ASTM F2880-11a

(Specification)Standard Specification for Lap-Joint Type Flange Adapters for Polyethylene Pressure Pipe in Nominal Pipe Sizes ¾ in. to 65 in.

Standard Specification for Lap-Joint Type Flange Adapters for Polyethylene Pressure Pipe in Nominal Pipe Sizes <span class='unicode'>¾</span> in. to 65 in.

ABSTRACT

This specification covers the polyethylene material and dimensions applicable to flange adapters (FAs) used to connect polyethylene pipes to other flanged pipe and components such as valves and flanged fittings. It describes outside diameter controlled polyethylene (PE) pipe FAs which may be manufactured by various methods including injection molding, compression molding, and machining from thick-wall polyethylene pipe.

SCOPE

1.1 This specification covers the polyethylene material and dimensions applicable to flange adapters (FAs) used to connect polyethylene pipes to other flanged pipe and components such as valves and flanged fittings. This standard describes outside diameter controlled polyethylene (PE) pipe flange adapters (FAs) in diameters ranging from ¾in. through 65 in. (12 mm through 1600 mm). The flange adapters may be manufactured by various methods including injection molding, compression molding, and machining from thick-wall polyethylene pipe.

1.2 The flange adapter (FA) is the principal component of the lap-joint flanged assembly widely used for several decades in low-pressure to high-pressure polyethylene pipe systems for all types of pressurized flow (gas and liquid) applications. The flange adapter’s physical shape consists of the pipe-like Neck which is monolithic with its Hub. The Neck is intended to be butt-fused or fusion coupled to the pipe-line; while the Hub face is intended to affect the seal when subjected to the distributed load from the back up ring with its properly torqued bolt-studs and nuts.

Note 1—Polyethylene pipe flange adapters with slip on bolt rings are intended for use being bolted to each other or to be bolted to metal flanges having (primarily) Class 150 bolt hole patterns such as those presented in metal flange standards ASME B16.5, ASME B16.47 and AWWA C207.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The use of gaskets and gasket selection are often an integral component of the flange adapter assembly. See the Plastic Pipe Institute Technical Note TN-38 for more information regarding HDPE flanged joints.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2880 −11a AnAmerican National Standard

Standard Specification for

Lap-Joint Type Flange Adapters for Polyethylene Pressure

Pipe in Nominal Pipe Sizes ⁄4 in. to 65 in.

This standard is issued under the fixed designation F2880; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

Table 5 has been included, editorial changes were made throughout, and the year date was changed on July 22, 2011.

1. Scope 1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This specification covers the polyethylene material and

responsibility of the user of this standard to establish appro-

dimensionsapplicabletoflangeadapters(FAs)usedtoconnect

priate safety and health practices and determine the applica-

polyethylene pipes to other flanged pipe and components such

bility of regulatory limitations prior to use.

as valves and flanged fittings. This standard describes outside

diameter controlled polyethylene (PE) pipe flange adapters

2. Referenced Documents

(FAs) in diameters ranging from ⁄4 in. through 65 in. (12 mm

2.1 ASTM Standards:

through 1600 mm). The flange adapters may be manufactured

D2122Test Method for Determining Dimensions of Ther-

by various methods including injection molding, compression

moplastic Pipe and Fittings

molding, and machining from thick-wall polyethylene pipe.

D2513Specification for Polyethylene (PE) Gas Pressure

1.2 The flange adapter (FA) is the principal component of

Pipe, Tubing, and Fittings

the lap-joint flanged assembly widely used for several decades

D2837Test Method for Obtaining Hydrostatic Design Basis

inlow-pressuretohigh-pressurepolyethylenepipesystemsfor

forThermoplasticPipeMaterialsorPressureDesignBasis

all types of pressurized flow (gas and liquid) applications. The

for Thermoplastic Pipe Products

flange adapter’s physical shape consists of the pipe-like Neck

D3035SpecificationforPolyethylene(PE)PlasticPipe(DR-

which is monolithic with its Hub. The Neck is intended to be

PR) Based on Controlled Outside Diameter

butt-fused or fusion coupled to the pipe-line; while the Hub

D3261SpecificationforButtHeatFusionPolyethylene(PE)

face is intended to affect the seal when subjected to the

Plastic Fittings for Polyethylene (PE) Plastic Pipe and

distributedloadfromthebackupringwithitsproperlytorqued

Tubing

bolt-studs and nuts.

