ASTM D4939-89(2003)

(Test Method)Standard Test Method for Subjecting Marine Antifouling Coating to Biofouling and Fluid Shear Forces in Natural Seawater

Standard Test Method for Subjecting Marine Antifouling Coating to Biofouling and Fluid Shear Forces in Natural Seawater

SCOPE

1.1 This test method covers the determination of antifouling performance and reduction of thickness of marine antifouling (AF) coatings by erosion or ablation (see Section 3) under specified conditions of hydrodynamic shear stress in seawater alternated with static exposure in seawater. An antifouling coating system of known performance is included to serve as a control in antifouling studies.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific hazards statement, see Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4939–89(Reapproved2003)

Standard Test Method for

Subjecting Marine Antifouling Coating to Biofouling and

Fluid Shear Forces in Natural Seawater

This standard is issued under the fixed designation D 4939; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope MIL-S-22698A Steel Plate, Carbon, Structural

1.1 This test method covers the determination of antifouling

3. Terminology

performance and reduction of thickness of marine antifouling

3.1 Definitions of Terms Specific to This Standard:

(AF) coatings by erosion or ablation (see Section 3) under

3.1.1 ablation, n—in this test method, the removal or

specified conditions of hydrodynamic shear stress in seawater

wearing away of the outer layers of coating caused by the

alternated with static exposure in seawater. An antifouling

combined action of hydrolysis and hydrodynamic shear stress.

coating system of known performance is included to serve as a

This action is often, but not necessarily, achieved by the

control in antifouling studies.

combined effects of hydrolysis and hydrodynamic shear stress.

1.2 This standard does not purport to address all of the

3.1.2 hydrolysis, n—softening or weakening of the outer

safety concerns, if any, associated with its use. It is the

layers, permitting the hydrodynamic shear stresses gradually to

responsibility of the user of this standard to establish appro-

remove them, continually exposing a fresh antifouling surface.

priate safety and health practices and determine the applica-

3.1.3 hydrodynamic shear stress, n—the force tangential to

bility of regulatory limitations prior to use. For a specific

the surface resulting from water in contact with and flowing

hazards statement, see Section 8.

parallel to the surface.

2. Referenced Documents

4. Summary of Test Method

2.1 ASTM Standards:

4.1 The antifouling coatings to be tested and a control

A 569/A 569M Specification for Steel, Carbon (0.15 Maxi-

coating are applied to steel panels and exposed in natural

mum Percent), Hot-Rolled, Sheet and Strip, Commercial

seawater at a site where the fouling rate is high. The exposure

D 1186 Test Methods for Nondestructive Measurement of

consists of alternate static and dynamic cycles of typically 30

Dry Film Thickness of Nonmagnetic Coatings Applied to

3 days each for a total length of time to be specified (such as one

a Ferrous Base

or two years) or until some selected degree of fouling is

D 2200 Pictorial Surface Preparation Standards for Painting

4 reached. The static exposure is conducted in accordance with

Steel Surfaces

Method D 3623 except that the panels are smaller and are

D 3623 Method for Testing Antifouling Panels in Shallow

4 preformed to fit a rotating drum. The dynamic exposure

Submergence

5 consists of subjecting the test panels to a shear stress by

2.2 U.S. Military Specifications:

rotating the drum underwater at some specified revolution rate;

MIL-P-24441 Primer, Epoxy (Formula 150, Formula Sheet

typically,thatratethatgivesaperipheralspeedof15knots(7.6

24441/1)

m/s). See Note 1 for an example. Photographs and film

MIL-P-15931B Paint, Antifouling, Vinyl, Red (Formula

thickness measurements (made in accordance with Test Meth-

121/63)

ods D 1186) are taken before exposure to seawater and, along

with fouling ratings, at intervals during exposure.

