ASTM C876-09

(Test Method)Standard Test Method for Corrosion Potentials of Uncoated Reinforcing Steel in Concrete

Standard Test Method for Corrosion Potentials of Uncoated Reinforcing Steel in Concrete

SIGNIFICANCE AND USE

This test method is suitable for in-service evaluation and for use in research and development work.

This test method is applicable to members regardless of their size or the depth of concrete cover over the reinforcing steel. Concrete cover in excess of 3 in. (75 mm) can result in an averaging of adjacent reinforcement corrosion potentials that can result in a loss of the ability to discriminate variation in relative corrosion activity.

This test method may be used at any time during the life of a concrete member.

The results obtained by the use of this test method shall not be considered as a means for estimating the structural properties of the steel or of the reinforced concrete member.

The potential measurements should be interpreted by engineers or technical specialists experienced in the fields of concrete materials and corrosion testing. It is often necessary to use other data such as chloride contents, depth of carbonation, delamination survey findings, rate of corrosion results, and environmental exposure conditions, in addition to corrosion potential measurements, to formulate conclusions concerning corrosion activity of embedded steel and its probable effect on the service life of a structure.

SCOPE

1.1 This test method covers the estimation of the electrical corrosion potential of uncoated reinforcing steel in field and laboratory concrete, for the purpose of determining the corrosion activity of the reinforcing steel.

1.2 This test method is limited by electrical circuitry. Concrete surface in building interiors and desert environments lose sufficient moisture so that the concrete resistivity becomes so high that special testing techniques not covered in this test method may be required (see 5.1.4.1). Concrete surfaces that are coated or treated with sealers may not provide an acceptable electrical circuit. The basic configuration of the electrical circuit is shown in Fig. 1.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

FIG. 1 Reference Electrode Circuitry

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C876 − 09

StandardTest Method for

Corrosion Potentials of Uncoated Reinforcing Steel in

1

Concrete

This standard is issued under the fixed designation C876; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G16Guide for Applying Statistics to Analysis of Corrosion

Data

1.1 This test method covers the estimation of the electrical

corrosion potential of uncoated reinforcing steel in field and

3. Terminology

laboratory concrete, for the purpose of determining the corro-

sion activity of the reinforcing steel.

3.1 Fordefinitionsoftermsusedinthistestmethod,referto

Terminology G15.

1.2 This test method is limited by electrical circuitry.

Concrete surface in building interiors and desert environments

4. Significance and Use

losesufficientmoisturesothattheconcreteresistivitybecomes

so high that special testing techniques not covered in this test

4.1 Thistestmethodissuitableforin-serviceevaluationand

method may be required (see 5.1.4.1). Concrete surfaces that

for use in research and development work.

are coated or treated with sealers may not provide an accept-

4.2 This test method is applicable to members regardless of

able electrical circuit. The basic configuration of the electrical

their size or the depth of concrete cover over the reinforcing

circuit is shown in Fig. 1.

steel. Concrete cover in excess of 3 in. (75 mm) can result in

1.3 Thevaluesstatedininch-poundunitsaretoberegarded

an averaging of adjacent reinforcement corrosion potentials

as standard. The values given in parentheses are mathematical

that can result in a loss of the ability to discriminate variation

conversions to SI units that are provided for information only

in relative corrosion activity.

and are not considered standard.

4.3 Thistestmethodmaybeusedatanytimeduringthelife

1.4 This standard does not purport to address all of the

of a concrete member.

safety concerns, if any, associated with its use. It is the

4.4 The results obtained by the use of this test method shall

responsibility of the user of this standard to establish appro-

not be considered as a means for estimating the structural

priate safety and health practices and determine the applica-

properties of the steel or of the reinforced concrete member.

bility of regulatory limitations prior to use.

