ASTM A513/A513M-14

(Specification)Standard Specification for Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing

Standard Specification for Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing

ABSTRACT

This specification covers round, square, rectangular, and special shape electric-resistance-welded carbon and alloy steel mechanical tubing produced by hot- or cold-rolling. The types of tubing covered here are: Type 1a, as-welded from hot-rolled steel (with mill scale); Type 1b, as-welded from hot-rolled pickled and oiled steel (mill scale removed); Type 2, as-welded from cold-rolled steel; Type 3, sink-drawn hot-rolled steel; Type 4, sink-drawn cold-rolled steel; Type 5, drawn over a mandrel; and Type 6, special smooth inside diameter. Heat and product analyses shall be made to determine the percentages of chemical elements, to which the steel specimens shall conform to. Tubing shall be free of injurious defects and shall have a workmanlike finish. When specified, tubing shall be coated with a film of rust retarding oil before shipping.

SCOPE

1.1 This specification covers electric-resistance-welded carbon and alloy steel tubing for use as mechanical tubing.

1.2 This specification covers mechanical tubing made from hot- or cold-rolled steel.

1.3 This specification covers round, square, rectangular, and special shape tubing.

Type

Size Range

(Round Tubing)

Electric-Resistance-Welded Tubing from Hot-Rolled Steel

outside diameter from 1/2 to 15 in.

[10 to 380 mm]

wall from 0.065 to 0.650 in.

[1.65 to 16.50 mm]

Electric-Resistance-Welded Tubing from Cold-Rolled Steel

outside diameter from 3/8 to 12 in.

[9.5 to 305 mm]

wall from 0.022 to 0.134 in.

[0.56 to 3.40 mm]

1.4 Optional supplementary requirements are provided and when desired, shall be so stated in the order.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text the SI units are shown in brackets or parentheses. The values stated in each system may not be exact equivalents; therefore each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order. In this specification hard or rationalized conversions apply to diameters, lengths and tensile properties. Soft conversion applies to other SI measurements.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A513/A513M −14

StandardSpecification for

Electric-Resistance-Welded Carbon and Alloy Steel

1

Mechanical Tubing

This standard is issued under the fixed designationA513/A513M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

2

1.1 This specification covers electric-resistance-welded car- 2.1 ASTM Standards:

bon and alloy steel tubing for use as mechanical tubing. A370 Test Methods and Definitions for Mechanical Testing

of Steel Products

1.2 This specification covers mechanical tubing made from

A700 Guide for Packaging, Marking, and Loading Methods

hot- or cold-rolled steel.

for Steel Products for Shipment

1.3 This specification covers round, square, rectangular, and

A751 Test Methods, Practices, and Terminology for Chemi-

special shape tubing.

cal Analysis of Steel Products

Size Range

A1008/A1008M Specification for Steel, Sheet, Cold-Rolled,

Type (Round Tubing)

Carbon, Structural, High-Strength Low-Alloy, High-

1

Electric-Resistance-Welded Tubing outside diameter from ⁄2 to 15 in.

Strength Low-Alloy with Improved Formability, Solution

from Hot-Rolled Steel [10 to 380 mm]

wall from 0.065 to 0.650 in.

Hardened, and Bake Hardenable

[1.65 to 16.50 mm]

A1011/A1011M Specification for Steel, Sheet and Strip,

3

Electric-Resistance-Welded Tubing outside diameter from ⁄8 to 12 in.

Hot-Rolled, Carbon, Structural, High-Strength Low-

from Cold-Rolled Steel [9.5 to 305 mm]

wall from 0.022 to 0.134 in.

Alloy, High-Strength Low-Alloy with Improved

[0.56 to 3.40 mm]

Formability, and Ultra-High Strength

1.4 Optional supplementary requirements are provided and

A1039/A1039M Specification for Steel, Sheet, Hot Rolled,

when desired, shall be so stated in the order.

Carbon, Commercial, Structural, and High-Strength Low-

Alloy, Produced by Twin-Roll Casting Process

1.5 The values stated in either SI units or inch-pound units

A1040 Guide for Specifying Harmonized Standard Grade

are to be regarded separately as standard.Within the text the SI

Compositions for Wrought Carbon, Low-Alloy, andAlloy

unitsareshowninbracketsorparentheses.Thevaluesstatedin

Steels

each system may not be exact equivalents; therefore each

E213 Practice for Ultrasonic Testing of Metal Pipe and

system shall be used independently of the other. Combining

Tubing

values from the two systems may result in non-conformance

E273 Practice for Ultrasonic Testing of the Weld Zone of

with the standard. The inch-pound units shall apply unless the

Welded Pipe and Tubing

“M” designation of this specification is specified in the order.

