ASTM C1513-01

(Specification)Standard Specification for Steel Tapping Screws for Cold-Formed Steel Framing Connections

Standard Specification for Steel Tapping Screws for Cold-Formed Steel Framing Connections

SCOPE

1.1 This specification covers steel self-drilling and self-piercing tapping screws for the connection of cold-formed steel members manufactured in accordance with Specifications C 645 and C 955. This specification also covers test methods for determining performance requirements and physical properties.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI equivalents of the inch-pound units are approximate.

1.3 The following safety hazards caveat pertains only to the test methods described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 1513 – 01

Standard Specification for

Steel Tapping Screws for Cold-Formed Steel Framing

Connections

This standard is issued under the fixed designation C 1513; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Threaded Fasteners (Unified Inch Screw Threads (UN/

UNR))

1.1 This specification covers steel self-drilling and self-

2.2 ANSI/ASME Documents:

piercing tapping screws for the connection of cold-formed steel

B18.18.1M Inspection and Quality Assurance for General

members manufactured in accordance with Specifications

Purpose Fasteners

C 645 and C 955. This specification also covers test methods

B18.6.4 Standard Specification for Thread Forming and

for determining performance requirements and physical prop-

Thread-Cutting Screws

erties.

2.3 SAE Standards:

1.2 The values stated in inch-pound units are to be regarded

SAE J78-1998 Steel Self-Drilling Tapping Screws

as the standard. The SI equivalents of the inch-pound units are

SAE J933 Mechanical and Quality Requirements for Tap-

approximate.

ping Screws

1.3 The following safety hazards caveat pertains only to the

test methods described in this specification. This standard does

3. Terminology

not purport to address all of the safety concerns, if any,

3.1 Definitions—For definitions relating to gypsum and

associated with its use. It is the responsibility of the user of this

related building materials and systems, use Terminology C 11.

standard to establish appropriate safety and health practices

3.2 Definitions of Terms Specific to This Standard:

and determine the applicability of regulatory requirements

3.2.1 bearing surface (of the screw), n—the supporting or

prior to use.

locating surface of a fastener with respect to the part which it

2. Referenced Documents fastens (mates). The loading of the fastener is usually through

the bearing surface, (that is, the bearing surface of the hex

2.1 ASTM Standards:

washer head style is under the head, the part that touches the

A 370 Test Methods and Definitions for Mechanical Testing

2 top material being fastened).

of Steel Products

3.2.2 case depth (of the screw), n—the thickness of the

A 510 Specification for General Requirements for Wire

2 hardened surface of the screw.

Rods and Coarse Round Wire, Carbon Steel

3.2.3 countersunk head style (for a screw), n—all screw

B 117 Practice for Operating Salt Spray (Fog) Apparatus

head designs that sink into the top material being fastened and

C 11 Terminology Relating to Gypsum and Related Build-

that have the bearing surface (see 3.2.1), at the top of the head

ing Materials and Systems

(that is, flat and bugle).

C 645 Specification for Nonstructural Steel Framing Mem-

3.2.4 crest (of the screw thread), n—the highest point of the

bers

screw thread.

C 955 Specification for Load-Bearing (Transverse and

3.2.5 drill capacity (of the self-drilling screw), n—the total

Axial) Steel Studs, Runners (Tracks) and Bracing or

thickness of material the fastener is designed to drill through,

Bridging for Screw Application of Gypsum Panel Products

including any space between the layers.

