ASTM E2014-99(2005)

(Guide)Standard Guide on Metallographic Laboratory Safety

Standard Guide on Metallographic Laboratory Safety

SCOPE

1.1 This guide covers the outline of the basic safety guidelines to be used in a metallographic laboratory. Safe working habits are discussed for various tasks performed in a metallographic laboratory.

1.2 The sections appear in the following order:

This guide does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2014–99 (Reapproved 2005)

Standard Guide on

Metallographic Laboratory Safety

This standard is issued under the fixed designation E2014; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E1558 Guide for Electrolytic Polishing of Metallographic

Specimens

1.1 This guide covers the outline of the basic safety guide-

lines to be used in a metallographic laboratory. Safe working

3. Terminology

habits are discussed for various tasks performed in a metallo-

3.1 Definitions—All terms used in this guide are either

graphic laboratory.

defined in Terminology E7 or are discussed in 3.2.

1.2 The sections appear in the following order:

3.2 Definitions of Terms Specific to This Standard:

Section

3.2.1 agreement state—a government body that has been

Scope 1

Referenced Documents 2

granted regulatory authority over by-product materials and

Terminology 3

radiation-producing devices by the United States Nuclear

Significance and Use 4

Regulatory Commission (USNRC).

Heat Treating 5

Specimen Preparation/Sectioning 6

Specimen Mounting 7

4. Significance and Use

Mechanical Grinding/Polishing 8

4.1 This guide is intended as a summary of safety practices

Chemical Safety 9

Electrolytic Polishing/Etching 10

in the metallography laboratory. It can be used as a training

Sulfur Printing 11

manual for those new to the field of metallography and as a

Laboratory Ventilation/Fume Hoods 12

refresher to those who are experienced.

Chemical Spills 13

Photography 14

4.2 This guide is not intended to be inclusive of all safety

X ray/Electron Microscopy 15

concerns encountered in a metallographic laboratory. Several

Keywords 16

books that provide safety information are available (1-16).

1.3 This guide does not purport to address all of the safety

4.3 Before operating any equipment, it is advisable to read

concerns, if any, associated with its use. It is the responsibility

and understand the accompanying manuals and to follow any

of the user of this standard to establish appropriate safety and

specified safety guidelines.

health practices and determine the applicability of regulatory

4.4 Materialsafetydatasheets(MSDS)forchemicalsbeing

limitations prior to use.

used in a laboratory should be on file and readily accessible.

Whenworkingwithanychemicals,especiallyforthefirsttime,

2. Referenced Documents

oneshouldreviewtheMSDSsuppliedbythemanufacturerand

2.1 ASTM Standards:

follow any safety guidelines suggested. The most current and

E3 Guide for Preparation of Metallographic Specimens

applicable MSDS should be on file for a given product or

E7 Terminology Relating to Metallography

chemical.

E340 Test Method for Macroetching Metals and Alloys

E407 Practice for Microetching Metals and Alloys 5. Heat Treating

E883 Guide for Reflected−Light Photomicrography

5.1 Personal Protective Equipment, should be utilized. The

E1180 Practice for Preparing Sulfur Prints for Macrostruc-

minimum protection should include safety shoes, safety

tural Evaluation

glasses, and heat resistant gloves. When utilizing furnaces at

high temperatures (>1900°C), a heat resistant suit and face

shield should be used in addition to gloves and glasses.

ThisguideisunderthejurisdictionofASTMCommitteeE04onMetallography 5.2 Furnace Load Weights—The weight limit that can be

and is the direct responsibility of Subcommittee E04.17 on Criteria for Metallo-

safely loaded and unloaded manually into a furnace at tem-

graphic Laboratory Evaluation and Safety.

perature should be established by the laboratory manager. The

Current edition approved Nov. 1, 2005. Published November 2005. Originally

weight limit for manual loading should be determined for

approved in 1999. Last previous edition approved in 1999 as E2014–99. DOI:

10.1520/E2014-99R05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

the ASTM website. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2014–99 (2005)

