ASTM G152-00

(Practice)Standard Practice for Operating Open Flame Carbon Arc Light Apparatus for Exposure of Nonmetallic Materials

Standard Practice for Operating Open Flame Carbon Arc Light Apparatus for Exposure of Nonmetallic Materials

SCOPE

1.1 This practice covers the basic principles and operating procedures for using open flame carbon-arc light and water apparatus intended to reproduce the weathering effects that occur when materials are exposed to sunlight (either direct or through window glass) and moisture as rain or dew in actual use. This practice is limited to the procedures for obtaining, measuring, and controlling conditions of exposure. A number of exposure procedures are listed in an appendix; however, this practice does not specify the exposure conditions best suited for the material to be tested.

Note 1--Practice G151 describes performance criteria for all exposure devices that use laboratory light sources. This practice replaces Practice G23, which describes very specific designs for devices used for carbon-arc exposures. The apparatus described in Practice G23 is covered by this practice.

1.2 Test specimens are exposed to filtered open flame carbon arc light under controlled environmental conditions. Different filters are described.

1.3 Specimen preparation and evaluation of the results are covered in methods or specifications for specific materials. General guidance is given in Practice G151 and ISO 4892-1. More specific information about methods for determining the change in properties after exposure and reporting these results is described in ISO 4582.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5.1 Should any ozone be generated from the operation of the light source, it shall be carried away from the test specimens and operating personnel by an exhaust system.

1.6 This practice is technically similar to ISO 4892-4.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: G 152 – 00

Standard Practice for

Operating Open Flame Carbon Arc Light Apparatus for

Exposure of Nonmetallic Materials

This standard is issued under the fixed designation G 152; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 3980 Practice for Interlaboratory Testing of Paint and

Related Materials

1.1 This practice covers the basic principles and operating

E 691 Practice for Conducting an Interlaboratory Study to

procedures for using open flame carbon-arc light and water

Determine the Precision of a Test Method

apparatus intended to reproduce the weathering effects that

G 23 Practice for Operating Light—Exposure Apparatus

occur when materials are exposed to sunlight (either direct or

(Carbon-Arc Type) With and Without Water for Exposure

through window glass) and moisture as rain or dew in actual

of Nonmetallic Materials

use. This practice is limited to the procedures for obtaining,

G 113 Terminology Relating to Natural and Artificial

measuring, and controlling conditions of exposure. A number

Weathering Tests of Nonmetallic Materials

of exposure procedures are listed in an appendix; however, this

G 151 Practice for Exposing Nonmetallic Materials in Ac-

practice does not specify the exposure conditions best suited

celerated Test Devices That Use Laboratory Light

for the material to be tested.

Sources

NOTE 1—Practice G 151 describes performance criteria for all exposure

2.2 CIE Standard:

devices that use laboratory light sources. This practice replaces Practice

CIE-Publ. No. 85: Recommendations for the Integrated

G 23, which describes very specific designs for devices used for carbon-

Irradiance and the Spectral Distribution of Simulated

arc exposures. The apparatus described in Practice G 23 is covered by this

Solar Radiation for Testing Purposes

practice.

2.3 ISO Standards:

1.2 Test specimens are exposed to filtered open flame

ISO 4582, Plastics—Determination of the Changes of

carbon arc light under controlled environmental conditions.

Colour and Variations in Properties After Exposure to

Different filters are described.

Daylight Under Glass, Natural Weathering or Artificial

1.3 Specimen preparation and evaluation of the results are

Light

covered in methods or specifications for specific materials.

ISO 4892-1, Plastics—Methods of Exposure to Laboratory

General guidance is given in Practice G 151 and ISO 4892-1.

Light Sources, Part 1, General Guidance

More specific information about methods for determining the

ISO 4892-4, Plastics—Methods of Exposure to Laboratory

change in properties after exposure and reporting these results

Light Sources, Part 4, Open-Flame Carbon Arc Lamp

is described in ISO 4582.

1.4 The values stated in SI units are to be regarded as the

3. Terminology

standard.