This test method is under the jurisdiction of ASTM Committee D01 on Paint

NOTE 1—Consider antifouling paint for a ship about 500 ft in length

and Related Coatings, Materials, andApplications and is the direct responsibility of

that cruises at about 20 knots. From Table 2, the column for 20 knots

Subcommittee D01.45 on Marine Coatings.

shows the hydrodynamic shear stress, t varying from 2.01 to 1.40 lbf/ft

Current edition approved March 10, 2003. Published May 2003. Originally

over a flat plate with approximately the same length as the ship. From

approved in 1989. Last previous edition approved in 1996 as D 4939 - 96.

Table 1, a rotating drum with a radius of 0.75 ft with a peripheral speed

Discontinued; see 2001 Annual Book of ASTM Standards, Vol 01.03.

3 of 15 knots gives a t of 1.72 lbf/ft . To subject the paint to about the same

Annual Book of ASTM Standards, Vol 06.01.

rangeof tasontheship,thepaintcanbetestedonthedrumwith tof1.72

Annual Book of ASTM Standards, Vol 06.02.

lbf/ft . Because t for the plate (and ships) decreases from the leading to

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098 the trailing edge, it is considered adequate to select t for the drum as the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4939–89 (2003)

TABLE 1 Approximate Hydrodynamic Shear Stress, t, For

2 A

Rotating Drum Apparatus, lbf/ft

Peripheral Speed of Drum, knots

Drum Radius, ft

10 15 20 22 25 30

0.75 0.82 1.72 2.91 3.48 4.39 6.14

1.0 0.78 1.64 2.78 3.31 4.19 5.86

1.25 0.75 1.58 2.68 3.20 4.05 5.68

1.5 0.73 1.53 2.60 3.11 3.94 5.52

A

Values calculated as follows:

t = ⁄2 C rv ,

f

v = r v

vr

R =

, Reynolds Number

n

= −0.6 + 4.07 log [R C ] (from Dorfman, Hydrodynamic Resis-

=

f

C tance and the Heat Loss of Rotating Solids, Oliver and Boyd,

=

f

London, 1963, p. 176.

where

t = shear stress on drum surface, lbf/ft ,

r = water density = 1.99 slugs,

v = peripheral speed of drum surface, knots,

C = shear stress (drag) coefficient,

f

v = Rotational speed of drum, radions/s, and

r = drum radius, ft.

approximate midrange of the plate values matched to the length and

cruising speed of the vessels of interest.

