ASTM B754-10(2015)e1

(Test Method)Standard Test Method for Measuring and Recording the Deviations from Flatness in Copper and Copper Alloy Strip

Standard Test Method for Measuring and Recording the Deviations from Flatness in Copper and Copper Alloy Strip

SIGNIFICANCE AND USE

5.1 This test method is intended for measuring distortion in strip used for making close tolerance parts. Since distortion in this strip would influence the shape of the part being produced and cause difficulties in feeding through close-fitting dies and other manufacturing equipment, it is important that this material be flat.

5.2 This test method provides a universal procedure for measuring the irregularities that cause the deviation from flatness.

5.3 This test method allows the purchaser and manufacturer to inspect strip with a standard technique to a mutually agreed upon and acceptable percentage deviation from flatness.

SCOPE

1.1 This test method establishes a procedure for the measurement of distortions in thin metal strip and the application of these measurements to an equation that will indicate the deviation from flatness.

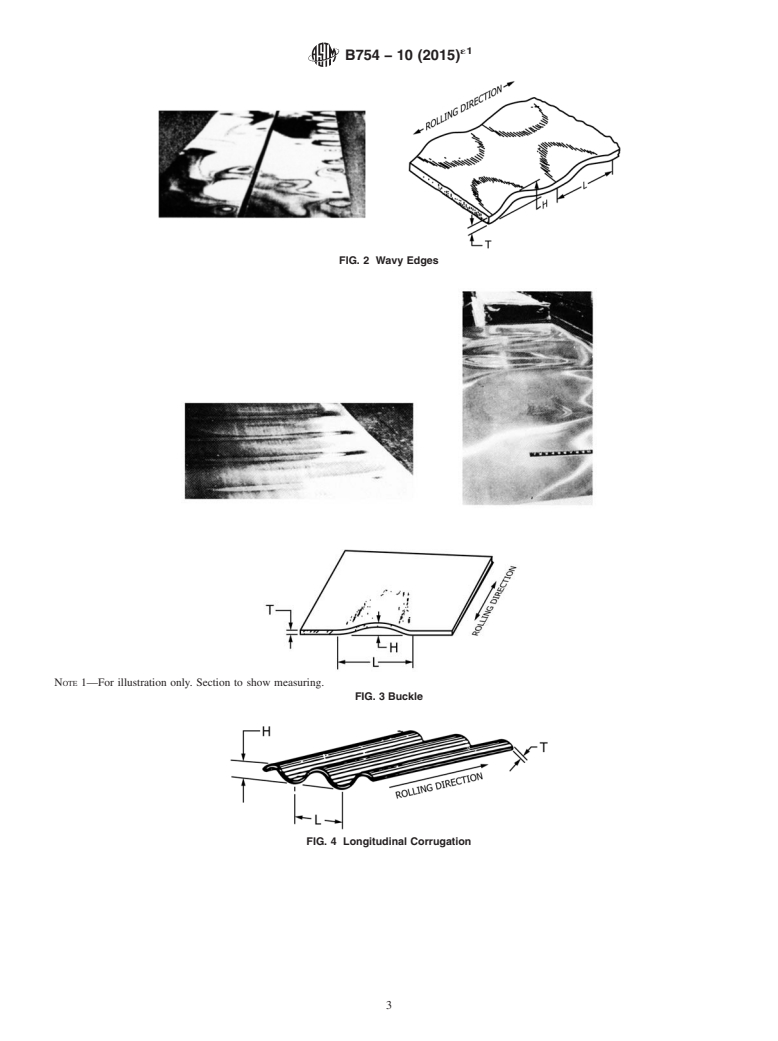

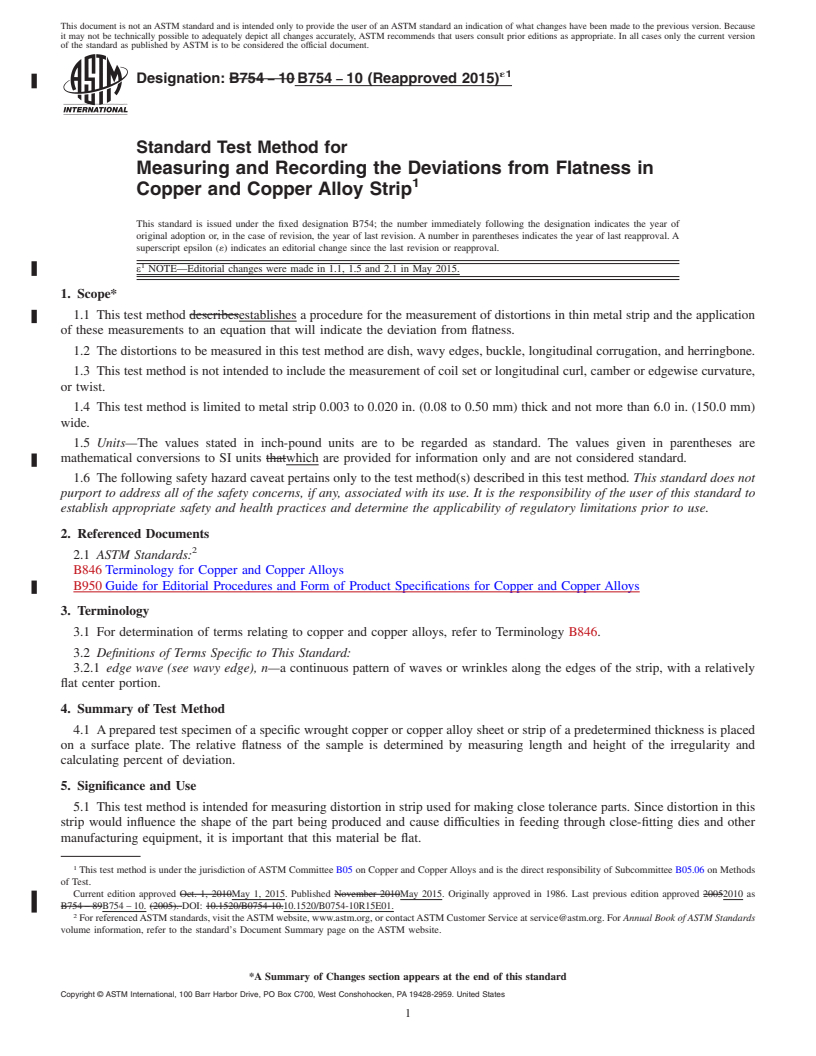

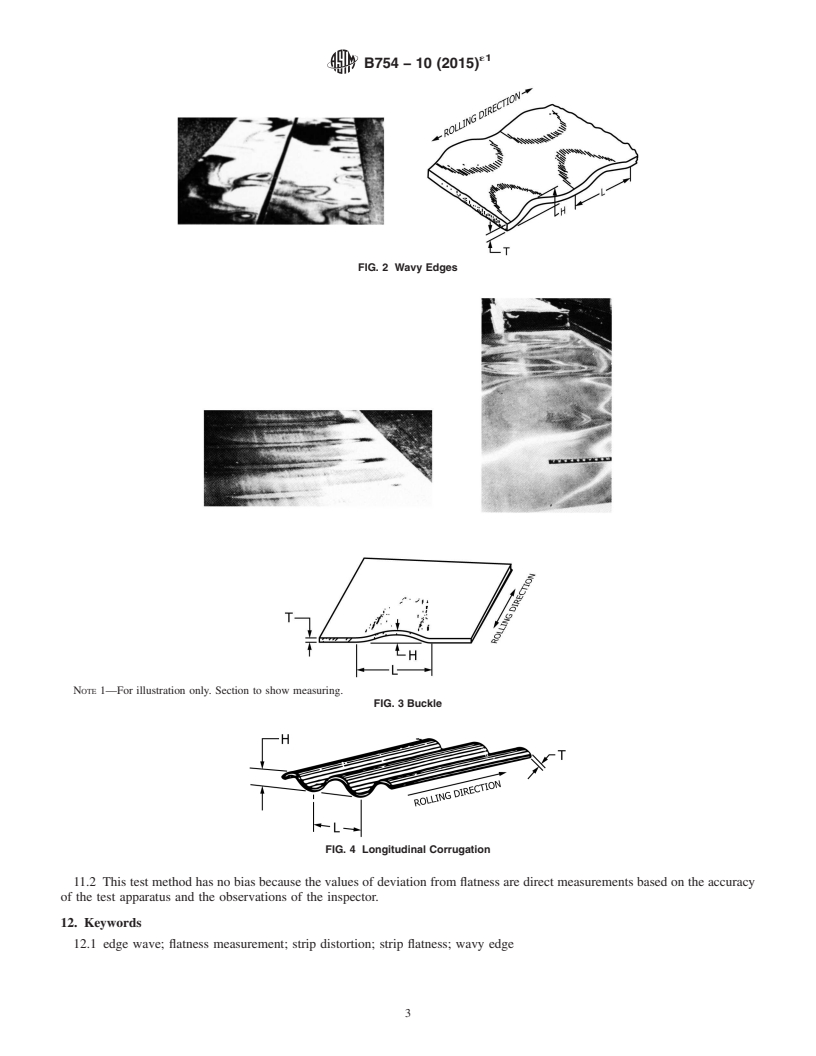

1.2 The distortions to be measured in this test method are dish, wavy edges, buckle, longitudinal corrugation, and herringbone.

1.3 This test method is not intended to include the measurement of coil set or longitudinal curl, camber or edgewise curvature, or twist.

1.4 This test method is limited to metal strip 0.003 to 0.020 in. (0.08 to 0.50 mm) thick and not more than 6.0 in. (150.0 mm) wide.

