ASTM D3999-91(2003)

(Test Method)Standard Test Methods for the Determination of the Modulus and Damping Properties of Soils Using the Cyclic Triaxial Apparatus

Standard Test Methods for the Determination of the Modulus and Damping Properties of Soils Using the Cyclic Triaxial Apparatus

SIGNIFICANCE AND USE

The cyclic triaxial modulus and damping test provides parameters that may be considered for use in dynamic, linear and non-linear analytical methods. These test methods are used for the performance evaluation of both natural and engineered structures under dynamic of cyclic loads such as caused by earthquakes, ocean wave, or blast.

One of the primary purposes of these test methods is to obtain data that are used to calculate Young’modulus.

Note 1—The quality of the result produced by this standard is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D 3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this standard are cautioned that compliance with Practice D 3740 does not in itself assure reliable results. Reliable results depend on many factors; Practice D 3740 provides a means of evaluating some of those factors.

SCOPE

1.1 These test methods cover the determination of the modulus and damping properties of soils in either undisturbed or reconstituted states by either load or stroke controlled cyclic triaxial techniques.

1.2 The cyclic triaxial properties of soil are evaluated relative to a number of factors including: strain level, density, number of cycles, material type, saturation, and effective stress.

1.3 These test methods are applicable to both fine-grained and coarse-grained soils as defined by the unified soil classification system or by Classification D 2487. Test specimens may be undisturbed or reconstituted by compaction in the laboratory.

1.4 Two test methods are provided for using a cyclic loader to determine Young's modulus (E) and damping (D) properties. The first test method (A) permits the determination of E and D using a constant load apparatus. The second test method (B) permits the determination of E and D using a constant stroke apparatus. The test methods are as follows:

1.4.1 Test Method AThis test method requires the application of a constant cyclic load to the test specimen. It is used for determining the Young's modulus and damping under a constant load condition.

1.4.2 Test Method BThis test method requires the application of a constant cyclic deformation to the test specimen. It is used for determining the Young's modulus and damping under a constant stroke condition.

1.5 The development of relationships to aid in interpreting and evaluating test results are left to the engineer or office requesting the test.

1.6 LimitationsThere are certain limitations inherent in using cyclic triaxial tests to simulate the stress and strain conditions of a soil element in the field during an earthquake.

1.6.1 Nonuniform stress conditions within the test specimen are imposed by the specimen end platens.

1.6.2 A 90 change in the direction of the major principal stress occurs during the two halves of the loading cycle on isotropically confined specimens and at certain levels of cyclic stress application on anisotropically confined specimens.

1.6.3 The maximum cyclic axial stress that can be applied to a saturated specimen is controlled by the stress conditions at the end of confining stress application and the pore-water pressures generated during testing. For an isotropically confined specimen tested in cyclic compression, the maximum cyclic axial stress that can be applied to the specimen is equal to the effective confining pressure. Since cohesionless soils are not capable of taking tension, cyclic axial stresses greater than this value tend to lift the top platen from the soil specimen. Also, as the pore-water pressure increases during tests performed on isotropically confined specimens, the effective confining pressure is reduced, contributing to the tendency of the specimen to neck during the extension portion of the load cycle, invalidating test results beyond that point.

1.6.4 While it is ...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3999 – 91 (Reapproved 2003)

Standard Test Methods for

the Determination of the Modulus and Damping Properties

of Soils Using the Cyclic Triaxial Apparatus

This standard is issued under the fixed designation D3999; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6.1 Nonuniformstressconditionswithinthetestspecimen

are imposed by the specimen end platens.

1.1 These test methods cover the determination of the

1.6.2 A90° change in the direction of the major principal

modulus and damping properties of soils in either undisturbed

stress occurs during the two halves of the loading cycle on

orreconstitutedstatesbyeitherloadorstrokecontrolledcyclic

isotropically confined specimens and at certain levels of cyclic

triaxial techniques.

stress application on anisotropically confined specimens.

