ASTM F1498-08(2020)

(Specification)Standard Specification for Taper Pipe Threads 60° for Thermoplastic Pipe and Fittings

Standard Specification for Taper Pipe Threads 60° for Thermoplastic Pipe and Fittings

ABSTRACT

This specification establishes requirements for dimensions and gaging of taper pipe threads used on threaded plastic pipe and fittings. The type of pipe threads are designated by specifying in sequence the nominal pipe size, number of threads per inch, and the thread series symbols as follows. For left-hand threads add LH to the designation, otherwise right-hand threads will be understood. Different physical properties of pipe threads such as form, dimensions, angle, truncation, height, sealing capacity, and tightness shall be in accordance with the requirements specified. The gages have two types which may be used to completely cover gage requirements: (1) master gages used to check working gages; and (2) working gages used to check threads during manufacture and for conformance inspection. Both external and internal taper threads shall be gaged.

SCOPE

1.1 This specification establishes requirements for dimensions and gaging of taper pipe threads used on threaded plastic pipe and fittings.

1.2 Threads meeting this specification shall only be used on those plastic materials deemed suitable by the manufacturer.

1.3 Specialty threads or threads not requiring a leak-tight joint are not covered in this specification.

Note 1: The terms “wrench makeup” and “wrench tight” are standard terminology for tightness and do not imply using a pipe wrench or other tools which would damage plastic pipe and fittings. The terms “hand-tight” and “hand-tight engagement” refer only to thread gaging (not pipe and fitting connections) and is the definition of the L1 gage length.

1.4 Thread Designations—The type of pipe threads included in this specification are designated by specifying in sequence the nominal pipe size, number of threads per inch, and the thread series symbols as follows in accordance with ANSI/ASME B 1.20.1: 3/8-18 NPT. For left-hand threads add LH to the end of the designation, otherwise right-hand threads will be understood. For example: 3/8-18 NPT-LH.

1.4.1 Each of these letters in the symbol has a definite significance as follows:

N

=

National (American Standard)

P

=

Pipe

T

=

Taper

1.5 The values stated in inch-pound units are to be regarded as the standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see 7.2.1 and 8.3.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F1498 −08 (Reapproved 2020) An American National Standard

Standard Specification for

Taper Pipe Threads 60° for Thermoplastic Pipe and Fittings

This standard is issued under the fixed designation F1498; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

1.1 This specification establishes requirements for dimen-

Barriers to Trade (TBT) Committee.

sions and gaging of taper pipe threads used on threaded plastic

pipe and fittings.

2. Referenced Documents

1.2 Threads meeting this specification shall only be used on

2.1 ASTM Standards:

those plastic materials deemed suitable by the manufacturer.

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

1.3 Specialty threads or threads not requiring a leak-tight

tics

joint are not covered in this specification.

E177Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

NOTE 1—The terms “wrench makeup” and “wrench tight” are standard

F412Terminology Relating to Plastic Piping Systems

terminology for tightness and do not imply using a pipe wrench or other

tools which would damage plastic pipe and fittings. The terms “hand-

2.2 ASME Standards:

tight” and “hand-tight engagement” refer only to thread gaging (not pipe

B1.20.1Pipe Threads, General Purpose (inch)

and fitting connections) and is the definition of the L gage length.

B1.7 Nomenclature, Definitions and Letter Symbols for

1.4 ThreadDesignations—Thetypeofpipethreadsincluded 3

Screw Threads

in this specification are designated by specifying in sequence

B47.1Gage Blanks

the nominal pipe size, number of threads per inch, and the

thread series symbols as follows in accordance with ANSI/

3. Terminology

ASME B 1.20.1: ⁄8-18 NPT. For left-hand threads add LH to

3.1 Terminology is in accordance with Terminology F412

theendofthedesignation,otherwiseright-handthreadswillbe

and abbreviations are in accordance with Terminology D1600,

understood. For example: ⁄8-18 NPT-LH.

unless otherwise indicated.

1.4.1 Each of these letters in the symbol has a definite

3.2 Nomenclature, definitions, and letter symbols for screw

significance as follows:

threads are in accordance with ASME/ANSI B1.7.

