ASTM A470-99

(Specification)Standard Specification for Vacuum-Treated Carbon and Alloy Steel Forgings For Turbine Rotors and Shafts

Standard Specification for Vacuum-Treated Carbon and Alloy Steel Forgings For Turbine Rotors and Shafts

SCOPE

1.1 This specification covers vacuum-treated carbon and alloy steel forgings for turbine rotors and shafts.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 470 – 99 An American National Standard

Standard Specification for

Vacuum-Treated Carbon and Alloy Steel Forgings For

Turbine Rotors and Shafts

This standard is issued under the fixed designation A 470; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.3 Forging Drawing—Each forging shall be manufactured

in accordance with a drawing furnished by the purchaser

1.1 This specification covers vacuum-treated carbon and

showing the dimensions of the forging and bore hole, if any,

alloy steel forgings for turbine rotors and shafts.

and the location of mechanical test specimens.

1.2 The values stated in inch-pound units are to be regarded

3.4 Supplementary Requirements—Supplementary require-

as the standard. The values given in parentheses are for

ments are provided. These requirements shall apply only when

information only.

specified in the purchase order.

2. Referenced Documents

3.5 If the requirements of this specification are in conflict

with the requirements of Specification A 788, the requirements

2.1 ASTM Standards:

of this specification shall prevail.

A 275/A 275M Test Method for Magnetic Particle Exami-

nation of Steel Forgings

4. Manufacture

A 370 Test Methods and Definitions for Mechanical Testing

4.1 Melting Process:

of Steel Products

4.1.1 The steel shall be made by the basic electric-furnace

A 418 Test Method for Ultrasonic Examination of Turbine

process.

and Generator Steel Rotor Forgings

4.1.2 Provisions for subsequent secondary melting of the

A 472 Test Method for Heat Stability of Steam Turbine

steel by the consumable electrode-electroslag or vacuum-arc

Shafts and Rotor Forgings

remelting processes are included in Supplementary Require-

A 751 Test Methods, Practices and Terminology for Chemi-

3 ment S7.

cal Analysis of Steel Products

4.2 Vacuum Treatment—The vacuum degassing require-

A 788 Specification for Steel Forgings, General Require-

2 ments of Specification A 788 are mandatory.

ments

4.3 Discard—Sufficient discard shall be taken from each

E 139 Test Methods for Conducting Creep, Creep-Rupture,

4 ingot to secure freedom from pipe and harmful segregation in

and Stress-Rupture Tests of Metallic Materials

the finished forging.

3. Ordering Information and General Requirements 4.4 Forging Process—The forging shall receive its hot

mechanical work under a press of ample power to adequately

3.1 Material supplied to this specification shall conform to

work the metal throughout the maximum section of the

the requirements of Specification A 788, which outlines addi-

forging. It is important to maintain the axial center of the

tional ordering information, manufacturing methods and pro-

forging in common with the axial center of the ingot.

cedures, marking, certification, production analysis variations,

4.5 Heat Treatment:

and additional supplementary requirements.

4.5.1 After forging and before reheating for heat treatment

3.2 In addition to the ordering information required by

for mechanical properties, the forging shall be allowed to cool

Specification A 788, the purchaser shall include with the

in a manner designed to prevent injury and accomplish

inquiry and order, the class of steel, the choice of yield strength

transformation.

offset (0.2 or 0.02 %) and any tests, supplementary require-

4.5.2 The heat treatment for mechanical properties shall

ments, and purchase options desired.

consist of double-normalizing and tempering for Classes 2, 3,

4, 8, and 9 and normalizing, quenching, and tempering for

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

Classes 5, 6, and 7. In normalizing treatments, the forging may

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

be cooled in still air or in an air blast at the manufacturer’s

A01.06 on Steel Forgings and Billets.

option. Faster cooling rates for Classes 2, 3, 4, 8, and 9 may be

Current edition approved Oct. 10, 1999. Published December 1999. Originally

published as A 470–62T. Last previous edition A 470–98.

used if authorized by the purchaser. These rates are obtained by

Annual Book of ASTM Standards, Vol 01.05.

liquid quenching, or by the addition of water sprays of fog to

Annual Book of ASTM Standards, Vol 01.03.

the air blast.