1.5 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units which are provided for information only and are not considered standard.

1.6 The following safety hazard caveat pertains only to the test method(s) described in this test method. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: B754 − 10 (Reapproved 2015)

Standard Test Method for

Measuring and Recording the Deviations from Flatness in

Copper and Copper Alloy Strip

This standard is issued under the fixed designation B754; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial changes were made in 1.1, 1.5 and 2.1 in May 2015.

1. Scope* B950 Guide for Editorial Procedures and Form of Product

Specifications for Copper and Copper Alloys

1.1 This test method establishes a procedure for the mea-

surementofdistortionsinthinmetalstripandtheapplicationof

3. Terminology

these measurements to an equation that will indicate the

3.1 Fordeterminationoftermsrelatingtocopperandcopper

deviation from flatness.

alloys, refer to Terminology B846.

1.2 The distortions to be measured in this test method are

3.2 Definitions of Terms Specific to This Standard:

dish, wavy edges, buckle, longitudinal corrugation, and her-

3.2.1 edge wave (see wavy edge), n—acontinuouspatternof

ringbone.

waves or wrinkles along the edges of the strip, with a relatively

1.3 This test method is not intended to include the measure-

flat center portion.

ment of coil set or longitudinal curl, camber or edgewise

curvature, or twist.

4. Summary of Test Method

1.4 This test method is limited to metal strip 0.003 to 0.020

4.1 A prepared test specimen of a specific wrought copper