D3350Specification for Polyethylene Plastics Pipe and Fit-

tings Materials

NOTE 1—Polyethylene pipe flange adapters with slip on bolt rings are

intendedforusebeingboltedtoeachotherortobeboltedtometalflanges F714Specification for Polyethylene (PE) Plastic Pipe (DR-

having (primarily) Class 150 bolt hole patterns such as those presented in

PR) Based on Outside Diameter

metal flange standards ASME B16.5, ASME B16.47 and AWWA C207.

F2206Specification for Fabricated Fittings of Butt-Fused

1.3 Thevaluesstatedininch-poundunitsaretoberegarded

Polyethylene (PE) Plastic Pipe, Fittings, Sheet Stock,

as standard. The values given in parentheses are mathematical

Plate Stock, or Block Stock

conversions to SI units that are provided for information only

2.2 ASME Standards:

and are not considered standard.

B16.5“Pipe Flanges and Flanged Fittings”

B16.47“Large Diameter Steel Flanges: NPS 26 through

1.4 The use of gaskets and gasket selection are often an

NPS 60” Class #150 – Series A

integral component of the flange adapter assembly. See the

B36.10MWelded and Seamless Wrought Steel Pipe

Plastic Pipe Institute Technical Note TN-38 for more informa-

tion regarding HDPE flanged joints.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This specification is under the jurisdiction ofASTM Committee F17 on Plastic Standards volume information, refer to the standard’s Document Summary page on

PipingSystemsandisthedirectresponsibilityofSubcommitteeF17.10onFittings. the ASTM website.

Current edition approved July 22, 2011. Published July 2011. Originally Available from American Society of Mechanical Engineers (ASME), ASME

approved in 2011. Last previous edition approved in 2011 as F2880–11. DOI: International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

10.1520/F2880-11A. www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2880−11a

B36.19MStainless Steel Pipe 3.1.2 DIPS—Ductile-Iron Pipe Size; the outside diameter

(OD) of plastic pipe that matches the nominal standard

2.3 AWWA Standards:

diameters of metal ductile iron, or, cast-iron pipes; also

C207“Standard for Steel Pipe Flanges for Waterworks

commonly referred to as DIOD, Ductile Iron Outside Diam-

Service, Sizes 4 In. Through 144 In. (100 mm Through

eter, previously known as CIOD or cast-iron OD.

3,600 mm) ; Class #150 /Series B,D&E.

C901“Standard for Polyethylene (PE) pressure pipe and

3.1.3 flange adapter—One component of the two piece

tubing, ⁄2 ” through 3” for Water Service.”

lap-jointflangeassembly;Itisaonepiecepolyethylenedevice

C906Standard for Polyethylene (PE) Pressure Pipe and

whose geometry consists of two shapes: the wide, circular,

Fittings, 4 In. (100 mm) Through 63 In. (1,600 mm), for

seal-face disk, with central hole, which transitions along its

Water Distribution and Transmission

length into pipe of smaller diameter and wall thickness,

M55 Polyethylene Pipe - Design and Installation

matched to the pipe-main to which it is to be joined. (Refer to

2.4 NSF Standards: Fig. 1).

NSF/ANSI Standard No. 14for Plastic Piping Components

3.1.4 Hub—The disk ring, or collar, extending radially

and Related Materials

outward from the pipe OD at the pipe termination.

