ASTM D4216-22

(Specification)Standard Specification for Rigid Poly(Vinyl Chloride) (PVC) and Related PVC and Chlorinated Poly(Vinyl Chloride) (CPVC) Building Products Compounds

Standard Specification for Rigid Poly(Vinyl Chloride) (PVC) and Related PVC and Chlorinated Poly(Vinyl Chloride) (CPVC) Building Products Compounds

ABSTRACT

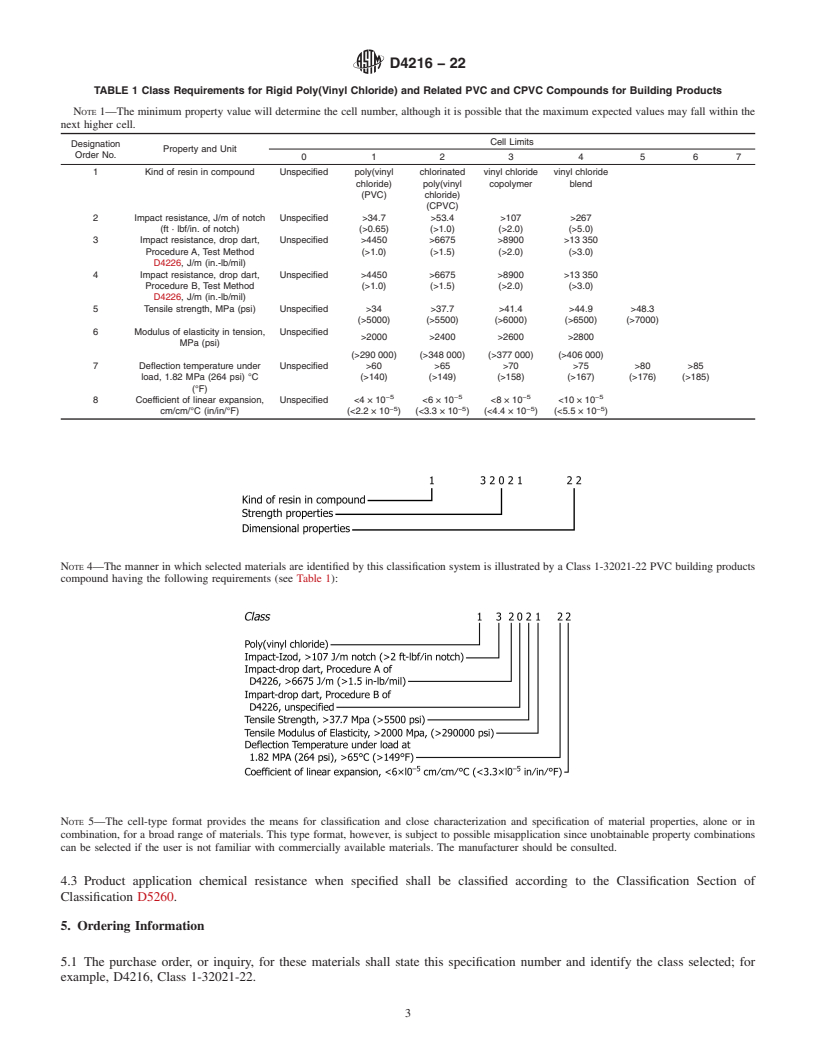

This specification covers rigid plastic PVC and CPVC exterior compounds composed of poly (vinyl chloride), chlorinated poly (vinyl chloride), vinyl chloride copolymers or vinyl chloride blends, and the necessary compound ingredients intended for use in making building products. The compounding ingredients may consist of lubricants, stabilizers, nonpoly-(vinyl chloride) resin modifiers, colorants or pigments, or both, and inorganic fillers. It is intended to provide classification of base compounds used to manufacture PVC and CPVC exterior building products. The means for classifying and identifying rigid PVC building products compounds are provided as follows: kind of resin in compound, impact resistance, tensile strength, modulus of elasticity in tension, deflection temperature under a specific load and coefficient of linear expansion. PVC compound shall be in the form of cubes, pellets, granules, free-flowing powder blends, or compacted powder blends. Materials shall be of uniform composition and size and shall be free of foreign matter to a level that is not expected to affect processability, serviceability, or finished product appearance adversely.