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 470

4.5.2.1 The first normalizing treatment shall be from well 4.6.2 Second Rough Machining—After heat treatment for

above the transformation temperature range. At the manufac- mechanical properties, all surfaces of the forging shall be rough

turer’s option, this operation may be performed as a part of the machined prior to stress relief and the stability test.

preliminary treatment of the forging before preliminary ma- 4.6.3 Axial Bore:

chining (see 4.6.1). 4.6.3.1 Forgings shall be bored to permissible bore size and

4.5.2.2 The second normalizing or quenching treatment tolerance when required by the purchaser’s drawing.

shall be from above the transformation range but below the first 4.6.3.2 Forgings may be bored to limits agreed to by the

normalizing temperature described in 4.5.2.1. This treatment purchaser or indicated on the purchaser’s drawing, to remove

shall be performed after preliminary machining (see 4.6.1). objectionable center conditions revealed by ultrasonic exami-

4.5.2.3 The final tempering temperature for Classes 2 to 7 nation.

and Class 9 shall be not less than 1075°F (580°C) and for Class 4.6.3.3 Unless otherwise specified by the purchaser, the

8 not less than 1200°F (650°C). With prior purchaser approval, manufacturer may bore the forging at any time prior to stress

a second tempering operation shall be performed prior to the relief (see Supplementary Requirement S2).

operations described in 4.6.2 and 4.6.3 to complete the heat 4.6.4 Machining to Purchaser’s Requirements for

treatment cycle. This second temper will be in place of the Shipment—The forging as shipped shall conform to the finish

stress relief specified in 4.5.2.4 and 4.5.2.5 and the tempera- and dimension requirements specified on the purchaser’s

tures applied to the second temper will meet the temperature drawing or order.

limits in 4.5.2.4. However, with the prior approval of the

5. Chemical Composition

purchaser, the second tempering temperature may approach,

equal or slightly exceed the first tempering temperature as a 5.1 The steel shall conform to the requirements for chemical

means of adjusting final strength or toughness. The required composition prescribed in Table 1.

tests for mechanical properties shall be made after the second 5.2 Chemical Analysis:

tempering operation. Mechanical property tests after the first 5.2.1 Heat Analysis—An analysis of each heat of steel shall

temper are optional with the manufacturer. be made by the manufacturer to determine the percentages of

4.5.2.4 After heat treatment and subsequent rough machin- the elements specified in Table 1. This analysis shall be made

ing and axial boring (see 4.6.2 and 4.6.3), the forging shall be from a test specimen preferably taken during the pouring of the

stress-relieved at a temperature not more than 100°F (55°C) heat. For forgings made from more than one heat, both

below the final tempering temperature, but not less than individual heat analyses (when appropriate for the process) and

1025°F (550°C). a weighted average analysis shall be reported. In this case, the

4.5.2.5 With the prior approval of the purchaser, the stress- weighted average analysis of the component heats shall con-

relief temperature may approach, equal, or slightly exceed the form to Table 1.

final tempering temperature as a means of adjusting final 5.2.1.1 If the test specimen taken for the heat analysis is lost

strength or toughness. If the stress-relief temperature is within or declared inadequate for chemical determinations, the manu-

25°F (14°C) of the final tempering temperature, or higher, facturer may take alternative specimens from appropriate

additional tension tests must be obtained (6.1.3). locations near the surface of the ingot or forging as necessary

4.6 Machining: to establish the analysis of the heat in question. Location and

depth of the alternative specimens shall be reported to the

4.6.1 Preliminary Rough Machining—All exterior surfaces

of the forging shall be machined prior to heat treatment for purchaser along with the chemical analysis.

5.2.2 Product Analysis—The manufacturer shall make a

mechanical properties.

TABLE 1 Chemical Requirements

Composition, %

Class 2, 3, and 4 Classes 5, 6, and 7 Class 8 Class 9

Carbon 0.22–0.30 0.28 max 0.25–0.35 0.30 max

Manganese 0.20–0.60 0.20–0.60 1.00 max 0.70 max

Phosphorus, max 0.012 0.012 0.012 0.025

Sulfur, max 0.012 0.015 0.015 0.025

A B

Silicon 0.15–0.30 0.10 max 0.15–0.35 0.15–0.35

Nickel 3.20–3.70 3.25–4.00 0.75 max 2.00 min

Chromium 0.75 max 1.25–2.00 1.05–1.50 0.75 max

C

Molybdenum 0.40–0.60 0.25–0.60 1.00–1.50 0.25 min

D

Vanadium 0.04–0.012 0.05–0.15 0.20–0.30 0.03–0.12

EEEE

Antimony

F

Equivalent . . Classes 2 and 3

Specification A 293

Grade Designation (replaced by

Specification A 470)

A

Optional: Classes 2 to 4, incl, and 9 may be vacuum-carbon deoxidized, silicon 0.10 max. For Class 8 see Supplementary Requirement S6.

