ASTM F2987-12

(Specification)Standard Specification for Corrugated Polyethylene Pipe and Fittings for Mine Heap Leach Aeration Applications

Standard Specification for Corrugated Polyethylene Pipe and Fittings for Mine Heap Leach Aeration Applications

ABSTRACT

This specification establishes requirements and test methods for double wall, annular extruded corrugated polyethylene (PE) pipe and fittings used in mine heap leach pile aeration. It covers materials, workmanship, dimensions, perforations, pipe stiffness, elongation, joint separation resistance, quality of extruded polyethylene, brittleness, testing, and marking of corrugated PE pipe and fittings with diameters of 100 mm (4 inch), 150 mm (6 inch), 200 mm (8 inch), 250 mm (10 inch), 300 mm (12 inch), 375 mm (15 inch), and 450 mm (18 inch).

SCOPE

1.1 This specification covers requirements and test methods for materials, workmanship, dimensions, perforations, pipe stiffness, elongation, joint separation resistance, quality of extruded polyethylene, brittleness, testing, and marking of corrugated polyethylene (PE) pipe and fittings for mine heap leach pile aeration. It covers with nominal sizes 100 mm (4 inch), 150 mm (6 inch), 200 mm (8 inch), 250 mm (10 inch) 300 mm (12 inch), 375 mm (15 inch), and 450 mm (18 inch) diameter.

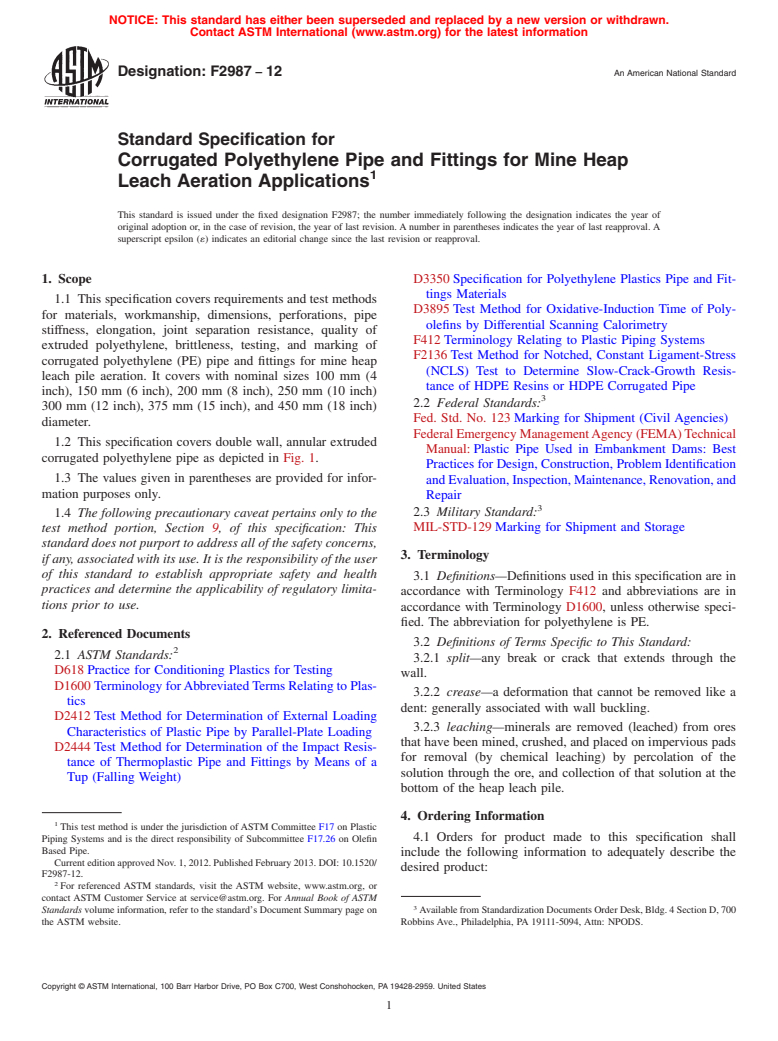

1.2 This specification covers double wall, annular extruded corrugated polyethylene pipe as depicted in Fig. 1.FIG. 1 Typical Double Wall Profile Cross-Section

