ASTM D6940-18

(Practice)Standard Practice for Measuring Sifting Segregation Tendencies of Bulk Solids

Standard Practice for Measuring Sifting Segregation Tendencies of Bulk Solids

SIGNIFICANCE AND USE

5.1 Sifting segregation can cause horizontal segregation (for example, center-to-periphery) within bins used to hold and transport bulk solids. This can affect final product quality or subsequent processes in industrial applications.

5.2 By measuring a bulk solid's segregation tendency, one can compare results to other bulk solids with known history, or determine if the given bulk solid may have a tendency to segregate in a given process.

5.3 Sifting, which is a process by which smaller particles move through a matrix of larger ones, is a common method of segregation. Four conditions must exist for sifting to occur:

5.3.1 A Difference in Particle Size between the Individual Components—This ratio can be as low as 1.3 to 1. In general, the larger the ratio of particle sizes, the greater the tendency for particles to segregate by sifting.

5.3.2 A Sufficiently Large Mean Particle Size—Sifting segregation can occur with a mean particle size in the 50 μm range and can become a dominant segregation mechanism if the mean particle size is above 100 μm.

5.3.3 Sufficiently Free Flowing Material—This allows the smaller particles to sift through the matrix of larger particles. With cohesive materials, the fine particles are bound to one another and do not enter the voids among the coarse particles.

5.3.4 Interparticle Motion—This can be caused during formation of a pile, by vibration, or by a velocity gradient across the flowing material.

5.4 All four of these conditions must exist for sifting segregation to occur. If any one of these conditions does not exist, the material will not segregate by this mechanism.

Note 1: The quality of the result produced by this practice is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this practice are ...

SCOPE

1.1 This practice covers an apparatus and procedure for simulating the segregation tendencies of bulk solids by means of the sifting mechanism.

1.2 Temperature- and humidity-sensitive bulk solids may need to be tested at different temperatures and moisture contents, as would happen in an industrial environment.

1.3 The maximum particle size should be limited to 3 mm, to reduce the likelihood of binding the slide gate.

1.4 This standard is not applicable to all bulk solids and segregation mechanisms: while sifting is a common segregation mechanism experienced by many bulk solids, other segregation mechanisms not evaluated by this standard might induce segregation in practice. Practice D6941 covers another common mechanism: fluidization.

1.5 The extent to which segregation will occur in an industrial situation is not only a function of the bulk solid and its tendency to segregate, but also the handling equipment (for example, bin design), process (for example, transfer rates), and environment.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This practice offers a set of instructions for performing one or more specific operations. This document cannot replace education or experience and should be used in conjunction with professional judgment. Not all aspects of this practice may be applicable in all circumstances. This ASTM standard is not intended to represent or replace the standard of care by which the adequacy of a given professional service must be judged, nor should this document be applied without consideration of a project’s many unique aspects. The word “Standard” in the title of this document means only that the document has been approved through the ASTM consensus process.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the ...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6940 − 18

Standard Practice for

1

Measuring Sifting Segregation Tendencies of Bulk Solids

This standard is issued under the fixed designation D6940; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.8 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This practice covers an apparatus and procedure for

responsibility of the user of this standard to establish appro-

simulating the segregation tendencies of bulk solids by means

priate safety, health, and environmental practices and deter-

of the sifting mechanism.

mine the applicability of regulatory limitations prior to use.

1.2 Temperature- and humidity-sensitive bulk solids may

1.9 This international standard was developed in accor-

need to be tested at different temperatures and moisture

dance with internationally recognized principles on standard-

contents, as would happen in an industrial environment.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.3 The maximum particle size should be limited to 3 mm,

mendations issued by the World Trade Organization Technical

to reduce the likelihood of binding the slide gate.

Barriers to Trade (TBT) Committee.

1.4 This standard is not applicable to all bulk solids and

segregation mechanisms: while sifting is a common segrega-

2. Referenced Documents

tion mechanism experienced by many bulk solids, other

2

2.1 ASTM Standards:

segregation mechanisms not evaluated by this standard might

D653 Terminology Relating to Soil, Rock, and Contained

induce segregation in practice. Practice D6941 covers another

Fluids

common mechanism: fluidization.

