ASTM E2029-11(2019)

(Test Method)Standard Test Method for Volumetric and Mass Flow Rate Measurement in a Duct Using Tracer Gas Dilution

Standard Test Method for Volumetric and Mass Flow Rate Measurement in a Duct Using Tracer Gas Dilution

SIGNIFICANCE AND USE

5.1 The method presented here is a field method that may be used to determine mass and volume flow rates in ducts where flow conditions may be irregular and nonuniform. The gas flowing in the duct is considered to be an ideal gas. The method may be especially useful in those locations where conventional pitot tube or thermal anemometer velocity measurements are difficult or inappropriate due either to very low average flow velocity or the lack of a suitable run of duct upstream and downstream of the measurement location.

5.2 This test method can produce the volumetric flow rate at standard conditions without the need to determine gas stream composition, temperature, and water vapor content.

5.3 This test method is useful for determining mass or volumetric flow rates in HVAC ducts, fume hoods, vent stacks, and mine tunnels, as well as in performing model studies of pollution control devices.

5.4 This test method is based on first principles (conservation of mass) and does not require engineering assumptions.

5.5 This test method does not require the measurement of the area of the duct or stack.

5.6 The test method does not require flow straightening.

5.7 The test method is independent of flow conditions, such as angle, swirl, turbulence, reversals, and hence, does not require flow straightening.

5.8 The dry volumetric airflow can be determined by drying the air samples without measuring the water vapor concentration.

SCOPE

1.1 This test method describes the measurement of the volumetric and mass flow rate of a gas stream within a duct, stack, pipe, mine tunnel, or flue using a tracer gas dilution technique. For editorial convenience all references in the text will be to a duct, but it should be understood that this could refer equally well to a stack, pipe, mine tunnel, or flue. This test method is limited to those applications where the gas stream and the tracer gas can be treated as ideal gases at the conditions of the measurement. In this test method, the gas stream will be referred as air, though it could be any another gas that exhibits ideal gas law behavior.

1.2 This test method is not restricted to any particular tracer gas although experimental experience has shown that certain gases are used more readily than others as suitable tracer gases. It is preferable that the tracer gas not be a natural component of the gas stream.

1.3 Use of this test method requires a knowledge of the principles of gas analysis and instrumentation. Correct use of the formulas presented here requires consistent use of units.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and to determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 7.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2029 − 11 (Reapproved 2019)

Standard Test Method for

Volumetric and Mass Flow Rate Measurement in a Duct

Using Tracer Gas Dilution

This standard is issued under the fixed designation E2029; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standard:

1.1 This test method describes the measurement of the

E631Terminology of Building Constructions

volumetric and mass flow rate of a gas stream within a duct,

2.2 ANSI/ASME Standard:

stack, pipe, mine tunnel, or flue using a tracer gas dilution

ANSI/ASMETC19.1–1985(1994) Measurement Uncer-

technique. For editorial convenience all references in the text

tainty: Instrument Apparatus

will be to a duct, but it should be understood that this could

referequallywelltoastack,pipe,minetunnel,orflue.Thistest

3. Terminology

method is limited to those applications where the gas stream

3.1 Definitions:

andthetracergascanbetreatedasidealgasesattheconditions

3.1.1 For definitions of general terms related to building

of the measurement. In this test method, the gas stream will be

construction used in this test method, refer to Terminology

referred as air, though it could be any another gas that exhibits

E631.

ideal gas law behavior.

3.2 Definitions of Terms Specific to This Standard:

1.2 Thistestmethodisnotrestrictedtoanyparticulartracer 3.2.1 ideal gas, n—a gas or gas mixture for which the ratio

of the pressure divided by product of the density and tempera-

gas although experimental experience has shown that certain

ture is a constant.

gasesareusedmorereadilythanothersassuitabletracergases.

It is preferable that the tracer gas not be a natural component

3.2.2 mass flow, n—the total mass of air passing the sam-

of the gas stream.

pling point per unit time (kg/s, lb/min).

3.2.3 tracer gas, n—a gas that can be mixed with air and

1.3 Use of this test method requires a knowledge of the

measured in very low concentrations.

principles of gas analysis and instrumentation. Correct use of

3.2.4 tracer gas analyzer, n—a device that measures the

the formulas presented here requires consistent use of units.

concentration of tracer gas in an air sample.

