ASTM E2014-17

(Guide)Standard Guide on Metallographic Laboratory Safety

Standard Guide on Metallographic Laboratory Safety

SIGNIFICANCE AND USE

4.1 This guide is intended as a summary of safety practices in the metallography laboratory. It can be used as a training reference for those new to the field of metallography and as a refresher to those who are experienced.

4.2 This guide is not intended to be inclusive of all safety concerns encountered in a metallographic laboratory. Several books that provide safety information are available (1-15).5

4.3 Before operating any equipment, it is advisable to read and understand the accompanying manuals and to follow any specified safety guidelines.

4.4 Safety data sheets (SDS) for chemicals being used in a laboratory should be on file and readily accessible. When working with any chemicals, especially for the first time, one should review the SDS supplied by the manufacturer and follow any safety guidelines suggested. The most current and applicable SDS should be on file for a given product or chemical.

SCOPE

1.1 This guide outlines the basic safety guidelines to be used in a metallographic laboratory. Safe working habits are discussed for various tasks performed in a metallographic laboratory.

1.2 The sections appear in the following order:

Section

Scope

1

Referenced Documents

2

Terminology

3

Significance and Use

4

General

5

Heat Treating

6

Specimen Preparation/Sectioning

7

Specimen Mounting

8

Mechanical Grinding/Polishing

9

Chemical Safety

10

Electrolytic Polishing/Etching

11

Sulfur Printing

12

Laboratory Ventilation/Fume Hoods

13

Chemical Spills

14

Photography

15

X ray/Electron Microscopy

16

Laboratory Ergonomics

17

Disposal of Residues

18

Keywords

19

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2014 − 17

Standard Guide on

1

Metallographic Laboratory Safety

This standard is issued under the fixed designation E2014; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 Thisguideoutlinesthebasicsafetyguidelinestobeused 2.1 ASTM Standards:

in a metallographic laboratory. Safe working habits are dis- E3 Guide for Preparation of Metallographic Specimens

cussed for various tasks performed in a metallographic labo- E7 Terminology Relating to Metallography

ratory. E340 Practice for Macroetching Metals and Alloys

E407 Practice for Microetching Metals and Alloys

1.2 The sections appear in the following order:

E883 Guide for Reflected–Light Photomicrography

Section

E1180 Practice for Preparing Sulfur Prints for Macrostruc-

Scope 1

Referenced Documents 2 tural Evaluation

Terminology 3

E1558 Guide for Electrolytic Polishing of Metallographic

Significance and Use 4

Specimens

General 5

3

Heat Treating 6

2.2 ANSI Standard:

Specimen Preparation/Sectioning 7

ANSI/AIHA Z9.5 Laboratory Ventelation

Specimen Mounting 8

4

Mechanical Grinding/Polishing 9 2.3 NFPA Standard:

Chemical Safety 10

NFPA45 StandardonFireProtectionforLaboratoriesUsing

Electrolytic Polishing/Etching 11

Chemicals

Sulfur Printing 12

Laboratory Ventilation/Fume Hoods 13

NFPA 70E Standard for Electrical Safety in the Workplace

Chemical Spills 14

Photography 15

3. Terminology

X ray/Electron Microscopy 16

Laboratory Ergonomics 17

3.1 Definitions—All terms used in this guide are either

Disposal of Residues 18

defined in Terminology E7 or are discussed in 3.2.

Keywords 19

1.3 This standard does not purport to address all of the 3.2 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the 3.2.1 agreement state—a government body that has been

responsibility of the user of this standard to establish appro- granted regulatory authority over by-product materials and

priate safety, health, and environmental practices and deter- radiation-producing devices by the United States Nuclear

mine the applicability of regulatory limitations prior to use. Regulatory Commission (USNRC).

1.4 This international standard was developed in accor-

4. Significance and Use

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

4.1 This guide is intended as a summary of safety practices

Development of International Standards, Guides and Recom-

in the metallography laboratory. It can be used as a training

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

ThisguideisunderthejurisdictionofASTMCommitteeE04onMetallography the ASTM website.

3

and is the direct responsibility of Subcommittee E04.01 on Specimen Preparation. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

CurrenteditionapprovedJune1,2017.PublishedJuly2017.Originallyapproved 4th Floor, New York, NY 10036, http://www.ansi.org.