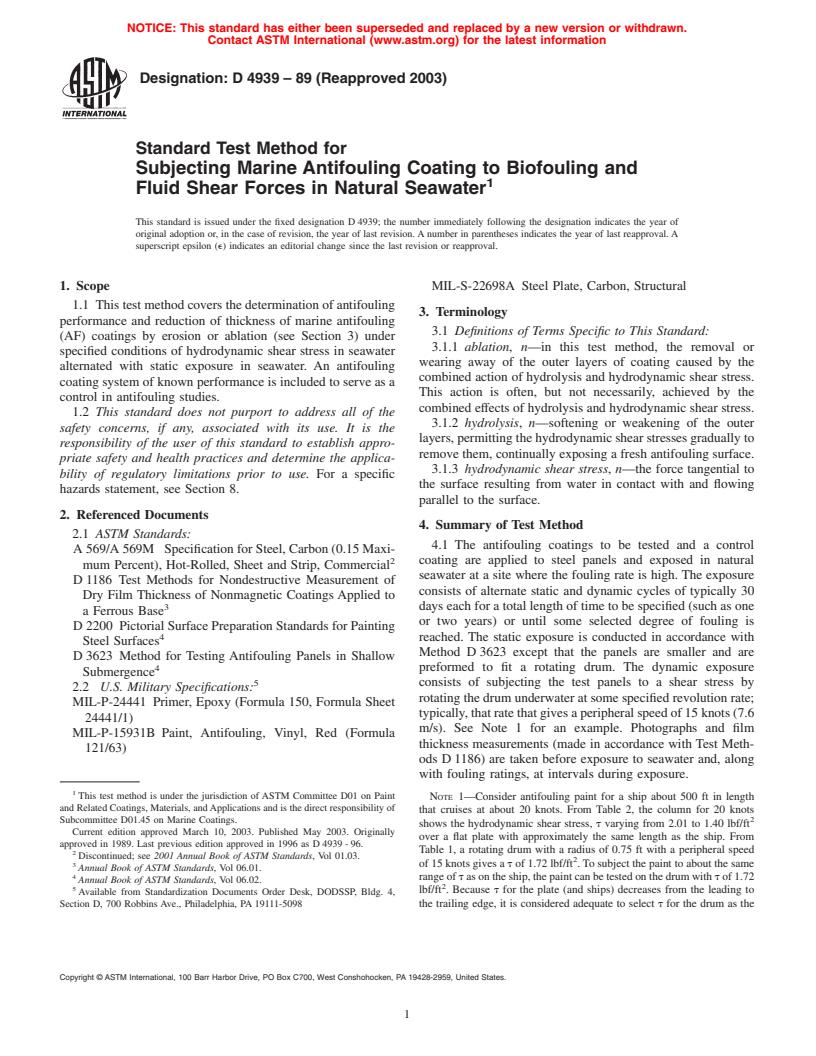

NOTE 1—Specific components and arrangements may vary to suit user

5. Significance and Use

and site requirements.

NOTE 2—1 ft = 305 mm.