1.4 This standard does not purport to address all of the

3.2.5 tracer gas mass concentration, n—the ratio of the

safety concerns, if any, associated with its use. It is the

mass of tracer gas in air to the total mass of the air-tracer

responsibility of the user of this standard to establish appro-

mixture. For an ideal gas, the mass concentration is indepen-

priate safety, health, and environmental practices and to

dent of temperature and pressure.

determine the applicability of regulatory limitations prior to

3.2.6 tracer gas molar concentration, n—the ratio of the

use. For specific precautionary statements, see Section 7.

number of moles of tracer gas in air to the total number of

1.5 This international standard was developed in accor-

moles of the air-tracer mixture.

dance with internationally recognized principles on standard-

3.2.7 tracer gas volume concentration, n—the ratio of the

ization established in the Decision on Principles for the

volume of tracer gas in air to the total volume of the air-tracer

Development of International Standards, Guides and Recom-

mixture. For an ideal gas, the volume concentration is inde-

mendations issued by the World Trade Organization Technical

pendent of temperature and pressure and is equal to the molar

Barriers to Trade (TBT) Committee.

concentration.

1 2

This test method is under the jurisdiction of ASTM Committee E06 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Performance of Buildings and is the direct responsibility of Subcommittee E06.41 contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

on Air Leakage and Ventilation Performance. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 15, 2019. Published April 2019. Originally the ASTM website.

approved in 1999. Last previous edition approved in 2011 as E2029–11. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/E2029–11R19. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2029 − 11 (2019)

3.2.8 volumetric flow, n—the total volume of air passing the mass or volumetric flow rate. Downstream of the injection

3 3

sampling point per unit time (m /s, ft /min). point gas samples are taken and are analyzed for the resulting

tracerconcentration.Theratiooftheinjectionflowrateandthe

3.3 Symbols:

downstream concentration represents the dilution volume per

unit time or volumetric flow rate in the duct.

C = mass concentration of tracer gas (ppb-mass, ppm-

5. Significance and Use

mass, ppt-mass)

C = upstream mass concentration of tracer gas (ppb-

U 5.1 Themethodpresentedhereisafieldmethodthatmaybe

mass, ppm-mass, ppt-mass)

used to determine mass and volume flow rates in ducts where

C = downstream mass concentration of tracer gas (ppb-

D

flow conditions may be irregular and nonuniform. The gas

mass, ppm-mass, ppt-mass)

flowingintheductisconsideredtobeanidealgas.Themethod

C = injection stream mass concentration of tracer gas

I

maybeespeciallyusefulinthoselocationswhereconventional

(ppb-mass, ppm-mass, ppt-mass)

pitot tube or thermal anemometer velocity measurements are

c = volume concentration of tracer gas (ppb, ppm, ppt)

difficult or inappropriate due either to very low average flow

c = upstream volume concentration of tracer gas (ppb,

U

velocity or the lack of a suitable run of duct upstream and

ppm, ppt)

downstream of the measurement location.

c = downstream volume concentration of tracer gas

D

5.2 Thistestmethodcanproducethevolumetricflowrateat

(ppb, ppm, ppt)

standard conditions without the need to determine gas stream

c = injection volume concentration of tracer gas (ppb,

I

composition, temperature, and water vapor content.

ppm, ppt)

F = mass flow rate (kg⁄s, g/min, lb/min)

5.3 This test method is useful for determining mass or

F = injection mass flow rate (kg⁄s, g/min, lb/min)

I

volumetricflowratesinHVACducts,fumehoods,ventstacks,

F = upstream mass flow rate (kg⁄s, g/min, lb/min)

U

and mine tunnels, as well as in performing model studies of

F = downstream mass flow rate (kg⁄s, g/min, lb/min)

D

5 3 pollution control devices.

f = volumetric flow rate (m /s, L/min, cfm)

std 5 3

f = volumetric flow rate at standard conditions (m /s, 5.4 This test method is based on first principles (conserva-

L/min, cfm)

tion of mass) and does not require engineering assumptions.

5 3

f = injection volumetric flow rate (m /s, L/min, cfm)

I

5.5 This test method does not require the measurement of

5 3

f = upstream volumetric flow rate (m /s, L/min, cfm)

U

5 3 the area of the duct or stack.

f = downstreamvolumetricflowrate (m /s,L/min,cfm)

D

std 5

f = injection volumetric flow rate at standard conditions 5.6 The test method does not require flow straightening.

I

(m /s, L/min, cfm)

5.7 The test method is independent of flow conditions, such

std 5

f = upstreamvolumetricflowrate atstandardconditions

U

as angle, swirl, turbulence, reversals, and hence, does not

(m /s, L/min, cfm)

require flow straightening.

std 5

f = downstream volumetric flow rate at standard condi-

D

5.8 Thedryvolumetricairflowcanbedeterminedbydrying

tions (m /s, L/min, cfm)

6 3 3

the air samples without measuring the water vapor concentra-

ρ = density (kg⁄m , g/L, lb/ft )

6 3

tion.

