ASTM F1506-98

(Specification)Standard Performance Specification for Textile Materials for Wearing Apparel for Use by Electrical Workers Exposed to Momentary Electric Arc and Related Thermal Hazards

Standard Performance Specification for Textile Materials for Wearing Apparel for Use by Electrical Workers Exposed to Momentary Electric Arc and Related Thermal Hazards

SCOPE

1.1 This performance specification covers the flame resistance of textile materials to be used for wearing apparel for use by electrical workers exposed to momentary electric arc and related thermal hazards.

Note 1—This performance specification does not cover coated fabrics commonly used in rainwear.

Note 2—At present, a bench scale arc test for laboratory use is not available. It is the intent of the committee to continue the search for an acceptable laboratory test based on either an electric arc exposure or an acceptable alternative, which will form the basis of a modification of this specification.

1.2 Materials used for basic protection levels are covered.

1.3 Protective properties relate to thermal exposure from momentary arc and associated exposure to open flame and radiant heat. (See Appendix X1.)

1.4 This performance specification covers wearing apparel design characteristics that relate specifically to protection from exposure to momentary electric arc and that relate to the utility of the wearing apparel.

Note 3—A number of other thermal test methods are under consideration and development and, when evaluated and proved effective by Committee F18, will be incorporated in either this specification or an appropriate alternative test method or specification.

1.5 This standard should be used to evaluate and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions. It should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions

1.5.1 The results of this evaluation may be used as elements of a fire-risk assessment that takes into account all of the factors that are pertinent to an assessment of the fire hazard of a particular end use.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.7 The following precautionary caveat pertains only to the test methods portion, Section 8, of this performance specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 1506 – 98

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Performance Specification for

Textile Materials for Wearing Apparel for Use by Electrical

Workers Exposed to Momentary Electric Arc and Related

Thermal Hazards

This standard is issued under the fixed designation F 1506; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 The following precautionary caveat pertains only to the

test methods portion, Section 8, of this specification: This

1.1 This performance specification covers the flame resis-

standard does not purport to address all of the safety concerns,

tance of textile materials to be used for wearing apparel for use

if any, associated with its use. It is the responsibility of the user

by electrical workers exposed to momentary electric arc and

of this standard to establish appropriate safety and health

related thermal hazards.

practices and determine the applicability of regulatory limita-

NOTE 1—This performance specification does not cover coated fabrics

tions prior to use.

commonly used in rainwear.

NOTE 2—At present, a bench scale arc test for laboratory use is not

2. Referenced Documents

available. It is the intent of the committee to continue the search for an

2.1 ASTM Standards:

acceptable laboratory test based on either an electric arc exposure or an

D 123 Terminology Relating to Textiles

acceptable alternative which will form the basis of a modification of this

specification.

D 434 Test Method for Resistance to Slippage of Yarns in

Woven Fabrics Using a Standard Seam

1.2 Materials used for basic protection levels are covered.

D 1424 Test Method for Tear Resistance of Woven Fabrics

1.3 Protective properties relate to thermal exposure from

by Falling-Pendulum (Elmendorf) Apparatus

momentary arc and associated exposure to open flame and

D 1682 Test Methods for Breaking Load and Elongation of

radiant heat. (See Appendix X1.)

Textile Fabrics

1.4 This performance specification covers wearing apparel

D 2262 Test Method for Tearing Strength of Woven Fabrics

design characteristics that relate specifically to protection from

by the Tongue (Single Rip) Method (Constant-Rate-of-

exposure to momentary electric arc and that relate to the utility

Traverse Tensile Testing Machine)

of the wearing apparel.

D 2724 Test Methods for Bonded, Fused and Laminated

NOTE 3—A number of other thermal test methods are under consider- 2

Apparel Fabrics

ation and development and when evaluated and proved effective by

D 3786 Test Method for Hydraulic Bursting Strength of

Committee F-18 will be incorporated in either this specification or an

Knitted Goods and Nonwoven Fabrics: Diaphragm Burst-

appropriate alternative test method or specification.

ing Strength Tester Method

1.5 This standard should be used to evaluate and describe

F 1449 Guide for Care and Maintenance for Flame Resis-

the properties of materials, products, or assemblies in response 5

tant and Thermal Protective Clothing

to heat and flame under controlled laboratory condition. It

2.2 AATCC Test Methods:

should not be used to describe or appraise the fire hazard or

Method 61 Colorfastness to Washing, Domestic and Laun-

fire risk of materials, products, or assemblies under actual fire

dering, Commercial: Accelerated

conditions.