D2216 Test Methods for Laboratory Determination of Water

1.5 The extent to which segregation will occur in an (Moisture) Content of Soil and Rock by Mass

industrial situation is not only a function of the bulk solid and

D3740 Practice for Minimum Requirements for Agencies

its tendency to segregate, but also the handling equipment (for Engaged in Testing and/or Inspection of Soil and Rock as

example, bin design), process (for example, transfer rates), and

Used in Engineering Design and Construction

environment. D6941 Practice for Measuring Fluidization SegregationTen-

dencies of Powders

1.6 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

3. Terminology

standard.

3.1 Definitions:

1.7 This practice offers a set of instructions for performing

3.1.1 Forcommondefinitionsoftermsinthisstandard,refer

one or more specific operations. This document cannot replace

to Terminology D653.

educationorexperienceandshouldbeusedinconjunctionwith

professional judgment. Not all aspects of this practice may be

4. Summary of Practice

applicable in all circumstances. This ASTM standard is not

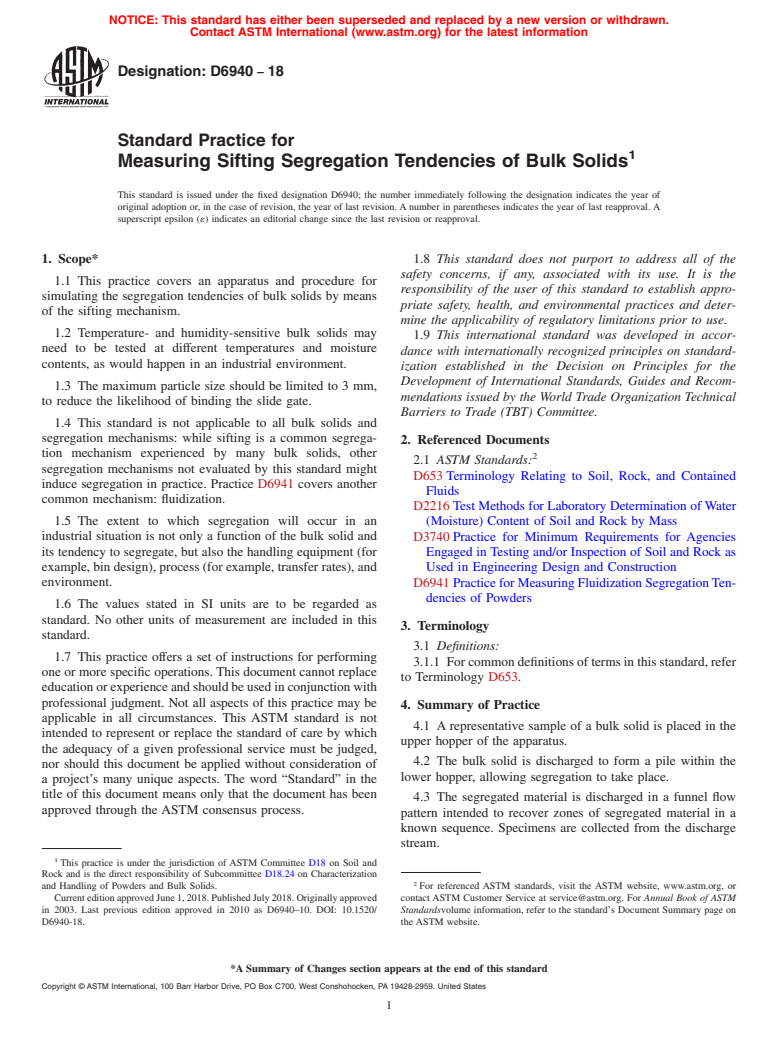

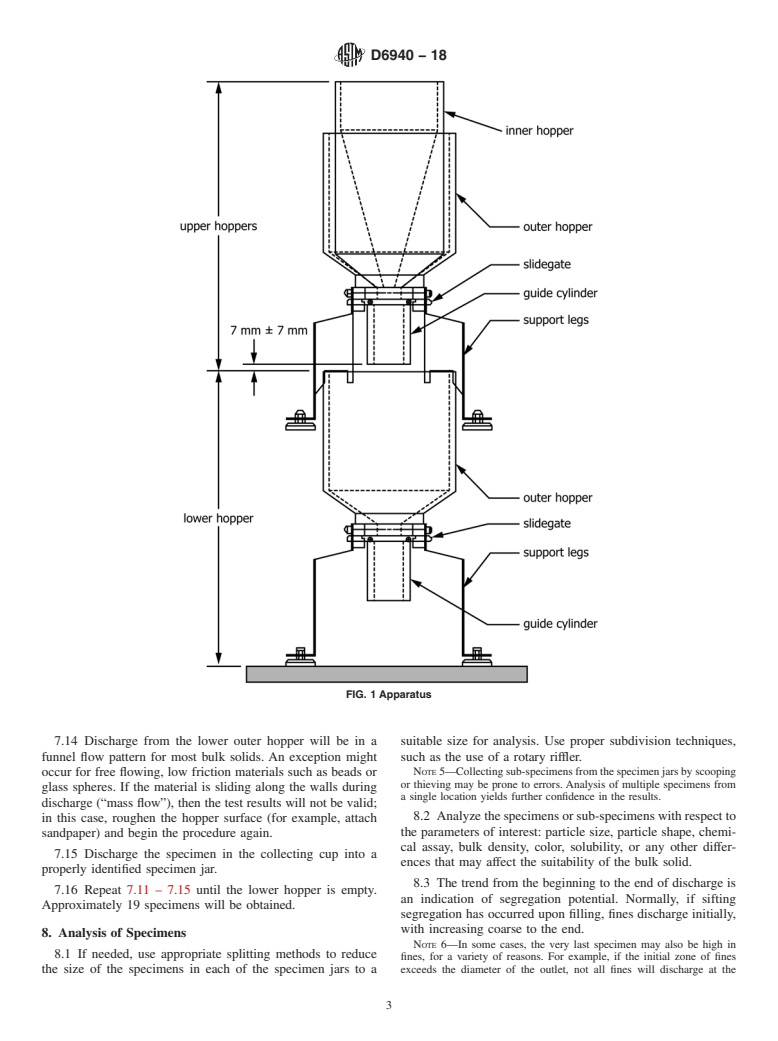

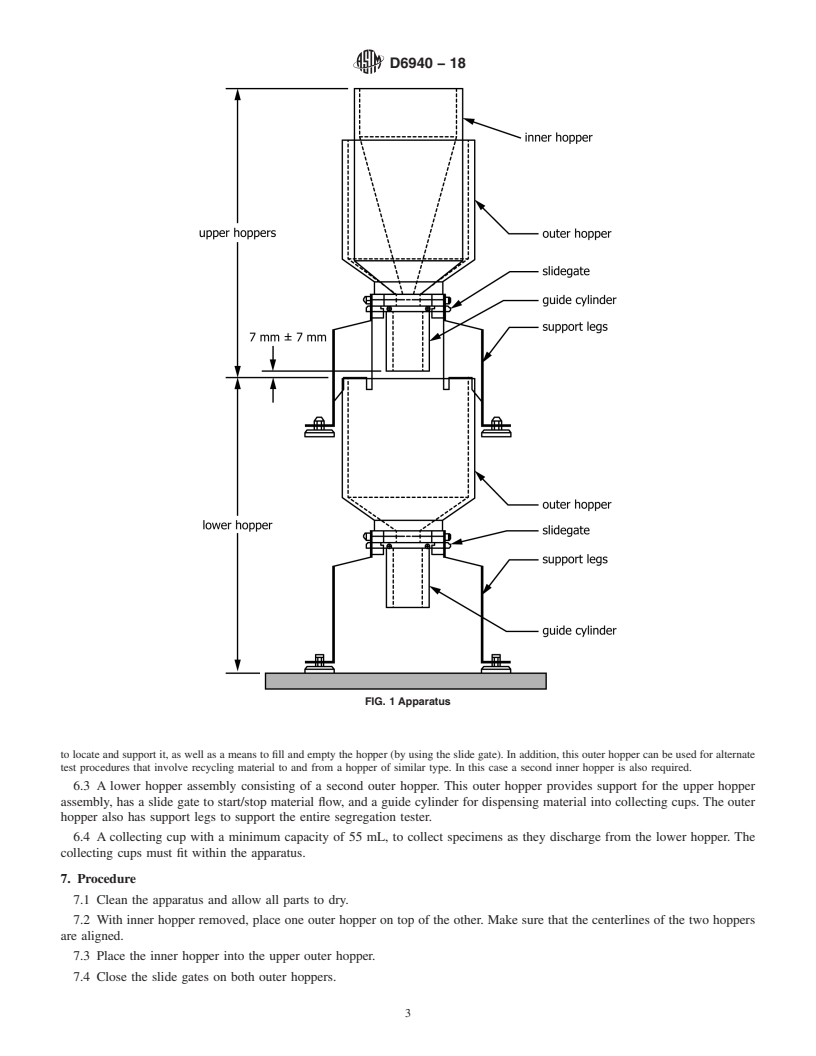

4.1 A representative sample of a bulk solid is placed in the

intended to represent or replace the standard of care by which

upper hopper of the apparatus.

the adequacy of a given professional service must be judged,

4.2 The bulk solid is discharged to form a pile within the

nor should this document be applied without consideration of

lower hopper, allowing segregation to take place.

a project’s many unique aspects. The word “Standard” in the

title of this document means only that the document has been

4.3 The segregated material is discharged in a funnel flow

approved through the ASTM consensus process.

pattern intended to recover zones of segregated material in a

known sequence. Specimens are collected from the discharge

stream.

1

