ASTM D559-96

(Test Method)Standard Test Methods for Wetting and Drying Compacted Soil-Cement Mixtures

Standard Test Methods for Wetting and Drying Compacted Soil-Cement Mixtures

SCOPE

1.1 These test methods cover procedures for determining the soil-cement losses, water content changes, and volume changes (swell and shrinkage) produced by repeated wetting and drying of hardened soil-cement specimens. The specimens are compacted in a mold, before cement hydration, to maximum density at optimum moisture content using the compaction procedure described in Test Methods D 558.

1.2 Two test methods, depending on soil gradation, are covered for preparation of material for molding specimens and for molding specimens as follows: Sections Test Method A, using soil material passing a No. 4 (4.75-mm) sieve. This method shall be used when 100% of the soil sample passes the No. 4 (4.75-mm) sieve 5 Test Method B, using soil material passing a 3/4-in. (19.0- mm) sieve. This method shall be used when part of the soil sample is retained on the No. 4 (4.75-mm) sieve 6

1.3 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 559 – 96

Standard Test Methods for

Wetting and Drying Compacted Soil-Cement Mixtures

This standard is issued under the fixed designation D 559; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * D 2168 Test Methods for Calibration of Laboratory

Mechanical-Rammer Soil Compactors

1.1 These test methods cover procedures for determining

D 3740 Practice for the Minimum Requirements for Agen-

the soil-cement losses, water content changes, and volume

cies Engaged in the Testing and/or Inspection of Soil and

changes (swell and shrinkage) produced by repeated wetting

Rock Used in Engineering Design and Construction

and drying of hardened soil-cement specimens. The specimens

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

are compacted in a mold, before cement hydration, to maxi-

poses

mum density at optimum water content using the compaction

procedure described in Test Methods D 558.

3. Significance and Use

1.2 Two test methods, depending on soil gradation, are

3.1 These test methods are used to determine the resistance

covered for preparation of material for molding specimens and

of compacted soil-cement specimens to repeated wetting and

for molding specimens as follows:

drying. These test methods were developed to be used in

Sections

conjunction with Test Methods D 560 and criteria given in the

Test Method A, using soil material passing a No. 4

(4.75-mm) sieve. This method shall be used when 100 %

Soil-Cement Laboratory Handbook to determine the mini-

of the soil sample passes the No. 4 (4.75-mm) sieve . 5

mum amount of cement required in soil-cement to achieve a

Test Method B, using soil material passing a ⁄4-in. (19.0-

degree of hardness adequate to resist field weathering.

mm) sieve. This method shall be used when part of the

soil sample is retained on the No. 4 (4.75-mm) sieve. This

NOTE 1—The agency performing these test methods can be evaluated in

test method may be used only on materials with 30 % or

less retained on the ⁄4-in. (19.0-mm) sieve. . 6 accordance with Practice D 3740. Not withstanding statements on preci-

sion and bias contained in these test methods: the precision of these test

1.3 The values stated in inch-pound units are to be regarded

methods is dependent on the competence of the personnel performing it

as the standard. The SI units given in parentheses are for

and the suitability of the equipment and facilities used. Agencies that meet

information only.

the criteria of Practice D 3740 are generally considered capable of

competent and objective testing. Users of these test methods are cautioned

1.4 This standard does not purport to address all of the

that compliance with Practice D 3740 does not, in itself, ensure reliable

safety concerns, if any, associated with its use. It is the

testing. Reliable testing depends on many factors; Practice D 3740

responsibility of the user of this standard to establish appro-

provides a means of evaluating some of these factors.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Apparatus

