ASTM C1583/C1583M-20

(Test Method)Standard Test Method for Tensile Strength of Concrete Surfaces and the Bond Strength or Tensile Strength of Concrete Repair and Overlay Materials by Direct Tension (Pull-off Method)

Standard Test Method for Tensile Strength of Concrete Surfaces and the Bond Strength or Tensile Strength of Concrete Repair and Overlay Materials by Direct Tension (Pull-off Method)

ABSTRACT

This specification covers standard test method for tensile strength of concrete surfaces and the bond strength or tensile strength of concrete repair and overlay materials by direct tension (pull-off method). This test method is suitable for both field and laboratory use to determine one or more of the following: the near-surface tensile strength of the substrate as an indicator of the adequacy of surface preparation before application of a repair or overlay material; the bond strength of a repair or an overlay material to the substrate; and the tensile strength of a repair or overlay material, or an adhesive used in repairs, after the material has been applied to a surface. The following apparatus shall be utilized: core drill; core barrel; steel disk; tensile loading device; and a coupling device. This test shall be performed on the surface of a prepared concrete base before application of a concrete repair overlay material, or on the surface of a concrete repair overlay material after the material has been applied to the prepared concrete surface. The test specimen shall be formed by drilling a shallow core into and perpendicular to the surface of the substrate, and leaving the intact core attached to the concrete. A steel disk shall be bonded to the top surface of the test specimen. A tensile load shall be applied to the steel disk until failure occurs. The failure load and the failure mode shall be recorded and the nominal tensile stress at failure shall be calculated.

SIGNIFICANCE AND USE

5.1 This test method determines the tensile strength of concrete near to the prepared surface, which can be used as an indicator of the adequacy of surface preparation before applying a repair or an overlay material.

5.2 When the test is performed on the surface of a repair or an overlay material, it determines the bond strength to the substrate or the tensile strength of either the overlay or substrate, whichever is weaker.

5.3 The method may also be used to evaluate the adhesive strength of bonding agents.

5.4 When the test is performed on the surface of a material applied to the substrate, the measured strength is controlled by the failure mechanism requiring the least stress. Thus it is not possible to know beforehand which strength will be measured by the test. For this reason, the failure mode has to be reported for each individual test result, and tests results are averaged only if the same failure mode occurs.

SCOPE

1.1 This test method is suitable for both field and laboratory use to determine one or more of the following:

1.1.1 The near-surface tensile strength of the substrate as an indicator of the adequacy of surface preparation before application of a repair or overlay material.

1.1.2 The bond strength of a repair or an overlay material to the substrate.

1.1.3 The tensile strength of a repair or overlay material, or an adhesive used in repairs, after the material has been applied to a surface.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 The text of this standard refers to notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision o...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1583/C1583M − 20

Standard Test Method for

Tensile Strength of Concrete Surfaces and the Bond

Strength or Tensile Strength of Concrete Repair and Overlay

1

Materials by Direct Tension (Pull-off Method)

This standard is issued under the fixed designation C1583/C1583M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method is suitable for both field and laboratory

C125 Terminology Relating to Concrete and Concrete Ag-

use to determine one or more of the following:

gregates

1.1.1 The near-surface tensile strength of the substrate as an

C881/C881M Specification for Epoxy-Resin-Base Bonding

indicator of the adequacy of surface preparation before appli-

Systems for Concrete

cation of a repair or overlay material.

C900 Test Method for Pullout Strength of Hardened Con-

1.1.2 The bond strength of a repair or an overlay material to

crete

the substrate.

1.1.3 The tensile strength of a repair or overlay material, or

3. Terminology

an adhesive used in repairs, after the material has been applied

3.1 Definitions—For definitions of terms used in this test

to a surface.

3

method refer to Terminology C125 and ACI 503R .

1.2 The values stated in either SI units or inch-pound units

4. Summary of Test Method

are to be regarded separately as standard. The values stated in

each system may not be exact equivalents; therefore, each

4.1 This test is performed on the surface of a prepared

system shall be used independently of the other. Combining

concrete base before application of a concrete repair or overlay

values from the two systems may result in non-conformance

material, or on the surface of a concrete repair or overlay

with the standard.

material after the material has been applied to the prepared

concrete surface.

