ASTM C308-00(2005)

(Test Method)Standard Test Methods for Working, Initial Setting, and Service Strength Setting Times of Chemical-Resistant Resin Mortars

Standard Test Methods for Working, Initial Setting, and Service Strength Setting Times of Chemical-Resistant Resin Mortars

SIGNIFICANCE AND USE

These test methods offer a means of determining the working time, initial setting time and service strength setting time of chemical-resistant resin mortars. The results obtained should serve as a guide in, but not as the sole basis for, selection of a chemical-resistant mortar for a particular application.

SCOPE

1.1 These test methods cover the determination of the working, setting and service strength setting times of chemical-resistant resin mortars.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C308 − 00(Reapproved 2005)

Standard Test Methods for

Working, Initial Setting, and Service Strength Setting Times

1

of Chemical-Resistant Resin Mortars

This standard is issued under the fixed designation C308; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Apparatus

1.1 These test methods cover the determination of the 5.1 Weighing Equipment—Shall be capable of weighing

working, initial setting, and service strength setting times of materials or specimens to 60.3 % accuracy.

chemical-resistant resin mortars.

5.2 Mixing Equipment:

5.2.1 Porcelain Enameled Pan—Measuring approximately

1.2 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information 250 mm long by 400 mm wide by 50 mm deep (10 in. by 16

in. by 2 in.).

only.

5.2.2 Bricklayer’s Triangular Trowel —Approximately 100

1.3 This standard does not purport to address all of the

mm (4 in.) in length.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 5.3 Bricks—As per Specification C279, Type III.

priate safety and health practices and determine the applica-

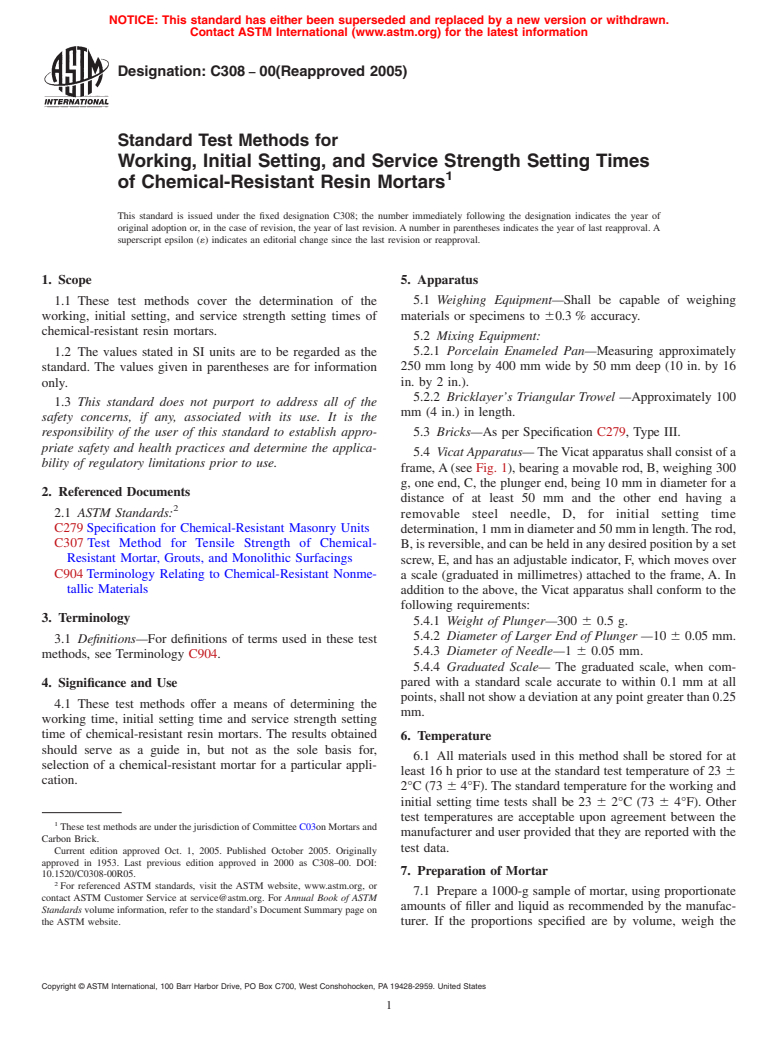

5.4 Vicat Apparatus— The Vicat apparatus shall consist of a

bility of regulatory limitations prior to use.

frame,A(see Fig. 1), bearing a movable rod, B, weighing 300

g, one end, C, the plunger end, being 10 mm in diameter for a

2. Referenced Documents

distance of at least 50 mm and the other end having a

2

2.1 ASTM Standards:

removable steel needle, D, for initial setting time

C279 Specification for Chemical-Resistant Masonry Units

determination,1mmindiameterand50mminlength.Therod,

C307 Test Method for Tensile Strength of Chemical-

B,isreversible,andcanbeheldinanydesiredpositionbyaset

Resistant Mortar, Grouts, and Monolithic Surfacings

screw, E, and has an adjustable indicator, F, which moves over

C904 Terminology Relating to Chemical-Resistant Nonme-

a scale (graduated in millimetres) attached to the frame, A. In

tallic Materials

addition to the above, the Vicat apparatus shall conform to the

following requirements:

3. Terminology

5.4.1 Weight of Plunger—300 6 0.5 g.

5.4.2 Diameter of Larger End of Plunger —10 6 0.05 mm.

3.1 Definitions—For definitions of terms used in these test

5.4.3 Diameter of Needle—1 6 0.05 mm.

methods, see Terminology C904.

5.4.4 Graduated Scale— The graduated scale, when com-

pared with a standard scale accurate to within 0.1 mm at all

4. Significance and Use

points, shall not show a deviation at any point greater than 0.25

4.1 These test methods offer a means of determining the

mm.

working time, initial setting time and service strength setting

time of chemical-resistant resin mortars. The results obtained

6. Temperature

should serve as a guide in, but not as the sole basis for,

6.1 All materials used in this method shall be stored for at

selection of a chemical-resistant mortar for a particular appli-

least 16 h prior to use at the standard test temperature of 23 6

cation.

2°C (73 6 4°F). The standard temperature for the working and

initial setting time tests shall be 23 6 2°C (73 6 4°F). Other

test temperatures are acceptable upon agreement between the

1

These test methods are under the jurisdiction of Committee C03on Mortars and

manufacturer and user provided that they are reported with the

Carbon Brick.

test data.

Current edition approved Oct. 1, 2005. Published October 2005. Originally

approved in 1953. Last previous edition approved in 2000 as C308–00. DOI:

7. Preparation of Mortar

10.1520/C0308-00R05.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

7.1 Prepare a 1000-g sample of mortar, using proportionate

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

amounts of filler and liquid as recommended by the manufac-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. turer. If the proportions specified are by volume, weigh the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C308 − 00 (2005)

NOTE 1—Ring, G, and plate, H, are not required for this test.

FIG. 1 Vicat Apparatus

1

materials and report the corresponding proportions by weight. clean, dry bricks to providea6mm( ⁄4 in.) joint. The bricks

Pour an appropriate amount of liquid into the pan, gradually should be laid on freezer paper and the buttered sides pushed

1

add the powder to the liquid resin, and mix thoroughly with the togethertofor

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.