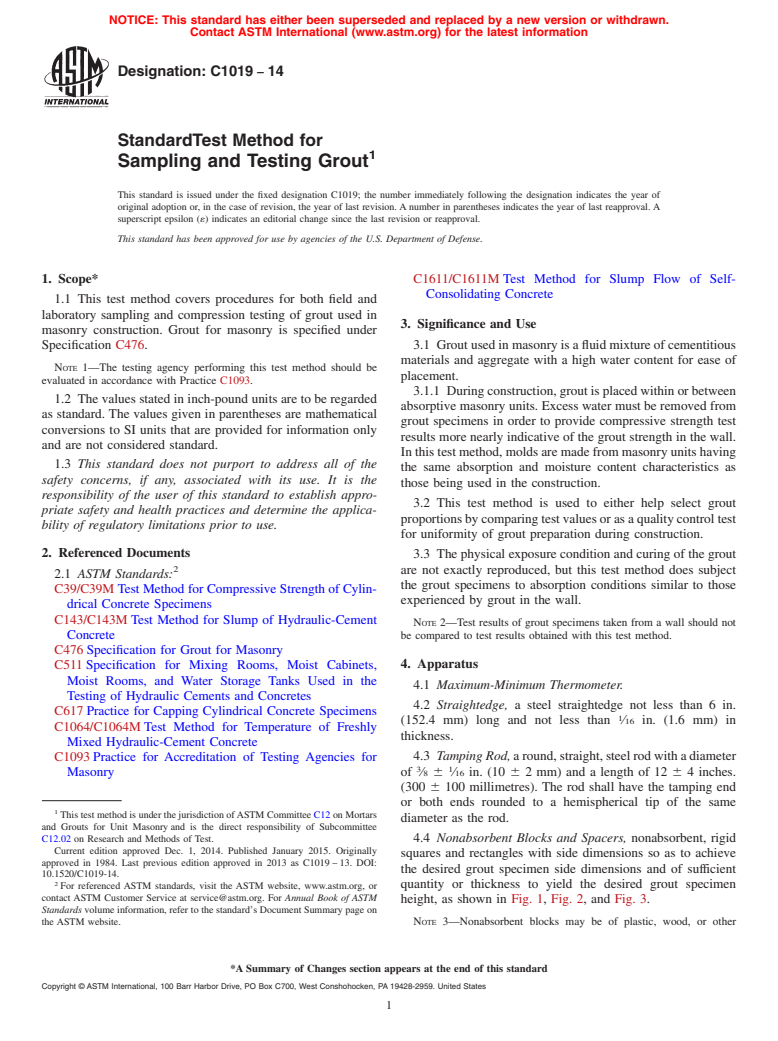

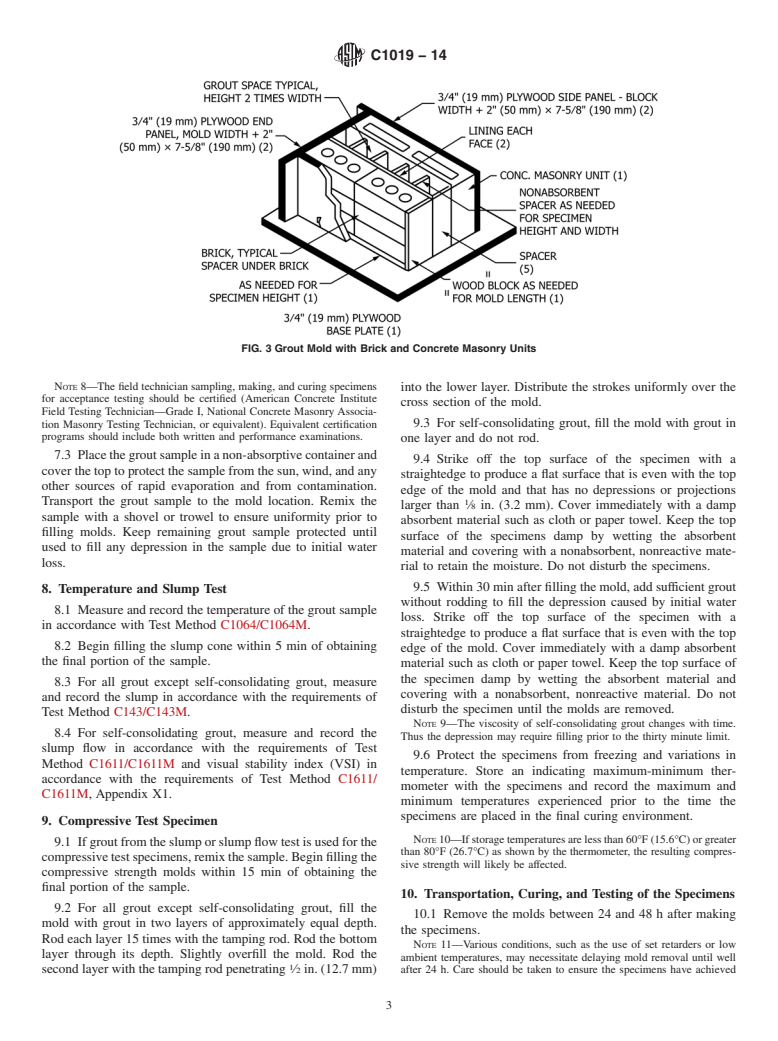

NOTE 1—Front masonry unit stack not shown to allow view of

quantity, at the bottom of the space to achieve the necessary

specimen.

height of specimen. Tolerance on space and specimen dimen-

FIG. 1 Grout Mold (Units 6 in. (152.4 mm) or Less in Height, 2 ⁄4

sions shall be within 5 % of the specimen width. See Fig. 1,

in. (57.2 mm) High Brick Shown)

Fig. 2, and Fig. 3 and accompanying notes.

6.1.4 Line the masonry surfaces that will be in contact with

the grout specimen with a thin, permeable material to prevent

bond to the masonry units. New lining material shall be used

for each specimen.

NOTE 6—The lining, such as paper towel, is used to aid in stripping the

grout specimen from the mold. Proper installation of the lining prevents

irregularly sized specimens and varying test results.

6.1.5 Brace units to prevent displacement during grouting

NOTE 1—Front masonry unit not shown to allow view of specimen.

and curing.

FIG. 2 Grout Mold (Units Greater than 6 in. (152.4 mm) High, 8 in.

(203.2 mm) High Concrete Masonry Unit Shown) 6.2 Alternative Methods—Alternative methods of forming

the specimens shall be used only with the approval of the

specifier. Such approval shall be based on comparative testing

of grout specimens constructed from molds as described in 6.1

nonabsorbent material. Certain species of wood contain sugars which

and the alternative method. Approval shall be limited to a

cause retardation of cement. In order to prevent this from occurring, new

single specimen shape, method of forming, masonry units

wooden blocks shall be soaked in limewater for 24 h, sealed with varnish

used, and grout mix.Aconversion factor based on comparative

or wax, or covered with an impermeable material prior to use.

testing of a minimum of ten pairs of specimens shall be used to

4.5 Panels and plates, pieces of ⁄4 in. (19 mm) plywood

modify results from alternative methods.

with dimensions as needed to contain units and grout speci-