This practice is under the jurisdiction of ASTM Committee D18 on Soil and

Rock and is the direct responsibility of Subcommittee D18.24 on Characterization

2

and Handling of Powders and Bulk Solids. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedJune1,2018.PublishedJuly2018.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 2003. Last previous edition approved in 2010 as D6940–10. DOI: 10.1520/ Standardsvolume information, refer to the standard’s Document Summary page on

D6940-18. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6940 − 18

solid being tested, placing this hopper inside the outer hopper provides a

4.4 The specimens are then available to be tested for

means

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6940 − 10 D6940 − 18

Standard Practice for

1

Measuring Sifting Segregation Tendencies of Bulk Solids

This standard is issued under the fixed designation D6940; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice covers an apparatus and procedure for simulating the segregation tendencies of bulk solids by means of the

sifting mechanism.

1.2 Temperature- and humidity-sensitive bulk solids may need to be tested at different temperatures and moisture contents, as

would happen in an industrial environment.

1.3 The maximum particle size should be limited to 3 mm, to reduce the likelihood of binding the slide gate.

1.4 This standard is not applicable to all bulk solids and segregation mechanisms: while sifting is a common segregation

mechanism experienced by many bulk solids, other segregation mechanisms not evaluated by this standard might induce

segregation in practice. Practice D6941 covers another common mechanism: fluidization.

1.5 The extent to which segregation will occur in an industrial situation is not only a function of the bulk solid and its tendency

to segregate, but also the handling equipment (for example, bin design), process (for example, transfer rates), and environment.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This practice offers a set of instructions for performing one or more specific operations. This document cannot replace