1.2 The cyclic triaxial properties of soil are evaluated

1.6.3 Themaximumcyclicaxialstressthatcanbeappliedto

relative to a number of factors including: strain level, density,

a saturated specimen is controlled by the stress conditions at

numberofcycles,materialtype,saturation,andeffectivestress.

the end of confining stress application and the pore-water

1.3 These test methods are applicable to both fine-grained

pressures generated during testing. For an isotropically con-

and coarse-grained soils as defined by the unified soil classi-

fined specimen tested in cyclic compression, the maximum

fication system or by Classification D2487. Test specimens

cyclic axial stress that can be applied to the specimen is equal

may be undisturbed or reconstituted by compaction in the

to the effective confining pressure. Since cohesionless soils are

laboratory.

not capable of taking tension, cyclic axial stresses greater than

1.4 Two test methods are provided for using a cyclic loader

this value tend to lift the top platen from the soil specimen.

todetermineYoung’smodulus(E)anddamping(D)properties.

Also, as the pore-water pressure increases during tests per-

The first test method (A) permits the determination of E and D

formed on isotropically confined specimens, the effective

using a constant load apparatus. The second test method (B)

confining pressure is reduced, contributing to the tendency of

permits the determination of E and D using a constant stroke

the specimen to neck during the extension portion of the load

apparatus. The test methods are as follows:

cycle, invalidating test results beyond that point.

1.4.1 Test Method A—This test method requires the appli-

1.6.4 While it is advised that the best possible undisturbed

cation of a constant cyclic load to the test specimen. It is used

specimens be obtained for cyclic testing, it is sometimes

for determining the Young’s modulus and damping under a

necessarytoreconstitutesoilspecimens.Ithasbeenshownthat

constant load condition.

different methods of reconstituting specimens to the same

1.4.2 Test Method B—This test method requires the appli-

density may result in significantly different cyclic behavior.

cation of a constant cyclic deformation to the test specimen. It

Also, undisturbed specimens will almost always be stronger

is used for determining the Young’s modulus and damping

than reconstituted specimens of the same density.

under a constant stroke condition.

1.6.5 Theinteractionbetweenthespecimen,membrane,and

1.5 The development of relationships to aid in interpreting

confining fluid has an influence on cyclic behavior. Membrane

and evaluating test results are left to the engineer or office

compliance effects cannot be readily accounted for in the test

requesting the test.

procedure or in interpretation of test results. Changes in

1.6 Limitations—There are certain limitations inherent in

pore-water pressure can cause changes in membrane penetra-

using cyclic triaxial tests to simulate the stress and strain

tion in specimens of cohesionless soils. These changes can

conditions of a soil element in the field during an earthquake.

significantly influence the test results.

1.6.6 Despite these limitations, with due consideration for

ThesetestmethodsareunderthejurisdictionofASTMCommitteeD18onSoil

the factors affecting test results, carefully conducted cyclic

and Rock and are the direct responsibility of Subcommittee D18.09 on Dynamic

triaxial tests can provide data on the cyclic behavior of soils

Properties of Soils.

Current edition approved August 15, 1991. Published October 1991. DOI:

10.1520/D3999-91R03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3999 – 91 (2003)

with a degree of accuracy adequate for meaningful evaluations 3.2.2 cycle duration—the time interval between successive

of modulus and damping below a shearing strain level of applications of a deviator stress.

−2

0.5%. 3.2.3 deviator stress [FL ]—the difference between the

1.7 The values stated in either SI or inch-pound units shall major and minor principal stresses in a triaxial test.

be regarded separately as standard. The values in each system 3.2.4 effective confining stress—the confining pressure (the

may not be exact equivalents, therefore, each system must be difference between the cell pressure and the pore-water pres-

used independently of the other, without combining values in sure) prior to shearing the specimen.

any way. 3.2.5 effective force, (F)—the force transmitted through a

1.8 This standard does not purport to address all of the soil or rock mass by intergranular pressures.

safety concerns, if any, associated with its use. It is the 3.2.6 hysteresis loop—a trace of load versus deformation

responsibility of the user of this standard to establish appro- resulting from the application of one complete cycle of either

priate safety and health practices and determine the applica- acyclicloadordeformation.Theareawithintheresultingloop

bility of regulatory limitations prior to use. is due to energy dissipated by the specimen and apparatus, see

Fig. 1.

2. Referenced Documents

3.2.7 load duration—the time interval the specimen is

subjected to a cyclic deviator stress.

2.1 ASTM Standards:

3.2.8 principal stress—the stress normal to one of three

D422 Test Method for Particle-Size Analysis of Soils

mutually perpendicular planes on which the shear stresses at a

D653 Terminology Relating to Soil, Rock, and Contained

point in a body are zero.