1.3 The values given in parentheses are provided for information purposes only.

1.4 The following precautionary caveat pertains only to the test method portion, Section 9, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2987 −12 An American National Standard

Standard Specification for

Corrugated Polyethylene Pipe and Fittings for Mine Heap

1

Leach Aeration Applications

This standard is issued under the fixed designation F2987; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3350 Specification for Polyethylene Plastics Pipe and Fit-

tings Materials

1.1 This specification covers requirements and test methods

D3895 Test Method for Oxidative-Induction Time of Poly-

for materials, workmanship, dimensions, perforations, pipe

olefins by Differential Scanning Calorimetry

stiffness, elongation, joint separation resistance, quality of

F412 Terminology Relating to Plastic Piping Systems

extruded polyethylene, brittleness, testing, and marking of

F2136 Test Method for Notched, Constant Ligament-Stress

corrugated polyethylene (PE) pipe and fittings for mine heap

(NCLS) Test to Determine Slow-Crack-Growth Resis-

leach pile aeration. It covers with nominal sizes 100 mm (4

tance of HDPE Resins or HDPE Corrugated Pipe

inch), 150 mm (6 inch), 200 mm (8 inch), 250 mm (10 inch)

3

2.2 Federal Standards:

300 mm (12 inch), 375 mm (15 inch), and 450 mm (18 inch)

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

diameter.

FederalEmergencyManagementAgency(FEMA)Technical

1.2 This specification covers double wall, annular extruded

Manual: Plastic Pipe Used in Embankment Dams: Best

corrugated polyethylene pipe as depicted in Fig. 1.

Practices for Design, Construction, Problem Identification

1.3 The values given in parentheses are provided for infor-

andEvaluation,Inspection,Maintenance,Renovation,and

mation purposes only.

Repair

3

2.3 Military Standard:

1.4 The following precautionary caveat pertains only to the

test method portion, Section 9, of this specification: This MIL-STD-129 Marking for Shipment and Storage

standard does not purport to address all of the safety concerns,

3. Terminology

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

3.1 Definitions—Definitions used in this specification are in

practices and determine the applicability of regulatory limita-

accordance with Terminology F412 and abbreviations are in

tions prior to use.

accordance with Terminology D1600, unless otherwise speci-

fied. The abbreviation for polyethylene is PE.

2. Referenced Documents

3.2 Definitions of Terms Specific to This Standard:

2

2.1 ASTM Standards:

3.2.1 split—any break or crack that extends through the

D618 Practice for Conditioning Plastics for Testing

wall.

D1600 Terminology forAbbreviatedTerms Relating to Plas-

3.2.2 crease—a deformation that cannot be removed like a

tics

dent: generally associated with wall buckling.

D2412 Test Method for Determination of External Loading

3.2.3 leaching—minerals are removed (leached) from ores

Characteristics of Plastic Pipe by Parallel-Plate Loading

that have been mined, crushed, and placed on impervious pads

D2444 Test Method for Determination of the Impact Resis-

for removal (by chemical leaching) by percolation of the

tance of Thermoplastic Pipe and Fittings by Means of a

solution through the ore, and collection of that solution at the

Tup (Falling Weight)

bottom of the heap leach pile.

4. Ordering Information

1

This test method is under the jurisdiction of ASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.26 on Olefin 4.1 Orders for product made to this specification shall

Based Pipe.

include the following information to adequately describe the

Current edition approved Nov. 1, 2012. Published February 2013. DOI: 10.1520/

desired product:

F2987-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2987−12

FIG. 1Typical Double Wall Profile Cross-Section

4.1.1 This ASTM designation and year of issue, Oxidative-Induction-Time of 20 minutes when tested in accor-

4.1.2 Perforations: dance with in accordance with ASTM D3895.

4.1.2.1 With perforations,

6.2 Rework Material—Clean rework material, generated

4.1.2.2 Without perforations,

from the manufacturer’s own production of this product,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.