1.3 The text of this standard refers to notes and footnotes

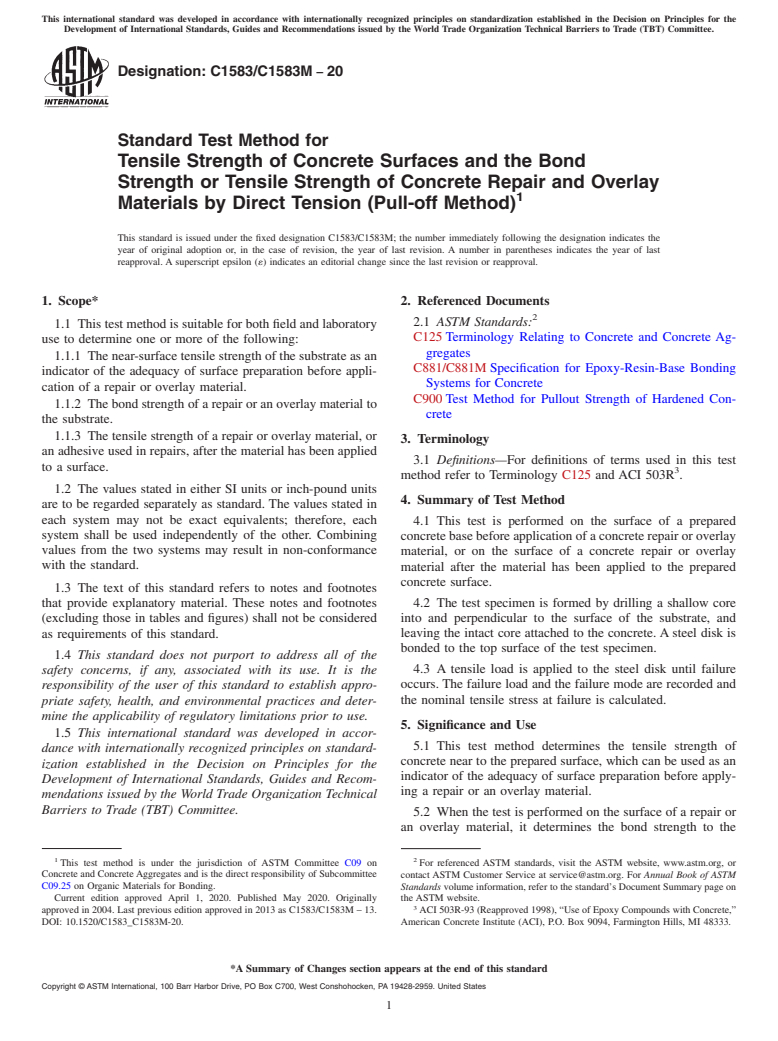

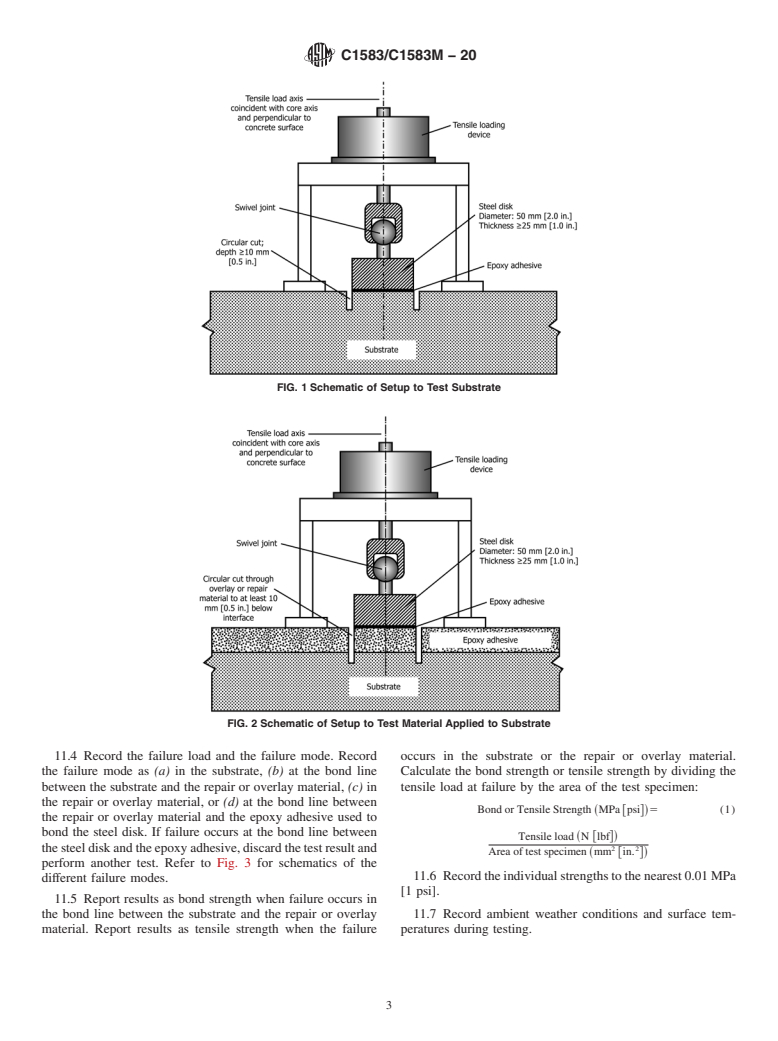

that provide explanatory material. These notes and footnotes 4.2 The test specimen is formed by drilling a shallow core

into and perpendicular to the surface of the substrate, and

(excluding those in tables and figures) shall not be considered

as requirements of this standard. leaving the intact core attached to the concrete. A steel disk is

bonded to the top surface of the test specimen.

1.4 This standard does not purport to address all of the

4.3 A tensile load is applied to the steel disk until failure

safety concerns, if any, associated with its use. It is the

occurs. The failure load and the failure mode are recorded and

responsibility of the user of this standard to establish appro-

the nominal tensile stress at failure is calculated.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

5. Significance and Use

1.5 This international standard was developed in accor-

5.1 This test method determines the tensile strength of

dance with internationally recognized principles on standard-

concrete near to the prepared surface, which can be used as an

ization established in the Decision on Principles for the

indicator of the adequacy of surface preparation before apply-

Development of International Standards, Guides and Recom-

ing a repair or an overlay material.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

5.2 When the test is performed on the surface of a repair or

an overlay material, it determines the bond strength to the

1 2

This test method is under the jurisdiction of ASTM Committee C09 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

C09.25 on Organic Materials for Bonding. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 1, 2020. Published May 2020. Originally the ASTM website.

3