ρ = density ofgasstreamwithoutanytracer(kg/m ,g/L,

a

lb/ft )

6 3 3

6. Apparatus

ρ = density of the tracer gas (kg/m , g/L, lb/ft )

t

6 3

ρ = density of the injection gas mixture (kg/m , g/L,

I

6.1 Theapparatusincludesasourceoftracergas,meansfor

lb/ft )

distributing the tracer gas in the duct, means for obtaining air

6 3

ρ = density of the upstream gas mixture (kg/m , g/L,

U

samplesfromtheduct,andagasanalyzertomeasuretracergas

lb/ft )

concentrations in the air samples.

6 3

ρ = density of the downstream gas mixture (kg/m , g/L,

D

6.2 TracerGas—SeeAppendixX1forinformationontracer

lb/ft )

t 6

gases and equipment used to measure their concentrations.

ρ = density of the tracer gas at upstream conditions

U

3 3

AppendixX1alsocontainstracergastargetconcentrationsand

(kg/m , g/L, lb/ft )

t 6

safety information.

ρ = density of the tracer gas at downstream conditions

D

3 3

(kg/m , g/L, lb/ft )

6.3 Tracer Gas Injection Source—This normally is a cylin-

der of compressed tracer gas either pure or diluted in a carrier

4. Summary of Test Method

such as air or nitrogen. Tracer release from the cylinder is

4.1 This test method describes the use of a tracer gas

controlled by a critical orifice or nozzle, a metering valve, an

dilution technique to infer the volumetric flow rate through a

electronicmassflowmeterormassflowcontroller,orothergas

duct. In practice, tracer gas is injected into a duct at a known

flow rate measurement and control device. A rotameter is not

recommended for this measurement unless of special design,

calibration, and a corresponding decrease in measurement

Equationsinthistestmethodassumethatallmassorvolumeconcentrationsare

in the same units. accuracy is acceptable.

Equations in this test method assume that all mass or volume flow rates are in

6.4 Tracer Gas Distribution—A single tube or a tubing

the same units.

Equations in this test method assume that all densities are in the same units. network is inserted into the duct to dispense tracer gas. The

E2029 − 11 (2019)

tubeortubesmayhaveeitherasingleormultiplereleasepoints 7.2 Health Limitations—Use current OSHAinformation on

for tracer gas. For large cross-section ducts a network that the permissible exposure limit (PEL), or theACGIH threshold

distributes tracer gas over a wide area will facilitate measure-

limit value (TLV) if the particular tracer is not listed with a

ment.

PEL,todeterminethesafeconcentrationforthegaschosenfor

the test. Never exceed the maximum safe concentration. It is

6.5 Tracer Sampling—This is performed using tubing in-

goodpracticetouseaconcentrationthatisatmostonetenthof

sertedintotheductdownstreamoftheinjectionpoint.Asingle

the maximum safe concentration.Avoid using tracer gases for

tubeisinsertedintotheduct.Airsamplesareremovedfromthe

which no PEL or TLV exists.

ductbymeansofasamplingpumptodistributetracerladenair

to the analyzer either directly or by means of syringe samples.

7.3 Compressed Gas Equipment—Observe the supplier’s

6.6 Gas Analyzer—This device must be suited for the tracer

safety information and CGAinformation on the transportation,

gas used and the concentrations expected in the duct being

use, and storage of compressed gas cylinders, regulators, and

measured. It should be calibrated properly and exhibit a

related equipment.

accuracy of better than 63% at concentrations employed in

the measurement.

8. Procedure for Measuring Mass and Volumetric

Flowrate

7. Hazards

8.1 Inject tracer of known concentration, C(c), and at a

I I

7.1 Safety is the responsibility of the user of this test

known rate, F(f), into a flowing duct using procedures

I I

method. Tracer gases have safe maximum concentration limits

provided in Section 9.

