ASTM E1696-04

(Test Method)Standard Test Method for Field Measurement of Raised Retroreflective Pavement Markers Using a Portable Retroreflectometer (Withdrawn 2013)

Standard Test Method for Field Measurement of Raised Retroreflective Pavement Markers Using a Portable Retroreflectometer (Withdrawn 2013)

SIGNIFICANCE AND USE

Measurements of RI made by this test method, with the 0.2° observation angle, are related to visual observation of raised retroreflective pavement markers at distances of approximately 220 m (720 ft) for cars or approximately 440 m (1440 ft) for trucks when illuminated by tungsten filament light sources such as car headlights.

There are some castings that block vehicle illumination of a portion of the marker mounted within it. In this case, measured RI can be significantly lower than when the marker is photometered outside the casting, but will correspond to the visual observation.

The test method is not applicable to raised pavement markers mounted in depressions cut into the pavement.

The coefficient of luminous intensity of raised retroreflective pavement markers degrades with traffic wear and requires periodic measurement to ensure that sufficient visibility is provided to the driver.

The quality of the pavement markers as to materials used, age and wear pattern, will have an effect on the coefficient of (retroreflected) luminous intensity. These conditions need to be observed and noted by the user.

SCOPE

1.1 This test method covers the measurement of the retroreflective properties of raised retroreflective pavement markers at a prescribed geometry, by means of a portable retroreflectometer that can be used in the field. The measurements can be compared to minimum requirements to determine the need for replacement.

1.2 The observation angle specified for retroreflectometers in this test method is that currently specified for raised pavement markers in the United States and may differ from the angles used elsewhere. For other jurisdictions, replace the observations angle specified herein with the observation angle specified by the pertinent agency.

1.3 This test method is intended to be used for field measurement of raised retroreflective pavement markers but may also be used to measure the performance of new markers before they are placed in the field.

1.4 This test method covers measurements of raised pavement markers mounted on a road surface or mounted in snow-plowable metal castings.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 The standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the measurement of the retroreflective properties of raised retroreflective pavement markers at a prescribed geometry, by means of a portable retroreflectometer that can be used in the field. The measurements can be compared to minimum requirements to determine the need for replacement.

Formerly under the jurisdiction of Committee E12 on Color and Appearance, this test method was withdrawn in January 2013 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1696 −04

StandardTest Method for

Field Measurement of Raised Retroreflective Pavement

1

Markers Using a Portable Retroreflectometer

This standard is issued under the fixed designation E1696; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E808Practice for Describing Retroreflection

E809Practice for Measuring Photometric Characteristics of

1.1 This test method covers the measurement of the retrore-

Retroreflectors

flectivepropertiesofraisedretroreflectivepavementmarkersat

a prescribed geometry, by means of a portable retroreflecto-

3. Terminology

meter that can be used in the field. The measurements can be

compared to minimum requirements to determine the need for

3.1 The terms and definitions in Terminology E284 are

replacement.

applicable to this test method. Some terms particular to

retroreflection are defined and illustrated in Practice E808.

1.2 The observation angle specified for retroreflectometers

in this test method is that currently specified for raised 3.2 Definitions:

pavementmarkersintheUnitedStatesandmaydifferfromthe

3.2.1 The delimiting phrase “in retroreflection” applies to

angles used elsewhere. For other jurisdictions, replace the

eachofthefollowingdefinitionswhenusedoutsidethecontext

observations angle specified herein with the observation angle

of this or other retroreflection standards.

specified by the pertinent agency.

3.2.2 coeffıcient of luminous intensity, R , n—of a

I

retroreflector, ratio of the luminous intensity (I) of the retrore-

1.3 This test method is intended to be used for field

flector in the direction of observation to the illuminance (E|nt)

measurement of raised retroreflective pavement markers but

at the retroreflector on a plane perpendicular to the direction of

may also be used to measure the performance of new markers

−1

incident light, expressed in candelas per lux (cd·lx ).

before they are placed in the field.

