ASTM F1249-13

(Test Method)Standard Test Method for Water Vapor Transmission Rate Through Plastic Film and Sheeting Using a Modulated Infrared Sensor

Standard Test Method for Water Vapor Transmission Rate Through Plastic Film and Sheeting Using a Modulated Infrared Sensor

SIGNIFICANCE AND USE

5.1 The purpose of this test method is to obtain reliable values for the WVTR of plastic film and sheeting.

5.2 WVTR is an important property of packaging materials and can be directly related to shelf life and packaged product stability.

5.3 Data from this test method is suitable as a referee method of testing, provided that the purchaser and seller have agreed on sampling procedures, standardization procedures, test conditions, and acceptance criteria.

SCOPE

1.1 This test method covers a procedure for determining the rate of water vapor transmission through flexible barrier materials. The method is applicable to sheets and films up to 3 mm (0.1 in.) in thickness, consisting of single or multilayer synthetic or natural polymers and foils, including coated materials. It provides for the determination of (1) water vapor transmission rate (WVTR), (2) the permeance of the film to water vapor, and (3) for homogeneous materials, water vapor permeability coefficient. Note 1—Values for water vapor permeance and water vapor permeability must be used with caution. The inverse relationship of WVTR to thickness and the direct relationship of WVTR to the partial pressure differential of water vapor may not always apply.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1249 − 13

Standard Test Method for

Water Vapor Transmission Rate Through Plastic Film and

1

Sheeting Using a Modulated Infrared Sensor

This standard is issued under the fixed designation F1249; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E178 Practice for Dealing With Outlying Observations

E691 Practice for Conducting an Interlaboratory Study to

1.1 This test method covers a procedure for determining the

Determine the Precision of a Test Method

rate of water vapor transmission through flexible barrier

materials. The method is applicable to sheets and films up to 3

3. Terminology

mm (0.1 in.) in thickness, consisting of single or multilayer

synthetic or natural polymers and foils, including coated

3.1 Definitions:

materials. It provides for the determination of (1) water vapor

3.1.1 water vapor permeability coeffıcient—the product of

transmission rate (WVTR), (2) the permeance of the film to

the permeance and the thickness of the film. The permeability

water vapor, and (3) for homogeneous materials, water vapor

is meaningful only for homogeneous materials, in which case

permeability coefficient.

it is a property characteristic of bulk material.

3.1.1.1 Discussion—This quantity should not be used unless

NOTE 1—Values for water vapor permeance and water vapor perme-

ability must be used with caution. The inverse relationship of WVTR to the relationship between thickness and permeance has been

thickness and the direct relationship of WVTR to the partial pressure

verified in tests using several thicknesses of the material. An

differential of water vapor may not always apply.

accepted unit of permeability is the metric perm centimeter, or

2

1.2 This standard does not purport to address all of the

1 g/m per day per mm Hg·cm of thickness. The SI unit is the

2

safety concerns, if any, associated with its use. It is the

mol/m ·s·Pa·mm. The test conditions (see 3.1) must be stated.

responsibility of the user of this standard to establish appro-

3.1.2 water vapor permeance—the ratio of a barrier’s

priate safety and health practices and determine the applica-

WVTR to the vapor pressure difference between the two

bility of regulatory limitations prior to use.

surfaces.

3.1.2.1 Discussion—An accepted unit of permeance is the

2. Referenced Documents

2

metric perm, or 1 g/m per day per mm Hg. The SI unit is the

2

2.1 ASTM Standards: 2

mol/m ·s·Pa. Since the permeance of a specimen is generally a

D374 Test Methods for Thickness of Solid Electrical Insu-

function of relative humidity and temperature, the test condi-

3

lation (Withdrawn 2013)

tions must be stated.

3

D1898 Practice for Sampling of Plastics (Withdrawn 1998)

3.1.3 water vapor transmission rate (WVTR)—the time rate

E96/E96M Test Methods for Water Vapor Transmission of

of water vapor flow normal to the surfaces, under steady-state

Materials

conditions, per unit area.

E104 Practice for Maintaining Constant Relative Humidity

2

3.1.3.1 Discussion—An accepted unit of WVTR is g/m per

by Means of Aqueous Solutions

day. The test conditions of relative humidity and temperature

E177 Practice for Use of the Terms Precision and Bias in

where the humidity is the difference in relative humidity across

ASTM Test Methods

the specimens, must be stated.

1

This test method is under the jurisdiction ofASTM Committee F02 on Flexible

4. Summary of Test Method

Barrier Packaging and is the direct responsibility of Subcommittee F02.10 on

Permeation.

