ASTM D6115-97(2004)

(Test Method)Standard Test Method for Mode I Fatigue Delamination Growth Onset of Unidirectional Fiber-Reinforced Polymer Matrix Composites

Standard Test Method for Mode I Fatigue Delamination Growth Onset of Unidirectional Fiber-Reinforced Polymer Matrix Composites

SIGNIFICANCE AND USE

Susceptibility to delamination is one of the major weaknesses of many advanced laminated composite structures. Knowledge of a laminated composite material’resistance to interlaminar fracture under fatigue loads is useful for product development and material selection. Furthermore, a measurement of the relationship of the mode I cyclic strain energy release rate and the number of cycles to delamination growth onset, G–N, that is independent of specimen geometry or method of load introduction, is useful for establishing design allowables used in damage tolerance analyses of composite structures made from these materials.

This test method can serve the following purposes:

5.2.1 To establish quantitatively the effects of fiber surface treatment, local variations in fiber volume fraction, and processing and environmental variables on G–N of a particular composite material.

5.2.2 To compare quantitatively the relative values of G–N for composite materials with different constituents.

5.2.3 To develop criteria for avoiding the onset of delamination growth under fatigue loading for composite damage tolerance and durability analyses.

SCOPE

1.1 This test method determines the number of cycles (N) for the onset of delamination growth based on the opening mode I cyclic strain energy release rate (G), using the Double Cantilever Beam (DCB) specimen shown in . This test method applies to constant amplitude, tension-tension fatigue loading of continuous fiber-reinforced composite materials. When this test method is applied to multiple specimens at various G-levels, the results may be shown as a G-N curve, as illustrated in Fig 2.

1.2 This test method is limited to use with composites consisting of unidirectional carbon fiber tape laminates with single-phase polymer matrices. This limited scope reflects the experience gained in round robin testing. This test method may prove useful for other types and classes of composite materials, however, certain interferences have been noted (see Section 6.5 of Test Method D 5528).

1.3 The values stated in SI units are to be regarded as standard. The values provided in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6115–97 (Reapproved 2004)

Standard Test Method for

Mode I Fatigue Delamination Growth Onset of Unidirectional

Fiber-Reinforced Polymer Matrix Composites

This standard is issued under the fixed designation D6115; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

