ASTM C613-97(2008)e2

(Test Method)Standard Test Method for Constituent Content of Composite Prepreg by Soxhlet Extraction

Standard Test Method for Constituent Content of Composite Prepreg by Soxhlet Extraction

SIGNIFICANCE AND USE

5.1 The prepreg volatiles content, matrix content, reinforcement content, and filler content of composite prepreg materials are used to control material manufacture and subsequent fabrication processes, and are key parameters in the specification and production of such materials, as well as in the fabrication of products made with such materials.

5.2 The extraction products resulting from this test method (the extract, the residue, or both) can be analyzed to assess chemical composition and degree of purity.

SCOPE

1.1 This test method covers a Soxhlet extraction procedure to determine the matrix content, reinforcement content, and filler content of composite material prepreg. Volatiles content, if appropriate, and required, is determined by means of Test Method D3530/D3530M.

1.1.1 The reinforcement and filler must be substantially insoluble in the selected extraction reagent and any filler must be capable of being separated from the reinforcement by filtering the extraction residue.

1.1.2 Reinforcement and filler content test results are total reinforcement content and total filler content; hybrid material systems with more than one type of either reinforcement or filler cannot be distinguished.

1.2 This test method focuses on thermosetting matrix material systems for which the matrix may be extracted by an organic solvent. However, other, unspecified, reagents may be used with this test method to extract other matrix material types for the same purposes.

1.3 Alternate techniques for determining matrix and reinforcement content include Test Methods D3171 (matrix digestion), D2584 (matrix burn-off/ignition), and D3529/D3529M (matrix dissolution). Test Method D2584 is preferred for reinforcement materials, such as glass, quartz, or silica, that are unaffected by high-temperature environments.

1.4 The values stated in SI units are to be regarded as standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 9 and 7.2.3 and 8.2.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´2

Designation: C613 − 97(Reapproved 2008)

Standard Test Method for

Constituent Content of Composite Prepreg by Soxhlet

Extraction

This standard is issued under the fixed designation C613; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

ε NOTE—This standard was corrected to a single-designation standard editorially in October 2013.

ε NOTE—The designation of this standard was corrected editorially in November 2013.

1. Scope bility of regulatory limitations prior to use. Specific precau-

tionary statements are given in Section 9 and 7.2.3 and 8.2.1.

1.1 This test method covers a Soxhlet extraction procedure

to determine the matrix content, reinforcement content, and

2. Referenced Documents

filler content of composite material prepreg. Volatiles content,

2.1 ASTM Standards:

if appropriate, and required, is determined by means of Test

D883Terminology Relating to Plastics

Method D3530/D3530M.

D2584Test Method for Ignition Loss of Cured Reinforced

1.1.1 The reinforcement and filler must be substantially

Resins

insoluble in the selected extraction reagent and any filler must

D3171Test Methods for Constituent Content of Composite

be capable of being separated from the reinforcement by

Materials

filtering the extraction residue.

D3529/D3529MTest Method for Matrix Solids Content and

1.1.2 Reinforcement and filler content test results are total

Matrix Content of Composite Prepreg

reinforcement content and total filler content; hybrid material

D3530/D3530MTest Method for Volatiles Content of Com-

systems with more than one type of either reinforcement or

posite Material Prepreg

filler cannot be distinguished.

D3878Terminology for Composite Materials

1.2 This test method focuses on thermosetting matrix ma-

E122PracticeforCalculatingSampleSizetoEstimate,With

terial systems for which the matrix may be extracted by an

Specified Precision, the Average for a Characteristic of a

organic solvent. However, other, unspecified, reagents may be

Lot or Process

usedwiththistestmethodtoextractothermatrixmaterialtypes

E177Practice for Use of the Terms Precision and Bias in

for the same purposes.

ASTM Test Methods

1.3 Alternate techniques for determining matrix and rein-

E456Terminology Relating to Quality and Statistics

forcement content include Test Methods D3171 (matrix

E1309 Guide for Identification of Fiber-Reinforced

digestion), D2584 (matrix burn-off/ignition), and D3529/

Polymer-Matrix Composite Materials in Databases

D3529M (matrix dissolution).Test Method D2584 is preferred

E1471Guide for Identification of Fibers, Fillers, and Core

forreinforcementmaterials,suchasglass,quartz,orsilica,that

Materials in Computerized Material Property Databases

are unaffected by high-temperature environments.

2.2 NFPA Standard:

NFPA 86Standard for Ovens and Furnaces

1.4 The values stated in SI units are to be regarded as

standard.