4.5 The potential measurements should be interpreted by

2. Referenced Documents

engineers or technical specialists experienced in the fields of

2

concretematerialsandcorrosiontesting.Itisoftennecessaryto

2.1 ASTM Standards:

use other data such as chloride contents, depth of carbonation,

G3Practice for Conventions Applicable to Electrochemical

delamination survey findings, rate of corrosion results, and

Measurements in Corrosion Testing

environmental exposure conditions, in addition to corrosion

G15TerminologyRelatingtoCorrosionandCorrosionTest-

3

potential measurements, to formulate conclusions concerning

ing (Withdrawn 2010)

corrosion activity of embedded steel and its probable effect on

the service life of a structure.

1

This test method is under the jurisdiction of ASTM Committee G01 on

Corrosion of Metalsand is the direct responsibility of Subcommittee G01.14 on

5. Apparatus

Corrosion of Metals in Construction Materials.

5.1 The testing apparatus consists of the following:

Current edition approved April 1, 2009. Published May 2009. Originally

approvedin1977.Lastpreviouseditionapprovedin1999asC876–91(1999),which

5.1.1 Reference Electrode:

waswithdrawnSeptember2008andreinstatedinApril2009.DOI:10.1520/C0876-

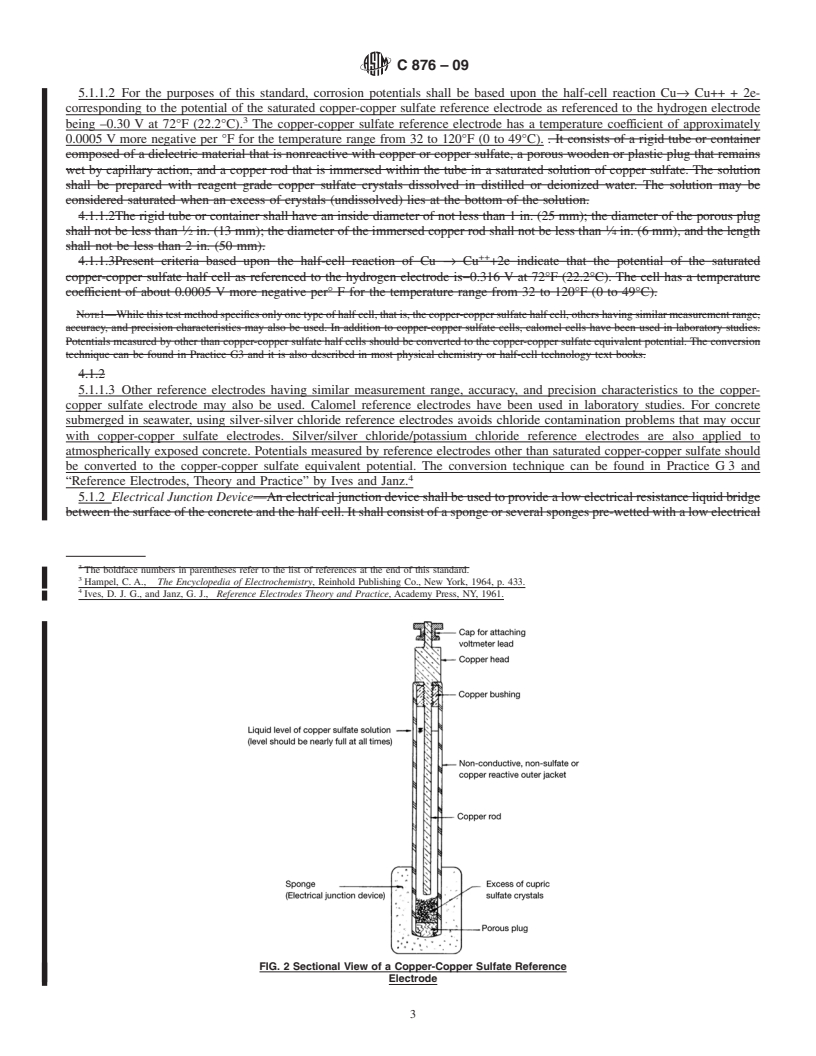

5.1.1.1 The reference electrode selected shall provide a

09.