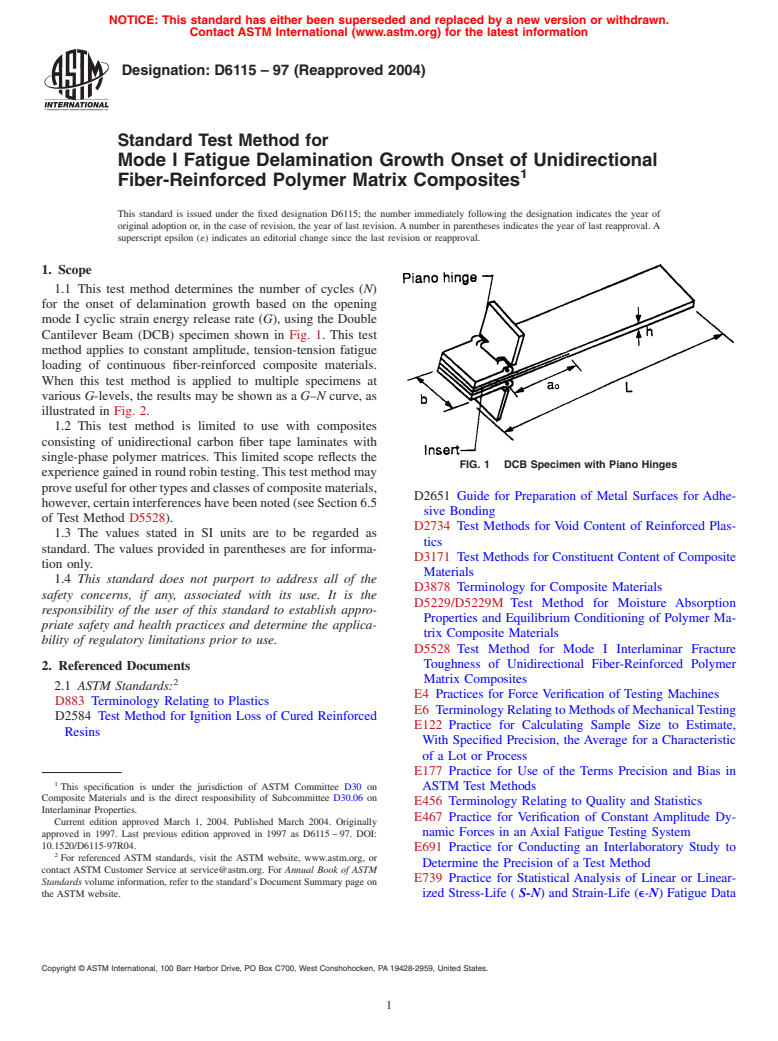

1.1 This test method determines the number of cycles (N)

for the onset of delamination growth based on the opening

mode I cyclic strain energy release rate (G), using the Double

Cantilever Beam (DCB) specimen shown in Fig. 1. This test

method applies to constant amplitude, tension-tension fatigue

loading of continuous fiber-reinforced composite materials.

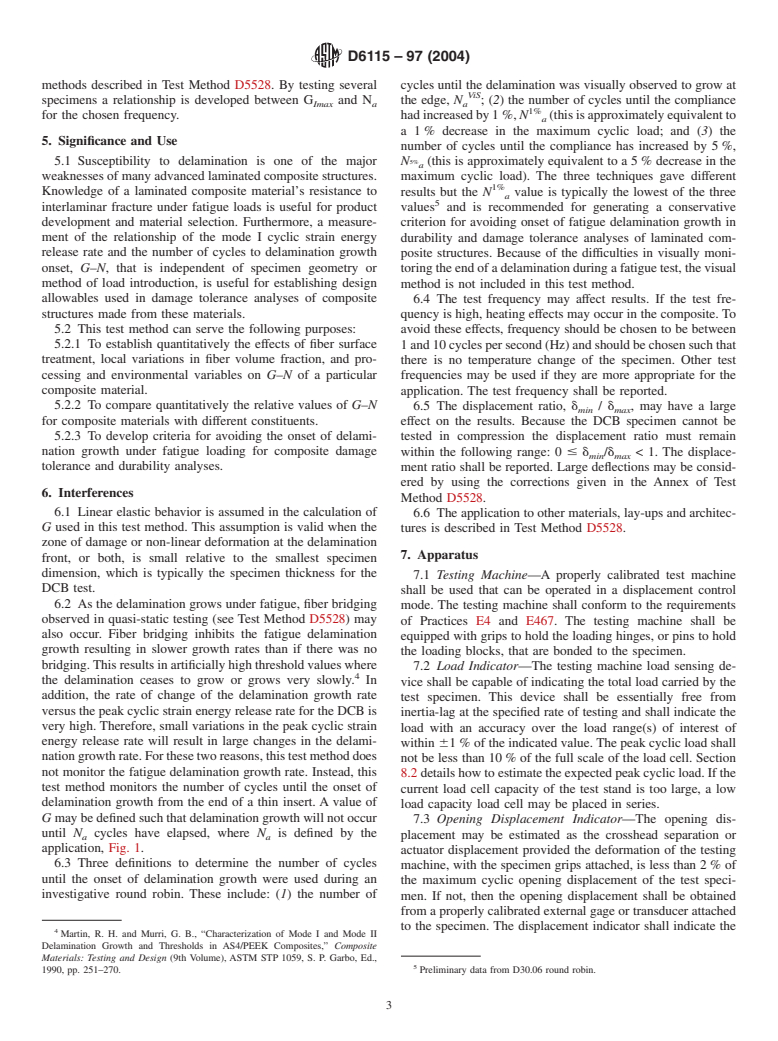

When this test method is applied to multiple specimens at

various G-levels, the results may be shown as a G–N curve, as

illustrated in Fig. 2.

1.2 This test method is limited to use with composites

consisting of unidirectional carbon fiber tape laminates with

single-phase polymer matrices. This limited scope reflects the

FIG. 1 DCB Specimen with Piano Hinges

experience gained in round robin testing.This test method may

proveusefulforothertypesandclassesofcompositematerials,

D2651 Guide for Preparation of Metal Surfaces for Adhe-

however,certaininterferenceshavebeennoted(seeSection6.5

sive Bonding

of Test Method D5528).

