ASTM D3829-93(1998)

(Test Method)Standard Test Method for Predicting the Borderline Pumping Temperature of Engine Oil

Standard Test Method for Predicting the Borderline Pumping Temperature of Engine Oil

SCOPE

1.1 This test method covers the prediction of the borderline pumping temperature (BPT) of engine oils through the use of a 16-h cooling cycle over the temperature range from 0 to -40°C.

1.2 Applicability to petroleum products other than engine oils has not been determined.

1.3 This test method uses the millipascal (mPa[dot]s), as the unit of viscosity. For information, the equivalent centipoise unit is shown in parentheses.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3829 – 93 (Reapproved 1998) An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Predicting the Borderline Pumping Temperature of

Engine Oil

This standard is issued under the fixed designation D 3829; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

2VR

s

G 5 (1)

r 2

~R – R !

1.1 This test method covers the prediction of the borderline

s2 r

pumping temperature (BPT) of engine oils through the use of 2

4pR

s

G 5 (2)

a 16-h cooling cycle over the temperature range from 0 r

2 2

t R – R !

~

s r

to −40°C.

1.2 Applicability to petroleum products other than engine where:

oils has not been determined. G 5 shear rate at the surface of the rotor in reciprocal

r

−1

1.3 This test method uses the millipascal (mPa·s), as the unit

seconds, s ,

V5 angular velocity, rad/s,

of viscosity. For information, the equivalent centipoise unit is

R 5 stator radius, mm,

shown in parentheses.

s

R 5 rotor radius, mm, and

1.4 This standard does not purport to address all of the r

t 5 time in seconds for one revolution of the rotor.

safety concerns, if any, associated with its use. It is the

For the specific apparatus being described in 5.1.1,

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

G 5 (3)

r

t

bility of regulatory limitations prior to use.

2.1.6 shear stress—the motivating force per unit area for

2. Terminology

fluid flow. Area is the area under shear. For the rotary

2.1 Definitions:

viscometer being described, the rotor surface is the area under

2.1.1 viscosity—the ratio between the applied shear stress

shear.

and rate of shear. It is sometimes called the coefficient of

T 5 9.81M~R 1 R ! 3 10 (4)

r o t

dynamic viscosity. This value is thus a measure of the

T

resistance to flow of the liquid. The SI unit of viscosity is the

r

S 5 3 10 (5)

r 2

pascal second (Pa·s). The centipoise (cP) is one millipascal

2p R h

r

second (mPa·s) and is often used.

where:

2.1.2 Newtonian oil or fluid—an oil or fluid that at a given

T 5 torque applied to rotor, N·m,

r

temperature exhibits a constant viscosity at all shear rates or

M 5 applied mass, g,

shear stresses.

R 5 radius of the shaft, mm,

o

2.1.3 non-Newtonian oil or fluid—an oil or fluid that at a

R 5 radius of the thread, mm,

t

given temperature exhibits a viscosity that varies with chang-

S 5 shear stress at the rotor surface, Pa, and

r

ing shear stress or shear rate.

h 5 height of the rotor, mm.

2.1.4 apparent viscosity—the determined viscosity obtained

For the dimensions given in 5.1.1,

by use of this test method.

T 5 31.7M 3 10 (6)

r

2.1.5 shear rate—the velocity gradient in fluid flow. For a

Newtonian fluid in a concentric cylinder rotary viscometer in S 5 3.5M (7)

r

which the shear stress is measured at the inner cylinder surface

2.2 Definitions of Terms Specific to This Standard:

(such as the apparatus being described), and ignoring any end

2.2.1 calibration oils—those oils for establishing the instru-

effects, the shear rate is given as follows:

ment’s reference framework of apparent viscosity versus speed

from which the apparent viscosities of test oils are determined.

Calibration oils, which are essentially Newtonian fluids, are

This test method is under the jurisdiction of ASTM Committee D-2 on

available commercially, and have an approximate viscosity of

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

30 000 mPa·s (30 000 cP) at −20°C.

D02.07 on Flow Properties.

2.2.2 test oil—any oil for which the apparent viscosity and

Current edition approved Sept. 15, 1993. Published November 1993. Originally

published as D 3829 – 79. Last previous edition D 3829 – 87.

NOTICE:¬This¬standard¬has¬either¬been¬superseded¬and¬replaced¬by¬a¬new¬version¬or

discontinued.¬Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

D 3829

yield stress are to be determined by use of the test method 5.3 A means of lowering the temperature to the predeter-

under description. mined test temperature at a controlled, nonlinear rate.