SCOPE

1.1 This specification covers rigid plastic PVC and CPVC Exterior compounds composed of poly(vinyl chloride), chlorinated poly(vinyl chloride), vinyl chloride copolymers or vinyl chloride blends, and the necessary compound ingredients intended for use in making building products. The compounding ingredients are permitted to consist of lubricants, stabilizers, nonpoly(vinyl chloride) resin modifiers, colorants or pigments, or both, and inorganic fillers.

1.2 This specification is intended to provide classification of base compounds used to manufacture PVC and CPVC exterior building products. It is acceptable to determine physical properties by evaluating compounds of any color.

Note 1: Two year weathering studies, without specific requirements for color change and physical property change, are recommended for all colors of new compounds and compounds for new applications to provide the basis for agreement between producer and buyer on the suitability of the compound for the intended application.

1.3 The requirements in this specification are intended for qualification, as well as for quality control of compounds used to manufacture building products. They are not applicable to finished building products.

1.4 It will be necessary, in special cases, to select specific compounds for unusual applications that require consideration of other properties not covered in this specification.

1.5 The rate of burning test, Test Method D635, is used in this specification only as a screening test for identification of certain properties of the PVC compound; there is no flammability test or flammability requirement for the compound.

1.6 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.7 The following safety hazards caveat pertains only to the test methods portion, Section 11, of this specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 2: There is no known ISO equivalent to this standard.

1.8 The text of this standard references notes and footnotes, which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of this standard.

1.9 It is possible that rigid PVC recycle plastic meeting the requirements of this specification will be usable in some applications. Refer to the specific requirements in the Materials and Manufacture Section of the applicable product standard.

1.10 This international standard was developed in accorda...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D4216 −22

Standard Specification for

Rigid Poly(Vinyl Chloride) (PVC) and Related PVC and

Chlorinated Poly(Vinyl Chloride) (CPVC) Building Products

1

Compounds

This standard is issued under the fixed designation D4216; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 1.7 The following safety hazards caveat pertains only to the

test methods portion, Section 11, of this specification:This

1.1 This specification covers rigid plastic PVC and CPVC

standard does not purport to address all of the safety concerns,

Exterior compounds composed of poly(vinyl chloride), chlori-

if any, associated with its use. It is the responsibility of the user

nated poly(vinyl chloride), vinyl chloride copolymers or vinyl

of this standard to establish appropriate safety, health, and

chloride blends, and the necessary compound ingredients

environmental practices and determine the applicability of

intended for use in making building products. The compound-

regulatory limitations prior to use.

ing ingredients are permitted to consist of lubricants,

stabilizers, nonpoly(vinyl chloride) resin modifiers, colorants

NOTE 2—There is no known ISO equivalent to this standard.

or pigments, or both, and inorganic fillers.

1.8 The text of this standard references notes and footnotes,

1.2 Thisspecificationisintendedtoprovideclassificationof whichprovideexplanatorymaterial.Thesenotesandfootnotes

base compounds used to manufacture PVC and CPVC exterior (excluding those in tables and figures) shall not be considered

building products. It is acceptable to determine physical as requirements of this standard.

properties by evaluating compounds of any color.

1.9 It is possible that rigid PVC recycle plastic meeting the

requirements of this specification will be usable in some

NOTE 1—Two year weathering studies, without specific requirements

for color change and physical property change, are recommended for all

applications.RefertothespecificrequirementsintheMaterials

colorsofnewcompoundsandcompoundsfornewapplicationstoprovide

and Manufacture Section of the applicable product standard.

the basis for agreement between producer and buyer on the suitability of

1.10 This international standard was developed in accor-

the compound for the intended application.

dance with internationally recognized principles on standard-

1.3 The requirements in this specification are intended for

ization established in the Decision on Principles for the

qualification, as well as for quality control of compounds used

Development of International Standards, Guides and Recom-

to manufacture building products. They are not applicable to

mendations issued by the World Trade Organization Technical

finished building products.

