ASTM C1248-06

(Test Method)Standard Test Method for Staining of Porous Substrate by Joint Sealants

Standard Test Method for Staining of Porous Substrate by Joint Sealants

SIGNIFICANCE AND USE

Staining of building materials is an aesthetically undesirable occurrence. This test method evaluates the likelihood of a sealant causing an early stain on a porous substrate due to exudation of materials from the sealant. Since this is an accelerated test, it does not necessarily predict that the tested sealants will not stain or discolor porous substrates over longer periods of time.

SCOPE

1.1 This test method covers four types of laboratory tests to determine if a joint sealant has a probability of staining a porous substrate (such as marble, limestone, sandstone, and granite). The tests are on compressed samples and include (1) storage under standard laboratory conditions, (2) storage in an oven, and (3) exposure in a fluorescent UV/condensation device, and (4) exposure in a xenon arc device.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 The committee with jurisdiction over this standard is not aware of any comparable standards published by other organizations.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1248–06

Standard Test Method for

1

Staining of Porous Substrate by Joint Sealants

This standard is issued under the fixed designation C 1248; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope G 155 Practice for Operating Xenon Arc Light Apparatus

for Exposure of Non-Metallic Materials

1.1 This test method covers four types of laboratory tests to

determine if a joint sealant has a probability of staining a

3. Terminology

porous substrate (such as marble, limestone, sandstone, and

3.1 Definitions:

granite). The tests are on compressed samples and include (1)

3.1.1 Refer to Terminology C 717 andG113 for definitions

storage under standard laboratory conditions, (2) storage in an

of terms used in this test method.

oven, and (3) exposure in a fluorescent UV/condensation

device, and (4) exposure in a xenon arc device.

4. Summary of Test Method

1.2 The values stated in SI units are to be regarded as the

4.1 In this test method standard joint specimens are com-

standard. The values given in parentheses are for information

pressed and clamped at the manufacturer’s rated movement

only.

capabilityandsubjectedtothefollowingtreatments;(a)fourof

1.3 This standard does not purport to address all of the

the specimens are stored at standard conditions while under

safety problems, if any, associated with its use. It is the

compression for up to 28 days; (b) four of the specimens are

responsibility of the user of this standard to establish appro-

exposed in an oven while under compression for up to 28 days;

priate safety and health practices and determine the applica-

(c) four of the specimens are exposed either in a fluorescent

bility of regulatory limitations prior to use.

UV/condensation device or in a xenon arc device while under

1.4 Thecommitteewithjurisdictionoverthisstandardisnot

compression for up to 28 days.

aware of any comparable standards published by other orga-

4.2 The effects of the test are evaluated by visual inspection

nizations.

for changes in surface appearance and average measurements

2. Referenced Documents of any stain depth and stain width.

2 4.3 This test method is applicable to any type of elastomeric

2.1 ASTM Standards:

joint sealant and any type of porous substrate.

C 717 Terminology of Building Seals and Sealants

C 1442 Practice for Conducting Tests on Sealants Using

5. Significance and Use

Artificial Weathering Apparatus

5.1 Staining of building materials is an aesthetically unde-

G113 Terminology Relating to Natural and Artificial

sirable occurrence.This test method evaluates the likelihood of

Weathering Tests of Nonmetallic Materials

a sealant causing an early stain on a porous substrate due to

G 151 Practice for Exposing Nonmetallic Materials in Ac-

exudation of materials from the sealant. Since this is an

celerated Test Devices that Use Laboratory Light Sources

accelerated test, it does not necessarily predict that the tested

G 154 Practice for Operating Fluorescent Light Apparatus

sealants will not stain or discolor porous substrates over longer

for UV Exposure of Nonmetallic Materials

periods of time.

6. Apparatus

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC24onBuilding

6.1 Forced-Draft Oven.

Seals and Sealants and is the direct responsibility of Subcommittee C24.40 on

6.2 Exposure Apparatus:

Weathering.