education or experience and should be used in conjunction with professional judgment. Not all aspects of this practice may be

applicable in all circumstances. This ASTM standard is not intended to represent or replace the standard of care by which the

adequacy of a given professional service must be judged, nor should this document be applied without consideration of a project’s

many unique aspects. The word “Standard” in the title of this document means only that the document has been approved through

the ASTM consensus process.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D653 Terminology Relating to Soil, Rock, and Contained Fluids

D2216 Test Methods for Laboratory Determination of Water (Moisture) Content of Soil and Rock by Mass

D3740 Practice for Minimum Requirements for Agencies Engaged in Testing and/or Inspection of Soil and Rock as Used in

Engineering Design and Construction

D6941 Practice for Measuring Fluidization Segregation Tendencies of Powders

3. Terminology

3.1 Definitions:

3.1.1 For common definitions of terms in this standard, refer to Terminology D653.

1

This practice is under the jurisdiction of ASTM Committee D18 on Soil and Rock and is the direct responsibility of Subcommittee D18.24 on Characterization and

Handling of Powders and Bulk Solids.

Current edition approved July 1, 2010June 1, 2018. Published August 2010July 2018. Originally approved in 2003. Last previous edition approved in 20042010 as

D6940–04.–10. DOI: 10.1520/D6940-10.10.1520/D6940-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standardsvolume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6940 − 18

3.1.2 funnel flow pattern, n—a flow sequence in a bin or hopper characterized by having some bulk solids moving through

stagnant bulk solids. In general, there is no flow along the hopp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.