in. (0.08 to 0.50 mm) thick and not more than 6.0 in. (150.0

or copper alloy sheet or strip of a predetermined thickness is

mm) wide.

placed on a surface plate. The relative flatness of the sample is

1.5 Units—The values stated in inch-pound units are to be determined by measuring length and height of the irregularity

regarded as standard. The values given in parentheses are and calculating percent of deviation.

mathematical conversions to SI units which are provided for

5. Significance and Use

information only and are not considered standard.

1.6 The following safety hazard caveat pertains only to the 5.1 This test method is intended for measuring distortion in

strip used for making close tolerance parts. Since distortion in

testmethod(s)describedinthistestmethod. This standard does

not purport to address all of the safety concerns, if any, this strip would influence the shape of the part being produced

and cause difficulties in feeding through close-fitting dies and

associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices other manufacturing equipment, it is important that this mate-

rial be flat.

and determine the applicability of regulatory limitations prior

to use.

5.2 This test method provides a universal procedure for

measuring the irregularities that cause the deviation from

2. Referenced Documents

flatness.

2.1 ASTM Standards:

5.3 This test method allows the purchaser and manufacturer

B846 Terminology for Copper and Copper Alloys

to inspect strip with a standard technique to a mutually agreed

upon and acceptable percentage deviation from flatness.