B

0.15 to 0.30 % silicon is permitted for material that is subsequently VAR Processed.

C

Supplementary Requirement, see S1.

D

Vanadium addition optional for Class 1.

E

To be reported for information only on Classes 2 through 9, incl.

F

Phosphorus of 0.035 max and sulfur of 0.035 max were specified for Specification A 293.

A 470

product analysis from each forging. The sample location and 6.2.3 The impact tests shall be performed in accordance

product analysis tolerances shall conform to Specification with the section on Charpy impact testing of Test Methods and

A 788. Definitions A 370.

5.3 Referee Analysis—Test Methods, Practices and Termi- 6.3 The properties at the axial bore region may not neces-

nology A 751 shall be used for referee purposes. sarily be the same as those determined at the surface radial or

axial prolongation regions. Slight variations in chemical ho-

6. Mechanical Properties

mogeneity, different cooling rates, presence of non-metallics,

6.1 Tension Test:

and orientation of the test samples are some of the factors that

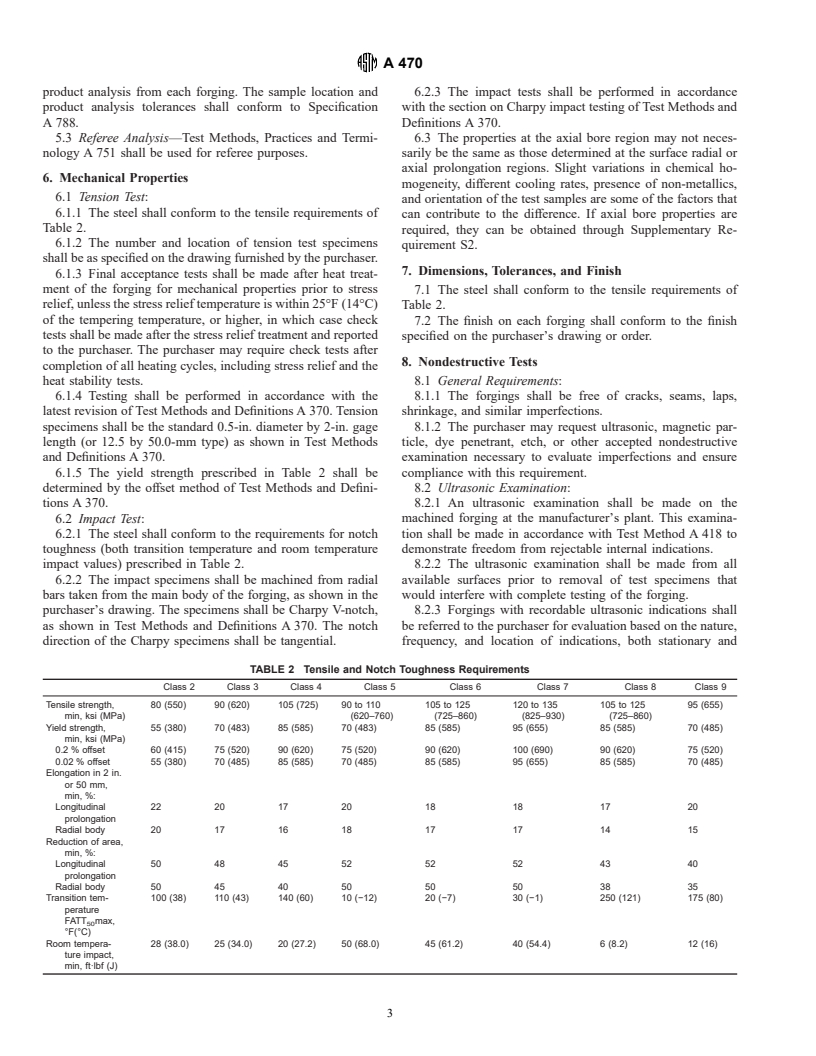

6.1.1 The steel shall conform to the tensile requirements of

can contribute to the difference. If axial bore properties are

Table 2.

required, they can be obtained through Supplementary Re-

6.1.2 The number and location of tension test specimens

quirement S2.

shall be as specified on the drawing furnished by the purchaser.