Fluids

−2

3.2.9 Young’s modulus (modulus of elasticity) [FL ]—the

D854 Test Methods for Specific Gravity of Soil Solids by

ratio of stress to strain for a material under given loading

Water Pycnometer

conditions; numerically equal to the slope of the tangent or the

D1587 PracticeforThin-WalledTubeSamplingofSoilsfor

secant of a stress-strain curve (same as Terminology D653).

Geotechnical Purposes

D2216 Test Methods for Laboratory Determination of Wa-

4. Summary of Test Method

ter (Moisture) Content of Soil and Rock by Mass

4.1 The cyclic triaxial test consists of imposing either a

D2435 Test Methods for One-Dimensional Consolidation

Properties of Soils Using Incremental Loading cyclicaxialdeviatorstressoffixedmagnitude(loadcontrol)or

cyclic axial deformation (stroke control) on a cylindrical soil

D2487 Practice for Classification of Soils for Engineering

Purposes (Unified Soil Classification System) specimen enclosed in a triaxial pressure cell. The resulting

D2488 Practice for Description and Identification of Soils axial strain and axial stress are measured and used to calculate

(Visual-Manual Procedure) either stress-dependent or stroke-dependent modulus and

D3740 Practice for Minimum Requirements for Agencies damping.

Engaged in Testing and/or Inspection of Soil and Rock as

Used in Engineering Design and Construction 5. Significance and Use

D4220 Practices for Preserving and Transporting Soil

5.1 The cyclic triaxial modulus and damping test provides

Samples

parameters that may be considered for use in dynamic, linear

D4318 Test Methods for Liquid Limit, Plastic Limit, and

andnon-linearanalyticalmethods.Thesetestmethodsareused

Plasticity Index of Soils

for the performance evaluation of both natural and engineered

D4767 Test Method for Consolidated Undrained Triaxial

structures under dynamic of cyclic loads such as caused by

Compression Test for Cohesive Soils

earthquakes, ocean wave, or blast.

2.2 USBR Standard:

USBR 5210 Practice for Preparing Compacted Soil Speci-

mens for Laboratory Use

3. Terminology

3.1 Definitions:

3.1.1 The definitions of terms used in these test methods

shall be in accordance with Terminology D653.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 back pressure—a pressure applied to the specimen

pore-water to cause air in the pore space to pass into solution

in the pore-water, that is, to saturate the specimen.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. FIG. 1 Schematic of Typical Hysteresis Loop Generated by Cyclic

Available from U.S. Department of the Interior, Bureau of Reclamation. Triaxial Apparatus

D3999 – 91 (2003)

5.2 One of the primary purposes of these test methods is to

obtain data that are used to calculate Young’s modulus.

NOTE 1—The quality of the result produced by this standard is

dependent on the competence of the personnel performing it, and the

suitability of the equipment and facilities used. Agencies that meet the

criteria of Practice D3740 are generally considered capable of competent

and objective testing/sampling/inspection/etc. Users of this standard are

cautioned that compliance with Practice D3740 does not in itself assure

reliable results. Reliable results depend on many factors; Practice D3740

provides a means of evaluating some of those factors.