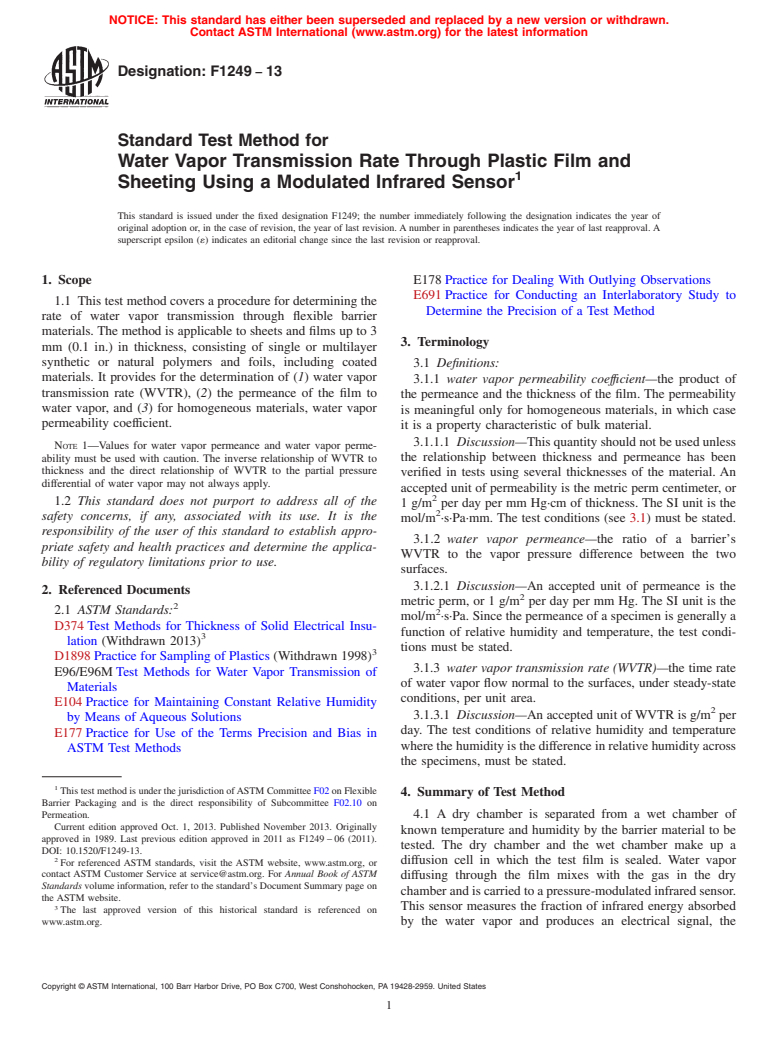

4.1 A dry chamber is separated from a wet chamber of

Current edition approved Oct. 1, 2013. Published November 2013. Originally

known temperature and humidity by the barrier material to be

approved in 1989. Last previous edition approved in 2011 as F1249 – 06 (2011).

tested. The dry chamber and the wet chamber make up a

DOI: 10.1520/F1249-13.

2

diffusion cell in which the test film is sealed. Water vapor

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

diffusing through the film mixes with the gas in the dry

Standards volume information, refer to the standard’s Document Summary page on

chamberandiscarriedtoapressure-modulatedinfraredsensor.

the ASTM website.

3

This sensor measures the fraction of infrared energy absorbed

The last approved version of this historical standard is referenced on

www.astm.org. by the water vapor and produces an electrical signal, the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1249 − 06 (Reapproved 2011) F1249 − 13

Standard Test Method for

Water Vapor Transmission Rate Through Plastic Film and

1

Sheeting Using a Modulated Infrared Sensor

This standard is issued under the fixed designation F1249; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a procedure for determining the rate of water vapor transmission through flexible barrier materials.

The method is applicable to sheets and films up to 3 mm (0.1 in.) in thickness, consisting of single or multilayer synthetic or natural

polymers and foils, including coated materials. It provides for the determination of (1) water vapor transmission rate (WVTR), (2)

the permeance of the film to water vapor, and (3) for homogeneous materials, water vapor permeability coefficient.

NOTE 1—Values for water vapor permeance and water vapor permeability must be used with caution. The inverse relationship of WVTR to thickness

and the direct relationship of WVTR to the partial pressure differential of water vapor may not always apply.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

3

D374 Test Methods for Thickness of Solid Electrical Insulation (Withdrawn 2013)

3

D1898 Practice for Sampling of Plastics (Withdrawn 1998)

E96/E96M Test Methods for Water Vapor Transmission of Materials

E104 Practice for Maintaining Constant Relative Humidity by Means of Aqueous Solutions

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E178 Practice for Dealing With Outlying Observations

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions:

3.1.1 water vapor permeability coeffıcient—the product of the permeance and the thickness of the film. The permeability is

meaningful only for homogeneous materials, in which case it is a property characteristic of bulk material.