NOTE7—Othermethodsofobtaininggroutspecimensandspecimensof

mens. Soak in limewater for 24 h, seal with varnish or wax, or

different geometry have been employed in grout testing, but are not

cover with an impermeable material prior to use. A nonabsor- described in this test method. Other methods used to obtain grout

specimens include: drilling grout-filled cores of regular units; filling cores

bant material of equivalent stiffness to the plywood is permit-

of masonry units specifically manufactured to provide grout specimens;

ted.

filling compartments in slotted corrugated cardboard boxes specifically

manufactured to provide grout specimens; and forming specimens from

PROCEDURES

different sized masonry units of the same or similar material.

Sincetestresultsvarywithmethodsofformingthespecimen,specimen

5. Test Specimens

geometry, and grout mix, comparative test results between specimens

made with molds described in 6.1 and specimens made with alternative

5.1 Each grout specimen shall have a square cross-section,

methods are required and confined to a single specimen shape, method of

3 in. (76 mm) or larger on the sides and twice as high as its

forming, masonry units used, and grout mix.

width. Dimensional tolerances shall be within 5 % of the width

selected.

7. Sampling Grout

5.2 Test at least three specimens at each age specified.

7.1 SizeofSample—Groutsamplestobeusedforslumpand

compressive strength tests shall be a minimum of ⁄2 ft (0.014

NOTE 4—Frequency of sampling and age of test is to be determined by

the specifier of this test method and is usually found in the construction

m ).

documents.

7.2 Procedure—The procedures used in sampling shall in-

clude the use of precautions that will assist in obtaining

6. Grout Specimen Molds

samples that are representative of the nature and condition of

6.1 Molds from Masonry Units:

the grout. After the final slump adjustment has been made,

6.1.1 Select a level location where the molds remain undis-

sample grout as the grout is being placed.

turbed for up to 48 h.