4

in 1999. Last previous edition approved in 2011 as E2014 – 11. DOI: 10.1520/ Available from National Fire Protection Association (NFPA), 1 Batterymarch

E2014-17. Park, Quincy, MA 02169-7471, http://www.nfpa.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2014 − 17

reference for those new to the field of metallography and as a availability of equipment to aid in loading or unloading

refresher to those who are experienced. material; configuration of samples, which could make loading

and unloading more or less risky; or the ability to utilize more

4.2 This guide is not intended to be inclusive of all safety

than one technician in loading and unloading, or combinations

concerns encountered in a metallographic laboratory. Several

5 thereof.

books that provide safety information are available (1-15).

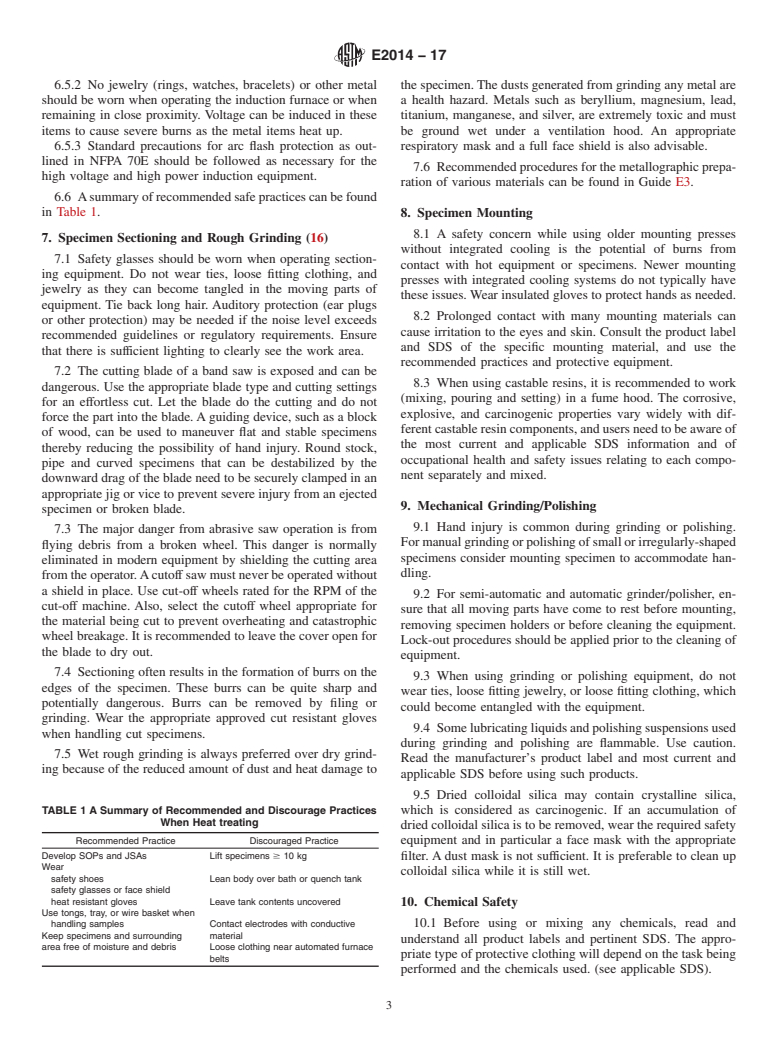

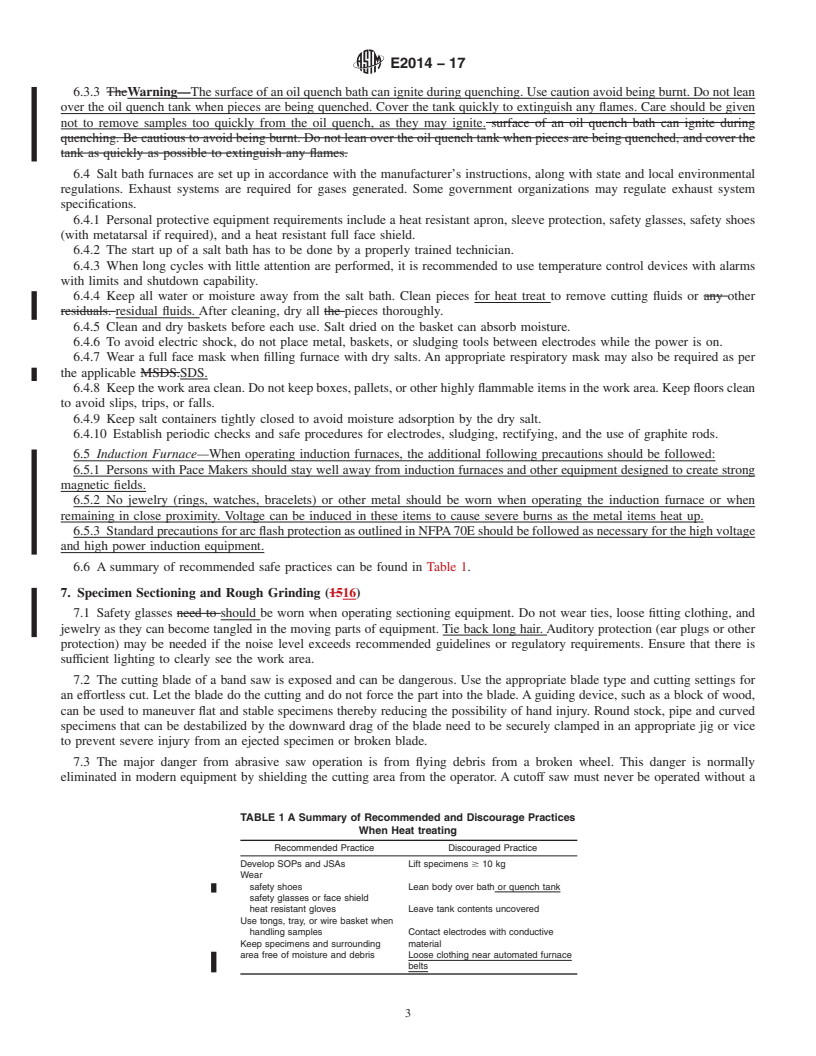

6.3 Furnace Loading and Unloading—When working with

4.3 Before operating any equipment, it is advisable to read

a furnace that requires removal of a thermocouple prior to

and understand the accompanying manuals and to follow any

loading or unloading, or both, handle th

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2014 − 11 E2014 − 17

Standard Guide on

1

Metallographic Laboratory Safety

This standard is issued under the fixed designation E2014; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide outlines the basic safety guidelines to be used in a metallographic laboratory. Safe working habits are discussed

for various tasks performed in a metallographic laboratory.

1.2 The sections appear in the following order:

Section

Scope 1

Referenced Documents 2

Terminology 3

Significance and Use 4

General 5

Heat Treating 6

Specimen Preparation/Sectioning 7

Specimen Mounting 8

Mechanical Grinding/Polishing 9

Chemical Safety 10

Electrolytic Polishing/Etching 11

Sulfur Printing 12

Laboratory Ventilation/Fume Hoods 13

Chemical Spills 14

Photography 15

X ray/Electron Microscopy 16

Laboratory Ergonomics 17

Disposal of Residues 18

Keywords 19

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E3 Guide for Preparation of Metallographic Specimens

E7 Terminology Relating to Metallography