D2734 Test Methods for Void Content of Reinforced Plas-

1.3 The values stated in SI units are to be regarded as

tics

standard. The values provided in parentheses are for informa-

D3171 Test Methods for Constituent Content of Composite

tion only.

Materials

1.4 This standard does not purport to address all of the

D3878 Terminology for Composite Materials

safety concerns, if any, associated with its use. It is the

D5229/D5229M Test Method for Moisture Absorption

responsibility of the user of this standard to establish appro-

Properties and Equilibrium Conditioning of Polymer Ma-

priate safety and health practices and determine the applica-

trix Composite Materials

bility of regulatory limitations prior to use.

D5528 Test Method for Mode I Interlaminar Fracture

Toughness of Unidirectional Fiber-Reinforced Polymer

2. Referenced Documents

Matrix Composites

2.1 ASTM Standards:

E4 Practices for Force Verification of Testing Machines

D883 Terminology Relating to Plastics

E6 TerminologyRelatingtoMethodsofMechanicalTesting

D2584 Test Method for Ignition Loss of Cured Reinforced

E122 Practice for Calculating Sample Size to Estimate,

Resins

With Specified Precision, the Average for a Characteristic

of a Lot or Process

E177 Practice for Use of the Terms Precision and Bias in

This specification is under the jurisdiction of ASTM Committee D30 on

ASTM Test Methods

Composite Materials and is the direct responsibility of Subcommittee D30.06 on

E456 Terminology Relating to Quality and Statistics

Interlaminar Properties.

E467 Practice for Verification of Constant Amplitude Dy-

Current edition approved March 1, 2004. Published March 2004. Originally

namic Forces in an Axial Fatigue Testing System

approved in 1997. Last previous edition approved in 1997 as D6115 – 97. DOI:

10.1520/D6115-97R04.

E691 Practice for Conducting an Interlaboratory Study to

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Determine the Precision of a Test Method

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

E739 Practice for Statistical Analysis of Linear or Linear-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ized Stress-Life ( S-N) and Strain-Life (e-N) Fatigue Data

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6115–97 (2004)

E1049 Practices for Cycle Counting in Fatigue Analysis 3.3.13 G–N—relationship between the cyclic strain energy

E1150 Definitions of Terms Relating to Fatigue release rate and the number of cycles to onset of delamination

growth.

3. Terminology 3.3.14 h—thickness of DCB specimen.

3.3.15 N—number of elapsed fatigue cycles.

3.1 Terminology D3878 defines terms relating to high-

3.3.16 N —application dependent value of N at which

a

modulus fibers and their composites. Terminology D883 de-

delamination growth onset will occur.

fines terms relating to plastics. Terminology E6 defines terms

1 %

3.3.17 N —numberoffatiguecyclesforthevalueof P

a max

relating to mechanical testing. Terminology E456 and Practice

at N = 1 to decrease by 1 %.

E177 define terms relating to statistics. Definition E1150

ViS

3.3.18 N —number of fatigue cycles at which the onset

a

defines terms relating to fatigue. In the event of conflict

of delamination growth is observed.

between terms, Terminology D3878 shall have precedence

5 %

3.3.19 N —numberoffatiguecyclesforthevalueof P

a max

over the other terminology standards.

at N = 1 to decrease by 5 %.

3.2 Definitions of Terms Specific to This Standard:

3.3.20 P—applied load.

3.2.1 crack opening mode (Mode I)—fracture mode in

3.3.21 P —value of load at the onset of delamination

cr

which the delamination faces open away from each other and

growth from the insert in the quasi-static tests.

in which these faces do not undergo any relative sliding.

3.3.22 P —maximum cyclic load.

max

3.2.2 cycles to onset of delamination growth, N —the num-

a

3.3.23 R—ratio of minimum and peak loads P /P .

min max

ber of fatigue cycles elapsed until the onset of delamination

3.3.24 SD—standard deviation.

growth from an implanted thin insert.