N = National (American Standard)

P = Pipe

T = Taper

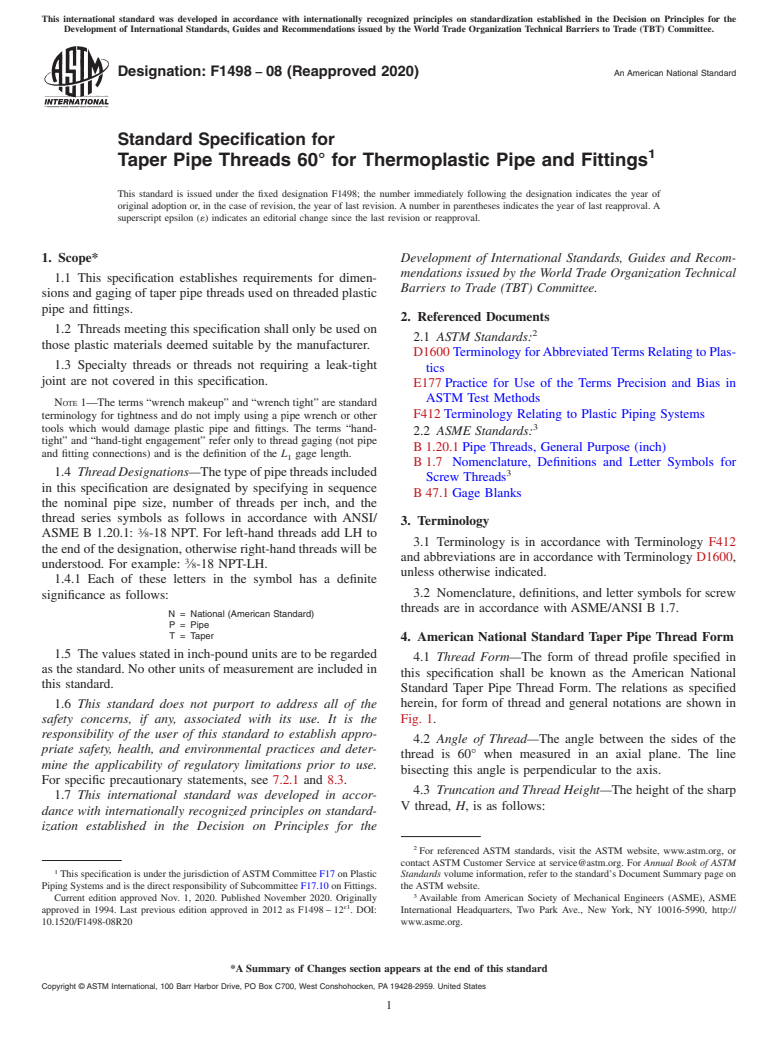

4. American National Standard Taper Pipe Thread Form

1.5 The values stated in inch-pound units are to be regarded

4.1 Thread Form—The form of thread profile specified in

as the standard. No other units of measurement are included in

this specification shall be known as the American National

this standard.

Standard Taper Pipe Thread Form. The relations as specified

1.6 This standard does not purport to address all of the herein, for form of thread and general notations are shown in

safety concerns, if any, associated with its use. It is the Fig. 1.

responsibility of the user of this standard to establish appro-

4.2 Angle of Thread—The angle between the sides of the

priate safety, health, and environmental practices and deter-

thread is 60° when measured in an axial plane. The line

mine the applicability of regulatory limitations prior to use.

bisecting this angle is perpendicular to the axis.

For specific precautionary statements, see 7.2.1 and 8.3.

4.3 Truncation and Thread Height—The height of the sharp

1.7 This international standard was developed in accor-

V thread, H, is as follows:

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This specification is under the jurisdiction ofASTM Committee F17 on Plastic Standards volume information, refer to the standard’s Document Summary page on

Piping Systems and is the direct responsibility of Subcommittee F17.10 on Fittings. the ASTM website.

Current edition approved Nov. 1, 2020. Published November 2020. Originally Available from American Society of Mechanical Engineers (ASME), ASME

ɛ1

approved in 1994. Last previous edition approved in 2012 as F1498–12 . DOI: International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

10.1520/F1498-08R20 www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1498−08 (2020)

H = 0.866025p = height of 60° sharp V thread β = 1° 47 min. = thread taper angle for ⁄16 taper

h = 0.800000p = height of thread on product f = depth of truncation at crest

c

p =1/n = pitch (measured parallel to axis) f = depth of truncation at root

r

n = number of threads per inch F = width of flat at crest

c

α = 30° = thread flank angle F = width of flat at root

r

NOTE 1—For a symmetrical straight screw thread, H = cot α/2n. For a symmetrical taper screw thread, H = (cot α − tan β tan α)/2n, so that the exact

value for anAmerican National Standard Taper Pipe Thread is H = 0.865743p as against H = 0.866025p, the value given above. For an 8-pitch thread,

which is the coarsest standard taper pipe thread pitch, the corresponding values of H are 0.108218 and 0.108253 respectively, the difference being

0.000035 in. This difference being too small to be significant, the value of H = 0.866025p continues in use for threads of 0.750 in., or less, taper/ft on

the diameter.