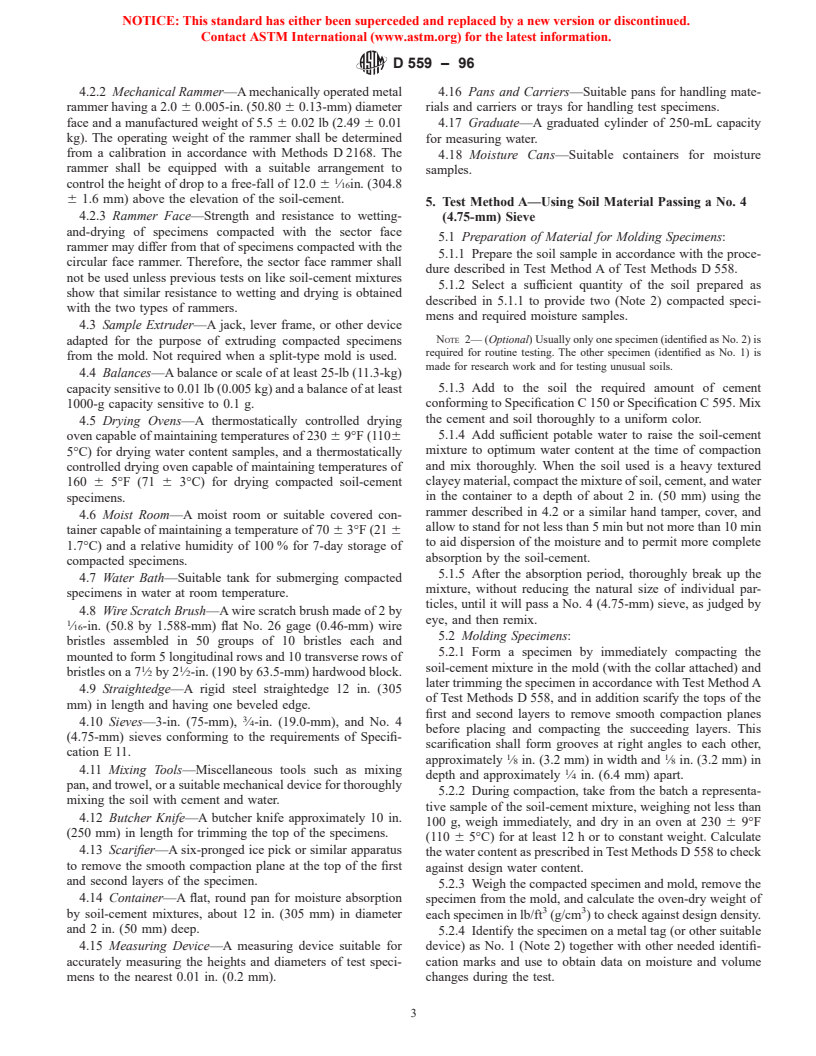

4.1 Mold—A cylindrical metal mold having a capacity of

2. Referenced Documents

3 3

⁄30 6 0.0004 ft (944 6 11 cm ) with an internal diameter of

2.1 ASTM Standards:

4.0 6 0.016 in. (101.60 6 0.41 mm) and conforming to Fig. 1

C 150 Specification for Portland Cement

to permit preparing compacted specimens of soil-cement

C 595 Specification for Blended Hydraulic Cements

mixtures of this size. The mold shall be provided with a

D 558 Test Methods for Moisture-Density Relations of

detachable collar assembly approximately 2 ⁄2 in. (63.5 mm) in

Soil-Cement Mixtures

height. The mold may be of the split type consisting of two

D 560 Test Methods for Freezing-and-Thawing Tests of

half-round sections or a section of pipe with one side split

Compacted Soil-Cement Mixtures

perpendicular to the pipe circumference and that can be

securely locked in place to form a closed cylinder having the

dimensions described above. The mold and collar assembly

These test methods are under the jurisdiction of the ASTM Committee D-18 on

shall be so constructed that it can be fastened firmly to a

Soil and Rock and are the direct responsibility of Subcommittee D18.15 on

detachable base.

Stabilization of Additives.

Current edition approved May 10, 1996. Published July 1996. Originally

published as D 559 – 39. Last previous edition D 559 – 89.

2 4

Annual Book of ASTM Standards, Vols 04.01 and 04.02. Annual Book of ASTM Standards, Vols 04.01, 04.06, and 14.02.

3 5

Annual Book of ASTM Standards, Vol 04.08. Soil-Cement Laboratory Handbook, Portland Cement Assn., 1971.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D559–96

Metric Equivalents

in. mm

0.016 0.41

0.026 0.66

⁄32 0.80

⁄16 1.6

⁄8 3.2

⁄4 6.4

⁄32 8.7

⁄8 9.5

⁄2 12.7

⁄8 15.9

2 50.8

2 ⁄2 63.5

4 101.6

4 ⁄4 108.0

4 ⁄2 114.3

4.584 116.43

6 152.4

6 ⁄2 165.1

8 203.2

ft cm

⁄30 944

0.004 11

⁄13 333 2124

0.0009 25

NOTE 1—The tolerance on the height is governed by the allowable volume and diameter tolerances.

NOTE 2—The methods shown for attaching the extension collar to the mold and the mold to the base plate are recommended. However, others methods

are acceptable, providing the attachments are equally as rigid as those shown.

FIG. 1 Cylindrical Mold

4.2 Rammer: 6 1.6 mm) above the elevation of the soil-cement. The

4.2.1 Manual Rammer—A manually operated metal ram- guidesleeve shall have at least four vent holes not smaller than

3 3

mer having a 2.0 6 0.005-in. (50.80 6 0.13-mm) diameter ⁄8 in. (9.5 mm) spaced 90° apart and located with centers ⁄4 6

circular face and weighing 5.5 6 0.02 lb (2.49 6 0.01 kg). The ⁄16 in. (19.0 6 1.6 mm) from each end and shall provide

rammer shall be equipped with a suitable guidesleeve to sufficient clearance that freefalls of the rammer shaft and head

control the height of drop to a free fall of 12 6 ⁄16 in. (304.8 will not be restricted.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D559–96

4.2.2 Mechanical Rammer—A mechanically operated metal 4.16 Pans and Carriers—Suitable pans for handling mate-

rammer having a 2.0 6 0.005-in. (50.80 6 0.13-mm) diameter rials and carriers or trays for handling test specimens.

face and a manufactured weight of 5.5 6 0.02 lb (2.49 6 0.01

4.17 Graduate—A graduated cylinder of 250-mL capacity

kg). The operating weight of the rammer shall be determined

for measuring water.

from a calibration in accordance with Methods D 2168. The

4.18 Moisture Cans—Suitable containers for moisture

rammer shall be equipped with a suitable arrangement to

samples.

control the height of drop to a free-fall of 12.0 6 ⁄16in. (304.8

6 1.6 mm) above the elevation of the soil-cement.