3. Terminology

1.5 This standard does not purport to address all of the

3.1 Definitions—Terminology D3878 defines terms relating

safety concerns, if any, associated with its use. It is the

to composite materials. Terminology D883 defines terms

responsibility of the user of this standard to establish appro-

relating to plastics. Terminology E456 and Practice E177

priate safety and health practices and determine the applica-

1 2

This test method is under the jurisdiction of ASTM Committee D30 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Composite Materialsand is the direct responsibility of Subcommittee D30.03 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Constituent/Precursor Properties. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved March 1, 2008. Published April 2008. Originally the ASTM website.

ε1 3

approved in 1967. Last previous edition approved in 2003 as C613–97(2003) . Available from National Fire Protection Association (NFPA), 1 Batterymarch

DOI: 10.1520/C0613_C0613M-97R08E02. Park, Quincy, MA 02269-9101.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´2

C613 − 97 (2008)

define terms relating to statistics. In the event of a conflict 3.3.1 A—initial mass of dry reinforcement during a reagent

between terms, Terminology D3878 shall have precedence exposure evaluation.

over the other documents.

3.3.2 B—final mass of dry reinforcement during a reagent

3.1.1 matrix content, n—the amount of matrix present in a

exposure evaluation.

composite or prepreg expressed either as percent by weight or

3.3.3 c—percent reinforcement mass change due to reagent

percentbyvolume.Forpolymermatrixcompositesthisisresin

exposure.

content. D3878

3.3.4 CV—coefficient of variation statistic of a sample

3.1.2 prepreg, n—the admixture of fibrous reinforcement

population for a given property.

andpolymericmatrixusedtofabricatecompositematerials.Its

3.3.5 M —additional mass of filler in the test specimen.

a

form may be sheet, tape, or tow. For thermosetting matrices it

has been partially cured to a controlled viscosity called “B

3.3.6 M —mass of the test specimen extraction residue.

e

stage”. D3878

3.3.7 M—initial mass of the test specimen.

i

3.1.3 resin content, n—see matrix content. D3878

3.3.8 M —mass of reinforcement in the test specimen.

r

3.1.4 sample, n—a small part or portion of a material or

3.3.9 n—number of replicates in the sample population.

product intended to be representative of the whole. D883

3.3.10 s —standard deviation statistic of a sample popu-

n−1

3.1.5 test result, n—the value obtained for a given property

lation for a given property.

from one test unit.

3.3.11 W—weight percent of filler in prepreg.

f

3.1.5.1 Discussion—A test result may be a single observa-

3.3.12 W —weight percent of matrix in prepreg.

tionoracombinationofanumberofobservationswhentwoor m

more test specimens are measured for each test.

3.3.13 W —weight percent of reinforcement in prepreg.

r

3.1.6 test specimen, n—a test unit or portion of a test unit

3.3.14 x—test result for an individual test specimen from

i

upon which a single or multiple observation is to be made.

the sample population for a given property.

3.1.7 test unit, n—a unit or portion of a material that is

3.3.15 x¯—average value of a sample population for a given

sufficienttoobtainatestresult(s)forthepropertyorproperties

property.

to be measured.

4. Summary of Test Method

3.1.7.1 Discussion—A test unit may be a subunit of a

primary (first stage) sampling unit or it may be a subunit of a

4.1 The exposed surface area of the prepreg material test

composite of primary sampling units or of increments from

specimenisincreasedbycuttingthetestspecimenintosmaller

these primary sampling units.

pieces. The test specimen is weighed and the matrix material

removedbymeansofSoxhletextraction.Theextractedresidue

3.2 Definitions of Terms Specific to This Standard:

is dried and weighed. If a filler is present in the residue, in

3.2.1 dry resin content, n—prepreg resin content calculated

addition to reinforcement, the two components are separated

by subtracting the average mass loss due to volatiles from the

initial test specimen mass. by filtering the residue. From mass measurements of the initial

test specimen, and of the residue taken at various stages in the

3.2.2 filler content, n—the amount of filler present in a

process, the matrix content, reinforcement content, and filler

prepreg or composite expressed either as percent by weight or

content are calculated and reported in weight percent.

percent by volume.