and Metal Plaster Bases

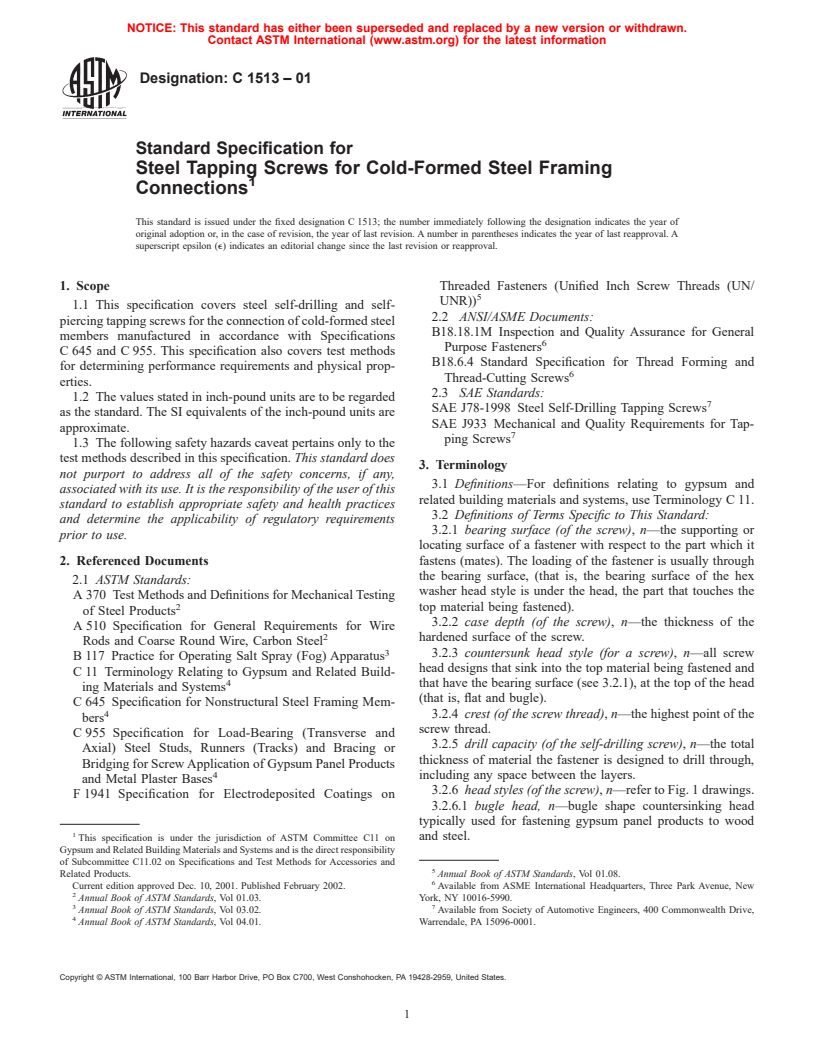

3.2.6 head styles (of the screw), n—refer to Fig. 1 drawings.

F 1941 Specification for Electrodeposited Coatings on

3.2.6.1 bugle head, n—bugle shape countersinking head

typically used for fastening gypsum panel products to wood

This specification is under the jurisdiction of ASTM Committee C11 on and steel.

Gypsum and Related Building Materials and Systems and is the direct responsibility

of Subcommittee C11.02 on Specifications and Test Methods for Accessories and

Related Products. Annual Book of ASTM Standards, Vol 01.08.

Current edition approved Dec. 10, 2001. Published February 2002. Available from ASME International Headquarters, Three Park Avenue, New

Annual Book of ASTM Standards, Vol 01.03. York, NY 10016-5990.

3 7

Annual Book of ASTM Standards, Vol 03.02. Available from Society of Automotive Engineers, 400 Commonwealth Drive,

Annual Book of ASTM Standards, Vol 04.01. Warrendale, PA 15096-0001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 1513