5.1 Effective antifouling coatings are essential for the reten-

FIG. 1 Rotating Drum Assembly

tionofspeedandreductionofoperatingcostsofships.Thistest

method is designed as a screening test to evaluate antifouling

coating systems under conditions of hydrodynamic stress

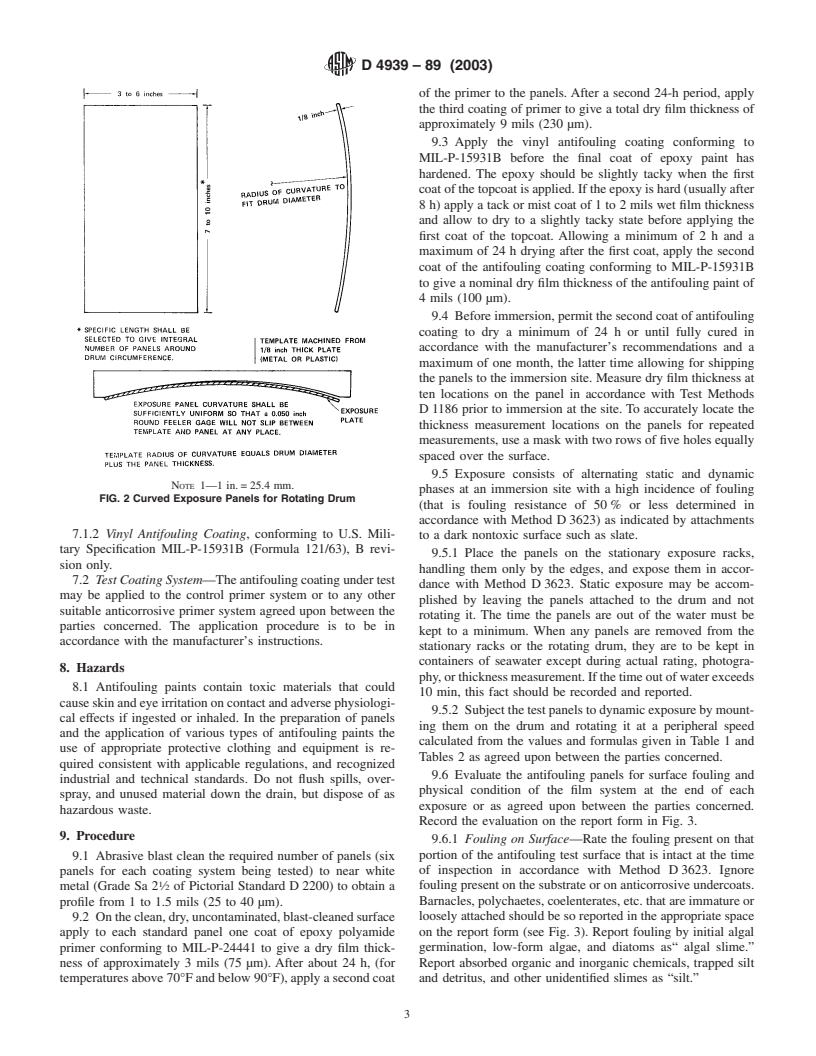

6.2 Panels—The panels shall be made from medium low-

caused by water flow alternated with static exposure to a

carbon steel plate in accordance with Specification A 569/

fouling environment. A dynamic test is necessary because of

A 569M, ⁄8in. thick by 3 to 6 by 7 to 10 in. (3 mm thick by 80

the increasing availability of AF coatings that are designed to

to 150 by 180 to 250 mm) curved to fit the drum surface as

ablate in service to expose a fresh antifouling surface. Because

shown in Fig. 2. Panel length must be selected in order to

no ship is underway continually, a static exposure phase is

prevent gaps greater than ⁄16 in. (1.6 mm).

included to give fouling microorganisms the opportunity to

6.3 Static Exposure Rack—The static exposure rack shall

attach under static conditions. After an initial 30-day static

provide firm positioning of the specimen panels so that the

exposure, alternated 30-day dynamic and static exposures are

coated surfaces are held vertically in place in spite of the

recommended as a standard cycle.The initial static exposure is

currentandareelectricallyinsulatedfrommetalliccontactwith

selected to represent vessels coming out of drydock and sitting

therackorotherpanels.Therackshallbesopositionedthatthe

pierside while work is being completed. This gives the paint

prevailing tidal currents move parallel to the panel face, and

time to lose any remaining solvents, complete curing, absorb

the panels are immersed to a depth of a minimum of 1 ft (0.3

water, and, in general, stabilize to the in-water environment.

m) and a maximum of 10 ft (3 m). In a rack where panels are

5.2 This test method is intended to provide a comparison

stacked front to back, they should be spaced at least 2 ⁄2 in. (64

with a control antifouling coating of known performance in

mm) apart, with the two end positions filled with blank panels.

protectingunderwaterportionsofships’hulls.Thistestmethod

In a rack where the panels are mounted side by side, the

gives an indication of the performance and anticipated service

distance between adjacent panels should be not less than ⁄2 in.

life of antifouling coatings for use on seagoing vessels.

(13 mm).

However, the degree of correlation between this test method

and service performance has not been determined.

7. Materials

6. Apparatus

7.1 Control Coating System—The control antifouling coat-

6.1 Rotating Drum Assembly—The basic system consists of ing system shall consist of the following system unless an

alternative control coating system is specified.

a rotating drum assembly as shown in Fig. 1. The drum

diameter and rotational rate shall be calculated to give the 7.1.1 Polyamide Epoxy Anticorrosive Coating, conforming

desired hydrodynamic shear stress.The drum diameter shall be to U.S. Military Specification MIL-P-24441 (Navy Formula

not less than 18 in. (460 mm). 150, Type I).

D4939–89 (2003)

of the primer to the panels. After a second 24-h period, apply

the third coating of primer to give a total dry film thickness of

approximately 9 mils (230 µm).

9.3 Apply the vinyl antifouling coating conforming to

MIL-P-15931B before the final coat of epoxy paint has

hardened. The epoxy should be slightly tacky when the first

coat of the topcoat is applied. If the epoxy is hard (usually after

8 h) apply a tack or mist coat of 1 to 2 mils wet film thickness

and allow to dry to a slightly tacky state before applying the

first coat of the topcoat. Allowing a minimum of 2 h and a

maximum of 24 h drying after the first coat, apply the second

coat of the antifouling coating conforming to MIL-P-15931B

to give a nominal dry film thickness of the antifouling paint of

4 mils (100 µm).

9.4 Before immersion, permit the second coat of antifouling

coating to dry a minimum of 24 h or until fully cured in

accordance with the manufacturer’s recommendations and a

maximum of one month, the latter time allowing for shipping

the panels to the immersion site.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.