NSF/ANSI Standard No. 61for Drinking Water System

3.1.5 Hydrostatic design stress (HDS)—The maximum al-

Components—Health Effects

lowable hoop stress in the pipe wall for pipe that is subjected

2.5 PPI Documents:

to sustained long-term hydrostatic pressure. The hydrostatic

TN-38“Bolt Torque for Polyethylene Flanged Joints”

design stress is determined by multiplying the hydrostatic

TR-3 “Policies and Procedures for Developing Hydrostatic

design basis by the PPI recommended design factor for water

Design Basis (HDB), Pressure Design Basis (PDB),

service. HDS ratings for PE materials are published by PPI in

Strength Design Basis (SDB), and Minimum Required

TR-4.

Strength (MRS) Ratings for Thermoplastic Piping Mate-

3.1.6 IPS—Iron Pipe Size (steel pipe) outside diameters;

rials or Pipe

replaced with nominal pipe sizes (NPS) per as listed with the

TR-4“HDB/HDS/SDB/PDB/MRS Listed Materials”

plastic pipe standards and B36.10M and B36.19M.

PPIHandbook of Polyethylene Pipe and Fittings

3.1.7 lap-joint flange ring—the loose metal ring that trans-

3. Terminology

fers the load from the bolts through the hub to the seal face.

3.1 Definitions of Terms Specific to This Standard:

3.1.8 neck—The long barrel of the flange adapter with OD

3.1.1 dimension ratio (DR)—The ratio of a pipe’s specified

and wall thickness matched to the pipeline dimensions. The

nominal outside diameter to its specified minimum wall

neck length must be sufficient for fusion joining in the fusion

thickness. DR as applied to Flange Adapters is Neck OD ÷

machine used.

neck minimum wall.

3.1.9 seal face—The front of the Hub, which contacts the

mating flange, which radially confines fluid pressure by com-

pressivestresswhensubjectedtodistributedloadfromtorqued

4 bolts.

Available fromAmericanWaterWorksAssociation (AWWA), 6666W. Quincy

Ave., Denver, CO 80235, http://www.awwa.org.

3.1.10 residual sealing stress—The long-term compressive

Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd.,Ann

stressintensityfromtheloaddistributedoverthesealfacearea

Arbor, MI 48113-0140, http://www.nsf.org.

which is in contact with a mating flange.

Available from Plastics Pipe Institute (PPI), 105 Decker Court, Suite 825,

Irving, TX 75062, http://www.plasticpipe.org.

FIG. 1Polyethylene Flange Adapter Geometry

F2880−11a

3.1.11 pressure rating (PR)—maximum sustained internal 4.4 PotableWater—Materialsusedforproductsintendedfor

water pressure at 80°F (27°C) and lower service temperature use in the transport of potable water shall be evaluated and

with specified maximum allowances for pressure surges. certifiedassafeforthispurposebyatestingagencyacceptable

to the local health authority. The evaluation shall be in

2 3HDS 3F

T

PR5 (1)

accordance with requirements for chemical extraction, taste,

DR21

~ !

and odor that are no less restrictive than those included in

where:

NSF/ANSI Standard No. 14 or NSF/ANSI Standard No. 61.

HDS = hydrostaticdesignstressforwaterat73ºF,psi(kPa) The seal or mark of the laboratory making the evaluation

F = temperature factor (1.00 for 80ºF (27ºC) and lower

should be included on the piping per 7.1.3.7.

T

water service temperature)

DR = dimension ratio. Surge pressure allowances are

5. Flange Adaptor Dimensions and Working Pressure

applied above the sustained internal pressure and

Ratings

are integral to the working pressure rating.

5.1 General—This standard describes 10 dimension ratios

(DR’s) for nominal flange adapter sizes ranging from ⁄4 in.