FIG. 1Basic Form of American National Standard Taper Pipe Thread

H 50.866025p 50.866025/n (1) h 50.800p 50.800/n (2)

where:

The crest and root of pipe threads are truncated a minimum

p = pitch of thread, and

of 0.033p. Maximum truncation for the crest and root of these

n = threads per inch.

pipe threads is in Table 1. The crests and roots of the external

and internal threads may be truncated either parallel to the

4.3.1 The basic maximum height of the truncated thread, h

pitchlineorparalleltotheaxis.ThesketchesinTables2-6give

(seeFig.1)isbasedonfactorsenteringintothemanufactureof

cutting tools and the making of tight joints. a sectional view of this standard thread form, which represents

F1498−08 (2020)

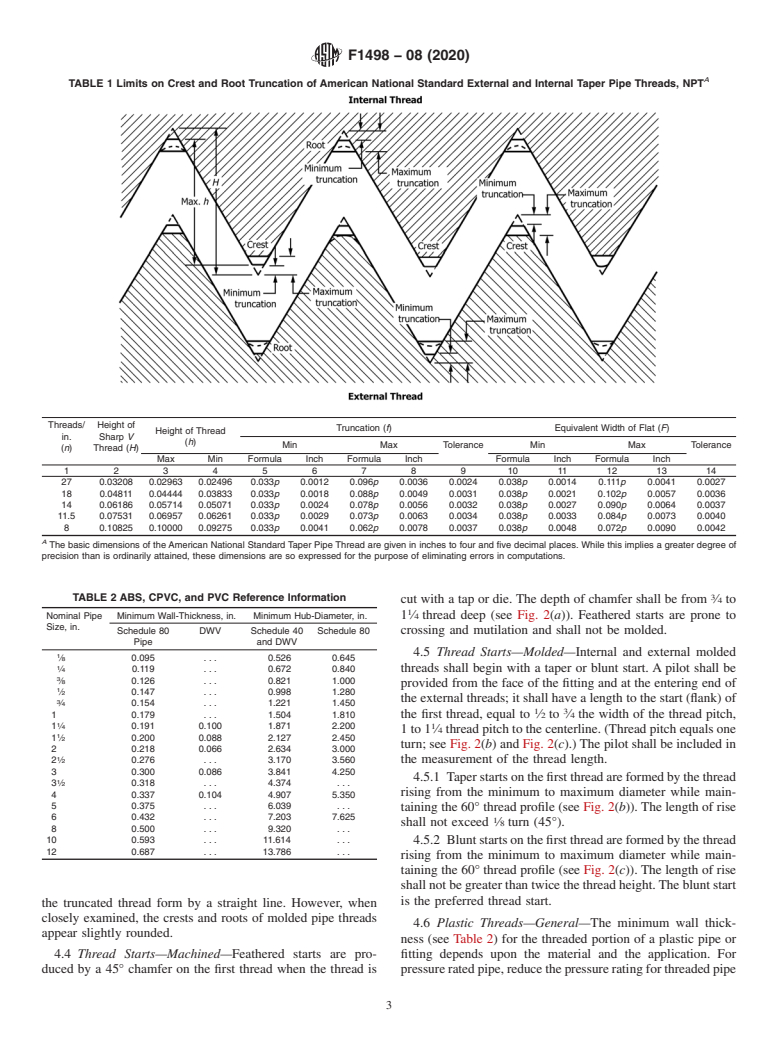

A

TABLE 1 Limits on Crest and Root Truncation of American National Standard External and Internal Taper Pipe Threads, NPT

Threads/ Height of

Truncation (f) Equivalent Width of Flat (F)

Height of Thread

in. Sharp V

(h)

Min Max Tolerance Min Max Tolerance

(n) Thread (H)

Max Min Formula Inch Formula Inch Formula Inch Formula Inch

123456789 10 11 12 13 14

27 0.03208 0.02963 0.02496 0.033p 0.0012 0.096p 0.0036 0.0024 0.038p 0.0014 0.111p 0.0041 0.0027

18 0.04811 0.04444 0.03833 0.033p 0.0018 0.088p 0.0049 0.0031 0.038p 0.0021 0.102p 0.0057 0.0036

14 0.06186 0.05714 0.05071 0.033p 0.0024 0.078p 0.0056 0.0032 0.038p 0.0027 0.090p 0.0064 0.0037

11.5 0.07531 0.06957 0.06261 0.033p 0.0029 0.073p 0.0063 0.0034 0.038p 0.0033 0.084p 0.0073 0.0040

8 0.10825 0.10000 0.09275 0.033p 0.0041 0.062p 0.0078 0.0037 0.038p 0.0048 0.072p 0.0090 0.0042

A

The basic dimensions of the American National Standard Taper Pipe Thread are given in inches to four and five decimal places. While this implies a greater degree of

precision than is ordinarily attained, these dimensions are so expressed for the purpose of eliminating errors in computations.