TABLE 1 A Summary of Recommended and Discourage

specific procedures. This may be increased or decreased

Practices When Heat treating

depending on availability of equipment to aid in loading or

Recommended Practice Discouraged Practice

unloading material; configuration of samples, which could

Develop SOPs and JSAs Lift specimens$ 10 kg

make loading and unloading more or less dangerous; or the

Wear

ability to utilize more than one heat treating technician in

safety shoes Lean body over bath

loading and unloading, or combination thereof.

safety glasses or face shield

heat resistant gloves Leave tank contents uncovered

5.3 Furnace Loading and Unloading—When working with

Use tongs, tray, or wire basket when

a furnace that requires a removal of a thermocouple prior to

handling samples Contact electrodes with conductive

Keep specimens and surrounding material

loading, care should be taken to handle the thermocouple with

area free of moisture and debris

heat resistant gloves or tongs.

5.3.1 Materialshouldbeloadedintothefurnacewithtongs.

The tongs used should have the proper configuration for the

6. Specimen Preparation/Sectioning (17)

specimen to be loaded. Tongs should be properly maintained.

6.1 Safety glasses should always be worn when operating

5.3.2 When several small or oddly shaped specimens are to

sectioning equipment. Ties, loose fitting clothing, and jewelry

beheattreated,atrayorwirebasketmayfacilitateloadingand

can become tangled in the moving parts of equipment and

unloading. should not be worn.

6.2 The cutting blade of a bandsaw is exposed and can be

5.3.3 The surface of an oil quench bath can ignite during

dangerous.Aguiding device, such as a block of wood, should

quenching. Caution should be taken to avoid being burnt. Do

be used to maneuver the specimen, thereby, reducing the

not lean over the oil quench tank when pieces are being

possibility of hand injury.

quenched, and cover the tank as quickly as possible to

6.3 The major danger from abrasive saw operations is from

extinguish the flames.

flying debris from a broken wheel. This danger is normally

5.4 Salt bath furnaces should be set up in accordance with

eliminated in modern equipment by shielding the cutting area

the manufacturer’s instructions, along with state and local

from the operator. A cutoff saw should never be operated

environmental regulations. Exhaust systems are required for

without a shield in place.

gases generated. Some states may regulate exhaust system

6.4 Sectioning often results in the formation of burrs on the

specifications.

edges of the specimen. These burrs can be quite sharp and

5.4.1 Personal protective equipment should include a heat potentially dangerous. The burrs should be carefully removed

resistant apron, sleeve protection, safety glasses, safety shoes, by filing or grinding.

6.5 Wet grinding is always preferred over dry grinding

and face shield.

because of the reduced amount of dust and reduced heat

5.4.2 The start up of a salt bath should be performed by a

damage to the specimen. The dusts generated from grinding

properly trained technician.

any metal are a health hazard. Those generated by grinding

5.4.3 When long cycles with little attention are performed,

materials,suchasberyllium,magnesium,lead,manganese,and

thetemperaturecontroldevicesshouldhavealarmswithlimits

silver, are extremely toxic. These materials should be ground

and shutdown capability.

wet under a ventilation hood, and a face mask should be worn.

5.4.4 Keep all water or moisture away from and out of the

6.6 A SOP, including a JSA, should be completed for each

saltbath.Cleanthepiecestoremovecuttingfluidsoranyother

piece of equipment being used while sectioning or preparing

residuals. After cleaning, dry all the pieces thoroughly. specimens,listinganypotentialhazardsanddescribingthesafe

operating procedure. Recommended procedures for the metal-

5.4.5 Clean and dry baskets before each use. Moisture may

lographic preparation of various materials can be found in

build up on the salt dried on the basket.

Methods E3.

5.4.6 To avoid shock, do not place metal, baskets, or

sludging tools between electrodes while power is on.

7. Specimen Mounting

5.4.7 Wear a face mask when filling furnace with dry salts.

7.1 The major safety concern while using either automatic

5.4.8 Keep work area clean. Do not keep boxes, pallets, or

or manual mounting presses involves the potential of burns

other highly flammable items in work area. Keep floors clean from contact with hot equipment or specimens. Operators

should wear insulated gloves to protect hands.

to avoid slips, trips, or falls.