3.2.2.1 Discussion—When values are low, the coefficient of

1.4 This test method covers measurements of raised pave-

(retroreflected) luminous intensity may be given in millican-

ment markers mounted on a road surface or mounted in −1

delas per lux (mcd·lx ). R =(I/E|nt).

I

snow-plowable metal castings.

3.2.3 portable retroreflectometer—a hand-held instrument

1.5 The values stated in SI units are to be regarded as the

that can be used in the field or in the laboratory for measure-

standard. The values given in parentheses are for information

ment of retroreflectance.

only.

3.2.3.1 Discussion—In this test method, “portable retrore-

1.6 The standard does not purport to address all of the

flectometer”referstoahand-heldinstrumentthatcanbeplaced

safety concerns, if any, associated with its use. It is the

over a raised retroreflective pavement marker to measure the

responsibility of the user of this standard to establish appro-

coefficient of luminous intensity with a prescribed geometry.

priate safety and health practices and determine the applica-

3.2.4 instrument standard, n—a working standard used to

bility of regulatory limitations prior to use

standardize the portable retroreflectometer.

2. Referenced Documents

4. Summary of Test Method

2

2.1 ASTM Standards:

E284Terminology of Appearance 4.1 This test method involves the use of commercial por-

table retroreflectometers for determining the coefficient of

1

luminous intensity of pavement markers.

This test method is under the jurisdiction of ASTM Committee E12 on Color

and Appearance and is the direct responsibility of Subcommittee E12.10 on

4.2 Entrance angle component β shall be between −2° and

1

Retroreflection.

CurrenteditionapprovedMay1,2004.PublishedJuly2004.Originallyapproved 0°; entrance angle component β shall be 0° 6 2°.

2

in 1995. Last previous edition approved in 2002 as E1696–02. DOI: 10.1520/

4.3 Unless otherwise specified by the user, the observation

E1696-04.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or angle shall be 0.2° 6 0.01°.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.4 The observation half plane shall be vertical. Rotation