Barriers to Trade (TBT) Committee.

1.4 It will be necessary, in special cases, to select specific

compounds for unusual applications that require consideration

2. Referenced Documents

of other properties not covered in this specification.

2

2.1 ASTM Standards:

1.5 The rate of burning test, Test Method D635, is used in

D256Test Methods for Determining the Izod Pendulum

this specification only as a screening test for identification of

Impact Resistance of Plastics

certain properties of the PVC compound; there is no flamma-

D618Practice for Conditioning Plastics for Testing

bility test or flammability requirement for the compound.

D635Test Method for Rate of Burning and/or Extent and

Time of Burning of Plastics in a Horizontal Position

1.6 The values stated in SI units are to be regarded as

D638Test Method for Tensile Properties of Plastics

standard. The values given in parentheses are for information

D648Test Method for Deflection Temperature of Plastics

only.

Under Flexural Load in the Edgewise Position

1

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

2

Materials (Section D20.15.08). For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2022. Published May 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1983. Last previous edition approved in 2017 as D4216–17. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D4216-22. the ASTM website.

*A Summary of Changes section appe

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4216 − 17 D4216 − 22

Standard Specification for

Rigid Poly(Vinyl Chloride) (PVC) and Related PVC and

Chlorinated Poly(Vinyl Chloride) (CPVC) Building Products

1

Compounds

This standard is issued under the fixed designation D4216; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers rigid plastic PVC and CPVC Exterior compounds composed of poly(vinyl chloride), chlorinated

poly(vinyl chloride), vinyl chloride copolymers or vinyl chloride blends, and the necessary compound ingredients intended for use

in making building products. The compounding ingredients are permitted to consist of lubricants, stabilizers, nonpoly(vinyl

chloride) resin modifiers, colorants or pigments, or both, and inorganic fillers.

1.2 This specification is intended to provide classification of base compounds used to manufacture PVC and CPVC exterior

building products. It is acceptable to determine physical properties by evaluating compounds of any color.

NOTE 1—Two year weathering studies, without specific requirements for color change and physical property change, are recommended for all colors of

new compounds and compounds for new applications to provide the basis for agreement between producer and buyer on the suitability of the compound

for the intended application.

1.3 The requirements in this specification are intended for qualification, as well as for quality control of compounds used to

manufacture building products. They are not applicable to finished building products.

1.4 It will be necessary, in special cases, to select specific compounds for unusual applications that require consideration of other

properties not covered in this specification.

1.5 The rate of burning test, Test Method D635, is used in this specification only as a screening test for identification of certain

properties of the PVC compound; there is no flammability test or flammability requirement for the compound.

1.6 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.7 The following safety hazards caveat pertains only to the test methods portion, Section 11, of this specification:This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory

limitations prior to use.

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materials

(Section D20.15.08).

Current edition approved Dec. 1, 2017May 1, 2022. Published January 2018May 2022. Originally approved in 1983. Last previous edition approved in 20132017 as

D4216 – 13.D4216 – 17. DOI: 10.1520/D4216-17.10.1520/D4216-22.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4216 − 22

NOTE 2—There is no known ISO equivalent to this standard.

1.8 The text of this standard references notes and footnotes, which provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of this standard.

1.9 It is possible that rigid PVC recycle plastic meeting the requirements of this specification will be usable in some applications.

Refer to the specific requirements in the Materials and Manufacture Section of the applicable product standard.

1.10 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D256 Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics

D618 Practice for Conditioning Plastics for Testing

D635 Test Method for Rate of Burning and/or Extent and Time of Bur

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.