7.2.1 Field Sampling—Collect two or more portions taken

NOTE 5—The location of specimen construction should be protected at regularly spaced intervals during the discharge of the middle

and as free from perceptible vibration as possible.

portion of the batch. The elapsed time between obtaining the

first and final portions of the sample shall be not more than 15

6.1.2 The construction of the mold shall simulate the in-situ

min.

construction. If the grout is placed between two different types

of masonry units, both types shall be used to construct the 7.2.2 Laboratory Sampling—The entire mixed batch of

mold. grout is the sample.

C1019 − 14

FIG. 3 Grout Mold with Brick and Concrete Masonry Units

NOTE 8—The field technician sampling, making, and curing specimens

into the lower layer. Distribute the strokes uniformly over the

for acceptance testing should be certified (American Concrete Institute

cross section of the mold.

Field Testing Technician—Grade I, National Concrete Masonry Associa-

9.3 For self-consolidating grout, fill the mold with grout in

tion Masonry Testing Technician, or equivalent). Equivalent certification

programs should include both written and performance examinations.

one layer and do not rod.

7.3 Placethegroutsampleinanon-absorptivecontainerand

9.4 Strike off the top surface of the specimen with a

cover the top to protect the sample from the sun, wind, and any

straightedge to produce a flat surface that is even with the top

other sources of rapid evaporation and from contamination.

edge of the mold and that has no depressions or projections

Transport the grout sample to the mold location. Remix the 1

larger than ⁄8 in. (3.2 mm). Cover immediately with a damp

sample with a shovel or trowel to ensure uniformity prior to

absorbent material such as cloth or paper towel. Keep the top

filling molds. Keep remaining grout sample protected until

surface of t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1019 − 13 C1019 − 14

Standard Test Method for

Sampling and Testing Grout

This standard is issued under the fixed designation C1019; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This test method covers procedures for both field and laboratory sampling and compression testing of grout used in masonry

construction. Grout for masonry is specified under Specification C476.

NOTE 1—The testing agency performing this test method should be evaluated in accordance with Practice C1093.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C39/C39M Test Method for Compressive Strength of Cylindrical Concrete Specimens

C143/C143M Test Method for Slump of Hydraulic-Cement Concrete

C476 Specification for Grout for Masonry

C511 Specification for Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in the Testing of Hydraulic

Cements and Concretes

C617 Practice for Capping Cylindrical Concrete Specimens

C1064/C1064M Test Method for Temperature of Freshly Mixed Hydraulic-Cement Concrete

C1093 Practice for Accreditation of Testing Agencies for Masonry

C1611/C1611M Test Method for Slump Flow of Self-Consolidating Concrete

3. Significance and Use

3.1 Grout used in masonry is a fluid mixture of cementitious materials and aggregate with a high water content for ease of

placement.

3.1.1 During construction, grout is placed within or between absorptive masonry units. Excess water must be removed from

grout specimens in order to provide compressive strength test results more nearly indicative of the grout strength in the wall. In

this test method, molds are made from masonry units having the same absorption and moisture content characteristics as those

being used in the construction.

3.2 This test method is used to either help select grout proportions by comparing test values or as a quality control test for

uniformity of grout preparation during construction.

3.3 The physical exposure condition and curing of the grout are not exactly reproduced, but this test method does subject the

grout specimens to absorption conditions similar to those experienced by grout in the wall.

NOTE 2—Test results of grout specimens taken from a wall should not be compared to test results obtained with this test method.

This test method is under the jurisdiction of ASTM Committee C12 on Mortars and Grouts for Unit Masonryand and is the direct responsibility of Subcommittee C12.02

on Research and Methods of Test.

Current edition approved June 15, 2013Dec. 1, 2014. Published June 2013January 2015. Originally approved in 1984. Last previous edition approved in 20112013 as

C1019 – 11.C1019 – 13. DOI: 10.1520/C1019-13.10.1520/C1019-14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1019 − 14

4. Apparatus

4.1 Maximum-Minimum Thermometer.

4.2 Straightedge, a steel straightedge not less than 6 in. (152.4 mm) long and not less than ⁄16 in. (1.6 mm) in thickness.

3 1

4.3 Tamping Rod, a round, straight, steel rod with a diameter of ⁄8 6 ⁄16 in. (10 6 2 mm) and a length of 12 6 4 inches. (300

6 100 millimetres). The rod shall have the tamping end or both ends rounded to a hemispherical tip of the same diameter as the

rod.

