ASTM C932-06

(Specification)Standard Specification for Surface-Applied Bonding Compounds for Exterior Plastering

Standard Specification for Surface-Applied Bonding Compounds for Exterior Plastering

ABSTRACT

This specification covers the minimum requirements and test methods for determining the performance and physical properties of exterior surface-applied bonding compounds. These compounds are used for the improvement of adhesion of cementitious materials to concrete, other masonry surfaces, or any structurally sound surfaces. The methods described here are tested for surface applied bonding compound composition, consistency, film characteristics, re-emulsification, bonding capability, degradation, high temperature performance, freeze-thaw stability, and tensile bind strength.

SCOPE

1.1 This specification covers minimum requirements for exterior surface-applied bonding compounds for improving the adhesion of cementitious material to concrete or other masonry surfaces or any structurally sound surfaces.

1.2 This specification also covers test methods for determining performance requirements and physical properties.

1.3 The values stated in inch-pound units are to be regarded as the standard. The SI metric values given in parentheses are approximate and are provided for information purposes only.

1.4 The following safety hazards caveat pertains only to the test methods described in Sections , , , and in this specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C932 −06

StandardSpecification for

Surface-Applied Bonding Compounds for Exterior

1

Plastering

This standard is issued under the fixed designation C932; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* Testing of Hydraulic Cements and Concretes

C778Specification for Sand

1.1 This specification covers minimum requirements for

exteriorsurface-appliedbondingcompoundsforimprovingthe

3. Terminology

adhesionofcementitiousmaterialtoconcreteorothermasonry

surfaces or any structurally sound surfaces.

3.1 Definitions used in this specification shall be in accor-

dance with Terminology C11.

1.2 Thisspecificationalsocoverstestmethodsfordetermin-

ing performance requirements and physical properties.

4. Physical Properties

1.3 The values stated in inch-pound units are to be regarded

4.1 Surface Applied Bonding Compound—A freeze-thaw

as the standard. The SI metric values given in parentheses are

stable composition, suitable for brush, roller, or spray applica-

approximate and are provided for information purposes only.

tion.Itshallbetintedtoshowbyvisualinspectionwhereithas

1.4 The following safety hazards caveat pertains only to the

been applied. The tint shall not bleed through the material

test methods described in Sections 9, 10, 11, and 12 in this

being bonded.

specification: This standard does not purport to address all of

the safety concerns, if any, associated with its use. It is the

4.2 Consistency—The bonding compound shall be free of

responsibility of the user of this standard to establish appro-

foreign matter as determined by visual inspection and shall be

priate safety and health practices and determine the applica-

of such uniform consistency that when applied in accordance

bility of regulatory limitations prior to use. with the producers directions by brush, roller, or spray to

concrete, masonry, or other structurally sound surface, the

2. Referenced Documents

bonding compound shall flow on evenly and dry uniformly.

2

2.1 ASTM Standards:

4.3 Film Characteristics—The film-forming property shall

C11Terminology Relating to Gypsum and Related Building

be determined by visual inspection to determine the presence

Materials and Systems

of a continuous film not broken by fisheyes, cracking, pull-

C109/C109MTest Method for Compressive Strength of

back, or any other discontinuity in the film surface. It shall not

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

be noticeably affected by alkaline surfaces or weak acids.

Specimens)

4.4 Re-Emulsification—Product conforming with this speci-

C150Specification for Portland Cement

fication shall not re-emulsify.

C305Practice for Mechanical Mixing of Hydraulic Cement

Pastes and Mortars of Plastic Consistency

5. Performance Requirements

C511Specification for Mixing Rooms, Moist Cabinets,

Moist Rooms, and Water Storage Tanks Used in the

5.1 Bonding Capability—The bonding compound shall be

capable of bonding cementitious materials when applied in

1

This specification is under the jurisdiction of ASTM Committee C11 on accordance with the producer’s directions and tested as speci-

GypsumandRelatedBuildingMaterialsandSystemsandisthedirectresponsibility

fied in Section 12.

of Subcommittee C11.02 on Specifications and Test Methods for Accessories and

Related Products.

5.2 Degradation—Bonding compound which separates

Current edition approved March 1, 2006. Published March 2006. Originally

shall be able to be re-mixed to a uniform consistency when

approved in 1980. Last previous edition approved in 2005 as C932–05. DOI:

tested as specified in Section 10.

