ASTM E834-81(1998)

(Practice)Standard Practice for Determining Vacuum Chamber Gaseous Environment Using a Cold Finger

Standard Practice for Determining Vacuum Chamber Gaseous Environment Using a Cold Finger

SCOPE

1.1 This practice covers a technique for collecting samples of materials that are part of the residual gas environment of an evacuated vacuum chamber. The practice employs a device designated as a "cold finger" that is placed within the environment to be sampled and is cooled so that constituents of the environment are retained on the cold-finger surface.

1.2 The practice covers a method for obtaining a sample from the cold finger and determining the weight of the material removed from the cold finger.

1.3 The practice contains recommendations as to ways in which the sample may be analyzed in order to identify the constituents that comprise the sample.

1.4 By determining the species that constitute the sample, the practice may be used to assist in defining the source of the constituents and whether the sample is generally representative of samples similarly obtained from the vacuum chamber itself.

1.5 This practice covers alternative approaches and usages to which the practice can be put.

1.6 The degree of molecular flux anisotropy significantly affects the assurance with which one can attribute characteristics determined by this procedure to the vacuum chamber environment in general.

1.7 The temperature of the cold finger significantly affects the quantity and species of materials collected.

1.8 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 834 – 81 (Reapproved 1998)

Standard Practice for

Determining Vacuum Chamber Gaseous Environment Using

a Cold Finger

This standard is issued under the fixed designation E 834; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This practice covers a technique for collecting samples 3.1 pretest cold finger sample residue mass, M —the mass

i

of materials that are part of the residual gas environment of an of material collected from the cold finger during the pretest

evacuated vacuum chamber. The practice uses a device desig- operation and as measured by the techniques specified in

nated as a “cold finger” that is placed within the environment Section 9. The mass is based on a sample volume of 50 mL.

to be sampled and is cooled so that constituents of the 3.2 posttest stock sample residue mass, M —the mass of

f

environment are retained on the cold-finger surface. residue in a sample collected from the cold finger during the

1.2 The practice covers a method for obtaining a sample posttest operation and as measured by the technique specified

from the cold finger and determining the weight of the material in Section 9. The mass is based on a sample volume of 50 mL.

removed from the cold finger. 3.3 pretest stock sample residue mass, S —the mass of

i

1.3 The practice contains recommendations as to ways in residue in a sample of the solvent (used to obtain the pretest

which the sample may be analyzed to identify the constituents cold finger sample) as measured by the technique specified in

that comprise the sample. Section 9. The mass is based on a sample volume of 50 mL.

1.4 By determining the species that constitute the sample, 3.4 posttest stock sample residue mass, S —the mass of

f

the practice may be used to assist in defining the source of the residue in a sample of the solvent (used to obtain the posttest

constituents and whether the sample is generally representative cold finger sample) as measured by the technique specified in

of samples similarly obtained from the vacuum chamber itself. Section 9. The mass is based on a sample volume of 50 mL.

1.5 This practice covers alternative approaches and usages 3.5 cold finger—the device that is used in collecting the

to which the practice can be put. sample of the residual gases in an evacuated vacuum chamber