2.2.3 yield stress—the shear stress required to initiate flow. 5.4 Circulating System, for supplying suitable liquid cool-

For all Newtonian fluids and some non-Newtonian fluids, yield ant to the block as needed. Methanol is a suitable coolant. One

stress is zero. Some engine oils have a yield stress that is a should observe toxicity and flammability precautions that

function of their low-temperature cooling rate, soak time, and apply to the use of methanol. The circulating system must be

temperature. capable of maintaining test temperature over a 16-h test period.

2.2.4 critical yield stress—the maximum yield stress that If methanol is leaking from the system, discontinue the test and

allows oil to flow to the inlet oil screen in an automotive repair the leak before continuing.

engine. With a higher yield stress, air may be drawn into the 5.5 Chart Recorder, to verify that the correct cooling curve

pump and cause failure to maintain adequate oil pressure is being followed, it is recommended that a chart recorder be

through air-binding of the pump. used to monitor the block temperature.

2.2.5 critical viscosity—the maximum viscosity at a defined

6. Reagents and Materials

shear rate to allow adequate flow of oil to the oil pump in an

automotive engine. A higher viscosity can cause failure to 6.1 Low Cloud-Point, Newtonian Oil, of approximately

30 Pa·s (30 000 cP) viscosity at −20°C for calibration of the

maintain adequate oil pressure through the limiting of flow

through the oil screen or oil inlet tubes. viscometric cells.

6.2 Methanol, commercial or technical grade of dry metha-

2.2.6 borderline pumping temperature—the maximum tem-

perature at which the critical yield stress or critical viscosity nol is suitable for the cooling bath.

occurs, whichever is the higher temperature. 6.3 Oil Solvent, commercial Heptanes or similar solvent is

suitable.

3. Summary of Test Method

6.4 Acetone, technical grade of acetone is suitable provided

it does not leave a residue upon evaporation.

3.1 An engine oil sample is cooled from 80°C to the desired

test temperature at a nonlinear programmed cooling rate over a

7. Sampling

10-h period and held at the test temperature for the remainder

7.1 A representative sample of test oil free from suspended

of a 16-h period. After completion of the soak period, two

solid material and water is necessary to obtain valid results. If

standard torques of increasing severity are applied to the rotor

the sample in its container is received below the dew-point

shaft and the speed of rotation in each case is measured. From

temperature of the room, allow to warm to room temperature

the results at three or more temperatures, the borderline

before opening.

pumping temperature is determined.

3.2 Alternatively, for some specification or classification

8. Calibration and Standardization

purposes it may be sufficient to determine that the BPT is less

8.1 Calibration is required for the temperature dial on the

than a certain specified temperature.

panel.

8.1.1 Place calibrated thermometer in position (see assem-

4. Significance and Use

bly instructions) and turn the RESET dial fully counterclock-

4.1 Borderline pumping temperature is a measure of the

wise.

lowest temperature at which an engine oil can be continuously

8.1.2 Set the dial at 100 and allow to cool to control

and adequately supplied to the oil pump inlet of an automotive

temperature. Allow approximately 30 min for temperature

engine.

equilibrium to be established.

8.1.3 Record the temperature.

5. Apparatus

8.1.4 Repeat 8.1.3 and 8.1.4 for dial settings of 200, 300,

5.1 Mini-Rotary Viscometer, consisting of one or more

500, 700, and 900 or until −37°C has been reached.

viscometric cells including a calibrated rotor-stator assembly,

8.1.5 On one- or two-cycle semilog graph paper, plot log

which are contained in a temperature-controlled aluminum

(reading) versus temperature (°C) to establish calibration

block.

curve. See Fig. 1.

5.1.1 The viscometric cell has the following nominal di-

8.2 The calibration of each viscometric cell (viscometer

mensions:

constants) can be determined with the viscosity standard and

Diameter of rotor 17.0 mm

the following procedure at −20 6 0.2°C.

Length of rotor 20.0 mm

Inside of diameter of cup 19.0 mm 8.2.1 Use steps 9.1.1-9.1.5.

Radius of shaft 3.18 mm

8.2.2 Set the temperature-control, ten-turn dial to corre-

Radius of string 0.05 mm

spond to −20°C and turn switch to cool.

5.2 Thermometers, for measuring temperature of the

8.2.3 Allow to soak at −20 6 0.2°C for at least 1 h, making

block. Two are required, one graduated from at least + 70 to

small temperature adjustments, if necessary, to maintain the

90°C in 1°C subdivisions, the other with a scale from at

test temperature.

least −36 to +5°C in 0.2°C subdivisions.