10.1520/C0932-06.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

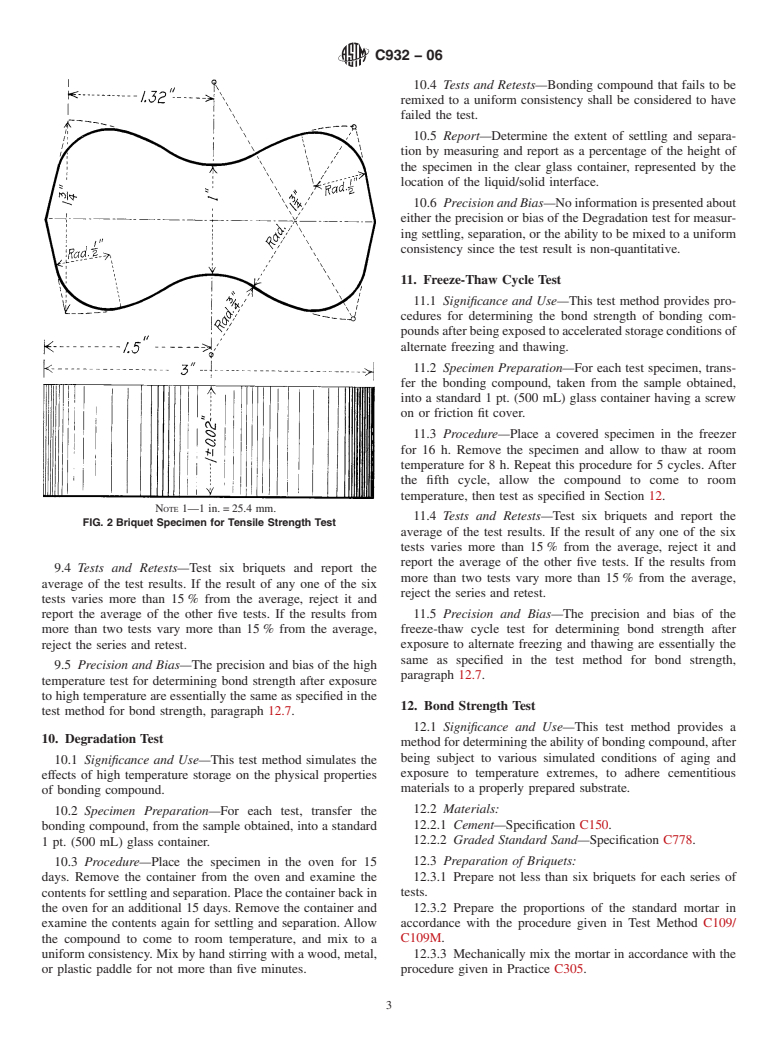

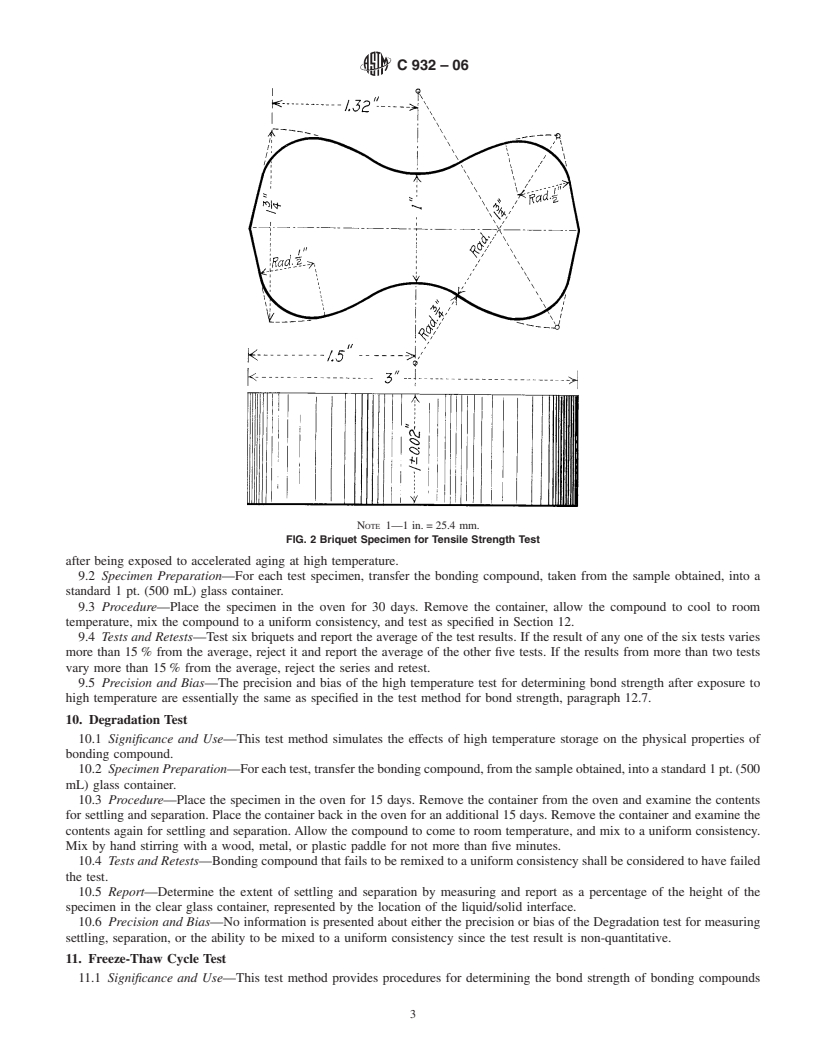

5.3 High Temperature Test—The bond strength shall be not

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

lessthan150psi(1034kPa)whentestedasspecifiedinSection

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 9.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C932−06

5.4 Freeze-Thaw Stability—The bond strength shall be not 7.10 Testing Machine—Any type that is of sufficient capac-

lessthan150psi(1034kPa)and100psi(690kPa)whentested ity and that is capable of applying the load continuously and

under the dry and wet conditions, respectively, as specified in withoutshockattherateof0.05in.(1.27mm

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C932–05 Designation: C 932 – 06

Standard Specification for

Surface-Applied Bonding Compounds for Exterior

1

Plastering

This standard is issued under the fixed designation C932; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers minimum requirements for exterior surface-applied bonding compounds for improving the

adhesion of cementitious material to concrete or other masonry surfaces or any structurally sound surfaces.

1.2 This specification also covers test methods for determining performance requirements and physical properties.

1.3 The values stated in inch-pound units are to be regarded as the standard. The SI metric values given in parentheses are

approximate and are provided for information purposes only.

1.4 The following safety hazards caveat pertains only to the test methods described in Sections 9, 10, 11, and 12 in this

specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of

regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C11 Terminology Relating to Gypsum and Related Building Materials and Systems

C109/C109M TestMethodforCompressiveStrengthofHydraulicCementMortars(Using2-in.or[50-mm]CubeSpecimens)

C150 Specification for Portland Cement

C305 Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency

C511 Specification for Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in the Testing of

Hydraulic Cements and Concretes