3.1 Definitions—The definitions given in Terminology

1.5 This standard does not purport to address all of the

G 113 are applicable to this practice.

safety concerns, if any, associated with its use. It is the

3.1.1 As used in this practice, the term sunlight is identical

responsibility of the user of this standard to establish appro-

to the terms daylight and solar irradiance, global as they are

priate safety and health practices and determine the applica-

defined in Terminology G 113.

bility of regulatory limitations prior to use.

1.5.1 Should any ozone be generated from the operation of

4. Summary of Practice

the light source, it shall be carried away from the test

4.1 Specimens are exposed to repetitive cycles of light and

specimens and operating personnel by an exhaust system.

moisture under controlled environmental conditions.

1.6 This practice is technically similar to ISO 4892-4.

4.1.1 Moisture usually is produced by spraying the test

2. Referenced Documents

2.1 ASTM Standards:

Discontinued 1998; see 1998 Annual Book of ASTM Standards, Vol 06.01.

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 14.04.

This practice is under the jurisdiction of ASTM Committee G3 on Weathering

and Durability and is the direct responsibility of Subcommittee G03.03 on Available from Secretary, U.S. National Committee, CIE, National Institute of

Simulated and Controlled Exposure Tests. Standards and Technology, Gaithersburg, MD 20899.

Current edition approved March 10, 2000. Published May 2000. Originally Available from American National Standards Institute, 11 W. 42nd St., 13th

published as G 152 – 97. Last previous edition G 152 – 98. Floor, New York, NY 10036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

G 152

specimen with demineralized/deionized water or by condensa- distribution of the open flame carbon arc to make it match

tion of water vapor onto the specimen. daylight in the long wavelength UV or the visible light regions

4.2 The exposure condition may be varied by selection of: of the spectrum.

4.2.1 Light source filter, 6.1.3 The following factors can affect the spectral power

4.2.2 The type of moisture exposure, distribution of open flame carbon arc light sources:

4.2.3 The timing of the light and moisture exposure, 6.1.3.1 Differences in the composition and thickness of

4.2.4 The temperature of light exposure, and filters can have large effects on the amount of short wavelength

4.2.5 The timing of a light/dark cycle. UV radiation transmitted.

4.3 Comparison of results obtained from specimens exposed 6.1.3.2 Aging of filters can result in changes in filter

in same model of apparatus should not be made unless transmission. The aging properties of filters can be influenced

reproducibility has been established among devices for the by the composition. Aging of filters can result in a significant

material to be tested. reduction in the short wavelength UV emission of a burner.

4.4 Comparison of results obtained from specimens exposed 6.1.3.3 Accumulation of dirt or other residue on filters can

in different models of apparatus should not be made unless affect filter transmission.

correlation has been established among devices for the material 6.1.3.4 Differences in the composition of the metallic salts

to be tested. used in he carbon rods can affect the spectral power distribu-

tion.

5. Significance and Use

6.1.4 Spectral Irradiance:

5.1 The use of this apparatus is intended to induce property

6.1.4.1 Spectral Irradiance of Open Flame Carbon Arc with

changes associated with the end use conditions, including the Daylight Filters—Daylight filters are used to reduce the short

effects of sunlight, moisture, and heat. These exposures may

wavelength UV irradiance of the open flame carbon arc in an

include a means to introduce moisture to the test specimen. attempt to provide simulation of the short wavelength UV

Exposures are not intended to simulate the deterioration caused

region of daylight. Although these filters are specified in many

by localized weather phenomena, such as atmospheric pollu- tests because of historical precedent, they transmit significant

tion, biological attack, and saltwater exposure. Alternatively,

radiant energy below 300 nm (the typical cut-on wavelength

the exposure may simulate the effects of sunlight through for terrestrial sunlight) and may result in aging processes not

window glass. Typically, these exposures would include mois-

occurring outdoors. The data in Table 1 is representative of the

ture in the form of humidity.

spectral irradiance received by a test specimen mounted in the

5.2 Cautions—Refer to Practice G 151 for full cautionary

specimen plane of an open flame carbon arc equipped with

guidance applicable to all laboratory weathering devices.

daylight filters.