3.3.25 U—strain energy.

3.2.3 fatigue delamination growth onset relationship,

3.3.26 V —fiber volume fraction, %.

f

G–N—the relationship between the peak cyclic value of strain

3.3.27 d—load point deflection.

energy release rate to the number of fatigue cycles until the

3.3.28 d —value of displacement at the onset of delamina-

cr

onset of delamination growth, N .

a

tion growth from the insert in a quasi-static test.

3.2.4 mode I interlaminar fracture toughness, G —the

Ic

3.3.29 d —maximum value of cyclic displacement.

max

critical value of G for delamination growth because of an

3.3.30 d —mean value of cyclic displacement.

mean

opening load or displacement.

3.3.31 d —minimum value of cyclic displacement.

mm

3.2.5 strain energy release rate, G—the loss of strain

3.3.32 D—effective delamination extension to correct for

energy, dU, in the test specimen per unit of specimen width for

rotation of DCB arms at delamination front.

an infinitesimal increase in delamination length, da, for a

3.3.33 [D] —average value of D from the quasi-static tests.

av

delamination growing under a constant displacement. In math-

ematical form:

4. Summary of Test Method

1 dU

4.1 The Double Cantilever Beam (DCB) shown in Fig. 2 is

G52 (1)

b da

described in Test Method D5528.

where:

U = total elastic strain energy in the test specimen,

b = specimen width, and

a = delamination length.

3.3 Symbols:

3.3.1 a—delamination length.

3.3.2 a —initial delamination length.

3.3.3 b—width of DCB specimen.

3.3.4 C—compliance, d/P, of DCB specimen.

3.3.5 CV—coefficient of variation, %.

3.3.6 da—infinitesimal increase in delamination length.

3.3.7 dU—infinitesimal increase in strain energy.

3.3.8 E —modulus of elasticity in the fiber direction.

II

3.3.9 G—strain energy release rate.

3.3.10 G —opening mode I interlaminar fracture tough-

Ic FIG. 2 G–N Curve

ness.

3.3.11 [G ] —average values of G from the quasi-static

Ic av Ic

4.2 The DCB specimen is cycled between a minimum and

tests.

maximum displacement, d , and d , at a specified fre-

min max

3.3.12 G —maximum or peak cyclic mode I strain en-

Imax

quency. For linear elasticity and small deflections (d/a < 0.4)

ergy release rate.

the displacement ratio, d / d , is identical to the R-ratio.

min max

The number of displacement cycles at which the onset of

delaminationgrowthoccurs, N ,isrecorded.ThemodeIcyclic

a

strain energy release rate, for example the maximum value,

Withdrawn. The last approved version of this historical standard is referenced

on www.astm.org. G is calculated using a modified beam theory or other

Imax

D6115–97 (2004)

methods described in Test Method D5528. By testing several cycles until the delamination was visually observed to grow at

ViS

specimens a relationship is developed between G and N the edge, N ;(2) the number of cycles until the compliance

Imax a a

1%

for the chosen frequency. hadincreasedby1 %, N (thisisapproximatelyequivalentto

a

a 1 % decrease in the maximum cyclic load; and (3) the

5. Significance and Use

number of cycles until the compliance has increased by 5 %,

5.1 Susceptibility to delamination is one of the major 5%

N (this is approximately equivalent to a 5 % decrease in the

a

weaknesses of many advanced laminated composite structures. maximum cyclic load). The three techniques gave different

1%

Knowledge of a laminated composite material’s resistance to

results but the N value is typically the lowest of the three

a

interlaminar fracture under fatigue loads is useful for product values and is recommended for generating a conservative

development and material selection. Furthermore, a measure-

criterion for avoiding onset of fatigue delamination growth in

ment of the relationship of the mode I cyclic strain energy durability and damage tolerance analyses of laminated com-

release rate and the number of cycles to delamination growth

posite structures. Because of the difficulties in visually moni-

onset, G–N, that is independent of specimen geometry or toringtheendofadelaminationduringafatiguetest,thevisual

method of load introduction, is useful for establishing design

method is not included in this test method.

allowables used in damage tolerance analyses of composite 6.4 The test frequency may affect results. If the test fre-

structures made from these materials. quency is high, heating effects may occur in the composite. To

5.2 This test method can serve the following purposes: avoid these effects, frequency should be chosen to be between

5.2.1 To establish quantitatively the effects of fiber surface 1and10cyclespersecond(Hz)andshouldbechosensuchthat

treatment, local variations in fiber volume fraction, and pro-

there is no temperature change of the specimen. Other test

cessing and environmental variables on G–N of a particular frequencies may be used if they are more appropriate for the

composite material.

application. The test frequency shall be reported.