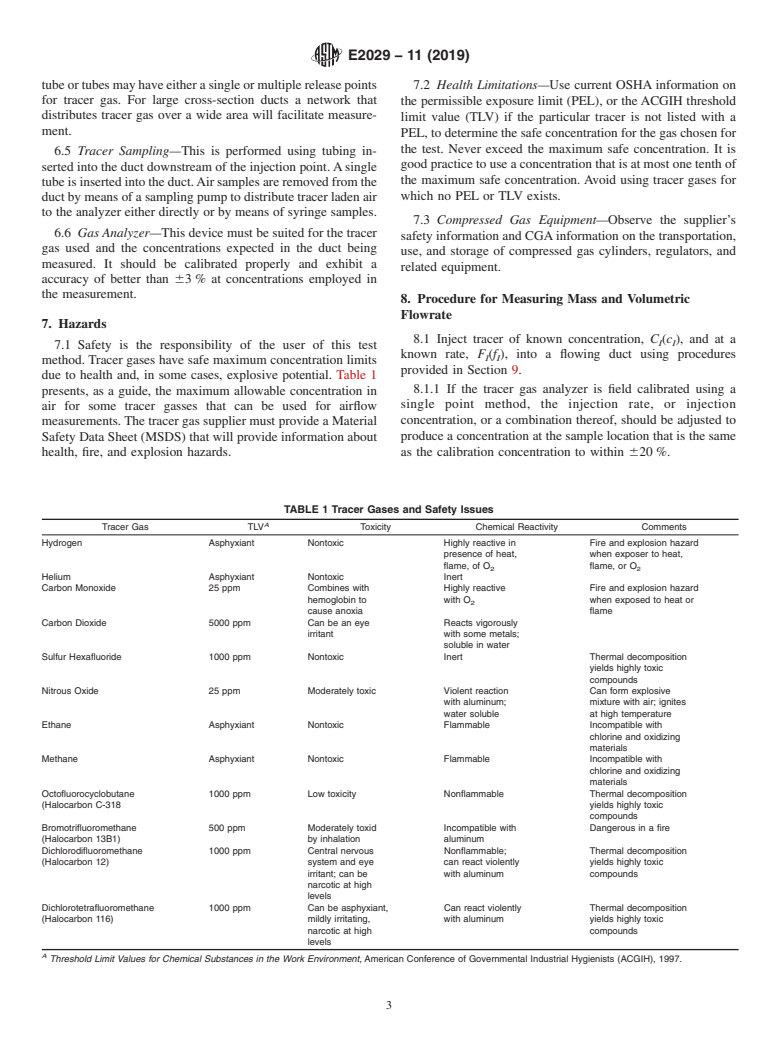

due to health and, in some cases, explosive potential. Table 1

8.1.1 If the tracer gas analyzer is field calibrated using a

presents, as a guide, the maximum allowable concentration in

single point method, the injection rate, or injection

air for some tracer gasses that can be used for airflow

concentration, or a combination thereof, should be adjusted to

measurements.ThetracergassuppliermustprovideaMaterial

Safety Data Sheet (MSDS) that will provide information about produce a concentration at the sample location that is the same

health, fire, and explosion hazards. as the calibration concentration to within 620%.

TABLE 1 Tracer Gases and Safety Issues

A

Tracer Gas TLV Toxicity Chemical Reactivity Comments

Hydrogen Asphyxiant Nontoxic Highly reactive in Fire and explosion hazard

presence of heat, when exposer to heat,

flame, of O flame, or O

2 2

Helium Asphyxiant Nontoxic Inert

Carbon Monoxide 25 ppm Combines with Highly reactive Fire and explosion hazard

hemoglobin to with O when exposed to heat or

cause anoxia flame

Carbon Dioxide 5000 ppm Can be an eye Reacts vigorously

irritant with some metals;

soluble in water

Sulfur Hexafluoride 1000 ppm Nontoxic Inert Thermal decomposition

yields highly toxic

compounds

Nitrous Oxide 25 ppm Moderately toxic Violent reaction Can form explosive

with aluminum; mixture with air; ignites

water soluble at high temperature

Ethane Asphyxiant Nontoxic Flammable Incompatible with

chlorine and oxidizing

materials

Methane Asphyxiant Nontoxic Flammable Incompatible with

chlorine and oxidizing

materials

Octofluorocyclobutane 1000 ppm Low toxicity Nonflammable Thermal decomposition

(Halocarbon C-318 yields highly toxic

compounds

Bromotrifluoromethane 500 ppm Moderately toxid Incompatible with Dangerous in a fire

(Halocarbon 13B1) by inhalation aluminum

Dichlorodifluoromethane 1000 ppm Central nervous Nonflammable; Thermal decomposition

(Halocarbon 12) system and eye can react violently yields highly toxic

irritant; can be with aluminum compounds

narcotic at high

levels

Dichlorotetrafluoromethane 1000 ppm Can be asphyxiant, Can react violently Thermal decomposition

(Halocarbon 116) mildly irritating, with aluminum yields highly toxic

narcotic at high compounds

levels

A

Threshold Limit Values for Chemical Substances in the Work Environment, American Conference of Governmental Industrial Hygienists (ACGIH), 1997.

E2029 − 11 (2019)

TABLE 2 Minimum Number of Down Stream Sample Locations ρ

n

where r [ is the ratio of the density of the main

na

2 2

ρ

Duct Cross Sectional Area m (ft ) Number of Areas Number of Samples a

constituentoftheinjectiongasmixturetothedensityofthegas

Less then 0.2 (2) 4 5

stream without any tracer. If c = 1, than r =1.

0.2 to 2.3 (2 to 25) 12 13

I na

Greater than 2.3 (25) 20 21

8.6 The volumetric flow rate in the duct at standard condi-

tions is given by:

c 2 r c 2 ~1 2 r !c c

I na D na I D

std std

f 5 ·f volumeconcentrations (7)

~ !

8.1.2 If the tracer gas analyzer is field calibrated using two U I

c 2 c

~ !

D U

calibrationpoints,theinjection

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.