ASTM D3617-02

(Practice)Standard Practice for Sampling and Analysis of New Built-Up Roof Membranes

Standard Practice for Sampling and Analysis of New Built-Up Roof Membranes

SCOPE

1.1 This practice is a guide for removing specimens from new built-up bituminous roof membranes before the application of flood coating and top surfacing for determining the approximate quantities of the components and the possible presence of moisture, or dry spots between plies, in the field. Components may consist of:

1.1.1 Insulation, when part of the roof membrane system,

1.1.2 Plies of roofing felt,

1.1.3 Interply layers of bituminous material, and

1.1.4 Top coating, if present, before any surfacing aggregate has been applied.

1.2 The values stated in SI (metric) units are to be regarded as the standard.

1.3 This standard is applicable to 910-mm (36-in.) wide felt rolls and does not apply to metric-sized (that is, 1000-mm [39 3/8-in.] wide) felt rolls.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3617–02

Standard Practice for

1

Sampling and Analysis of New Built-Up Roof Membranes

This standard is issued under the fixed designation D 3617; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 3158 Specification for Asphalt-Saturated and Coated Or-

4

ganic Felt Used in Roofing

1.1 This practice is a guide for removing specimens from

D 3378 Specification for Asphalt-Saturated and Coated As-

new built-up bituminous roof membranes before the applica-

5

bestos Felt Base Sheet Used in Roofing

tion of flood coating and top surfacing for determining the

approximate quantities of the components and the possible

3. Sampling

presence of moisture, or dry spots between plies, in the field.

3.1 Unless otherwise specified, take at least one specimen

Components may consist of:

2 2

for each separate roof, plus one for each 929 m (10 000 ft );

1.1.1 Insulation, when part of the roof membrane system,

take specimens at random.

1.1.2 Plies of roofing felt,

3.2 Take additional specimens in which deficiencies are

1.1.3 Interply layers of bituminous material, and

indicated in the membrane to determine the extent of the

1.1.4 Top coating, if present, before any surfacing aggregate

deficient area.

has been applied.

1.2 The values stated in SI (metric) units are to be regarded

4. Test Specimen

as the standard.

4.1 Sweep the surface of the membrane clean where each

1.3 This standard is applicable to 910-mm (36-in.) wide felt

test specimen will be taken.

rolls and does not apply to metric-sized (that is, 1000-mm

4.2 For determining approximate quantities of components,

3

[39 ⁄8–in.] wide) felt rolls.

cut a 300- by 300-mm (12- by 12-in.) specimen from the

1.4 This standard does not purport to address all of the

membrane using a template (Fig. 1).

safety concerns, if any, associated with its use. It is the

4.2.1 If the membrane is adhered to the insulation, remove

responsibility of the user of this standard to establish appro-

the membrane with the adhering insulation.

priate safety and health practices and determine the applica-

4.2.2 If the membrane is adhered directly to the roof deck,

bility of regulatory limitations prior to use.

estimate the quantity of bitumen remaining on the deck after

2. Referenced Documents the specimen is removed.

4.3 For the purpose of determining the felt spacing, cut a

2.1 ASTM Standards:

100- by 1000-mm (4- by 40-in.) rectangular specimen from the

D 226 Specification for Asphalt-Saturated Organic Felt

2 membrane, using a template (Fig. 1) placed at right angles to

Used in Roofing and Waterproofing

the long dimension of the felts.

D 227 Specification for Coal-Tar Saturated Organic Felt

2 4.4 Identify each specimen by location and record the

Used in Roofing and Waterproofing

presence of insulation or the estimated quantity of bitumen

D 250 Specification for Asphalt-Saturated Asbestos Felt

3 remaining on the deck.

Used in Roofing and Waterproofing

4.5 If practicable, return the cut membrane specimen to its

D 2178 Specification for Asphalt Glass Felt Used in Roof-

2 original location in the roof. Make adequate repairs to the

ing and Waterproofing

roofing system, using at least the same number of felt plies as

D 2626 Specification for Asphalt-Saturated and Coated Or-

2 the original roof membrane after testing.

ganic Felt Base Sheet Used in Roofing

5. Procedure

5.1 Remove insulation fully from the 300- by 300-mm (12-

1

This practice is under the jurisdiction of ASTM Committee D08 on Roofing, by 12-in.) specimen, if present, being careful to remove as little

Waterproofing, and Bituminous Materials and is the direct responsibility of Sub-

bituminous material as possible or leave the insulation in place

committee D08.20 on Roofing Membrane Systems.