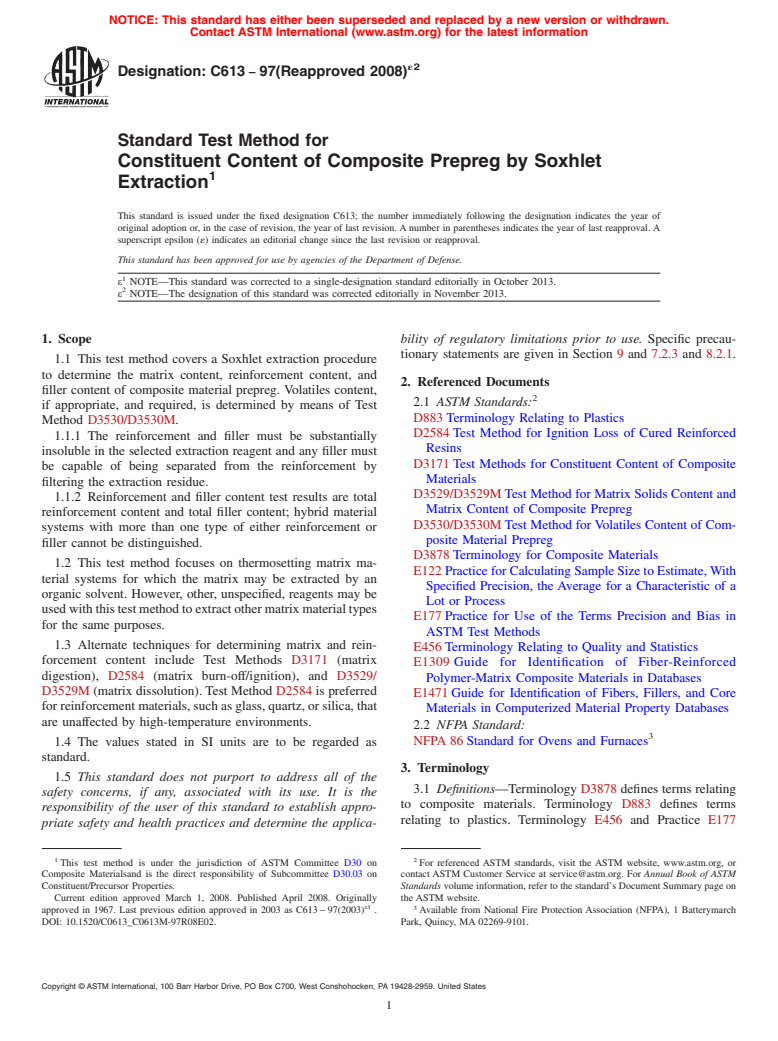

4.1.1 Soxhlet Process—While described in detail in com-

3.2.2.1 Discussion—Inthistestmethodthereinforcementis

mon quantitative chemical analysis textbooks, the Soxhlet

separated from the remainder of the material, which includes

process is summarized as follows. The test specimen is loaded

the matrix and the filler. If the filler is not then separated from

into a filtering extraction thimble, which is placed into the

the matrix to determine the proportion of each, then the filler

extraction chamber of a Soxhlet extraction assembly (see Fig.

content is included in the matrix content.

1) containing an appropriate extraction reagent. The porous

3.2.3 reinforcement content, n—the amount of reinforce-

thimble allows the liquid extraction reagent to pass while

ment present in a composite or prepreg expressed either as

retaining the test specimen. Freshly distilled liquid reagent

percent by weight or percent by volume. This is sometimes

entersfromthetopoftheextractionchamber,fillingituntilthe

stated as a fraction, that is, reinforcement volume fraction.

liquid reaches the highest level of the reagent-return tube. At

3.2.4 replicate, n—a test specimen tested under nominally

this moment the tube operates as a siphon, draining the

identical conditions as other test specimens from the same

extraction chamber completely as it returns the liquid reagent

sample.

andanyextractedmaterialtoareservoirbeneaththeextraction

chamber. The heated reservoir boils the reagent, the vapor of

3.2.5 volatilescontent,n—theamountofvolatilespresentin

which is led to a condenser placed above the extraction

a prepreg expressed as percent by weight.

chamber. The distilled condensate then drips down into the

3.2.6 wetresincontent,n—prepregresincontentdetermined

thimble,startingonceagaintheprocessoffillingtheextraction

by considering volatiles as part of the resin mass.

chamber. The Soxhlet operation is not a continuous operation,

3.3 Symbols:

but rather a sequence of fillings and siphonings, each cycle of

which is called a reflux change. The heat input and reagent

See Form and Style for ASTM Standards. volumeareadjustedtocausetheboilingreagenttoreturntothe

´2

C613 − 97 (2008)

6.4 Reinforcement Mass Change As a Result of Reagent—

The calculations of this test method assume that the reinforce-

mentmass(orfiller,iffillercontentisbeingdetermined)isnot

significantly affected (whether mass increase or mass loss) by

exposure to the reagent. Small, consistent changes in the

reinforcement mass caused by exposure to the reagent can be

corrected by the process described in 14.4.5. The resulting

correction may be used if this change is sufficiently reproduc-

ible under the conditions of the test, and if this change has the

samevalueforthereinforcementaloneasforthereinforcement

in the matrix. Otherwise, a different reagent, or another test

method, must be selected.