Standards volume information, refer to the standard’s Document Summary page on

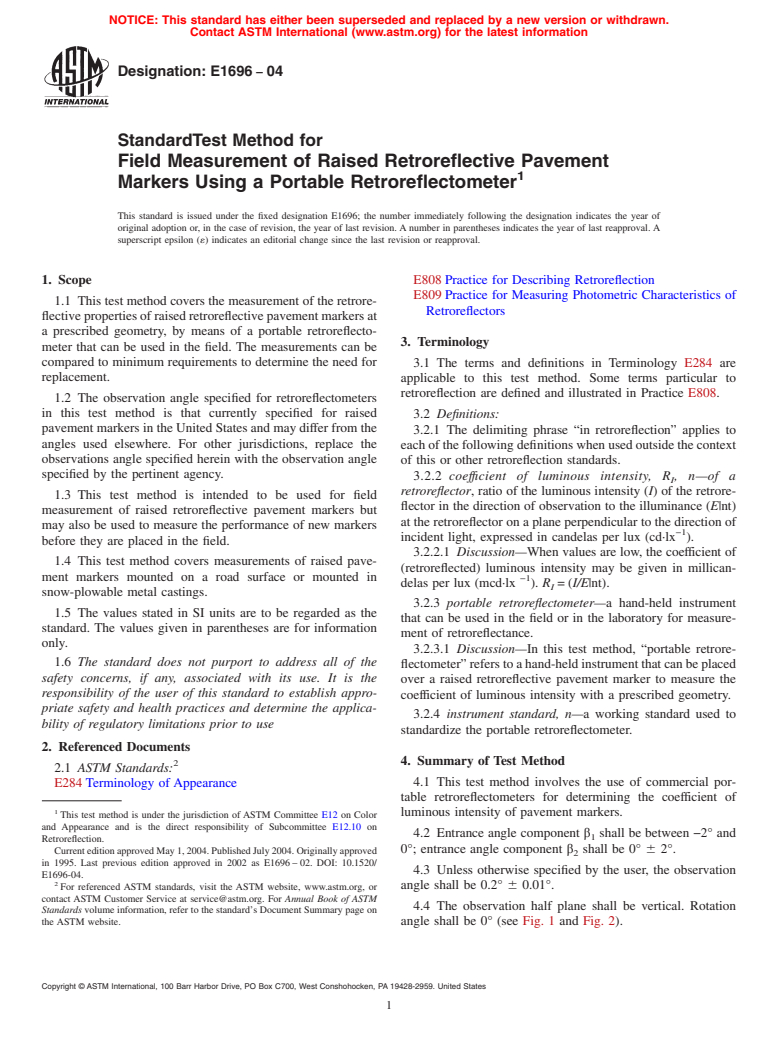

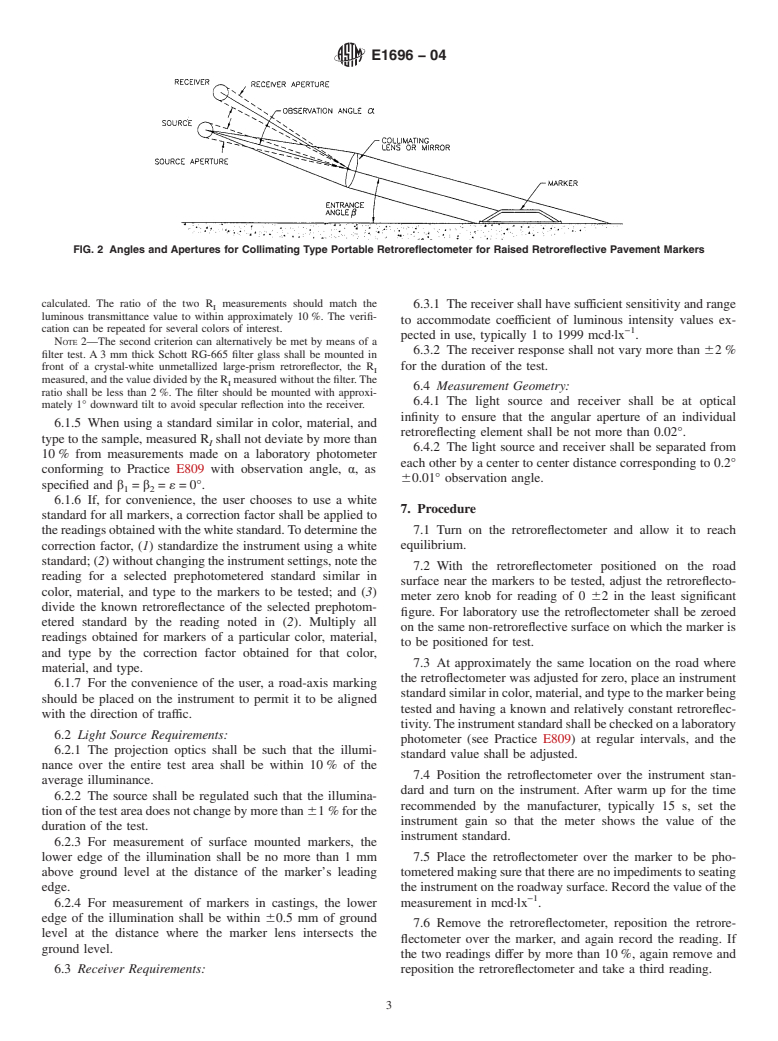

the ASTM website. angle shall be 0° (see Fig. 1 and Fig. 2).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1696−04

5.2 There are some castings that block vehicle illumination

of a portion of the marker mounted within it. In this case,

measured R can be significantly lower than when the marker

I

is photometered

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.