E309 Practice for Eddy-Current Examination of Steel Tubu-

In this specification hard or rationalized conversions apply to

lar Products Using Magnetic Saturation

diameters, lengths and tensile properties. Soft conversion

E570 Practice for Flux Leakage Examination of Ferromag-

applies to other SI measurements.

netic Steel Tubular Products

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee

2

A01.09 on Carbon Steel Tubular Products. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2014. Published May 2014. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1964. Last previous edition approved in 2012 as A513/A513M – 12. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/A0513_A0513M-14. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A513/A513M−14

3

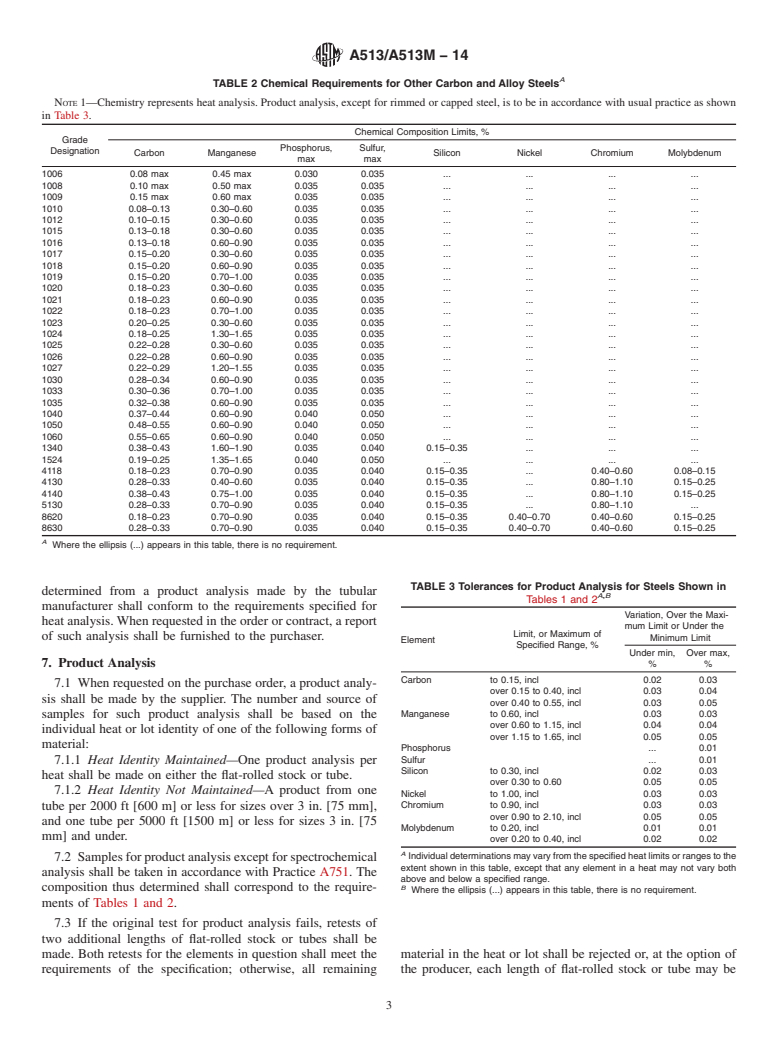

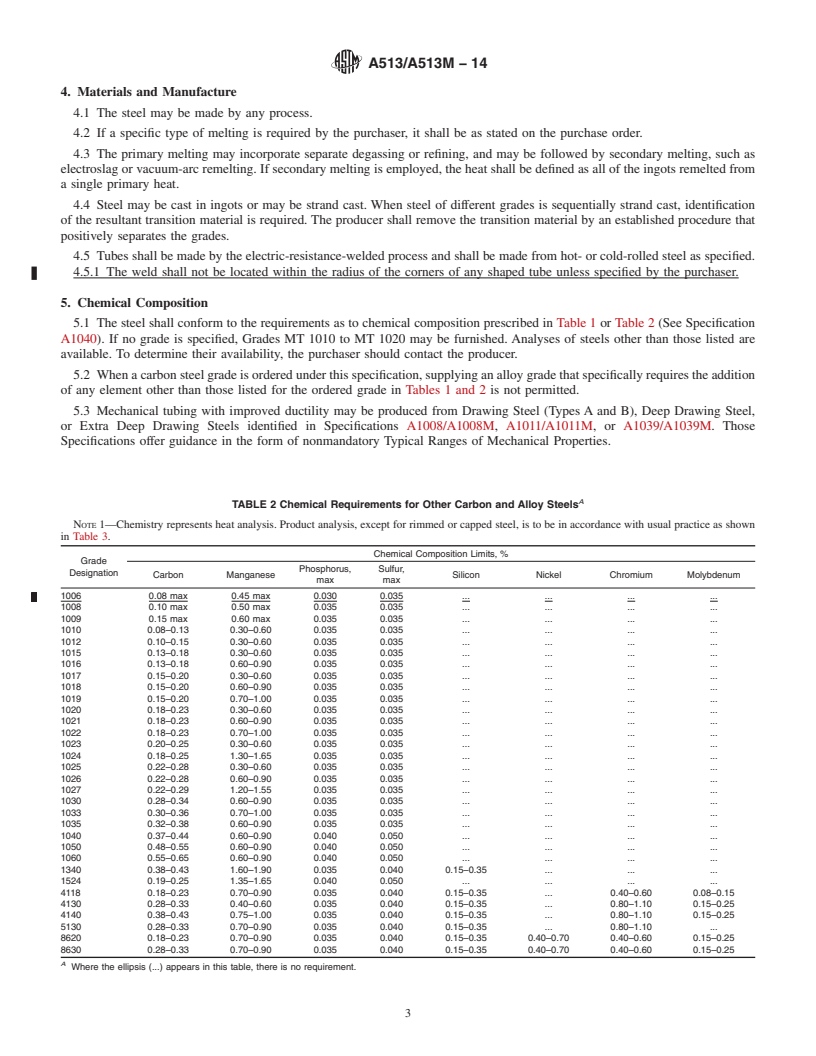

TABLE 1 Chemical Requirements for Standard Low-Carbon

2.2 ANSI Standard:

A

Steels

B 46.1 Surface Texture

4 NOTE 1— Chemistry represents heat analysis. Product analysis, except

2.3 Military Standards:

for rimmed or capped steel, is to be in accordance with usual practice as

MIL-STD-129 Marking for Shipment and Storage

shown in Table 3.

4

2.4 Federal Standard: Chemical Composition Limits, %

Grade

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

Sulfur,

Phosphorus,

Designation

Carbon Manganese max

max

3. Ordering Information

B

MT 1010 0.02–0.15 0.30–0.60 0.035 0.035

3.1 Orders for material under this specification should

MT 1015 0.10–0.20 0.30–0.60 0.035 0.035

include the following as required to adequately describe the

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A513/A513M − 12 A513/A513M − 14

Standard Specification for

Electric-Resistance-Welded Carbon and Alloy Steel

1

Mechanical Tubing

This standard is issued under the fixed designation A513/A513M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers electric-resistance-welded carbon and alloy steel tubing for use as mechanical tubing.

1.2 This specification covers mechanical tubing made from hot- or cold-rolled steel.

1.3 This specification covers round, square, rectangular, and special shape tubing.

Size Range

Type (Round Tubing)

1

Electric-Resistance-Welded Tubing outside diameter from ⁄2 to 15 in.

from Hot-Rolled Steel [10 to 380 mm]

wall from 0.065 to 0.650 in.

[1.65 to 16.50 mm]

3

Electric-Resistance-Welded Tubing outside diameter from ⁄8 to 12 in.

from Cold-Rolled Steel [9.5 to 305 mm]

wall from 0.022 to 0.134 in.

