ASTM D8303-20

(Test Method)Standard Test Method for Determining Thermal Cracking Properties of Asphalt Mixtures Through Measurement of Thermally Induced Stress and Strain

Standard Test Method for Determining Thermal Cracking Properties of Asphalt Mixtures Through Measurement of Thermally Induced Stress and Strain

SIGNIFICANCE AND USE

5.1 The thermal strain measurements allow for the calculation of the coefficient of axial thermal contraction, which can be directly used in the mechanistic-empirical pavement design methods.

5.2 The thermal stress and strain measurements allow calculations of the modulus of asphalt mixture in the temperature domain.

5.3 From modulus versus temperature and thermal stress versus temperature relationships the thermal viscoelastic and fracture properties are determined for asphalt mixtures.

5.4 The derived modulus, thermal viscoelastic, and fracture properties may be used in evaluating the low-temperature cracking resistance of asphalt mixtures.

Note 1: The quality of the results produced by this standard are dependent on the competence of the personnel performing the procedure and the capability, calibration, and maintenance of the equipment used. Agencies that meet the criteria of Specification D3666 are generally considered capable of competent and objective testing, sampling, inspection, etc. Users of this standard are cautioned that compliance with Specification D3666 alone does not completely ensure reliable results. Reliable results depend on many factors; following the suggestions of Specification D3666 or some similar acceptable guideline provides a means of evaluating and controlling some of those factors.

SCOPE

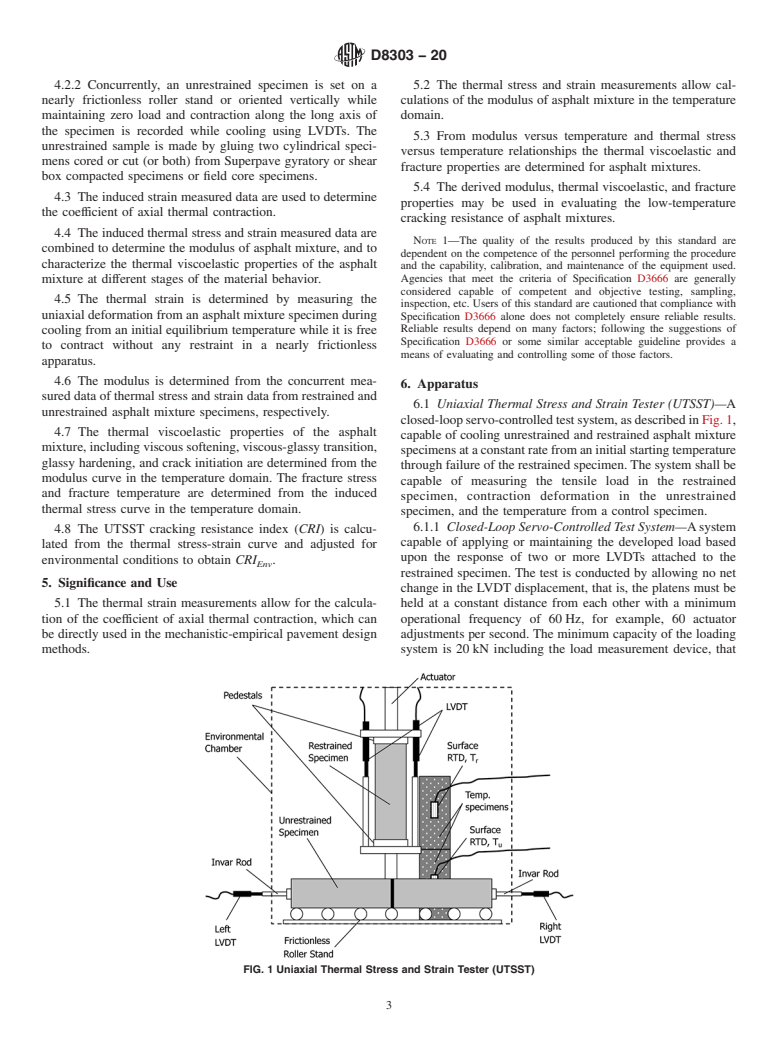

1.1 This method of test is used to determine the thermal viscoelastic and thermal volumetric properties of field-cored or laboratory-compacted asphalt mixture specimens by measuring the thermally induced stress and strain while being cooled at a constant rate from an initial equilibrium temperature. The thermal stress and strain shall be measured using the uniaxial thermal stress and strain tester (UTSST).

1.2 This standard test method covers procedures for preparing and testing asphalt mixtures to measure thermal stress and strain and directly calculate: (1) the coefficient of axial thermal contraction, and (2) the modulus of asphalt mixture over a range of temperatures.