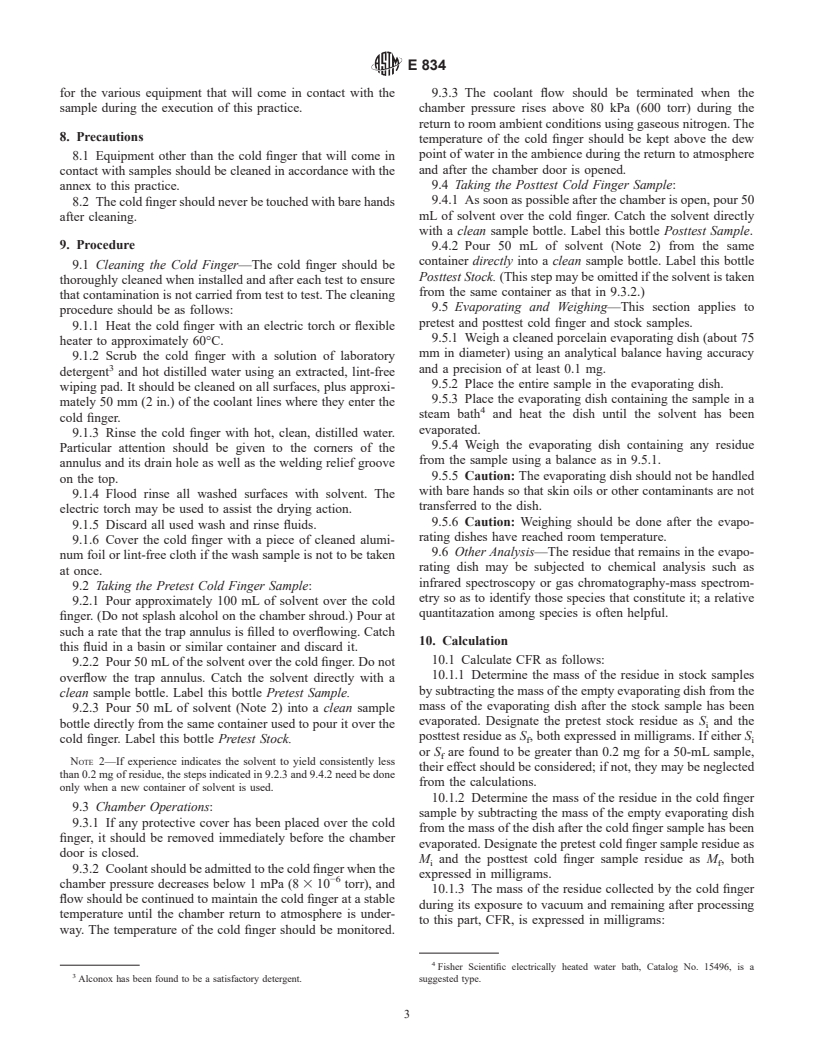

1.6 The degree of molecular flux anisotropy significantly (see Fig. 1).

affects the assurance with which one can attribute characteris- 3.6 CFR—the residue collected by the cold finger during the

tics determined by this procedure to the vacuum chamber vacuum exposure given in milligrams.

environment in general.

4. Summary of Practice

1.7 The temperature of the cold finger significantly affects

the quantity and species of materials collected. 4.1 The cold-finger technique provides a method for char-

acterizing the ambiance in a vacuum chamber when the

1.8 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the chamber is being operated with or without a test item.

4.2 In use, the cold finger is installed in the vacuum

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- chamber in such a location as to be exposed to fluxes

representative of those in the general ambiance. (Chamber

bility of regulatory limitations prior to use. For specific

precautionary statements, see Section 8. conditions that will exist under vacuum conditions must be

considered so as to assess the effects of molecular flux

2. Referenced Documents

anisotropy.)

2.1 ASTM Standards: 4.3 The cold finger is cleaned before the vacuum exposure

E 177 Practice for Use of the Terms Precision and Bias in and a sample of any residue on the surface is obtained. The

ASTM Test Methods pretest cleaning and sampling procedure consists of (a) heating

the cold finger and scrubbing it with a solution of laboratory

detergent and water; (b) rinsing the cold finger with deminer-

This practice is under the jurisdiction of ASTM Committee E-21 on Space

alized or distilled water; (c) rinsing the cold finger with

Simulation and Applications of Space Technology and is the direct responsibility of

1,1,1-trichloroethane and ethanol mixed 75 + 25 as the solvent;

Subcommittee E21.05 on Contamination.

Current edition approved Sept. 25, 1981. Published December 1981.

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 834

5. Significance and Use

5.1 When applied in the case in which there is no test item

in the vacuum chamber (such as during bake-out operations),

this procedure may be used to evaluate the performance of the

vacuum chamber in relation to other data from the same or

other chambers given that critical parameters (for example,

length of exposure, temperature of the chamber and cold finger,

anisotropy, and so forth) can be related.

5.2 The procedure can be used to evaluate the effects of

materials found in the residue on items placed in the vacuum

chamber.