6. Apparatus

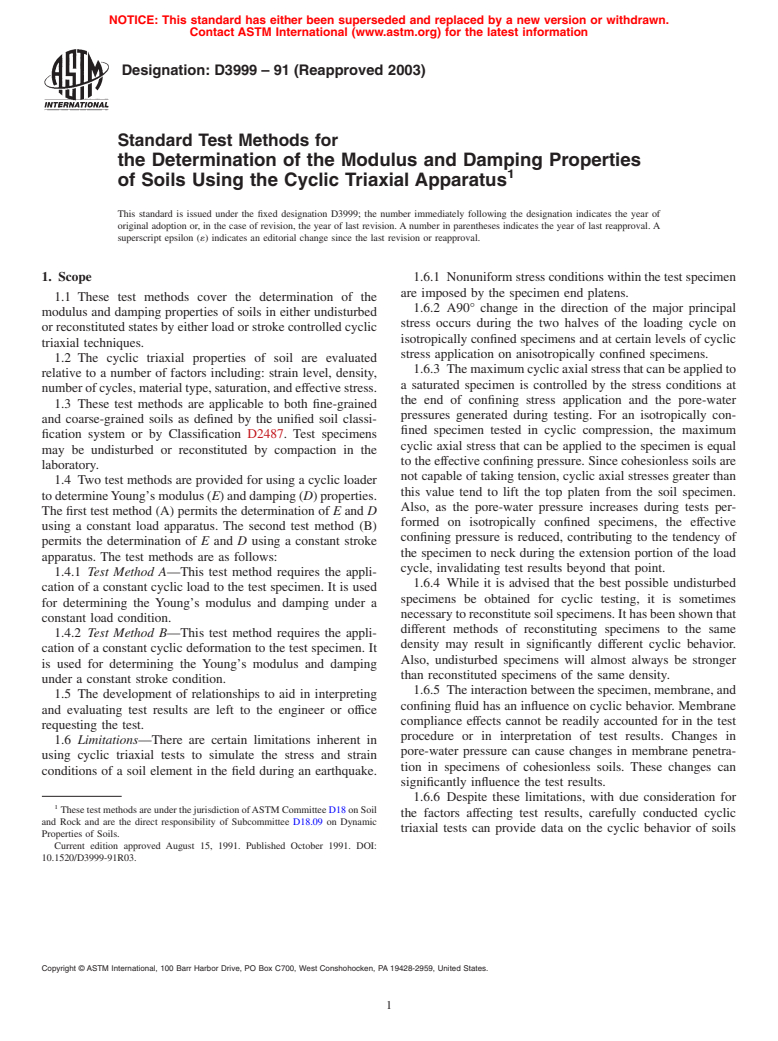

6.1 General—Inmanyways,triaxialequipmentsuitablefor

cyclic triaxial modulus and damping tests is similar to equip-

ment used for the consolidated-undrained triaxial compression

test (see Test Method D4767). However, there are special

featuresdescribedinthefollowingsectionsthatarerequiredto

perform acceptable cyclic triaxial tests.Aschematic represen-

tation of the various components comprising a typical triaxial

modulus and damping test setup is shown in Fig. 2.

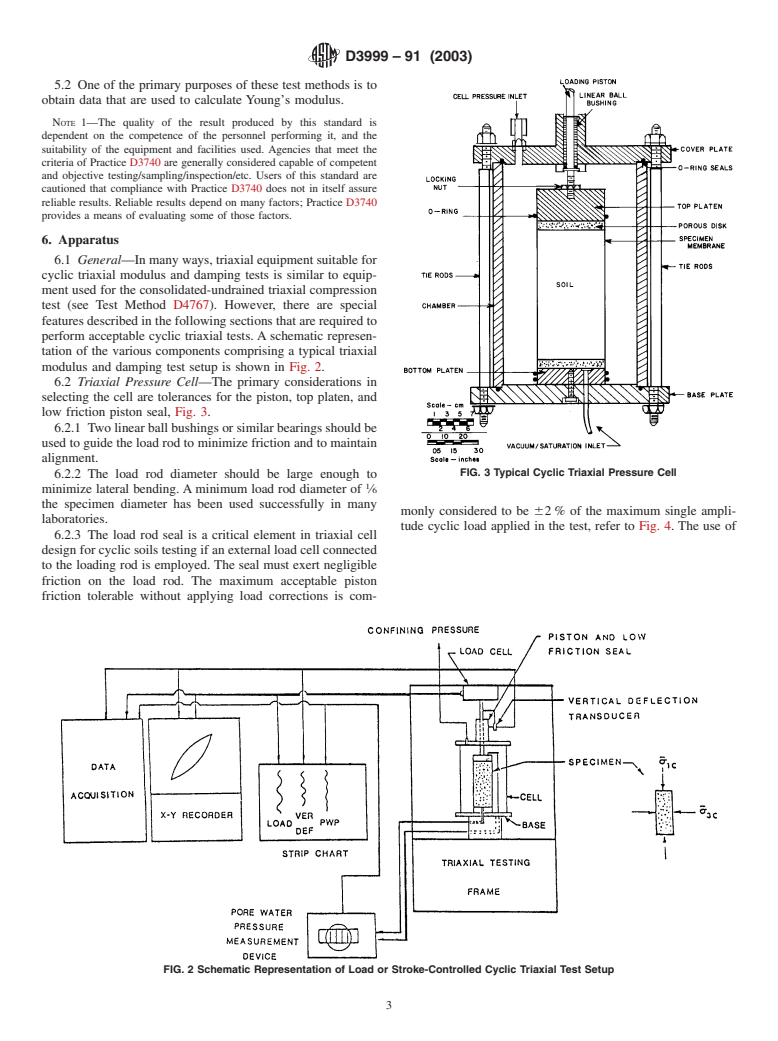

6.2 Triaxial Pressure Cell—The primary considerations in

selecting the cell are tolerances for the piston, top platen, and

low friction piston seal, Fig. 3.