4. Polyethylene Materials for Flange

through 65 in. (12 mm through 1 600 mm). Flange adapter

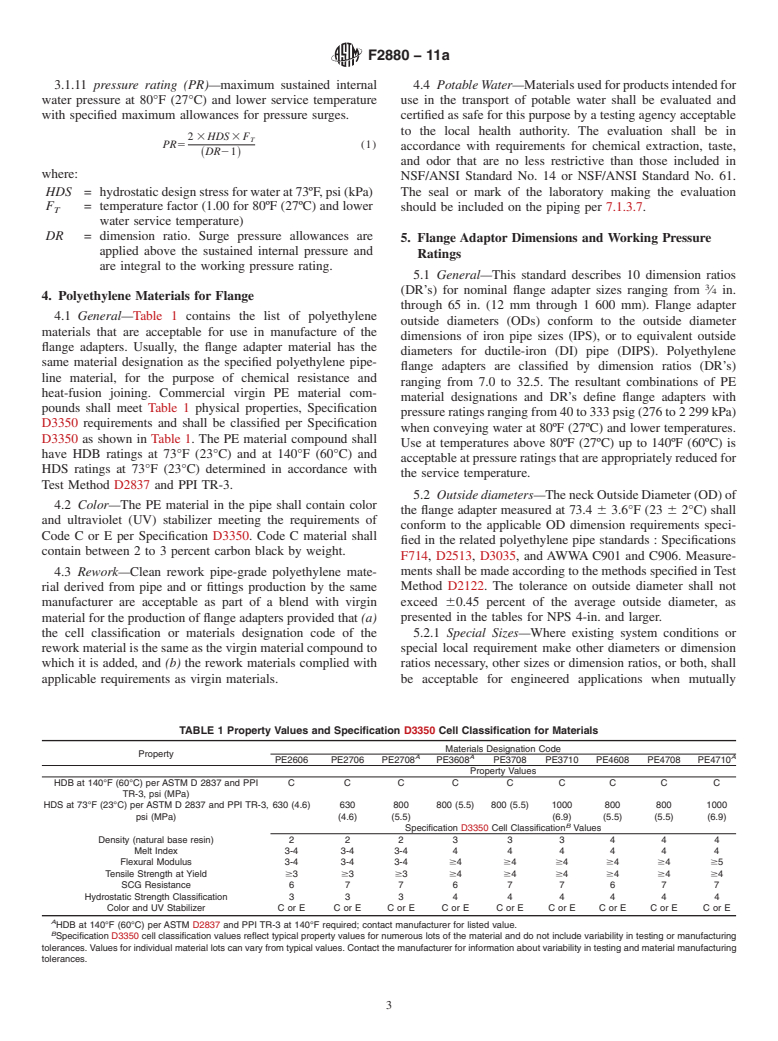

4.1 General—Table 1 contains the list of polyethylene

outside diameters (ODs) conform to the outside diameter

materials that are acceptable for use in manufacture of the

dimensions of iron pipe sizes (IPS), or to equivalent outside

flange adapters. Usually, the flange adapter material has the

diameters for ductile-iron (DI) pipe (DIPS). Polyethylene

same material designation as the specified polyethylene pipe-

flange adapters are classified by dimension ratios (DR’s)

line material, for the purpose of chemical resistance and

ranging from 7.0 to 32.5. The resultant combinations of PE

heat-fusion joining. Commercial virgin PE material com-

material designations and DR’s define flange adapters with

pounds shall meet Table 1 physical properties, Specification

pressureratingsrangingfrom40to333psig(276to2299kPa)

D3350 requirements and shall be classified per Specification

when conveying water at 80ºF (27ºC) and lower temperatures.

D3350 as shown in Table 1. The PE material compound shall

Use at temperatures above 80ºF (27ºC) up to 140ºF (60ºC) is

have HDB ratings at 73°F (23°C) and at 140°F (60°C) and

acceptableatpressureratingsthatareappropriatelyreducedfor

HDS ratings at 73°F (23°C) determined in accordance with

the service temperature.

Test Method D2837 and PPI TR-3.