Variation in results may be expected when operating conditions

6.1.4.2 Spectral Irradiance of Open Flame Carbon Arc With

are varied within the accepted limits of this practice. No

Window Glass Filters—Window glass filters use a heat resis-

reference, therefore, shall be made to results from the use of

tant glass to filter the open flame carbon arc in a simulation of

this practice unless accompanied by a report detailing the

sunlight filtered through single strength window glass. The

specific operating conditions in conformance with Section 10.

data in Table 2 is representative of the spectral irradiance

It is recommended that a similar material of known perfor-

received by a test specimen mounted in the specimen plane of

mance, a control, be exposed simultaneously with the test

an open flame carbon arc equipped with window glass filters.

specimen to provide a standard for comparative purposes. It is

NOTE 2—The most commonly used type of daylight filters are made

recommended that at least three replicates of each material

from Potash-Lithia glass and are commonly known as Corex D filters.

evaluated be exposed in each test to allow for statistical

6.2 Test Chamber—The design of the test chamber may

evaluation of results.

vary, but it should be constructed from corrosion resistant

6. Apparatus material, and in addition to the radiation source, may provide

for means of controlling temperature and relative humidity.

6.1 Laboratory Light Source—Open flame carbon arc light

When required, provision shall be made for the spraying of

sources typically use three or four pairs of carbon rods, which

water on the test specimen or for the formation of condensate

contain a mixture of rare-earth metal salts and have a metal

on the exposed face of the specimen.

coating such as copper on the surface. An electric current is

6.2.1 The radiant source(s) shall be located with respect to

passed between the carbon rods which burn and give off

the specimens such that the irradiance at the specimen face

ultraviolet, visible, and infrared radiation. The carbon rod pairs

complies with the requirements in Practice G 151.

are burned in sequence, with one pair burning at any one time.

6.3 Instrument Calibration—To ensure standardization and

Use carbon rods recommended by the device manufacturer.

accuracy, the instruments associated with the exposure appa-

6.1.1 Filter Types—Radiation emitted by the open flame

ratus, for example, timers, thermometers, wet bulb sensors, dry

carbon arc contains significant levels of very short wavelength

UV (less than 260 nm) and must be filtered. Two types of glass

filters are commonly used. Other filters may be used by mutual

Fischer, R., Ketola, W., Murray, W., “Inherent Variability in Accelerated

agreement by the interested parties as long as the filter type is

Weathering Devices,” Progress in Organic Coatings, Vol 19 (1991), pp. 165–179.

reported in conformance with the report section in Practice

Ketola, W., Robbins, J. S., “UV Transmission of Single Strength Window

G 151.