1

This test method is under the jurisdiction of ASTM Committee F02 on Flexible Barrier Packaging and is the direct responsibility of Subcommittee F02.10 on Permeation.

Current edition approved Aug. 1, 2011Oct. 1, 2013. Published November 2011November 2013. Originally approved in 1989. Last previous edition approved in 20062011

as F1249 – 06.F1249 – 06 (2011). DOI: 10.1520/F1249-06R11.10.1520/F1249-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

3.1.1.1 Discussion—

This quantity should not be used unless the relationship between thickness and permeance has been verified in tests using several

2

thicknesses of the material. An accepted unit of permeability is the metric perm centimeter, or 1 g/m per day per mm Hg·cm of

2

thickness. The SI unit is the mol/m ·s·Pa·mm. The test conditions (see 3.1) must be stated.

3.1.2 water vapor permeance—the ratio of a barrier’s WVTR to the vapor pressure difference between the two surfaces.

3.1.2.1 Discussion—

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1249 − 13

2 2

An accepted unit of permeance is the metric perm, or 1 g/m per day per mm Hg. The SI unit is the mol/m ·s·Pa. Since the

permeance of a specimen is generally a function of relative humidity and temperature, the test conditions must be stated.

3.1.3 water vapor transmission rate (WVTR)—the time rate of water vapor flow normal to the surfaces, under steady-state

conditions, per unit area.

3.1.3.1 Discussion—

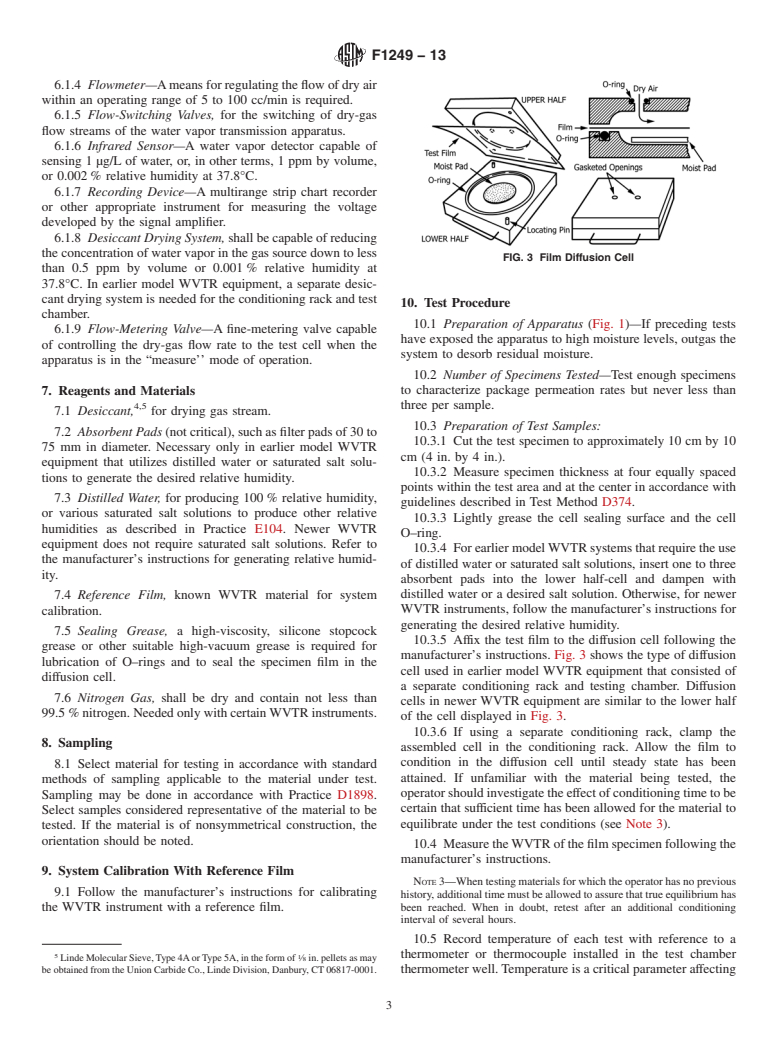

FIG. 1 Measuring System

2

An accepted unit of WVTR is g/m per day. The test conditions of relative humidity and temperature where the humidity is the

difference in relative humidity across the specimens, must be stated.

4. Summary of Test Method

4.1 A dry chamber is separated from a wet chamber

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.