Method 132 Colorfastness to Dry-Cleaning

1.5.1 The results of this evaluation may be used as elements

Method 135 Dimensional Changes Automatic Home Laun-

of a fire-risk assessment which takes into account all of the

dering of Woven and Knitted Fabrics

factors which are pertinent to an assessment of the fire hazard

Method 158 Dimensional Changes on Drycleaning in Per-

of a particular end use.

chloroethylene: Machine Method

1.6 The values stated in SI units are to be regarded as the

2.3 Federal Standard:

standard. The values given in parentheses are for information

Federal Test Method Standard (FTMS) No. 191A

only.

Annual Book of ASTM Standards, Vol 07.01.

1 3

This performance specification is under the jurisdiction of ASTM Committee Discontinued; see 1991 Annual Book of ASTM Standards, Vol 07.01.

F-18 on Electrical Protective Equipment for Workers and is the direct responsibility Annual Book of ASTM Standards, Vol 07.02.

of Subcommittee F18.65 on Wearing Apparel. Annual Book of ASTM Standards, Vol 11.03.

Current edition approved April 10, 1998. Published November 1998. Originally AATCC Technical Manual, available from American Association of Textile

e1

published as F 1506–1994. Last previous edition F 1506–1994 . Chemists and Colorists, PO Box 12215, Research Triangle Park, NC 27709.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

F 1506

Method 5903.1, Flame Resistance Cloth Vertical 5.1.1 Material tests may be performed on samples taken

from finished garments.

3. Terminology

5.2 Lot size for the initial (without laundering) flammability

3.1 Definitions—For definitions of textile terms used in this test shall be 4572 m (5000 yd) of manufactured fabric or the

manufactured yardage, whichever is less. One sample of 1.0 m

specification refer to Terminology D 123.

3.2 Definitions of Terms Specific to This Standard: shall be taken from each lot.

5.3 Lot size for all other tests except design tests shall be 45

3.2.1 basic protection level—the level of protection pro-

vided by flame-resistant materials that do not continue to burn 720 m (50 000 yd) or at least every three months, whichever is

more frequent. One sample of 4.0 m shall be taken from each

after exposure to and removal of a source of ignition. (See 7.6.)

3.2.2 basic protection level wearing apparel—clothing in- lot.

5.4 Design tests shall be run on the original and when

tended for continuous wear for work activities in designated

locations in which exposure to momentary electric arc and changes are made to flame resistant textile materials, for

example, fiber type, yarn type, weaving style, fabric weight,

related radiant heat and open-flame sources is possible.

3.2.3 findings—miscellaneous fabrics in garments such as dyeing, finishing procedure.

zipper tapes, linings, pockets, waistbands, and facings.

6. Requirements

3.2.4 momentary electric arc—a discharge of electricity

through a gaseous media, normally characterized by a voltage

6.1 Thread, findings, and closures used in garment construc-

drop in the immediate vicinity of the electrodes approximately

tion shall not contribute to the severity of injuries to the wearer

equal to the ionization potential of the gaseous media.

in the event of a momentary electric arc and related thermal

3.2.5 radiant heat—heat communicated by energy propa-

exposure.

gated through space and transmitted by electromagnetic waves.