approved in 2004. Last previous edition approved in 2013 as C1583/C1583M – 13. ACI 503R-93 (Reapproved 1998), “Use of Epoxy Compounds with Concrete,”

DOI: 10.1520/C1583_C1583M-20. American Concrete Institute (ACI), P.O. Box 9094, Farmington Hills, MI 48333.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 -------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1583/C1583M − 13 C1583/C1583M − 20

Standard Test Method for

Tensile Strength of Concrete Surfaces and the Bond

Strength or Tensile Strength of Concrete Repair and Overlay

1

Materials by Direct Tension (Pull-off Method)

This standard is issued under the fixed designation C1583/C1583M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method is suitable for both field and laboratory use to determine one or more of the following:

1.1.1 The near-surface tensile strength of the substrate as an indicator of the adequacy of surface preparation before application

of a repair or overlay material.

1.1.2 The bond strength of a repair or an overlay material to the substrate.

1.1.3 The tensile strength of a repair or overlay material, or an adhesive used in repairs, after the material has been applied to

a surface.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 The text of this standard refers to notes and footnotes that provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C125 Terminology Relating to Concrete and Concrete Aggregates

C881/C881M Specification for Epoxy-Resin-Base Bonding Systems for Concrete

C900 Test Method for Pullout Strength of Hardened Concrete

3. Terminology

3

3.1 Definitions—For definitions of terms used in this test method refer to Terminology C125 and ACI 503R .

4. Summary of Test Method

4.1 This test is performed on the surface of a prepared concrete base before application of a concrete repair or overlay material,

or on the surface of a concrete repair or overlay material after the material has been applied to the prepared concrete surface.