2

stable and reproducible potential for the measurement of the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

corrosion potential of reinforcing steel embedded in concrete

Standards volume information, refer to the standard’s Document Summary page on

over the temperature range from 32 to 120°F (0 to 49°C).

the ASTM website.

3

5.1.1.2 For the purposes of this standard, corrosion poten-

The last approved version of this historical standard is referenced on

www.astm.org. tials shall be based upon the half-cell reaction Cu→ Cu++ +

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C876 − 09

FIG. 1 Reference Electrode Circuitry

2e- corresponding to the potential of the saturated copper-

copper sulfate reference electrode as referenced to the hydro-

4

gen electrode being –0.30 V at 72°F

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C876–91 (Reapproved 1999) Designation: C 876 – 09

Standard Test Method for

Half-CellCorrosion Potentials of Uncoated Reinforcing Steel

1

in Concrete

This standard is issued under the fixed designation C876; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1Thistestmethodcoverstheestimationoftheelectricalhalf-cellpotentialofuncoatedreinforcingsteelinfieldandlaboratory

concrete, for the purpose of determining the corrosion activity of the reinforcing steel.

1.2This test method is limited by electrical circuitry. A concrete surface that has dried to the extent that it is a dielectric and

surfaces that are coated with a dielectric material will not provide an acceptable electrical circuit. The basic configuration of the

electrical circuit is shown in

1.1 This test method covers the estimation of the electrical corrosion potential of uncoated reinforcing steel in field and

laboratory concrete, for the purpose of determining the corrosion activity of the reinforcing steel.

1.2 This test method is limited by electrical circuitry. Concrete surface in building interiors and desert environments lose

sufficient moisture so that the concrete resistivity becomes so high that special testing techniques not covered in this test method

may be required (see 5.1.4.1). Concrete surfaces that are coated or treated with sealers may not provide an acceptable electrical

circuit. The basic configuration of the electrical circuit is shown in Fig. 1.

1.3The values stated in inch-pound units are to be regarded as the standard.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

G3 Practice for Conventions Applicable to Electrochemical Measurements in Corrosion Testing Practice for Conventions

Applicable to Electrochemical Measurements in Corrosion Testing

G15 Terminology Relating to Corrosion and Corrosion Testing

G16 Guide for Applying Statistics to Analysis of Corrosion Data

3. Significance and Use

3.1This test method is suitable for in-service evaluation and for use in research and development work.

3.2This test method is applicable to members regardless of their size or the depth of concrete cover over the reinforcing steel.

3.3This test method may be used at any time during the life of a concrete member.

3.4The results obtained by the use of this test method shall not be considered as a means for estimating the structural properties

of the steel or of the reinforced concrete member.

3.5The potential measurements should be interpreted by engineers or technical specialists experienced in the fields of concrete

materialsandcorrosiontesting.Itisoftennecessarytouseotherdatasuchaschloridecontents,depthofcarbonation,delamination

survey findings, rate of corrosion results, and environmental exposure conditions, in addition to half-cell potential measurements,

1

This test method is under the jurisdiction ofASTM Committee G01 on Corrosion of Metals and is the direct responsibility of Subcommittee G01.11 on Electrochemical

Measurements in Corrosion Testing.

CurrenteditionapprovedMarch11,1991.PublishedMay1991.OriginallypublishedasC876–77.LastpreviouseditionC876–87.onCorrosionofMetalsandisthedirect

responsibility of Subcommittee G01.14 on Corrosion of Metals in Construction Materials.

Current edition approved April 1, 2009. Published May 2009. Originally approved in 1977. Last previous edition approved in 1999 as C876–91(1999), which was

withdrawn September 2008 and reinstated in April 2009.

2

Annual Book of ASTM Standards, Vol 03.02.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, Unit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.