E340 Practice for Macroetching Metals and Alloys

E407 Practice for Microetching Metals and Alloys

E883 Guide for Reflected–Light Photomicrography

E1180 Practice for Preparing Sulfur Prints for Macrostructural Evaluation

E1558 Guide for Electrolytic Polishing of Metallographic Specimens

3

2.2 ANSI Standard:

ANSI/AIHA Z9.5 Laboratory Ventelation

1

This guide is under the jurisdiction of ASTM Committee E04 on Metallography and is the direct responsibility of Subcommittee E04.17 on Criteria for Metallographic

Laboratory Evaluation and Safety.

Current edition approved Oct. 1, 2011June 1, 2017. Published December 2011July 2017. Originally approved in 1999. Last previous edition approved in 20052011 as

E2014 – 05.E2014 – 11. DOI: 10.1520/E2014-11.10.1520/E2014-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2014 − 17

4

2.3 NFPA Standard:

NFPA 45 Standard on Fire Protection for Laboratories Using Chemicals

NFPA 70E Standard for Electrical Safety in the Workplace

3. Terminology

3.1 Definitions—All terms used in this guide are either defined in Terminology E7 or are discussed in 3.2.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 agreement state—a government body that has been granted regulatory authority over by-product materials and

radiation-producing devices by the United States Nuclear Regulatory Commission (USNRC).

4. Significance and Use

4.1 This guide is intended as a summary of safety practices in the metallography laboratory. It can be used as a training reference

for those new to the field of metallography and as a refresher to those who are experienced.

4.2 This guide is not intended to be inclusive of all safety concerns encountered in a metallographic laboratory. Several books

5

that provide safety information are available (1-1415).

4.3 Before operating any equipment, it is advisable to read and understand the accompanying manuals and to follow any

specified safety guidelines.

4.4 Material safety Safety data sheets (MSDS)(SDS) for chemicals being used in a laboratory should be on file and readily

accessible. When working with any chemicals, especially for the first time, one should review the MSDSSDS supplied by the

manufacturer and follow

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.