ASTM D4555-90(1995)

(Test Method)Standard Test Method for Determining Deformability and Strength of Weak Rock by an In Situ Uniaxial Compressive Test

Standard Test Method for Determining Deformability and Strength of Weak Rock by an In Situ Uniaxial Compressive Test

SCOPE

1.1 This test method covers the measurement of the deformability and strength of large in situ specimens of weak rock by a uniaxial - compressive test. The test results take into account the effect of both intact material behavior and the behavior of discontinuities contained within the specimen block.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4555 – 90 (Reapproved 1995)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Determining Deformability and Strength of Weak Rock by an

In Situ Uniaxial Compressive Test

This standard is issued under the fixed designation D 4555; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope asymptotically constant strength value is found. This value is

,

2 3

taken to represent the strength of the rock mass.

1.1 This test method covers the measurement of the deform-

ability and strength of large in situ specimens of weak rock by

4. Apparatus

a uniaxial compressive test. The test results take into account

4.1 Preparation Equipment—Equipment is needed for cut-

the effect of both intact material behavior and the behavior of

ting specimen blocks from existing underground exposed

discontinuities contained within the specimen block.

faces, for example, a coal cutting machine, pneumatic chisel, or

1.2 The values stated in SI units are to be regarded as the

other hand tools. No explosives are permitted.

standard.

4.2 Loading System:

1.3 This standard does not purport to address all of the

4.2.1 Hydraulic Jacks or Flatjacks—This equipment is

safety concerns, if any, associated with its use. It is the

required to apply a uniformly distributed load to the complete

responsibility of the user of this standard to establish appro-

upper face of the specimen. The loading system shall be of

priate safety and health practices and determine the applica-

sufficient capacity and travel to load the system to failure.

bility of regulatory limitations prior to use.

Multiple hydraulic jacks fed by a common manifold should be

2. Terminology avoided.

4.2.2 Hydraulic Pumping System—This system is needed to

2.1 Definitions of Terms Specific to This Standard:

supply oil at the required pressure to the jacks, the pressure

2.1.1 rock quality designation, RQD—a method for quanti-

being controlled to give a constant rate of displacement or

tatively describing the nature of a rock mass from core borings.

strain, rather than a constant rate of stress increase.

RQD is obtained by measuring the total length of all unweath-

ered pieces of core greater than or equal to 100 mm and

NOTE 1—Experience has shown that deformation-controlled loading is

dividing the total by the length of the particular core run. This

preferable to stress-controlled loading because it results in a more stable,

and thus safer, test. This result is a consequence of the strain softening

quantity is expressed as a percent and is used to classify in situ

nature of most rock or rock-like materials. A single stress level may

rock.

correspond to different values of strain during any test, with the level of

2.1.2 weak rock—rock containing numerous weathered

strain continuing to increase throughout a test. One way to achieve

joints spaced 30 to 500 mm, with gouge filling/waste rock with

uniform deformation of the specimen is to use a separate pump for each

fines. Weak rock has both rock and soil properties depending

jack and to set the oil delivery rate of each pump to the same value.

on condition of use. The compressive strength is less than 35

Standard diesel fuel injection pumps have been found suitable and are

MPa and the RQD is less than 50 %. capable of supplying pressures up to 100 MPa. The delivery rate of these

pumps can be set very accurately.

3. Significance and Use

4.3 Equipment to Measure Applied Load and Strain in the

3.1 Since there is no reliable method of predicting the

Specimen:

overall strength and deformation data of a rock mass from the

4.3.1 Load Measuring Equipment—This equipment, for

results of laboratory tests on small specimens, in situ tests on

example, electric, hydraulic, or mechanical load cells, permits

large specimens are necessary. Such tests also have the

the applied load to be measured with an accuracy better than

advantage that the rock specimen is tested under similar

65 % of the maximum in the test.

environmental conditions as prevailing for the rock mass.