6.2.1 Twolinearballbushingsorsimilarbearingsshouldbe

used to guide the load rod to minimize friction and to maintain

alignment.

FIG. 3 Typical Cyclic Triaxial Pressure Cell

6.2.2 The load rod diameter should be large enough to

minimize lateral bending.Aminimum load rod diameter of ⁄6

the specimen diameter has been used successfully in many

monly considered to be 62% of the maximum single ampli-

laboratories.

tude cyclic load applied in the test, refer to Fig. 4. The use of

6.2.3 The load rod seal is a critical element in triaxial cell

designforcyclicsoilstestingifanexternalloadcellconnected

to the loading rod is employed. The seal must exert negligible

friction on the load rod. The maximum acceptable piston

friction tolerable without applying load corrections is com-

FIG. 2 Schematic Representation of Load or Stroke-Controlled Cyclic Triaxial Test Setup

D3999 – 91 (2003)

1 1

NOTE 1—Frequency= ⁄PERIOD = ⁄T .

FIG. 4 Definitions Related to Cyclic Loading

a seal described in 9.1 and described by Ladd and Dutko , and

Chan will meet these requirements.

6.2.4 Top and bottom platen alignment is critical to avoid

increasing a nonuniform state of stress in the specimen.

Internal tie-rod triaxial cells have worked well at a number of

laboratories. These cells allow the placement of the cell wall

after the specimen is in place between the loading platens.

Acceptable limits on platen eccentricity and parallelism are

FIG. 5 Limits on Acceptable Platen and Load Rod Alignment: (a)

shown in Fig. 5.

eccentricity, (b) parallelism, (c) eccentricity between Top Platen

6.2.5 Since axial loading in cyclic triaxial tests is in exten-

and Sample

sion as well as in compression, the load rod shall be rigidly

connected to the top platen by a method such as one of those

shown in Fig. 6.

specimen as it deforms. The type of apparatus typically

6.2.6 Thereshallbeprovisionforspecimendrainageatboth

employed can range from a simple cam to a closed loop

the top and bottom platens.

electro-hydraulic system.

6.3 Cyclic Loading Equipment:

6.4 Recording Equipment:

6.3.1 Cyclic loading equipment used for load controlled

6.4.1 Load,displacement,andporewaterpressuretransduc-

cyclic triaxial tests must be capable of applying a uniform

ers are required to monitor specimen behavior during cyclic

sinusoidal load at a frequency within the range of 0.1 to 2 Hz.

loading;provisionsformonitoringthechamberpressureduring

The loading device must be able to maintain uniform cyclic

cyclic loading are optional.

loadings to at least 0.5% double amplitude stress, refer to Fig.

6.4.2 Load Measurement—Generally, the load cell capacity

4. Unsymmetrical compression-extension load peaks, nonuni-

should be no greater than five times the total maximum load

formity of pulse duration, “ringing”, or load fall-off at large

applied to the test specimen to ensure that the necessary

strains must not exceed tolerances illustrated in Fig. 7. The

measurementaccuracyisachieved.Theminimumperformance

equipment must also be able to apply the cyclic load about an

characteristics of the load cell are presented in Table 1.

initial static load on the loading rod.

6.4.3 Axial Deformation Measurement—Displacement

6.3.2 Cyclic loading equipment used for deformation-

measuring devices such as linear variable differential trans-

controlled cyclic triaxial tests must be capable of applying a

former (LVDT), Potentiometer-type deformation transducers,

uniform sinusoidal deformation at a frequency range of 0.1 to

andeddycurrentsensorsmaybeusediftheymeettherequired

2 Hz. The equipment must also be able to apply the cyclic

performance criteria (see Table 1). Accurate deformation

deformation about either an initial datum point or follow the

measurements require that the transducer be properly mounted

to avoid excessive mechanical system compression between

the load frame, the triaxial cell, the load cell, and the loading

Ladd, R. S., and Dutko, P., “Small Strain Measurements Using Triaxial

Apparatu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.