7. Dimensions, Tolerances, and Finish

6.1.3 Final acceptance tests shall be made after heat treat-

ment of the forging for mechanical properties prior to stress

7.1 The steel shall conform to the tensile requirements of

relief, unless the stress relief temperature is within 25°F (14°C) Table 2.

of the tempering temperature, or higher, in which case check

7.2 The finish on each forging shall conform to the finish

tests shall be made after the stress relief treatment and reported specified on the purchaser’s drawing or order.

to the purchaser. The purchaser may require check tests after

8. Nondestructive Tests

completion of all heating cycles, including stress relief and the

heat stability tests. 8.1 General Requirements:

6.1.4 Testing shall be performed in accordance with the 8.1.1 The forgings shall be free of cracks, seams, laps,

latest revision of Test Methods and Definitions A 370. Tension shrinkage, and similar imperfections.

specimens shall be the standard 0.5-in. diameter by 2-in. gage 8.1.2 The purchaser may request ultrasonic, magnetic par-

length (or 12.5 by 50.0-mm type) as shown in Test Methods ticle, dye penetrant, etch, or other accepted nondestructive

and Definitions A 370. examination necessary to evaluate imperfections and ensure

6.1.5 The yield strength prescribed in Table 2 shall be compliance with this requirement.

determined by the offset method of Test Methods and Defini- 8.2 Ultrasonic Examination:

tions A 370. 8.2.1 An ultrasonic examination shall be made on the

6.2 Impact Test: machined forging at the manufacturer’s plant. This examina-

6.2.1 The steel shall conform to the requirements for notch tion shall be made in accordance with Test Method A 418 to

toughness (both transition temperature and room temperature demonstrate freedom from rejectable internal indications.

impact values) prescribed in Table 2. 8.2.2 The ultrasonic examination shall be made from all

6.2.2 The impact specimens shall be machined from radial available surfaces prior to removal of test specimens that

bars taken from the main body of the forging, as shown in the would interfere with complete testing of the forging.

purchaser’s drawing. The specimens shall be Charpy V-notch, 8.2.3 Forgings with recordable ultrasonic indications shall

as shown in Test Methods and Definitions A 370. The notch be referred to the purchaser for evaluation based on the nature,

direction of the Charpy specimens shall be tangential. frequency, and location of indications, both stationary and

TABLE 2 Tensile and Notch Toughness Requirements

Class 2 Class 3 Class 4 Class 5 Class 6 Class 7 Class 8 Class 9

Tensile strength, 80 (550) 90 (620) 105 (725) 90 to 110 105 to 125 120 to 135 105 to 125 95 (655)

min, ksi (MPa) (620–760) (725–860) (825–930) (725–860)

Yield strength, 55 (380) 70 (483) 85 (585) 70 (483) 85 (585) 95 (655) 85 (585) 70 (485)

min, ksi (MPa)

0.2 % offset 60 (415) 75 (520) 90 (620) 75 (520) 90 (620) 100 (690) 90 (620) 75 (520)

0.02 % offset 55 (380) 70 (485) 85 (585) 70 (485) 85 (585) 95 (655) 85 (585) 70 (485)

Elongation in 2 in.

or 50 mm,

min, %:

Longitudinal 22 20 17 20 18 18 17 20

prolongation

Radial body 20 17 16 18 17 17 14 15

Reduction of area,

min, %:

Longitudinal 50 48 45 52 52 52 43 40

prolongation

Radial body 50 45 40 50 50 50 38 35

Transition tem- 100 (38) 110 (43) 140 (60) 10 (−12) 20 (−7) 30 (−1) 250 (121) 175 (80)

perature

FATT max,

°F(°C)

Room tempera- 28 (38.0) 25 (34.0) 20 (27.2) 50 (68.0) 45 (61.2) 40 (54.4) 6 (8.2) 12 (16)

ture impact,

min, ft·lbf (J)

A 470

traveling. If the ultrasonic indications are considered objection- ing portions of the bore core in the bore of the forging shall be

able, it sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.