8.2.4 At the end of the soak period record the temperature

reading (test temperature), and remove the cover of the

viscometer cell.

Available from Cannon Instrument Co., P.O. Box 16, State College, PA 16801. 8.2.5 Proceed to steps 9.2.1-9.2.3.

NOTICE:¬This¬standard¬has¬either¬been¬superseded¬and¬replaced¬by¬a¬new¬version¬or

discontinued.¬Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

D 3829

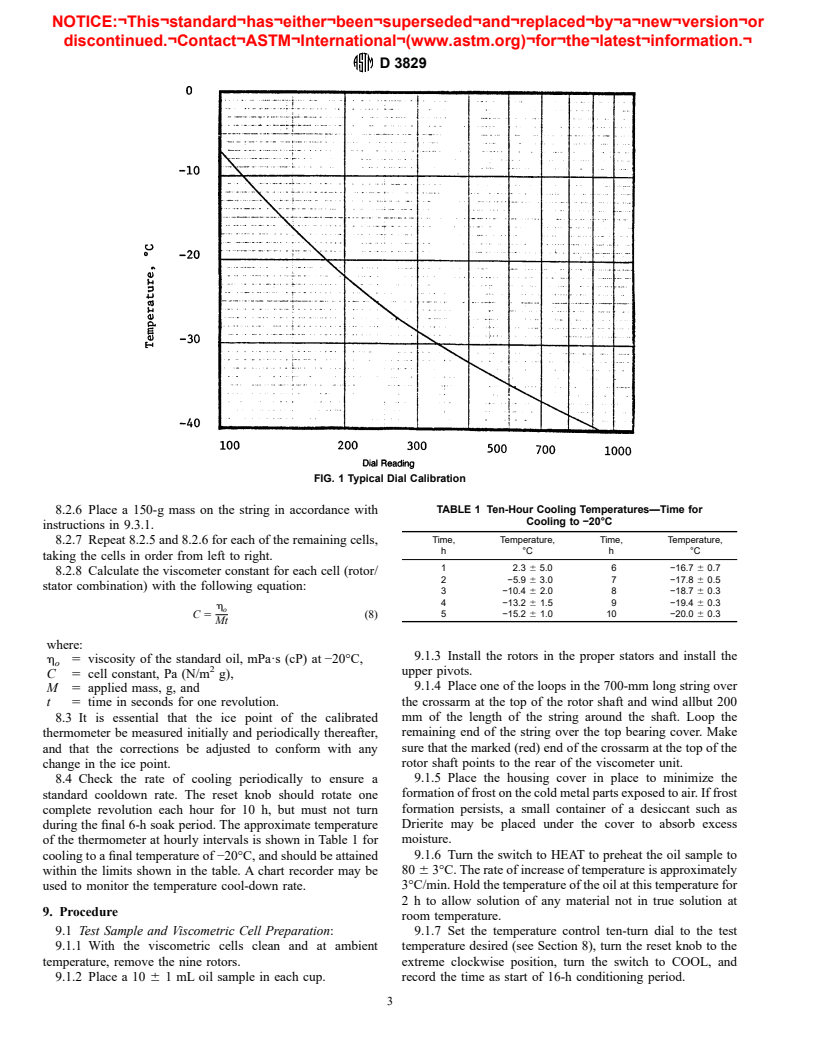

FIG. 1 Typical Dial Calibration

TABLE 1 Ten-Hour Cooling Temperatures—Time for

8.2.6 Place a 150-g mass on the string in accordance with

Cooling to −20°C

instructions in 9.3.1.

Time, Temperature, Time, Temperature,

8.2.7 Repeat 8.2.5 and 8.2.6 for each of the remaining cells,

h °C h °C

taking the cells in order from left to right.

1 2.3 6 5.0 6 −16.7 6 0.7

8.2.8 Calculate the viscometer constant for each cell (rotor/

2 −5.9 6 3.0 7 −17.8 6 0.5

stator combination) with the following equation:

3 −10.4 6 2.0 8 −18.7 6 0.3

4 −13.2 6 1.5 9 −19.4 6 0.3

h

o

5 −15.2 6 1.0 10 −20.0 6 0.3

C 5 (8)

Mt

where:

9.1.3 Install the rotors in the proper stators and install the

h 5 viscosity of the standard oil, mPa·s (cP) at −20°C,

o

upper pivots.

C 5 cell cons

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.