1.3 The procedure described in this standard provides required information for estimation of thermal cracking susceptibility of asphalt mixtures. The procedure applies to test specimens having a maximum aggregate size of 19 mm or less.

1.4 This standard can be used for conventional and nonconventional asphalt mixtures including but not limited to: hot asphalt mixtures, asphalt mixture with recycled materials, cold asphalt mixtures, warm asphalt mixtures, and neat or modified asphalt mixtures (for example, polymer or rubber-modified).

1.5 This standard can be used to determine the following:

1.5.1 Thermal stress buildup in asphalt mixture during a single cooling event.

1.5.2 Thermal strain in asphalt mixtures as a function of temperature.

1.5.3 Coefficient of axial thermal contraction.

1.5.4 Modulus of asphalt mixture as a function of temperature.

1.5.5 Thermal viscoelastic properties of asphalt mixture: viscous softening, viscous-glassy transition, glassy hardening, crack initiation, fracture temperature, and fracture stress.

1.5.6 UTSST cracking resistance index (CRI).

1.5.7 UTSST CRI adjusted for environmental condition (CRIEnv).

1.6 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally ...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8303 − 20

Standard Test Method for

Determining Thermal Cracking Properties of Asphalt

Mixtures Through Measurement of Thermally Induced

1

Stress and Strain

This standard is issued under the fixed designation D8303; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5.7 UTSST CRI adjusted for environmental condition

(CRI ).

Env

1.1 This method of test is used to determine the thermal

viscoelastic and thermal volumetric properties of field-cored or 1.6 Units—The values stated in SI units are to be regarded

laboratory-compactedasphaltmixturespecimensbymeasuring as standard. No other units of measurement are included in this

the thermally induced stress and strain while being cooled at a standard.

constant rate from an initial equilibrium temperature. The

1.7 The text of this standard references notes and footnotes

thermal stress and strain shall be measured using the uniaxial

which provide explanatory material.These notes and footnotes

thermal stress and strain tester (UTSST).

(excluding those in tables and figures) shall not be considered

1.2 This standard test method covers procedures for prepar- as requirements of the standard.

ing and testing asphalt mixtures to measure thermal stress and

1.8 This standard does not purport to address all of the

strain and directly calculate: (1) the coefficient of axial thermal

safety concerns, if any, associated with its use. It is the

contraction, and (2) the modulus of asphalt mixture over a

responsibility of the user of this standard to establish appro-

range of temperatures.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1.3 The procedure described in this standard provides re-

1.9 This international standard was developed in accor-

quired information for estimation of thermal cracking suscep-

dance with internationally recognized principles on standard-

tibility of asphalt mixtures. The procedure applies to test

ization established in the Decision on Principles for the

specimenshavingamaximumaggregatesizeof19 mmorless.

Development of International Standards, Guides and Recom-

1.4 This standard can be used for conventional and noncon-

mendations issued by the World Trade Organization Technical

ventional asphalt mixtures including but not limited to: hot

Barriers to Trade (TBT) Committee.

asphalt mixtures, asphalt mixture with recycled materials, cold

asphalt mixtures, warm asphalt mixtures, and neat or modified

2. Referenced Documents

asphalt mixtures (for example, polymer or rubber-modified).

2

2.1 ASTM Standards:

1.5 This standard can be used to determine the following:

A36/A36M Specification for Carbon Structural Steel

1.5.1 Thermal stress buildup in asphalt mixture during a

D8 Terminology Relating to Materials for Roads and Pave-

single cooling event.

ments

1.5.2 Thermal strain in asphalt mixtures as a function of

D979/D979M Practice for Sampling Bituminous Paving

temperature.

Mixtures

1.5.3 Coefficient of axial thermal contraction.

D2041/D2041M Test Method for Theoretical Maximum

1.5.4 Modulus of asphalt mixture as a function of tempera-

Specific Gravity and Density of Asphalt Mixtures

ture.

D2726/D2726M Test Method for Bulk Specific Gravity and

1.5.5 Thermal viscoelastic properties of asphalt mixture:

Density of Non-Absorptive Compacted Asphalt Mixtures

viscous softening, viscous-glassy transition, glassy hardening,

D3203/D3203M Test Method for PercentAir Voids in Com-

crack initiation, fracture temperature, and fracture stress.

pacted Asphalt Mixtures

1.5.6 UTSST cracking resistance index (CRI).

D3549/D3549M Test Method for Thickness or Height of

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

2

and Paving Materials and is the direct responsibility of Subcommittee D04.26 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Fundamental/Mechanistic Tests. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved July 1, 2020. Published July 2020. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

D8303-20. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8303 − 20

Compacted Asphalt Mixture Specimens 3.2.9 initial starting temperature (

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.