Glass,” Symposium on Accelerated and Outdoor Durability Testing of Organic

6.1.2 None of these fibers changes the spectral power Materials, ASTM STP 1202, ASTM, 1993.

G 152

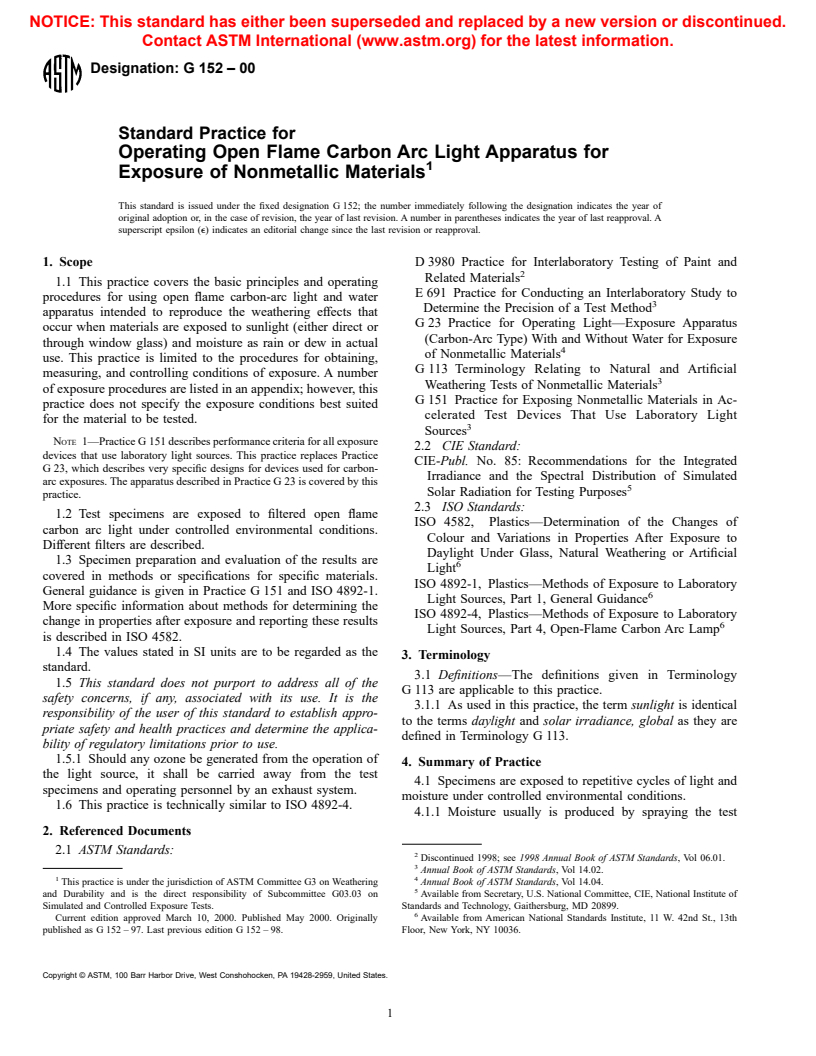

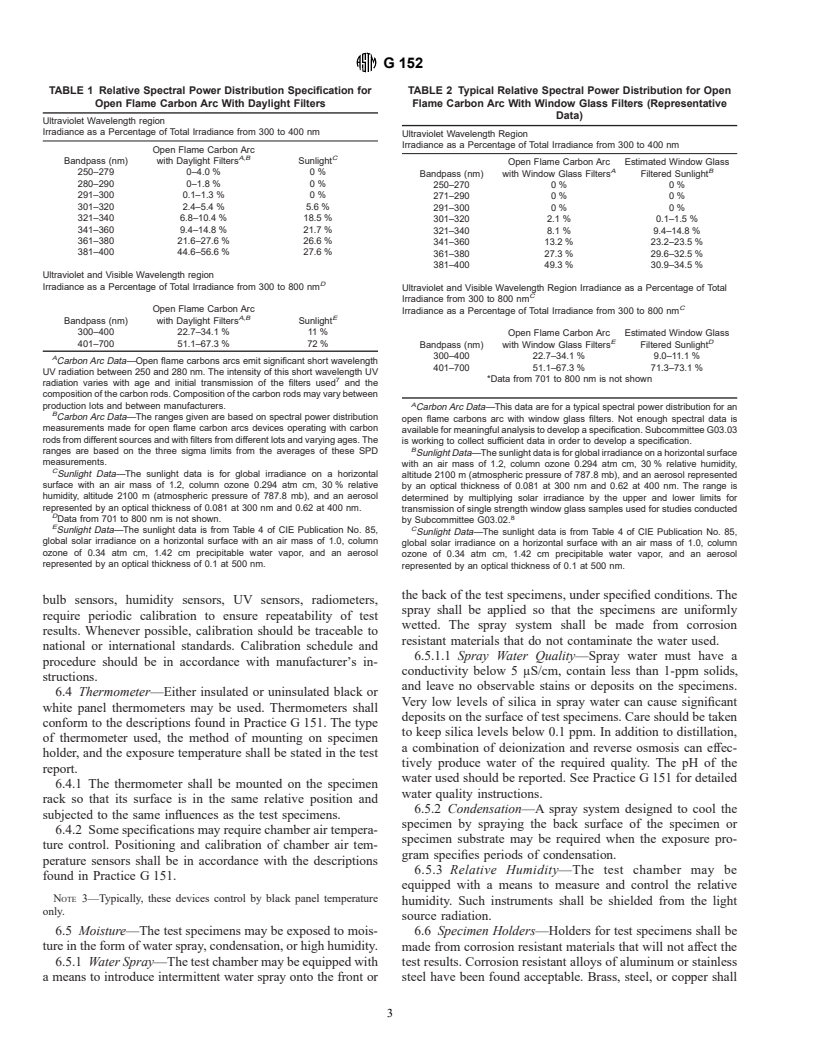

TABLE 1 Relative Spectral Power Distribution Specification for TABLE 2 Typical Relative Spectral Power Distribution for Open

