ASTM D4906-95(2023)

(Test Method)Standard Test Method for Total Solids and Ash Content in Leather Finishing Materials

Standard Test Method for Total Solids and Ash Content in Leather Finishing Materials

SIGNIFICANCE AND USE

2.1 This test method is intended for use in determining the total solids content and the ash content of a finishing material before its use on any leather.

SCOPE

1.1 This test method covers the total solids and ash content of finishing materials.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

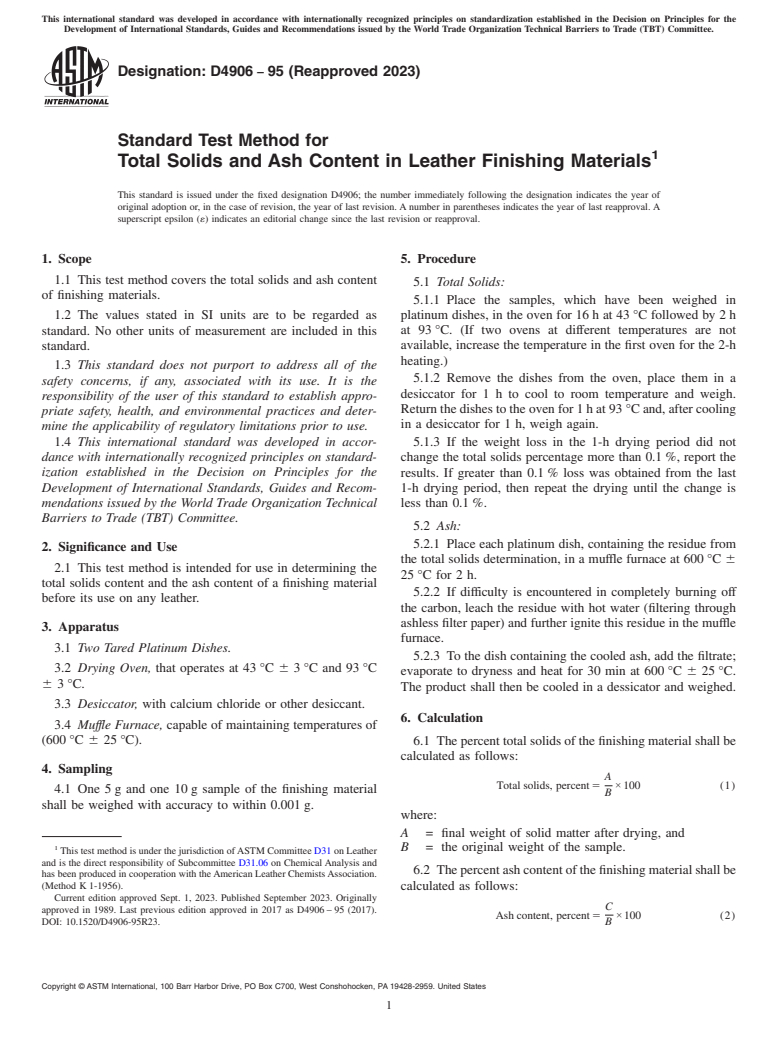

Designation: D4906 − 95 (Reapproved 2023)

Standard Test Method for

Total Solids and Ash Content in Leather Finishing Materials

This standard is issued under the fixed designation D4906; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Procedure

1.1 This test method covers the total solids and ash content

5.1 Total Solids:

of finishing materials.

5.1.1 Place the samples, which have been weighed in

1.2 The values stated in SI units are to be regarded as platinum dishes, in the oven for 16 h at 43 °C followed by 2 h

standard. No other units of measurement are included in this at 93 °C. (If two ovens at different temperatures are not

standard. available, increase the temperature in the first oven for the 2-h

heating.)

1.3 This standard does not purport to address all of the

5.1.2 Remove the dishes from the oven, place them in a

safety concerns, if any, associated with its use. It is the

desiccator for 1 h to cool to room temperature and weigh.

responsibility of the user of this standard to establish appro-

Return the dishes to the oven for 1 h at 93 °C and, after cooling

priate safety, health, and environmental practices and deter-

in a desiccator for 1 h, weigh again.

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor- 5.1.3 If the weight loss in the 1-h drying period did not

dance with internationally recognized principles on standard- change the total solids percentage more than 0.1 %, report the

ization established in the Decision on Principles for the results. If greater than 0.1 % loss was obtained from the last

Development of International Standards, Guides and Recom- 1-h drying period, then repeat the drying until the change is

mendations issued by the World Trade Organization Technical less than 0.1 %.

Barriers to Trade (TBT) Committee.

5.2 Ash:

5.2.1 Place each platinum dish, containing the residue from

2. Significance and Use

the total solids determination, in a muffle furnace at 600 °C 6

2.1 This test method is intended for use in determining the

25 °C for 2 h.

total solids content and the ash content of a finishing material

5.2.2 If difficulty is encountered in completely burning off

before its use on any leather.

the carbon, leach the residue with hot water (filtering through

ashless filter paper) and further ignite this residue in the muffle

3. Apparatus

furnace.

3.1 Two Tared Platinum Dishes.

5.2.3 To the dish containing the cooled ash, add the filtrate;

3.2 Drying Oven, that operates at 43 °C 6 3 °C and 93 °C

evaporate to dryness and heat for 30 min at 600 °C 6 25 °C.

6 3 °C.

The product shall then be cooled in a dessicator and weighed.

3.3 Desiccator, with calcium chloride or other desiccant.

6. Calculation

3.4 Muffle Furnace, capable of maintaining temperatures of

(600 °C 6 25 °C).

6.1 The percent tota

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.