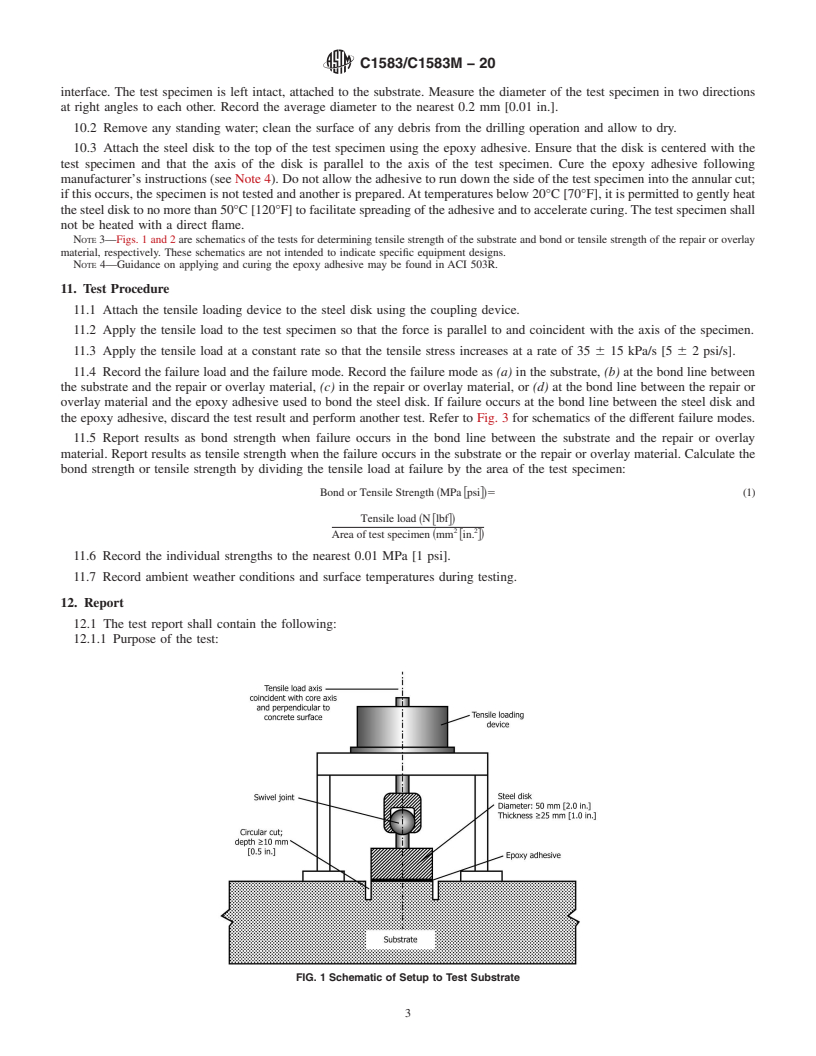

4.2 The test specimen is formed by drilling a shallow core into and perpendicular to the surface of the substrate, and leaving

the intact core attached to the concrete. A steel disk is bonded to the top surface of the test specimen.

1

This test method is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee C09.25 on

Organic Materials for Bonding.

Current edition approved April 1, 2013April 1, 2020. Published April 2013May 2020. Originally approved in 2004. Last previous edition approved in 20042013 as

C1583/C1583M – 04E01, which was withdrawn in January 2013 and reinstated in April 2013. DOI: 10.1520/C1583_C1583M-13.13. DOI: 10.1520/C1583_C1583M-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

ACI 503R-93 (Reapproved 1998), “Use of Epoxy Compounds with Concrete,” American Concrete Institute (ACI), P.O. Box 9094, Farmington Hills, MI 48333.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1583/C1583M − 20

4.3 A tensile load is applied to the steel disk until failure occurs. The failure load and the failure mode are recorded and the

nominal tensile stress at failure is calculated.

5. Significance and Use

5.1 This test method determines

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.