7. Apparatus

FIG. 1 Schematic of Soxhlet Extraction Apparatus 7.1 General Requirements:

7.1.1 Container Volume—Asuggested volume is shown for

each container. However, other sizes may be required depend-

ing upon the test specimen size, the amount of reagent needed

extraction flask from the condenser at 3 to 10 reflux changes

to complete the extraction process, and the relative sizes of

per hour, with the extraction continuing for a minimum of 4 h related equipment.

or 20 reflux changes, whichever comes first.

7.1.2 Thermal Shock—Laboratory equipment that is sub-

4.1.2 Volatiles Content—Volatiles content is primarily ap- jected to non-ambient temperatures (hot or cold) shall be of

plicable to thermosetting materials, and, if required, is deter- tempered-glass or PTFE materials.

mined by Test Method D3530/D3530M. Volatiles content 7.1.3 Post-Test Elemental Analysis—If a post-test elemental

determinationrequiresdifferenttestspecimensthanthoseused analysisoftheextractorresidueistobeperformed,laboratory

in the extraction process, since the process of determining equipment contacting the test specimen shall be constructed of

volatiles content renders thermosetting material specimens PTFEandtestspecimencuttingshallbelimitedtotoolsthatdo

unsuitable for subsequent organic solvent extraction. not leave an elemental trace.

7.2 General Equipment:

5. Significance and Use

7.2.1 Analytical Balance—The analytical balance shall be

5.1 Theprepregvolatilescontent,matrixcontent,reinforce- capable of reading to within 60.1 mg.

mentcontent,andfillercontentofcompositeprepregmaterials

7.2.2 MuffleFurnace—Themufflefurnaceusedtocondition

are used to control material manufacture and subsequent glass extraction thimbles shall be capable of maintaining a

fabrication processes, and are key parameters in the specifica-

temperature of 510 6 15°C.

tion and production of such materials, as well as in the 7.2.3 Air-Circulating Drying Oven—The drying oven shall

fabrication of products made with such materials.

be capable of maintaining a temperature of 163 6 3°C.

(Warning—ForsafetypurposeslistedinNFPA86,takecareto

5.2 The extraction products resulting from this test method

limit volatile concentration in the oven by controlling sample

(the extract, the residue, or both) can be analyzed to assess

quantity, temperature, and ventilation.)

chemical composition and degree of purity.

7.2.4 Desiccator—The desiccator shall be capable of con-

taining the required test specimens.

6. Interferences

7.3 Extraction Assembly:

6.1 Extent of Cure in Thermosetting Systems—The effi-

7.3.1 ExtractionThimbles—Theextractionthimblesshallbe

ciency of extraction for thermosetting matrix materials is

deep, narrow filtering cups, of either borosilicate glass in an

directlyrelatedtotheextentofcureoftheresinsystem.Resins

appropriate pore size, or fat-extracted cellulose paper, suitable

that have started to cross-link (such as B-staged resins) will be

for use in the extraction chamber.

increasinglymoredifficulttoextractasthecureadvances.This

7.3.2 Hot Plate—The hot plate shall have adjustable con-

test method may not be appropriate for such materials; Test

trols suitable for heating the reagent within the reservoir flask

Methods D3171 or D2584 may be better test method choices.

to 260°C and shall be capable of controlling the required

6.2 Reagent Selection—The proper reagent, in a suitable

reagent temperature within 615°C.

quantity, must be selected for the constituents under test. The

7.3.3 Reservoir Flask—The reservoir flask shall be of boro-

reagents listed in Section 8 are provided for consideration,

silicate glass, of suitable volume (125 mLis suggested) for the

particularly with regard to thermosetting materials, but cannot

reagent quantity and extraction chamber volume, and shall

be assured to perform well on all material systems within the

have a ground tapered joint capable of connection with the

scope of this test method.

remainder of the assembly.

6.3 Thimble Contamination—If the extract

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.