Open Flame Carbon Arc With Daylight Filters Flame Carbon Arc With Window Glass Filters (Representative

Data)

Ultraviolet Wavelength region

Irradiance as a Percentage of Total Irradiance from 300 to 400 nm

Ultraviolet Wavelength Region

Irradiance as a Percentage of Total Irradiance from 300 to 400 nm

Open Flame Carbon Arc

A,B C

Bandpass (nm) with Daylight Filters Sunlight

Open Flame Carbon Arc Estimated Window Glass

A B

250–279 0–4.0 % 0 %

Bandpass (nm) with Window Glass Filters Filtered Sunlight

280–290 0–1.8 % 0 %

250–270 0 % 0 %

291–300 0.1–1.3 % 0 %

271–290 0 % 0 %

301–320 2.4–5.4 % 5.6 %

291–300 0 % 0 %

321–340 6.8–10.4 % 18.5 %

301–320 2.1 % 0.1–1.5 %

341–360 9.4–14.8 % 21.7 %

321–340 8.1 % 9.4–14.8 %

361–380 21.6–27.6 % 26.6 %

341–360 13.2 % 23.2–23.5 %

381–400 44.6–56.6 % 27.6 %

361–380 27.3 % 29.6–32.5 %

381–400 49.3 % 30.9–34.5 %

Ultraviolet and Visible Wavelength region

D

Irradiance as a Percentage of Total Irradiance from 300 to 800 nm

Ultraviolet and Visible Wavelength Region Irradiance as a Percentage of Total

C

Irradiance from 300 to 800 nm

C

Open Flame Carbon Arc

Irradiance as a Percentage of Total Irradiance from 300 to 800 nm

A,B E

Bandpass (nm) with Daylight Filters Sunlight

300–400 22.7–34.1 % 11 %

Open Flame Carbon Arc Estimated Window Glass

E D

401–700 51.1–67.3 % 72 %

Bandpass (nm) with Window Glass Filters Filtered Sunlight

A 300–400 22.7–34.1 % 9.0–11.1 %

Carbon Arc Data—Open flame carbons arcs emit significant short wavelength

401–700 51.1–67.3 % 71.3–73.1 %

UV radiation between 250 and 280 nm. The intensity of this short wavelength UV

7 *Data from 701 to 800 nm is not shown

radiation varies with age and initial transmission of the filters used and the

composition of the carbon rods. Composition of the carbon rods may vary between

A

production lots and between manufacturers.

Carbon Arc Data—This data are for a typical spectral power distribution for an

B

Carbon Arc Data—The ranges given are based on spectral power distribution

open flame carbons arc with window glass filters. Not enough spectral data is

measurements made for open flame carbon arcs devices operating with carbon

available for meaningful analysis to develop a specification. Subcommittee G03.03

rods from different sources and with filters from different lots and varying ages. The

is working to collect sufficient data in order to develop a specification.

B

ranges are based on the three sigma limits from the averages of these SPD

Sunlight Data—The sunlight data is for global irradiance on a horizontal surface

measurements.

with an air mass of 1.2, column ozone 0.294 atm cm, 30 % relative humidity,

C

Sunlight Data—The sunlight data is for global irradiance on a horizontal

altitude 2100 m (atmospheric pressure of 787.8 mb), and an aerosol represented

surface with an air mass of 1.2, column ozone 0.294 atm cm, 30 % relative

by an optical thickness of 0.081 at 300 nm and 0.62 at 400 nm. The range is

humidity, altitude 2100 m (atmospheric pressure of 787.8 mb), and an aerosol

determined by multiplying solar irradiance by the upper and lower limits for

represented by an optical thickness of 0.081 at 300 nm and 0.62 at 400 nm.

transmission of single strength window glass samples used for studies conducted

D

Data from 701 to 800 nm is not shown.

by Subcommittee G03.02.

E

C

Sunlight Data—The sunlight data is from Table 4 of CIE Publication No. 85,

Sunlight Data—The sunlight data is from Table 4 of CIE Publication No. 85,

global solar irradiance on a horizontal surface with an air mass of 1.0, column

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.