4.4 Nonabsorbent Blocks and Spacers, nonabsorbent, rigid squares and rectangles with side dimensions so as to achieve the

desired grout specimen side dimensions and of sufficient quantity or thickness to yield the desired grout specimen height, as shown

in Fig. 1, Fig. 2, and Fig. 3.

NOTE 3—Nonabsorbent blocks may be of plastic, wood, or other nonabsorbent material. Certain species of wood contain sugars which cause retardation

of cement. In order to prevent this from occurring, new wooden blocks shall be soaked in limewater for 24 h, sealed with varnish or wax, or covered

with an impermeable material prior to use.

4.5 Panels and plates, pieces of ⁄4 in. (19 mm) plywood with dimensions as needed to contain units and grout specimens. Soak

in limewater for 24 h, seal with varnish or wax, or cover with an impermeable material prior to use. A nonabsorbant material of

equivalent stiffness to the plywood is permitted.

PROCEDURES

5. Test Specimens

5.1 Each grout specimen shall have a square cross-section, 3 in. (76 mm) or larger on the sides and twice as high as its width.

Dimensional tolerances shall be within 5 % of the width selected.

5.2 Test at least three specimens at each age specified.

NOTE 4—Frequency of sampling and age of test is to be determined by the specifier of this test method and is usually found in the construction

documents.

6. Grout Specimen Molds

6.1 Molds from Masonry Units:

6.1.1 Select a level location where the molds remain undisturbed for up to 48 h.

NOTE 5—The location of specimen construction should be protected and as free from perceptible vibration as possible.

6.1.2 The construction of the mold shall simulate the in-situ construction. If the grout is placed between two different types of

masonry units, both types shall be used to construct the mold.

6.1.3 Form a space with a square cross-section, 3 in. (76 mm) or larger on each side and twice as high as its width, by stacking

masonry units of the same type and moisture condition as those being used in the construction. The surface of the unit in contact

with the grout specimen shall not have been previously used to mold specimens. Place nonabsorbent blocks, cut to proper size and

of the proper thickness or quantity, at the bottom of the space to achieve the necessary height of specimen. Tolerance on space and

specimen dimensions shall be within 5 % of the specimen width. See Fig. 1, Fig. 2, and Fig. 3 and accompanying notes.

6.1.4 Line the masonry surfaces that will be in contact with the grout specimen with a thin, permeable material to prevent bond

to the masonry units. New lining material shall be used for each specimen.

NOTE 6—The lining, such as paper towel, is used to aid in stripping the grout specimen from the mold. Proper installation of the lining prevents

irregularly sized specimens and varying test results.

6.1.5 Brace units to prevent displacement during grouting and curing.

6.2 Alternative Methods—Alternative methods of forming the specimens shall be used only with the approval of the specifier.

Such approval shall be based on comparative testing of grout specimens constructed from molds as described in 6.1 and the

NOTE 1—Front masonry unit stack not shown to allow view of specimen.

FIG. 1 Grout Mold (Units 6 in. (152.4 mm) or Less in Height, 2 ⁄4 in. (57.2 mm) High Brick Shown)

C1019 − 14

NOTE 1—Front masonry unit not shown to allow view of specimen.

FIG. 2 Grout Mold (Units Greater than 6 in. (152.4 mm) High, 8 in. (203.2 mm) High Concrete Masonry Unit Shown)

alternative method. Approval shall be limited to a single specimen shape, method of forming, masonry units used, and grout mix.

A conversion factor based on comparative testing of a minimum of ten pairs of specimens shall be used to modify results from

alternative methods.

NOTE 7—Other methods of obtaining grout specimens and specimens of different geometry have been employed in grout testing, but are not described

in this test method. Other methods used to obtain grout specimens include: drilling grout-filled cores of regular units; filling cores of masonry units

specifically manufactured to provide grout specimens; filling compartments in slotted corrugated cardboard boxes specifically manufactured to provide

grout specimens; and forming specimens from different sized masonry units of the same or similar material.

Since test results vary with methods of forming the specimen, specimen geometry, and grout mix, comparative test results between specimens made

with molds described in 6.1 and specimens made with alternative methods are required and confined to a single specimen shape, method of forming,

masonry units used, and grout mix.

7. Sampling Grout

3 3

7.1 Size of Sample—Grout samples to be used for slump and compressive strength tests shall be a minimum of ⁄2 ft (0.014 m ).