TABLE 2 ABS, CPVC, and PVC Reference Information

cut with a tap or die. The depth of chamfer shall be from ⁄4to

Nominal Pipe Minimum Wall-Thickness, in. Minimum Hub-Diameter, in. 1 ⁄4thread deep (see Fig. 2(a)). Feathered starts are prone to

Size, in.

crossing and mutilation and shall not be molded.

Schedule 80 DWV Schedule 40 Schedule 80

Pipe and DWV

4.5 Thread Starts—Molded—Internal and external molded

⁄8 0.095 . . . 0.526 0.645

⁄4 0.119 . . . 0.672 0.840 threads shall begin with a taper or blunt start. A pilot shall be

⁄8 0.126 . . . 0.821 1.000

provided from the face of the fitting and at the entering end of

⁄2 0.147 . . . 0.998 1.280

theexternalthreads;itshallhavealengthtothestart(flank)of

⁄4 0.154 . . . 1.221 1.450

1 3

1 0.179 . . . 1.504 1.810 the first thread, equal to ⁄2to ⁄4the width of the thread pitch,

1 ⁄4 0.191 0.100 1.871 2.200 1

1to1 ⁄4threadpitchtothecenterline.(Threadpitchequalsone

1 ⁄2 0.200 0.088 2.127 2.450

turn; see Fig. 2(b) and Fig. 2(c).)The pilot shall be included in

2 0.218 0.066 2.634 3.000

2 ⁄2 0.276 . . . 3.170 3.560 the measurement of the thread length.

3 0.300 0.086 3.841 4.250

4.5.1 Taperstartsonthefirstthreadareformedbythethread

3 ⁄2 0.318 . . . 4.374 . . .

rising from the minimum to maximum diameter while main-

4 0.337 0.104 4.907 5.350

5 0.375 . . . 6.039 . . .

taining the 60° thread profile (see Fig. 2(b)).The length of rise

6 0.432 . . . 7.203 7.625

shall not exceed ⁄8turn (45°).

8 0.500 . . . 9.320 . . .

10 0.593 . . . 11.614 . . . 4.5.2 Bluntstartsonthefirstthreadareformedbythethread

12 0.687 . . . 13.786 . . .

rising from the minimum to maximum diameter while main-

taining the 60° thread profile (see Fig. 2(c)).The length of rise

shallnotbegreaterthantwicethethreadheight.Thebluntstart

is the preferred thread start.

the truncated thread form by a straight line. However, when

closely examined, the crests and roots of molded pipe threads

4.6 Plastic Threads—General—The minimum wall thick-

appear slightly rounded.

ness (see Table 2) for the threaded portion of a plastic pipe or

4.4 Thread Starts—Machined—Feathered starts are pro- fitting depends upon the material and the application. For

duced by a 45° chamfer on the first thread when the thread is pressureratedpipe,reducethepressureratingforthreadedpipe

F1498−08 (2020)

A

TABLE 3 Basic Dimensions of American National Standard Taper Thread, NPT

NOTE 1—Wrench makeup modified for plastic.

Hand-tight Gage Engagement Effective Thread, External

Nominal Outside Pitch Diameter at

Threads/in. Pitch of Thread

B D

Pipe Size, Diameter of Beginning of Ex- Length (L ) C Length (L )

1 Diameter 2 Diameter

(n) (P)

in. Pipe (D) ternal Thread (E ) (E )

0 (E )