5.2 Outsidediameters—TheneckOutsideDiameter(OD)of

4.2 Color—The PE material in the pipe shall contain color

the flange adapter measured at 73.4 6 3.6°F (23 6 2°C) shall

and ultraviolet (UV) stabilizer meeting the requirements of

conform to the applicable OD dimension requirements speci-

Code C or E per Specification D3350. Code C material shall

fied in the related polyethylene pipe standards : Specifications

contain between 2 to 3 percent carbon black by weight.

F714, D2513, D3035, and AWWA C901 and C906. Measure-

mentsshallbemadeaccordingtothemethodsspecifiedinTest

4.3 Rework—Clean rework pipe-grade polyethylene mate-

rial derived from pipe and or fittings production by the same Method D2122. The tolerance on outside diameter shall not

exceed 60.45 percent of the average outside diameter, as

manufacturer are acceptable as part of a blend with virgin

material for the production of flange adapters provided that (a) presented in the tables for NPS 4-in. and larger.

the cell classification or materials designation code of the 5.2.1 Special Sizes—Where existing system conditions or

reworkmaterialisthesameasthevirginmaterialcompoundto special local requirement make other diameters or dimension

which it is added, and (b) the rework materials complied with ratios necessary, other sizes or dimension ratios, or both, shall

applicable requirements as virgin materials. be acceptable for engineered applications when mutually

TABLE 1 Property Values and Specification D3350 Cell Classification for Materials

Materials Designation Code

Property

A A A

PE2606 PE2706 PE2708 PE3608 PE3708 PE3710 PE4608 PE4708 PE4710

Property Values

HDB at 140°F (60°C) per ASTM D 2837 and PPI CC C C C C C C C

TR-3, psi (MPa)

HDS at 73°F (23°C) per ASTM D 2837 and PPI TR-3, 630 (4.6) 630 800 800 (5.5) 800 (5.5) 1000 800 800 1000

psi (MPa) (4.6) (5.5) (6.9) (5.5) (5.5) (6.9)

B

Specification D3350 Cell Classification Values

Density (natural base resin) 2 2 2 3 3 3 4 4 4

Melt Index 3-4 3-4 3-4 4 4 4 4 4 4

Flexural Modulus 3-4 3-4 3-4 $4 $4 $4 $4 $4 $5

Tensile Strength at Yield $3 $3 $3 $4 $4 $4 $4 $4 $4

SCG Resistance 6 7 7 6 7 7 6 7 7

Hydrostatic Strength Classification 3 3 3 4 4 4 4 4 4

Color and UV Stabilizer CorE CorE CorE CorE CorE CorE CorE CorE CorE

A

HDB at 140°F (60°C) per ASTM D2837 and PPI TR-3 at 140°F required; contact manufacturer for listed value.

B

Specification D3350 cell classification values reflect typical property values for numerous lots of the material and do not include variability in testing or manufacturing

tolerances. Values for individual material lots can vary from typical values. Contact the manufacturer for information about variability in testing and material manufacturing

tolerances.

F2880−11a

agreed upon by the customer and the manufacturer, if the 5.5 Hub Width and Hub OD—The hub width must be

flange adapter is manufactured from plastic compounds meet- sufficiently stiff to resist shear, to resist fluid pressure bending

ing the material requirements of this specification, and the

moment flexing, to resist pipe beam bending, and to distribute

strength and design requirements are calculated on the same

concentrated back up ring load across the seal-face. The hub

basisasthoseuseinthisspecification.Fordiametersnotshown

minimum width shall be at least 1.10 times the nominal neck

in Table 2, Table 3 or Table 4, the tolerance shall be the same

wall thickness for a specified neck DR. The ratio of the hub

percentage as that shown in the corresponding tables for the

widthtoneckwallthicknessmayexceed1.5whenalowerDR

next smaller listed size.

flange adapter is machined into a thinner wall, higher DR

flange adapter. Hub width may be the minimum or thicker, as

5.3 Neck Wall thickness—The flange adapter manufacturer

specifiedbytheTargetHubWidthinTable3andTable4.Table

may provide extra wall thickness to compensate for PE pipe

5 specifies the nomin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.