7.2 Prolonged contact with many mounting materials can

5.4.9 Keep salt containers tightly closed to avoid moisture

cause irritation to the eyes and skin; gloves are recommended.

adsorption in dry salt.

Also prolonged exposure to the vapors and dust generated

5.4.10 Establish periodic checks and safe procedures for

during the mounting procedure is not recommended. Consult

electrodes, sludging, rectifying, and the use of graphite rods.

theproductlabelandMSDSofthespecificmountingmaterial,

5.5 A standard operating procedure (SOP), including a job

and use the protective equipment recommended.

safety analysis (JSA), should be completed for every heat

7.3 When using castable resins, work should be completed

treating practice performed, listing any potential hazards and

underafumehood.Thecorrosive,explosive,andcarcinogenic

describing the safe operating practice. A summary of recom-

properties vary widely with different castable resin compo-

mended safe practices can be found in Table 1. nents, and users should be aware of the most current and

E2014–99 (2005)

applicable MSDS information and occupational health and 9.3 The hazards involved with handling chemicals are

safetyissuesrelatingtoeachcomponentseparatelyandmixed. numerousandoftenspecifictothechemicalsbeingused.Users

7.4 A SOP, including a JSA, should be completed for each should be aware if there are dangers that are long term,

piece of equipment used for every mounting routine per- immediate, visible, invisible, and with or without odor.

formed.TheSOPshouldlistanypotentialhazardsanddescribe

9.4 Only small quantities should be mixed and stored in

the safe operating practice. glass-stoppered bottles filled to capacity. Exceptions include

fluorides and strong alkaline solutions, which should be stored

8. Mechanical Grinding/Polishing topolyethyleneoranotherappropriatecontainerrecommended

bythemanufacturerforthatspecificchemical.Anyevaporated

8.1 Injury to operator’s hands is a very common injury

solvents should be replaced to maintain a filled capacity.

received during grinding or polishing. For manual polishing,

9.5 Chemicals should always be protected from heat and

small or irregularly-shaped specimens should be mounted to

fire.

accommodate handling. For semi-automatic and automatic

9.6 Spent or exhausted chemicals should be disposed of

procedures, ensure that all moving parts have come to rest

promptly, following all applicable regulations.

before mounting or removing specimen holders or before

9.7 Specific Chemical Precautions—Paragraphs 9.7.1-

cleaning the equipment, or both.

9.7.13 list some specific safety situations that are often

8.2 When using grinding or polishing equipment, operators

encountered in a metallographic laboratory and known to be

should not wear ties, loose fitting jewelry, or loose fitting

dangerous.

clothing, which could become entangled with the equipment.

8.3 Some of the lubricating liquids and polishing suspen- 9.7.1 The addition of sulfuric acid to water produces an

extremely exothermic reaction. The solution must be cooled

sions used during grinding and polishing are flammable and

caution should be taken. The specific manufacturer’s product during mixing. While cooling, the acid must be slowly poured

in the water or solvent with constant stirring. Spattering of the

label and most current and applicable MSDS should be read

before it is used. solution must be avoided. Dilute solutions (anything less than

100% concentrated) of sulfuric acid strongly attack the skin,

8.4 A SOP, including a JSA, should be completed for all

mechanical grinding and polishing equipment, listing any are very hygroscopic, and vigorously attack most plastics.

potential hazards and describing the safe operating practice.

9.7.2 Theadditionofcrystallinechromiumtrioxidetowater

forms chromic acid, a strong oxidizing agent. The reaction

9. Chemical Safety liberates free oxygen, which can be incendiary in the presence

of oxidizable materials.