Inch Threads Inch Threads 2

1 2 3 4 5 6 789 10 11

⁄16 0.3125 27 0.03704 0.27118 0.160 4.32 0.28118 0.2611 7.05 0.28750

⁄8 0.405 27 0.03704 0.36351 0.1615 4.36 0.37360 0.2639 7.12 0.38000

⁄4 0.540 18 0.05556 0.47739 0.2278 4.10 0.49163 0.4018 7.23 0.50250

⁄8 0.675 18 0.05556 0.61201 0.240 4.32 0.62701 0.4078 7.34 0.63750

⁄2 0.840 14 0.07143 0.75843 0.320 4.48 0.77843 0.5337 7.47 0.79179

⁄4 1.050 14 0.07143 0.96768 0.339 4.75 0.98887 0.5457 7.64 1.00179

1 1.315 11.5 0.08696 1.21363 0.400 4.60 1.23863 0.6828 7.85 1.25630

1 ⁄4 1.660 11.5 0.08696 1.55713 0.420 4.83 1.58338 0.7068 8.13 1.60130

1 ⁄2 1.900 11.5 0.08696 1.79609 0.420 4.83 1.82234 0.7235 8.32 1.84130

2 2.375 11.5 0.08696 2.26902 0.436 5.01 2.29627 0.7565 8.70 2.31630

2 ⁄2 2.875 8 0.12500 2.71953 0.682 5.46 2.76216 1.1375 9.10 2.79062

3 3.500 8 0.12500 3.34062 0.766 6.13 3.38850 1.2000 9.60 3.41562

3 ⁄2 4.000 8 0.12500 3.83750 0.821 6.57 3.88881 1.2500 10.00 3.91562

4 4.500 8 0.12500 4.33438 0.844 6.75 4.38712 1.3000 10.40 4.41562

5 5.563 8 0.12500 5.39073 0.937 7.50 5.44929 1.4063 11.25 5.47862

6 6.625 8 0.12500 6.44609 0.958 7.66 6.50597 1.5125 12.10 6.54062

8 8.625 8 0.12500 8.43359 1.063 8.50 8.50003 1.7125 13.70 8.54062

10 10.750 8 0.12500 10.54531 1.210 9.68 10.62094 1.9250 15.40 10.66562

12 12.750 8 0.12500 12.53281 1.360 10.88 12.61781 2.1250 17.00 12.66562

A

The basic dimensions of the American National Standard Taper Pipe Thread are given in inches to four or five decimal places. While this implies a greater degree of

precision than is ordinarily attained, these dimensions are the basis of gage dimensions and are so expressed for the purpose of eliminating errors in computations.

B

Also length of thin ring gage and length from gaging notch to small end of plug gage.

C

Also pitch diameter at gaging notch (hand-tight plane).

D

Also length of plug gage.

are recommended by the manufacturer, may not be compatible with some

by one-half (50 %) that of unthreaded pipe. Some pressure

plastics.

rated pipe materials (for example, PP and PE) are not recom-

mended for threaded applications. If the wall thickness is not 4.8 Thread Tightness—Wrench Makeup—Some lubricants

specified in a pipe or fitting standard, the manufacturer must (PTFE pastes, silicones, etc.) will provide added lubricity,

determine the appropriate wall thickness. which can result in more finger-tight engagement than with

sealants. The maximum recommended tightness is two turns

4.7 Sealing—Where pressure-tight or leak-tight non-

past finger tight for both internal and external threads. Over

pressure joints are required, it is intended that taper pipe

tighteningofinternalthreadswillproducehoopstressesgreater

threadsconformingtothisspecificationbemadeupwithPTFE

than plastic can withstand, resulting in split fittings.

(polytetrafluoroethylene or equivalent) tape or a chemically

compatible a sealant-lubricant. Conventional pipe-thread

NOTE 3—When assembling metal and plastic threads, the preferred

method is plastic external (male) threads to metal internal (female)

compounds, putty, linseed oil-base products, and unknown

threads. Cyclic heating and cooling may result in dripping leaks.

mixtures shall not be used.

NOTE4—WhenPTFEtapeisusedtosealthethreads,wraptheexternal

NOTE 2—Some TFE-fluorocarbon-paste compounds, even though they threads with 2 to 3 layers.

F1498−08 (2020)

TABLE 3 Basic Dimensions of American National Standard Taper Thread, NPT (continued)

Wrench Makeup Length for

Basic

Length, L Plane to L A

1 2 B

Internal Thread

Overall

Increase in Minor

Plane External Thread Nominal Complete

Nominal

Length

Vanish Thread (V)

Diameter C Height of Diameter Diameter

(L −L ) External Thread

Pipe Size, 2 1 Length (L ) External

(E ) Thread (h) per Thread at Small

Thread

in.

(0.0625/n) End of

(L )

4 Length (L )Diameter

Inch Thread Inch Thread Inch Thread

Pipe (K )

(E )

1 12131415161718192021222324

⁄16 0.1011 2.73 0.0741 2 0.26656 0.1285 3.47 0.3896 0.1870 0.28287 0.02963 0.00231 0.2416

⁄8 0.1024 2.76 0.0741 2 0.35889 0.1285 3.47 0.3924 0.1898 0.37537 0.02963 0.00231 0.3339

⁄4 0.1740 3.13 0.1111 2 0.47045 0.1928 3.47 0.5946 0.2907 0.49556 0.04444 0.00347 0.4329

⁄8 0.1678 3.02 0.1111 2 0.60507

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.