5.2.2 To compare quantitatively the relative values of G–N 6.5 The displacement ratio, d / d , may have a large

min max

for composite materials with different constituents.

effect on the results. Because the DCB specimen cannot be

5.2.3 To develop criteria for avoiding the onset of delami- tested in compression the displacement ratio must remain

nation growth under fatigue loading for composite damage

within the following range: 0# d /d < 1. The displace-

min max

tolerance and durability analyses. ment ratio shall be reported. Large deflections may be consid-

ered by using the corrections given in the Annex of Test

6. Interferences

Method D5528.

6.1 Linear elastic behavior is assumed in the calculation of

6.6 The application to other materials, lay-ups and architec-

G used in this test method. This assumption is valid when the

tures is described in Test Method D5528.

zone of damage or non-linear deformation at the delamination

7. Apparatus

front, or both, is small relative to the smallest specimen

dimension, which is typically the specimen thickness for the

7.1 Testing Machine—A properly calibrated test machine

DCB test.

shall be used that can be operated in a displacement control

6.2 As the delamination grows under fatigue, fiber bridging

mode. The testing machine shall conform to the requirements

observed in quasi-static testing (see Test Method D5528) may

of Practices E4 and E467. The testing machine shall be

also occur. Fiber bridging inhibits the fatigue delamination

equipped with grips to hold the loading hinges, or pins to hold

growth resulting in slower growth rates than if there was no

the loading blocks, that are bonded to the specimen.

bridging.Thisresultsinartificiallyhighthresholdvalueswhere

7.2 Load Indicator—The testing machine load sensing de-

the delamination ceases to grow or grows very slowly. In

vice shall be capable of indicating the total load carried by the

addition, the rate of change of the delamination growth rate

test specimen. This device shall be essentially free from

versus the peak cyclic strain energy release rate for the DCB is

inertia-lag at the specified rate of testing and shall indicate the

very high. Therefore, small variations in the peak cyclic strain

load with an accuracy over the load range(s) of interest of

energy release rate will result in large changes in the delami-

within 61 % of the indicated value. The peak cyclic load shall

nationgrowthrate.Forthesetworeasons,thistestmethoddoes

not be less than 10 % of the full scale of the load cell. Section

not monitor the fatigue delamination growth rate. Instead, this

8.2detailshowtoestimatetheexpectedpeakcyclicload.Ifthe

test method monitors the number of cycles until the onset of

current load cell capacity of the test stand is too large, a low

delamination growth from the end of a thin insert. A value of

load capacity load cell may be placed in series.

G may be defined such that delamination growth will not occur

7.3 Opening Displacement Indicator—The opening dis-

until N cycles have elapsed, where N is defined by the

placement may be estimated as the crosshead separation or

a a

application, Fig. 1.

actuator displacement provided the deformation of the testing

6.3 Three definitions to determine the number of cycles

machine, with the specimen grips attached, is less than 2 % of

until the onset of delamination growth were used during an

the maximum cyclic opening displacement of the test speci-

investigative round robin. These include: (1) the number of

men. If not, then the opening displacement shall be obtained

from a properly calibrated external gage or transducer attached

to the specimen. The displacement indicator shall indicate the

Martin, R. H. and Murri, G. B., “Characterization of Mode I and Mode II

Delamination Growth and Thresholds in AS4/PEEK Composites,” Composite

Materials: Testing and Design (9th Volume), ASTM STP 1059, S. P. Garbo, Ed.,

1990, pp. 251–270. Preliminary data from D30.06 round robin.

D6115–97 (2004)

crack opening displacement with an accuracy of within 61% 11. Procedure

of the indicated value once the delami

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.