6.2 The properties of materials for basic protection level

3.2.6 thermal hazard—the heat energy sufficient to cause

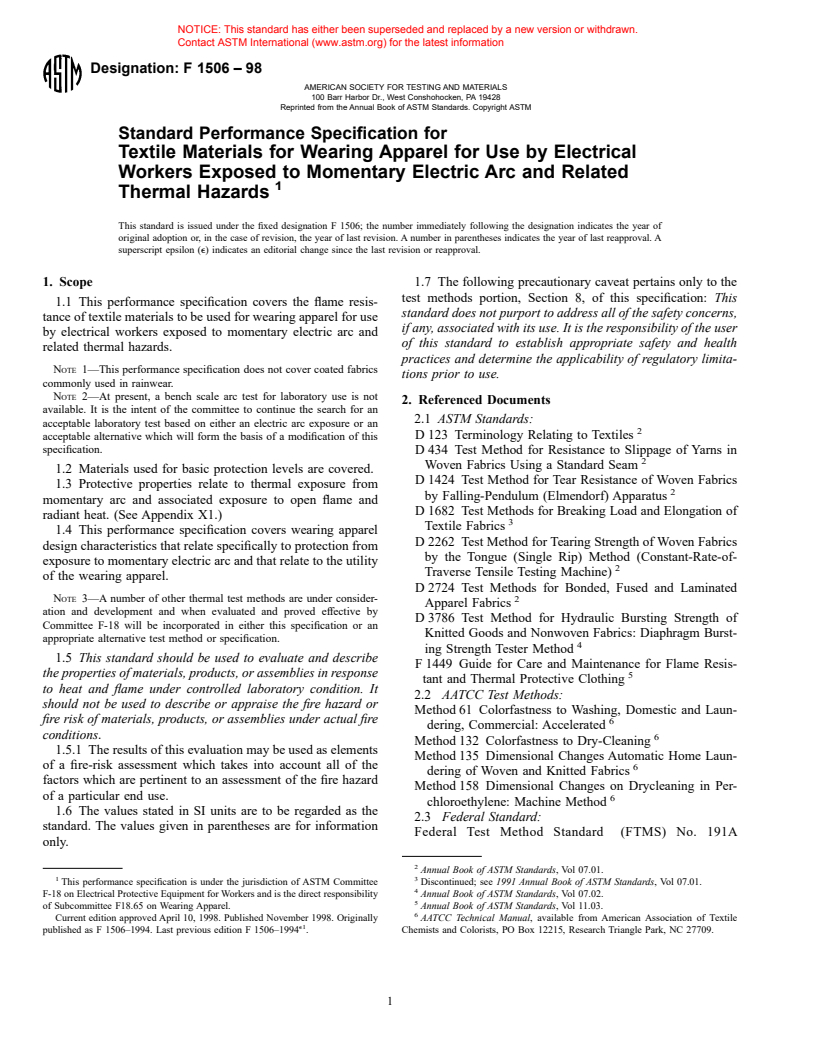

wearing apparel shall conform to the specifications in Table 1

burn injury to human tissue subjected to a momentary electric

and Table 2, when evaluated in accordance with Section 7.

arc.

NOTE 4—Physical characteristic tests and values in Section 7 and Table

3.2.7 user—the employer or entity purchasing the equip-

1 and Table 2 are based on experience from woven and knit fabrics

ment to be utilized by workers for their protection; in the

currently in use and may not be applicable to other fabric types.

absence of such an employer or entity, the individual purchas-

NOTE 5—Characteristics (for example, clothing ensembles, design, and

ing and utilizing the protective equipment.

laundry maintenance) of protective garments for basic protection level

wearing apparel should be guided by the information contained in

4. Significance and Use

Appendix X1.

4.1 This specification provides performance properties for

6.3 Garments shall be labeled with the following informa-

textile materials used in wearing apparel that represent initial

tion:

minimum requirements for basic protection levels.

6.3.1 Tracking identification code system;

4.1.1 The performance properties have been selected based

6.3.2 Meets requirements of ASTM F1506;

on materials in use and take into consideration durability

6.3.3 Manufacturer’s name;

requirements for specific apparel.

6.3.4 Size and other associated standard labeling; and

4.2 At the present time, the basic protection level for

6.3.5 Care instructions and fiber content.

exposure to momentary electric arc and related thermal hazards

is defined by a vertical flame-resistance test. (See 7.6 and the

7. Test Methods

other tests listed in Section 7.)

7.1 Breaking Load—Determine the breaking load in accor-

4.3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.