C778 Specification for Standard Sand

3. Terminology

3.1 Definitions used in this specification shall be in accordance with Terminology C11.

4. Physical Properties

4.1 Surface Applied Bonding Compound—Afreeze-thaw stable composition, suitable for brush, roller, or spray application. It

shall be tinted to show by visual inspection where it has been applied. The tint shall not bleed through the material being bonded.

4.2 Consistency—Thebondingcompoundshallbefreeofforeignmatterasdeterminedbyvisualinspectionandshallbeofsuch

uniform consistency that when applied in accordance with the producers directions by brush, roller, or spray to concrete, masonry,

or other structurally sound surface, the bonding compound shall flow on evenly and dry uniformly.

4.3 Film Characteristics—The film-forming property shall be determined by visual inspection to determine the presence of a

continuousfilmnotbrokenbyfisheyes,cracking,pull-back,oranyotherdiscontinuityinthefilmsurface.Itshallnotbenoticeably

affected by alkaline surfaces or weak acids.

4.4 Re-Emulsification— Product conforming with this specification shall not re-emulsify.

5. Performance Requirements

5.1 Bonding Capability—The bonding compound shall be capable of bonding cementitious materials when applied in

1

This specification is under the jurisdiction of ASTM Committee C11 on Gypsum and Related Building Materials and Systems and is the direct responsibility of

Subcommittee C11.02 on Specifications and Test Methods for Accessories and Related Products.

Current edition approved MayMarch 1, 2005.2006. Published May 2005.March 2006. Originally approved in 1980. Last previous edition approved in 20032005 as

C932–035.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C932–06

accordance with the producer’s directions and tested as specified in Section 12.

5.2 Degradation—Bonding compound which separates shall be able to be re-mixed to a uniform consistency when tested as

specified in Section 10.

5.3 High Temperature Test—The bond strength shall be not less than 150 psi (1034 kPa) when tested as specified in Section

9.

5.4 Freeze-ThawStability—Thebondstrength

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.