Current edition approved Jan. 10, 2002. Published March 2002. Originally

e1

published as D 3617-77. Last previous edition D 3617-83(1994) .

2 4

Annual Book of ASTM Standards, Vol 04.04. Discontinued—See 1983 Annual Book of ASTM Standards, Vol 04.04.

3 5

Discontinued—See 1991 Annual Book of ASTM Standards, Vol 04.04. Discontinued—See 1985 Annual Book of ASTM Standards, Vol 04.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3617

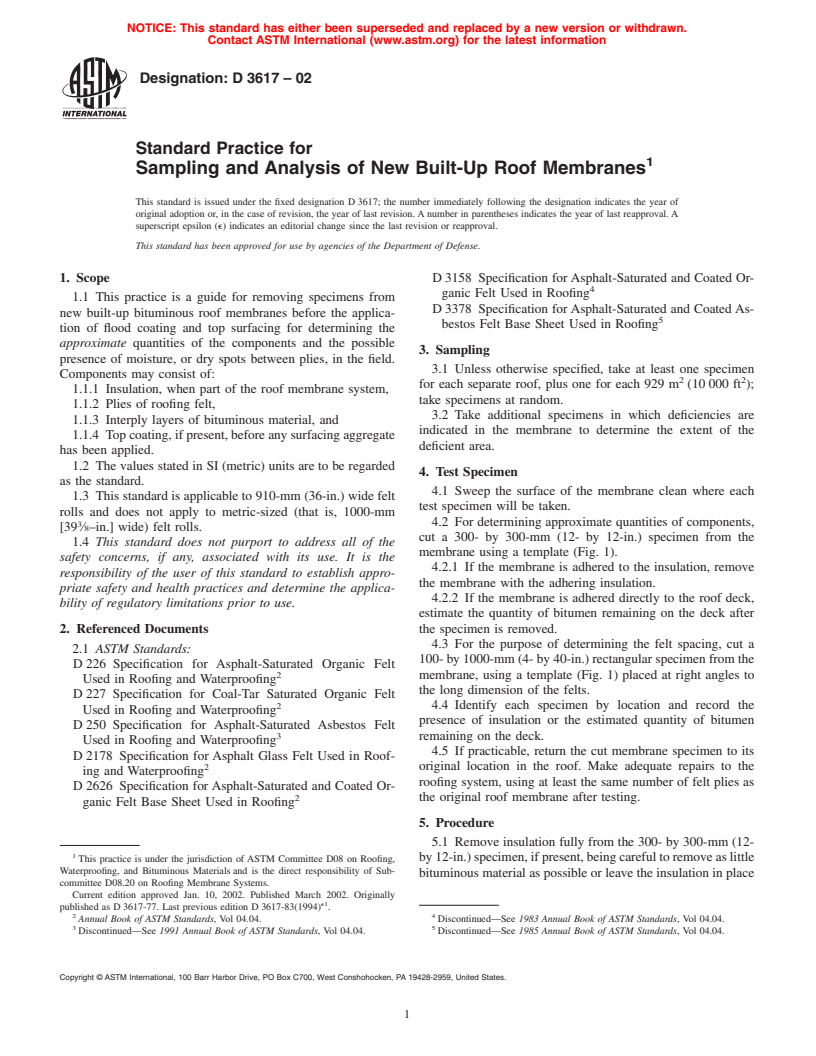

Square (4.2) Rectangular (4.3)

Dimension

mm in. mm in.

A 300 12 100 4

B 300 12 1000 40

C 150 6 150 6

D 40 1.5 40 1.5

E 40 1.5 40 1.5

1 1

F3 ⁄8 3 ⁄8

FIG. 1 Dimensions of Templates for Roof Sampling

and later use manufacturer’s in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.