6.2.1 Fluorescent UV/condensation apparatus that conforms

Current edition approved Jan. 1, 2006. Published February 2006. Originally

approved in 1993. Last previous edition approved in 2004 as C 1248-04.

to the requirements in Practices G 151 and G 154 with UVA-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

340 type lamps.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.2.2 Xenon-Arc apparatus that conforms to the require-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ments in Practices G 151 and G 155 with daylight type filters.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

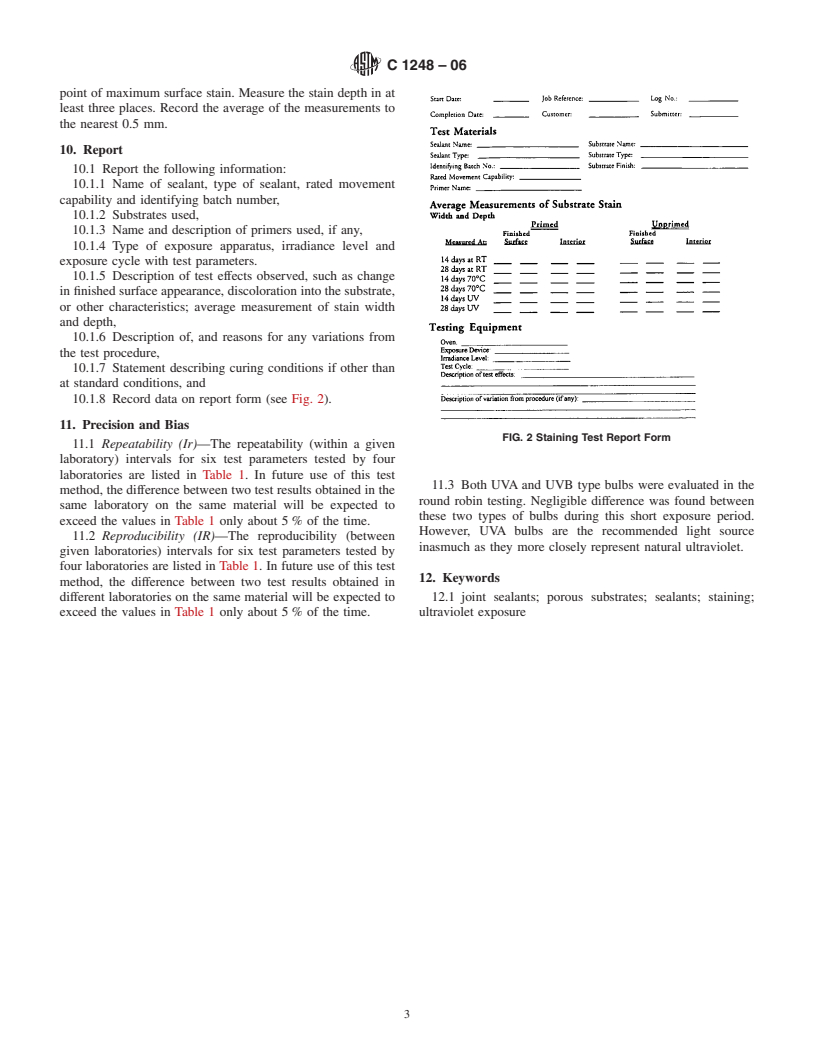

C1248–06

6.3 TFE-Fluorocarbon Spacers. other suitable tape to retain the sealant. Use masking tape on

6.4 Masking Tape. the top surface of substrates to prevent sealant from curing on

the finished surface. Remove the tape immediately following

7. Test Specimens

filling of the specimen joint cavity.

7.3.3 Single-Component Sealants—Prepare the specimens

7.1 Substrates shall be 25 by 25 by 75 mm (1 by 1 by 3 in.).

as described in 7.3.2 except that no mixing is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.