4.3.2 Dial Gage—A dial gage, or similar displacement

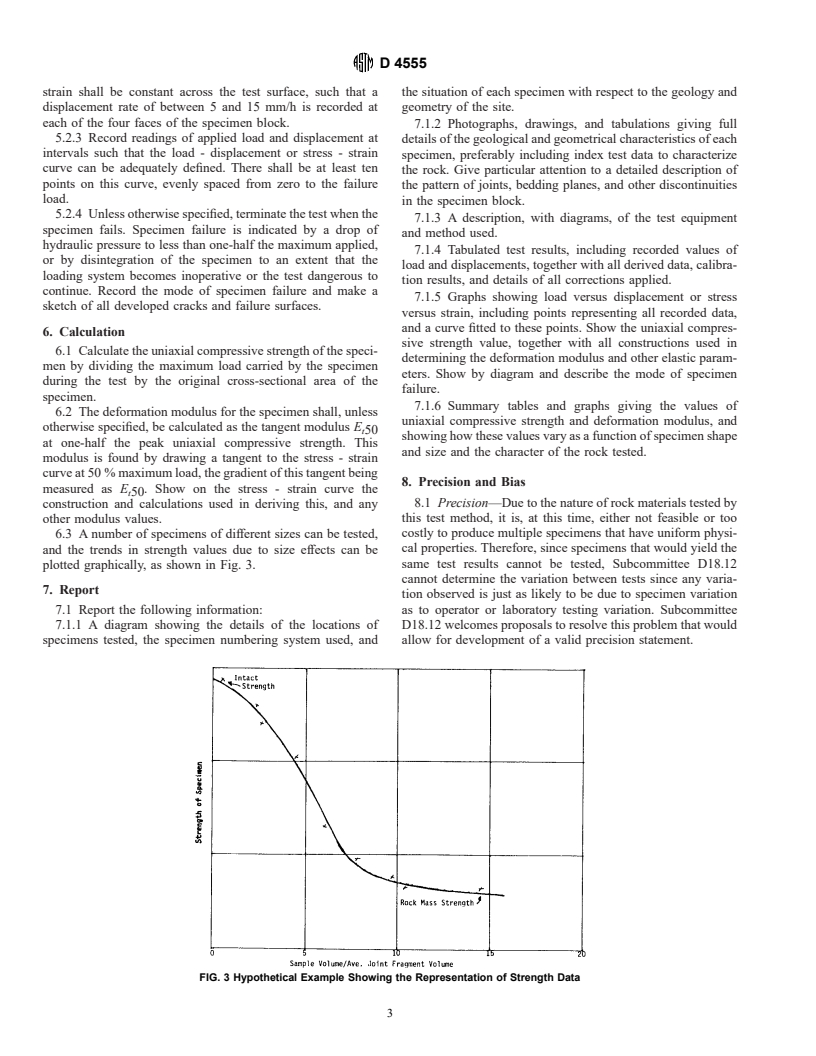

3.2 Since the strength of rock is dependent on the size of the

measuring devices, with robust fittings to enable the instru-

test specimen, it is necessary to test several specimens (labo-

ments to be mounted so that the strain in the central third of

ratory or field, or both) of progressively increasing size until an

each specimen face is measured with an accuracy better than 6

1 2

This test method is under the jurisdiction of Committee D-18 on Soil and Rock Bieniawski, Z. T., and Van Heerdan, W. L., “The Significance of Large-Scale In

and is the direct responsibility of Subcommittee D18.12 on Rock Mechanics. Situ Tests,” International Journal of Rock Mechanics Mining Sciences, Vol 1, 1975.

Current edition approved May 25, 1990. Published July 1990. Originally Heuze, F. E., “Scale Effects in the Determination of Rock Mass Strength and

published as D 4555 – 85. Last previous edition D 4555 – 85. Deformability,” Rock Mechanics, Vol 12, 1980, pp 167–192.

D 4555

−5

10 . Strain is to be measured in the direction of applied load faces of the block. Measure specimen geometry, including the

and also in a perpendicular direction if Poisson’s ratio values geometry of defects in the block, with an accuracy better than

are to be determined. 5 mm. Prepare photographs and drawings to illustrate both

4.4 Calibration Equipment—Equipment to calibrate the geological and geometric characteristics.

loading and displacement measuring systems, the accuracy of 5.1.3 Cast a concrete pad, suitably reinforced, to cover the

calibration to be better than the accuracies of test measurement top face of the specimen (Fig. 2). This pad shall be sufficient to

specified in 4.3.1 and 4.3.2. give adequate strength under the full applied load. The top face

of the pad shall be flat to within 65° of the basal plane of the

5. Procedure

block.

5.1 Preparation of Specimens:

5.1.4 Remove rock from above the specimen to make space

5.1.1 Cut specimens of the required dimensions from the

for the loading jacks. Cut back the rock to a stratum of

exposed rock faces (Fig. 1). The specimen shall have a

sufficient strength to provide safe reaction. Generally, a con-

height-to-minimum-width dimension ratio of 2.0 to 2.5. The

crete reaction pad must be cast to distribute the load on the roof

ratio of the maximum width of the specimen to the minimum

and to prevent undue deformation and movement of the jacks

width shall be as near to 1.0 as practicable.

during the test. The lower face of the reaction block shall be flat

5.1.1.1 First, remove loose and damaged rock. Make verti-

to within 65 mm and shall be parallel to the upper face of the

cal cuts as shown in Fig. 1 to form the vertical faces of the

specimen block within 65°. Cure all concrete for a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.