5.3 The procedure can be used to describe the effect of a

prior test on the residual gases within a vacuum chamber.

5.4 By selecting the time at which the coolant is introduced

into the cold finger, the environment present during a selected

portion of a test can be characterized. This can be used to

determine the relative efficacy of certain vacuum chamber

procedures such as bake-out.

5.5 The procedure may be used to define the outgassed

products of a test item that condense on the cold finger.

5.6 The procedure may be used in defining the relative

cleanliness of a vacuum chamber.

FIG. 1 Typical Cold Finger Assembly

5.7 In applying the results of the procedure to the vacuum

chamber in general, consideration must be given to the

anisotropy of the molecular fluxes within the chamber.

(d) obtaining a sample of any residue contained in a second

5.8 The procedure is sensitive to both the partial pressures

rinse with solvent; and (e) obtaining a sample of the solvent.

of the gases that form the condensibles and the time of

4.4 The vacuum chamber is then sealed and evacuated; after exposure of the cold finger at coolant temperatures.

−6

reaching a pressure of less than 1 mPa (8 3 10 torr), a

5.9 The procedure is sensitive to any losses of sample that

coolant is flowed through the cold finger so that materials in the

may occur during the various transfer operations and during

ambient environment can adhere to the surface. Generally,

that procedure wherein the solvent is evaporated by heating it

liquid nitrogen is used as the coolant. Other coolants may be on a steam bath.

used provided that the coolant temperature is controlled and

NOTE 1—Reactions between solvent and condensate can occur and

reported. This coolant flow is continued until the chamber

would affect the analysis.

pressure rises to greater than 80 kPa (600 torr) as the chamber

is being returned to room ambient conditions using dry gaseous

6. Apparatus

nitrogen. Caution: Too rapid a repressurization may dislodge

6.1 The apparatus used in this procedure is termed a cold

some of the condensate.

finger. Fig. 1 is a drawing of the cold finger. The cold finger

4.5 As soon as possible after the chamber door is opened,

consists of a stainless steel cylinder approximately 50 mm (2.0

the solvent is poured over the cold finger and a sample

in.) in diameter and 100 mm (4.0 in.) high. The base of the

containing any residue from the cold finger is collected. A

cylinder is extended to form a lip or trap annulus approxi-

second sample of the solvent is obtained if the solvent is taken

mately 10 mm ( ⁄2 in.) high with a diameter of 75 mm (3 in.)

from a container different than that used under 4.3.

so that fluid poured over the top of the cylinder and running

4.6 Both the pretest and posttest samples are placed in down the sides can be captured. A small drain is provided in

this lip and the fluid can drain through this aperture into a

previously cleaned and weighed evaporating dishes. The dishes

receptacle. Two tubes enter the cold finger through the base,

containing the samples are placed on a steam bath and the

one providing the inlet and the other the outlet for the coolant.

solvent is evaporated. The dishes containing the residue are

Temperatures shall be monitored. The coolant recommended in

then weighed using an analytical balance. The samples of the

this practice is liquid nitrogen. The apparatus should be

solvent are similarly handled and any residue weighed. The

thoroughly cleaned after the manufacture.

differences of mass between the pretest residue and posttest

6.2 Containers must not react with the solvents. Glass,

residue is then determined (corrected if necessary for any

austenitic stainless steels, or PTFE generally are acceptable.

significant residue found in the solvent); this difference in mass

is taken as the residue collected by the cold finger during its

7. Reagents

exposure to the vacuum environment, CFR.

4.7 Analytical procedures such as infrared spectroscopy or 7.1 Reagent grade 1,1,1-trichloroethane and ethanol mixed

gas chromatography-mass spectrometry may be used to iden-

3 + 1 is the solvent used for obtaining the sample from the cold

tify those species that constitute the residue. finger and as the final rinse material in the cleaning procedures

E 834

for the various equipment that will come in contact with the 9.3.3 The coolant flow should be terminated when the

sample during the execution of this practice. chamber pressure rises above 80 kPa (600 to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.