This test method is under the jurisdiction ofASTM Committee B05 on Copper

6. Apparatus

and Copper Alloys and is the direct responsibility of Subcommittee B05.06 on

Methods of Test.

6.1 Surface Plate,tobeusedasareferenceflat.Itmusthave

Current edition approved May 1, 2015. Published May 2015. Originally

alargeenoughsurfaceareatoaccommodatethemaximumsize

approved in 1986. Last previous edition approved 2010 as B754 – 10. DOI:

test specimen. It shall be flat within 0.0002 in. (0.005 mm) per

10.1520/B0754-10R15E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 1 in. (25 mm).

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.2 Micrometer, for measuring metal thickness. It shall be

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. graduated in 0.0001-in. (0.0025-mm) increments.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

B754 − 10 (2015)

6.3 Height Gage, for measuring the height of irregularities. 8.5 Repeat this procedure as often as necessary to satisfy

Thearmofthisgagemustbelongenoughtoextendbeyondthe quality level requiremen

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: B754 − 10 B754 − 10 (Reapproved 2015)

Standard Test Method for

Measuring and Recording the Deviations from Flatness in

Copper and Copper Alloy Strip

This standard is issued under the fixed designation B754; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial changes were made in 1.1, 1.5 and 2.1 in May 2015.

1. Scope*

1.1 This test method describesestablishes a procedure for the measurement of distortions in thin metal strip and the application

of these measurements to an equation that will indicate the deviation from flatness.

1.2 The distortions to be measured in this test method are dish, wavy edges, buckle, longitudinal corrugation, and herringbone.

1.3 This test method is not intended to include the measurement of coil set or longitudinal curl, camber or edgewise curvature,

or twist.

1.4 This test method is limited to metal strip 0.003 to 0.020 in. (0.08 to 0.50 mm) thick and not more than 6.0 in. (150.0 mm)

wide.

1.5 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are

mathematical conversions to SI units thatwhich are provided for information only and are not considered standard.

1.6 The following safety hazard caveat pertains only to the test method(s) described in this test method. This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

B846 Terminology for Copper and Copper Alloys

B950 Guide for Editorial Procedures and Form of Product Specifications for Copper and Copper Alloys

3. Terminology

3.1 For determination of terms relating to copper and copper alloys, refer to Terminology B846.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 edge wave (see wavy edge), n—a continuous pattern of waves or wrinkles along the edges of the strip, with a relatively

flat center portion.

4. Summary of Test Method

4.1 A prepared test specimen of a specific wrought copper or copper alloy sheet or strip of a predetermined thickness is placed

on a surface plate. The relative flatness of the sample is determined by measuring length and height of the irregularity and

calculating percent of deviation.

5. Significance and Use

5.1 This test method is intended for measuring distortion in strip used for making close tolerance parts. Since distortion in this

strip would influence the shape of the part being produced and cause difficulties in feeding through close-fitting dies and other

manufacturing equipment, it is important that this material be flat.

This test method is under the jurisdiction of ASTM Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.06 on Methods

of Test.

Current edition approved Oct. 1, 2010May 1, 2015. Published November 2010May 2015. Originally approved in 1986. Last previous edition approved 20052010 as

B754 – 89B754 – 10. (2005). DOI: 10.1520/B0754-10.10.1520/B0754-10R15E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

B754 − 10 (2015)

5.2 This test method provides a universal procedure for measuring the irregularities that cause the deviation from flatness.

5.3 This test method allows the purchaser and manufacturer to inspect strip with a standard technique to a mutually agreed upon

and acceptable percentage deviation from flatness.

6. Apparatus

6.1 Surface Plate, to be used as a reference flat. It must have a large enough surface area to accommodate the maximum size

test specimen. It shall be flat within 0.0002 in. (0.005 mm) per 1 in. (25 mm).

6.2 Micrometer, for measuring metal thickness. It shall be graduated in 0.0001-in. (0.0025-mm) increments.

6.3 Height Gage, for measuring the height of irregularities. The arm of this gage must be long enough to extend beyond the

ce

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.