7.2 Procedure—The procedures used in sampling shall include the use of precautions that will assist in obtaining samples that

are representative of the nature and condition of the grout. After the final slump adjustment has been made, sample grout as the

grout is being placed.

7.2.1 Field Sampling—Collect two or more portions taken at regularly spaced intervals during the discharge of the middle

portion of the batch. The elapsed time between obtaining the first and final portions of the sample shall be not more than 15 min.

7.2.2 Laboratory Sampling—The entire mixed batch of grout is the sample.

NOTE 8—The field technician sampling, making, and curing specimens for acceptance testing should be certified (American Concrete Institute Field

Testing Technician—Grade I, National Concrete Masonry Association Masonry Testing Technician, or equivalent). Equivalent certification programs

should include both written and performance examinations.

7.3 Place the grout sample in a non-absorptive container and cover the top to protect the sample from the sun, wind, and any

other sources of rapid evaporation and from contamination. Transport the grout sample to the mold location. Remix the sample

with a shovel or trowel to ensure uniformity prior to filling molds. Keep remaining grout sample protected until used to fill any

depression in the sample due to initial water loss.

8. Temperature and Slump Test

8.1 Measure and record the temperature of the grout sample in accordance with Test Method C1064/C1064M.

8.2 Begin filling the slump cone within 5 min of obtaining the final portion of the sample.

8.3 For all grout except self-consolidating grout, measure and record the slump in accordance with the requirements of Test

Method C143/C143M.

8.4 For self-consolidating grout, measure and record the slump flow in accordance with the requirements of Test Method

C1611/C1611M and visual stability index (VSI) in accordance with the requirements of Test Method C1611/C1611M, Appendix

X1.

9. Compressive Test Specimen

9.1 If grout from the slump or slump flow test is used for the compressive test specimens, remix the sample. Begin filling the

compressive strength molds within 15 min of obtaining the final portion of the sample.

9.2 For all grout except self-consolidating grout, fill the mold with grout in two layers of approximately equal depth. Rod each

layer 15 times with the tamping rod. Rod the bottom layer through its depth. Slightly overfill the mold. Rod the second layer with

the tamping rod penetrating ⁄2 in. (12.7 mm) into the lower layer. Distribute the strokes uniformly over the cross section of the

mold.

9.3 For self-consolidating grout, fill the mold with grout in one layer and do not rod.

C1019 − 14

FIG. 3 Grout Mold with Brick and Concrete Masonry Units

9.4 Strike off the top surface of the specimen with a straightedge to produce a flat surface that is even with the top edge of the

mold and that has no depressions or projections larger than ⁄8 in. (3.2 mm). Cover immediately with a damp absorbent material

such as cloth or paper towel. Keep the top surface of the specimens damp by wetting the absorbent material and covering with

a nonabsorbent, nonreactive material to retain the moisture. Do not disturb the specimens.

9.5 Within 30 min after filling the mold, add sufficient grout without rodding to fill the depression caused by initial water loss.

Strike off the top surface of the specimen with a straightedge to produce a flat surface that is even with the top edge of the mold.

Cover immediately with a damp absorbent material such as cloth or paper towel. Keep the top surface of the specimen damp by

wetting the absorbent material and covering with a nonabsorbent, nonreactive material. Do not disturb the specimen until the molds

are removed.

NOTE 9—The viscosity of self-consolidating grout changes with time. Thus the depression may require filling prior to the thirty minute limit.

9.6 Protect the specimens from freezing and variations in temperature. Store an indicating maximum-minimum thermometer

with the specimens and record the maximum and minimum temperatures experienced prior to the time the specimens are placed

in the final curing environment.

NOTE 10—If storage temperatures are less than 60°F (15.6°C) or greater than 80°F (26.7°C) as shown by the thermometer, the resulting compressive

strength will likely be affected.

10. Transportation, Curing, and Testing of the Specimens

10.1 Remove the molds between 24 and 48 h after making the specimens.

NOTE 11—Various conditions, such as the use of set retarders or low ambient temperatures, may necessitate delaying mold removal until well after

24 h. Care should be taken to ensure the specimens have achieved sufficient strength for transportation, which may include delaying mold removal and

transportation until 48 h.

10.2 Within 30 min after removing the molds, place specimens in a protective container and keep specimens damp.

10.3 Transport field specimens to the laboratory within 8 h after mold removal.

10.4 Within 8 h after mold removal, place in a moist room, moist cabinet, or water storage tank conforming to Specification

C511. Store there until day of testing.

10.5 S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.