9.1 Beforeusingormixinganychemicals,allproductlabels

9.7.2.1 Chromic acid cannot be safely mixed with acetic

and pertinent and most current MSDS should be read and

acid or most organic liquids, such as alcohols or glycerol.

understood. The appropriate type of protective clothing will

9.7.2.2 Chromic acid solutions cannot be used in contact

dependonthetaskbeingperformed.Again,consulttheproduct

with plastic parts without their eventual destruction.

label and the most current and applicable MSDS for recom-

9.7.2.3 Care should be taken to prevent chromic acid

mendations concerning protective clothing.

contact with the skin since repeated exposure to even dilute

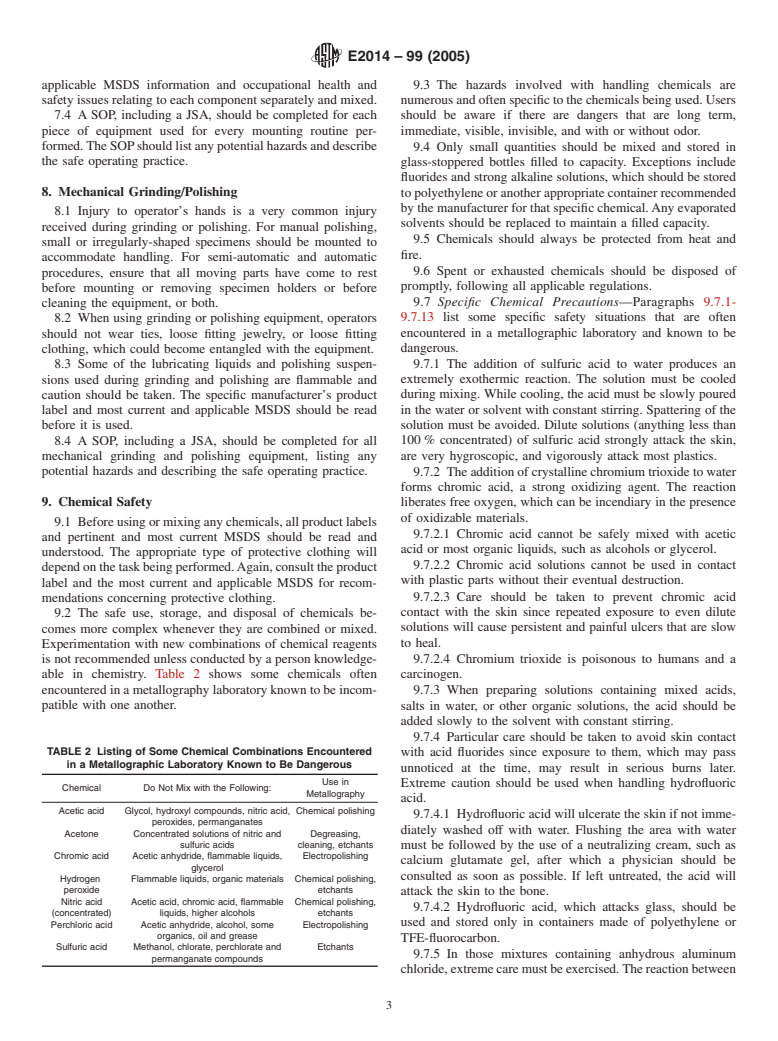

9.2 The safe use, storage, and disposal of chemicals be-

comes more complex whenever they are combined or mixed. solutions will cause persistent and painful ulcers that are slow

to heal.

Experimentation with new combinations of chemical reagents

is not recommended unless conducted by a person knowledge- 9.7.2.4 Chromium trioxide is poisonous to humans and a

able in chemistry. Table 2 shows some chemicals often carcinogen.

encounteredinametallographylaboratoryknowntobeincom-

9.7.3 When preparing solutions containing mixed acids,

patible with one another. salts in water, or other organic solutions, the acid should be

added slowly to the solvent with constant stirring.

9.7.4 Particular care should be taken to avoid skin contact

TABLE 2 Listing of Some Chemical Combinations Encountered with acid fluorides since exposure to them, which may pass

in a Metallographic Laboratory Known to Be Dangerous

unnoticed at the time, may result in serious burns later.

Use in

Extreme caution should be used when handling hydrofluoric

Chemical Do Not Mix with the Following:

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.