ASTM D6880-05

(Specification)Standard Specification for Wood Boxes

Standard Specification for Wood Boxes

ABSTRACT

This specification covers the fabrication methods for the production of wood boxes. The wood boxes produced are classified into two classes according to durability, six styles according to cleat and joint structure, and two treatment types. It is recommended that the boxes be made from recycled materials using standard-compliant fasteners. Each box side and joint should be assembled according to the recommended procedures.

SCOPE

1.1 This specification covers the fabrication of wood boxes. These wood boxes, when constructed, filled and closed, shall be used for the packing of contents not exceeding 1,000 pounds [454 kg].

1.2 If the use of other construction methods or techniques is acceptable and permitted (see 5.1), the resulting boxes shall be of equal or better performance than would result from the use of the specified materials and procedures. An appropriate distribution cycle, specified in Practice D 4169, can be used to develop comparative procedures and criteria.

1.3 The values stated in either inch-pound or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the standard. See IEEE/ASTM SI 10 for conversion of units.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6880 – 05

Standard Specification for

Wood Boxes

This standard is issued under the fixed designation D6880; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D6199 Practice for Quality of Wood Members of Contain-

ers and Pallets

1.1 This specification covers the fabrication of wood boxes.

F1667 Specification for Driven Fasteners: Nails, Spikes,

These wood boxes, when constructed, filled and closed, shall

and Staples

beusedforthepackingofcontentsnotexceeding1,000pounds

IEEE/ASTM SI 10 Standard for Use of the International

[454 kg].

System of Units (SI): The Modernized Metric System

1.2 If the use of other construction methods or techniques is

2.2 Federal Specification:

acceptable and permitted (see 5.1), the resulting boxes shall be

PPP-B-621 Boxes, Wood, Nailed and Lock-Corner

of equal or better performance than would result from the use

2.3 American Softwood Lumber Standard PS-20

of the specified materials and procedures. An appropriate

distribution cycle, specified in Practice D4169, can be used to

2.4 American Wood Preservers’Association Standard

develop comparative procedures and criteria.

1.3 The values stated in either inch-pound or SI units are to

2.5 National Design Specification for Wood Construction

be regarded separately as standard.Within the text, the SI units

are shown in brackets.The values stated in each system are not

exact equivalents; therefore, each system must be used inde-

3. Terminology

pendentlyoftheother.Combiningvaluesfromthetwosystems

3.1 Definitions—General definitions for packaging and dis-

may result in nonconformance with the standard. See IEEE/

tribution environments are found in Terminology D996.

ASTM SI 10 for conversion of units.

3.2 Definitions of Terms Specific to This Standard:

1.4 This standard does not purport to address all of the

3.2.1 part—asectionofthebox,suchastop,bottom,sideor

safety concerns, if any, associated with its use. It is the

end.

responsibility of the user of this standard to establish appro-

3.2.2 piece—a single solid piece of wood.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Classification

4.1 Classes

2. Referenced Documents

2 Class 1 – Light Duty

2.1 ASTM Standards:

Class 2 – Heavy Duty

D996 Terminology of Packaging and Distribution Environ-

4.2 Styles

ments

Style 1 - Uncleated Ends (Fig. 1)

D3951 Practice for Commercial Packaging

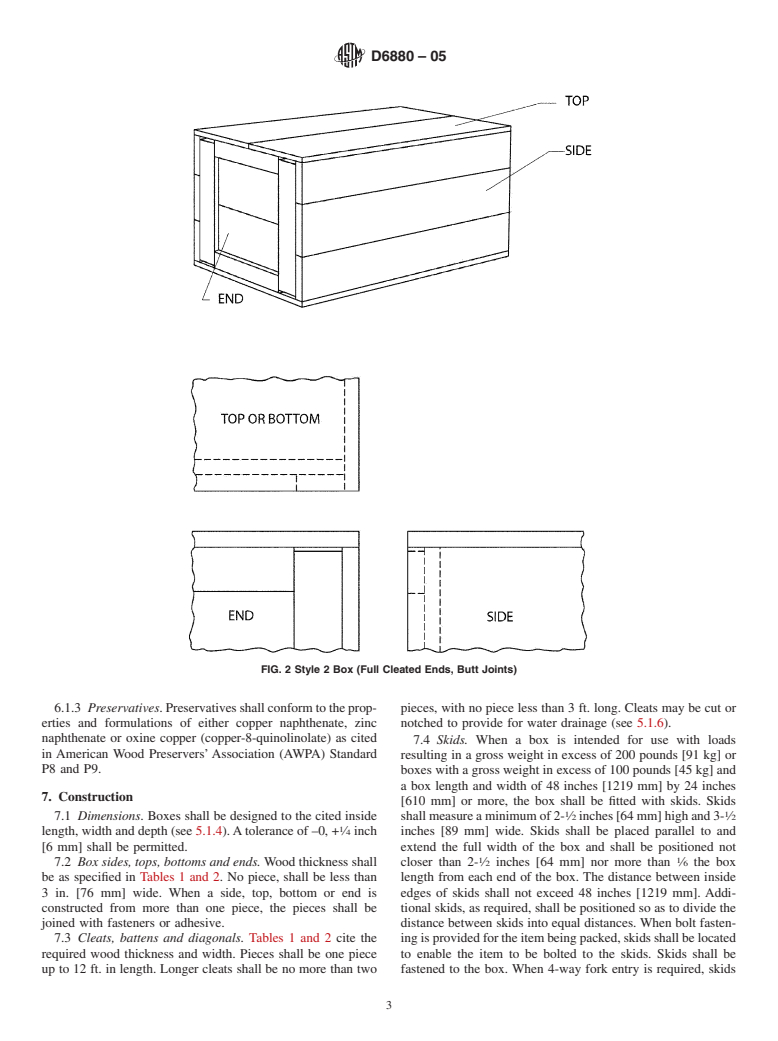

Style 2 - Full Cleated Ends, Butt Joints (Fig. 2)