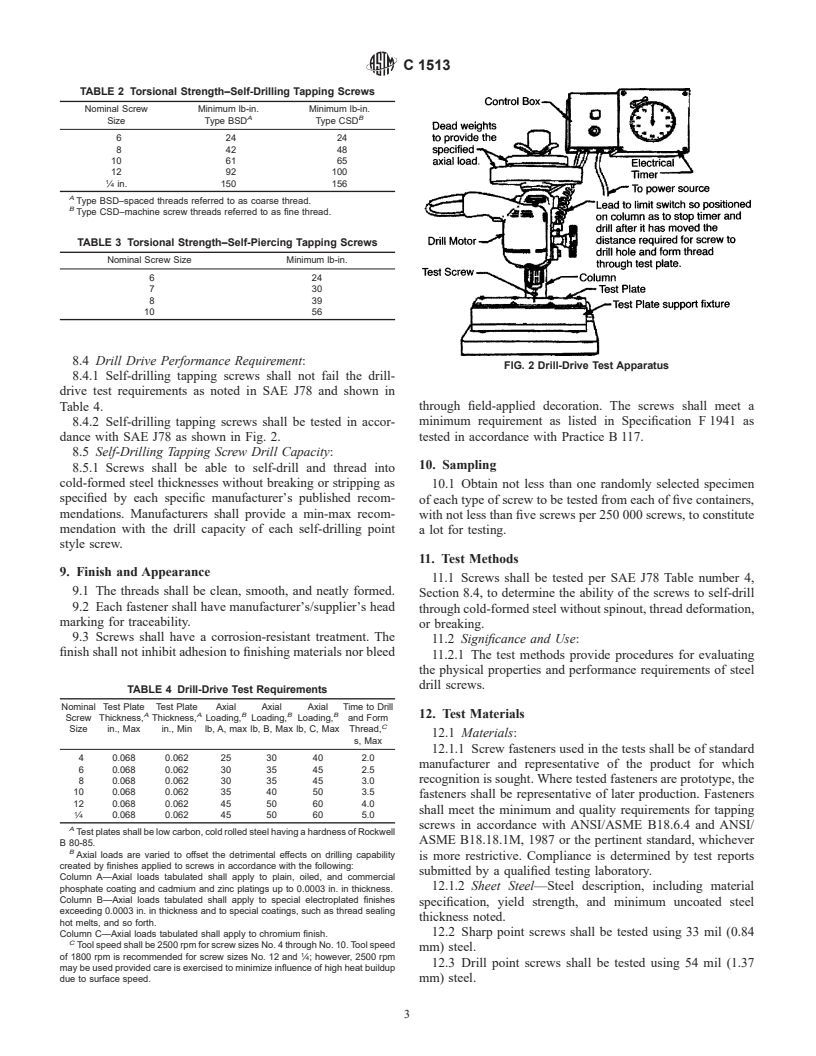

6.1.1 Self-drilling tapping screws shall be in accordance

with SAE J78.

6.1.2 Self-piercing tapping screws shall be in accordance

with head dimensions as shown in ANSI/ASME B18.6.4.

6.2 Total Case Depth—Screws shall have a total case depth

conforming to the tabulation in Table 1.

6.2.1 Case depth shall be measured at the mid-point be-

tween crest and root on the thread shank.

FIG. 1 Head Styles

7. Packaging and Head Marking

7.1 Screws shall be marked with manufacturer’s/supplier’s

3.2.6.2 hex washer face, n—see hex washer head.

head marking for traceability.

3.2.6.3 hex washer head, n—has an indented top surface

7.2 Screws shall be packaged in substantial commercial

and six flat sides formed integrally with a flat washer which

shipping containers, constructed so as to preserve the contents

projects beyond the sides and provides a flat bearing surface.

in good condition and to ensure acceptance and safe delivery

3.2.6.4 lath head, n—see modified truss.

by common or other carriers.

3.2.6.5 modified truss, n—low profile round washer head.

7.2.1 Individual packages shall be so constructed that the

3.2.6.6 pan framing head, n—flat top surface rounding into

contents shall be able to be partially removed without destroy-

cylindrical sides and a flat bearing surface.

ing the container’s ability to serve as a receptacle for the

3.2.6.7 pan head, n—a slightly rounded top surface round-

remainder of the contents.

ing into cylindrical sides and a flat bearing surface.

7.2.2 Individual packages and shipping containers shall be

3.2.6.8 pancake head, n—lower profile head style than the

marked with the type, size, use, and quantity of the screws

hex washer and pan head with a larger flat bearing surface.

contained therein, the name brand headmarking example and

3.2.6.9 wafer head, n—a countersinking head style with a

trademark of the producer or supplier, the ASTM designation,

large lip at the top of the countersinking contour that will

and any or all appropriate evaluation reports . Boxes shall be

“flush” with the substrate creating a greater bearing surface,

marked with the drill capacity of the self-drilling tapping

therefore a greater pull-over/pull-through value.

screws.

3.2.7 point style, n—of the self-drilling tapping screw is

designated by a number (that is, 1, 2, 3, 4, or 5). The higher the

8. Performance Requirements

number, the higher the drill capacity (see 3.2.5) of the screw.

3.2.8 root (of the screw thread), n—the lowest point of the 8.1 Hardness:

8.1.1 The self-drilling tapping screws shall have a surface

screw thread.

3.2.9 self-drilling tapping screw, n—externally threaded hardness of not less than Rockwell C 50 and core hardness of

not less than Rockwell C 32 as tested in accordance with SAE

fasteners with the ability to drill their own hole and form or cut

their own internal mating threads without breaking. J78.

8.1.2 The self-piercing screws shall have a surface hardness

3.2.10 self-piercing tapping screw, n—externally threaded

fasteners with the ability to pierce metallic material 33 mils of not less than Rockwell C 45 and core hardness of not less

than Rockwell C 28 as tested in accordance with SAE J933.

(0.84 mm), or less, form a sleeve by extruding metallic

material and “tap” their own mating threads when driven. 8.2 Ductility:

8.2.1 The self-drilling tapping screws shall have sufficient

Self-piercing screws have a sharp point with the point angle not

more than 30 degrees. ductility to be able to withstand a 5° bend without visible signs

of fracture as tested in accordance with SAE J78.

3.2.11 spin-out (for a screw), n—for a screw, the continued

rotation of a screw without further penetration into the sub- 8.2.2 The self-piercing tapping screws shall have sufficient

ductility to be able to withstand a 10° bend without visible

strate.

3.2.12 tapping screw, n—externally threaded fasteners with signs of fracture as tested in accordance with SAE J933.

8.3 Torsional Strength:

the ability to “tap” their own internal mating threads when

8.3.1 Self-drilling tapping screws shall not fail the applica-

installed.

tion of torque less than or equal to the torsional strength

specified in Table 2, when tested in accordance with SAE J78.

4.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.