[0.56 to 3.40 mm]

1.4 Optional supplementary requirements are provided and when desired, shall be so stated in the order.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text the SI units

are shown in brackets or parenthesis.parentheses. The values stated in each system may not be exact equivalents; therefore each

system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the

standard. The inch-pound untsunits shall apply unless the “M” designation of this specification is specified in the order. In this

specification hard or rationalized conversions apply to diameters, lengths and tensile properties. Soft conversion applies to other

SI measurements.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

3

A700 Practices for Packaging, Marking, and Loading Methods for Steel Products for Shipment (Withdrawn 2014)

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

A1008/A1008M Specification for Steel, Sheet, Cold-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength

Low-Alloy with Improved Formability, Solution Hardened, and Bake Hardenable

A1011/A1011M Specification for Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-

Strength Low-Alloy with Improved Formability, and Ultra-High Strength

A1039/A1039M Specification for Steel, Sheet, Hot Rolled, Carbon, Commercial, Structural, and High-Strength Low-Alloy,

Produced by Twin-Roll Casting Process

A1040 Guide for Specifying Harmonized Standard Grade Compositions for Wrought Carbon, Low-Alloy, and Alloy Steels

E1806 Practice for Sampling Steel and Iron for Determination of Chemical Composition

E213 Practice for Ultrasonic Testing of Metal Pipe and Tubing

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee A01.09

on Carbon Steel Tubular Products.

Current edition approved May 1, 2012May 1, 2014. Published July 2012May 2014. Originally approved in 1964. Last previous edition approved in 20082012 as

A513 – 08.A513/A513M – 12. DOI: 10.1520/A0513_A0513M-12.10.1520/A0513_A0513M-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A513/A513M − 14

E273 Practice for Ultrasonic Testing of the Weld Zone of Welded Pipe and Tubing

E309 Practice for Eddy-Current Examination of Steel Tubular Products Using Magnetic Saturation

E570 Practice for Flux Leakage Examination of Ferromagnetic Steel Tubular Products

4

2.2 ANSI Standard:

B 46.1 Surface Texture

5

2.3 Military Standards:

MIL-STD-129 Marking for Shipment and Storage

5

2.4 Federal Standard:

Fed. Std. No. 123 Markin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.