D4169 Practice for Performance Testing of Shipping Con-

Style 2- ⁄2 Full Cleated Ends, Notched Cleats (Fig. 3)

tainers and Systems

Style 4 - Exterior End Cleats (Fig. 4)

D4675 Guide for Selection and Use of Flat Strapping

Style 5 - Interior End Cleats (Fig. 5)

Materials

Style 7 - Skidded Base with Separate Hood (Fig. 6)

4.3 Water-Repellent Wood Preservative Treatment

This specification is under the jurisdiction of ASTM Committee D10 on

Packaging and is the direct responsibility of Subcommittee D10.12 on Shipping Available from the Federal Supply Service Bureau, Specification Section, Suite

Containers, Crates, Pallets, Skids, and Related Structures. 8100, 480 L”Enfant Plaza, SW, Washington, DC 20408

Current edition approved April 1, 2005. Published April 2005. DOI: 10.1520/ Available from National Institute of Standards and Technology, U.S. Depart-

D6880-05. ment of Commerce, 100 Bureau Dr, Stop 3460, Gaithersburg, MD 20899-3460

2 5

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Wood Preservers’ Association (AWPA), P.O. Box

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 5690, Granbury, TX 76049-0690

Standards volume information, refer to the standard’s Document Summary page on Available from American Forest and Paper Association, American Wood

the ASTM website. Council, 1111 19th St. NW, Suite 800 Washington, DC 20036

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6880 – 05

FIG. 1 Style 1 Box (Uncleated Ends)

Treatment A - Without treatment 5.1.12 When marking of boxes is required (see 7.9).

Treatment B - With treatment

5.1.13 Whenboxesareshippedassembledorknockeddown

(see 7.12 and 7.13).

5. Ordering Information

5.1 Purchasers should include the following information in

6. Material

procurement documents:

6.1 Materials. All materials shall meet the requirements of

5.1.1 Specification title, number and date.

this specification and referenced documents. Materials shall

5.1.2 Box class, style and treatment (see 4.1-4.3).

not affect or be affected by the product being packed. The use

5.1.3 Descriptionofcontentsandcontentsweight,ifknown.

of recycled material is encouraged.

5.1.4 When alternate materials and construction methods

6.1.1 Wood. Wood shall conform to Practice D6199 or the

are acceptable and permitted (see 1.2).

American Softwood Lumber Standard PS-20, as applicable.

5.1.5 Inside box dimensions. (see 7.1).

Tables 1 and 2 cite nominal dimensions for wood pieces

5.1.6 When cleats are cut or notched for water drainage (see

(commercial tolerances will apply). Thicker or wider pieces of

7.3).

wood are acceptable. For cleats, battens and diagonals, the

5.1.7 When skids are required (see 7.4).

wood shall conform to Class 1 or 2 of Practice D6199.

5.1.8 When 4-way entry skids are required (see 7.4).

6.1.2 Fasteners. Fasteners (bolts, nuts, screws, staples, and

5.1.9 When rubbing strips are required (see 7.4).

so forth) shall meet the stress design criteria of the National

5.1.10 When beveled skids are required (see 7.4).

Design Specification for Wood Construction.

5.1.11 When re-closable top panel closure is required (see

7.5.1). 6.1.2.1 Nails. Nails shall conform to Specification F1667.

D6880 – 05

FIG. 2 Style 2 Box (Full Cleated Ends, Butt Joints)

6.1.3 Preservatives.Preservativesshallconformtotheprop- pieces, with no piece less than 3 ft. long. Cleats may be cut or

erties and formulations of either copper naphthenate, zinc notched to provide for water drainage (see 5.1.6).

naphthenate or oxine copper (copper-8-quinolinolate) as cited

7.4 Skids. When a box is intended for use with loads

in American Wood Preservers’Association (AWPA) Standard

resulting in a gross weight in excess of 200 pounds [91 kg] or

P8 and P9.

boxes with a gross weight in excess of 100 pounds [45 kg] and

a box length and width of 48 inches [1219 mm] by 24 inches

7. Construction

[610 mm] or more, the box shall be fitted with skids. Skids

1 1

7.1 Dimensions. Boxes shall be designed to the cited inside shallmeasureaminimumof2- ⁄2inches[64mm]highand3- ⁄2

length, width and depth (see 5.1.4).Atolerance of –0, + ⁄4 inch inches [89 mm] wide. Skids shall be placed parallel to and

[6 mm] shall be permitted. extend the full width of the box and shall be positioned not

1 1

7.2 Box sides, tops, bottoms and ends. Wood thickness shall closer than 2- ⁄2 inches [64 mm] nor more than ⁄6 the box

be as specified in Tables 1 and 2. No piece, shall be less than length from each end of the box. The distance between inside

3 in. [76 mm] wide. When a side, top, bottom or end is edges of skids shall not exceed 48 inches [1219 mm]. Addi-

constructed from more than one piece, the pieces sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.