5. Test Method A—Using Soil Material Passing a No. 4

4.2.3 Rammer Face—Strength and resistance to wetting- (4.75-mm) Sieve

and-drying of specimens compacted with the sector face

5.1 Preparation of Material for Molding Specimens:

rammer may differ from that of specimens compacted with the

5.1.1 Prepare the soil sample in accordance with the proce-

circular face rammer. Therefore, the sector face rammer shall

dure described in Test Method A of Test Methods D 558.

not be used unless previous tests on like soil-cement mixtures

5.1.2 Select a sufficient quantity of the soil prepared as

show that similar resistance to wetting and drying is obtained

described in 5.1.1 to provide two (Note 2) compacted speci-

with the two types of rammers.

mens and required moisture samples.

4.3 Sample Extruder—A jack, lever frame, or other device

NOTE 2— (Optional) Usually only one specimen (identified as No. 2) is

adapted for the purpose of extruding compacted specimens

required for routine testing. The other specimen (identified as No. 1) is

from the mold. Not required when a split-type mold is used.

made for research work and for testing unusual soils.

4.4 Balances—A balance or scale of at least 25-lb (11.3-kg)

capacity sensitive to 0.01 lb (0.005 kg) and a balance of at least 5.1.3 Add to the soil the required amount of cement

1000-g capacity sensitive to 0.1 g. conforming to Specification C 150 or Specification C 595. Mix

the cement and soil thoroughly to a uniform color.

4.5 Drying Ovens—A thermostatically controlled drying

5.1.4 Add sufficient potable water to raise the soil-cement

oven capable of maintaining temperatures of 230 6 9°F (1106

mixture to optimum water content at the time of compaction

5°C) for drying water content samples, and a thermostatically

and mix thoroughly. When the soil used is a heavy textured

controlled drying oven capable of maintaining temperatures of

clayey material, compact the mixture of soil, cement, and water

160 6 5°F (71 6 3°C) for drying compacted soil-cement

in the container to a depth of about 2 in. (50 mm) using the

specimens.

rammer described in 4.2 or a similar hand tamper, cover, and

4.6 Moist Room—A moist room or suitable covered con-

allow to stand for not less than 5 min but not more than 10 min

tainer capable of maintaining a temperature of 70 6 3°F (21 6

to aid dispersion of the moisture and to permit more complete

1.7°C) and a relative humidity of 100 % for 7-day storage of

absorption by the soil-cement.

compacted specimens.

5.1.5 After the absorption period, thoroughly break up the

4.7 Water Bath—Suitable tank for submerging compacted

mixture, without reducing the natural size of individual par-

specimens in water at room temperature.

ticles, until it will pass a No. 4 (4.75-mm) sieve, as judged by

4.8 Wire Scratch Brush—A wire scratch brush made of 2 by

eye, and then remix.

⁄16-in. (50.8 by 1.588-mm) flat No. 26 gage (0.46-mm) wire

5.2 Molding Specimens:

bristles assembled in 50 groups of 10 bristles each and

5.2.1 Form a specimen by immediately compacting the

mounted to form 5 longitudinal rows and 10 transverse rows of

soil-cement mixture in the mold (with the collar attached) and

1 1

bristles on a 7 ⁄2 by 2 ⁄2-in. (190 by 63.5-mm) hardwood block.

later trimming the specimen in accordance with Test Method A

4.9 Straightedge—A rigid steel straightedge 12 in. (305

of Test Methods D 558, and in addition scarify the tops of the

mm) in length and having one beveled edge.

first and second layers to remove smooth compaction planes

4.10 Sieves—3-in. (75-mm), ⁄4-in. (19.0-mm), and No. 4

before placing and compacting the succeeding layers. This

(4.75-mm) sieves conforming to the requirements of Specifi-

scarification shall form grooves at right angles to each other,

cation E 11.

1 1

approximately ⁄8 in. (3.2 mm) in width and ⁄8 in. (3.2 mm) in

4.11 Mixing Tools—Miscellaneous tools such as mixing

depth and approximately ⁄4 in. (6.4 mm) apart.

pan, and trowel, or a suitable mechanical device for thoroughly

5.2.2 During compaction, take from the batch a representa-

mixing the soil with cement and water.

tive sample of the soil-cement mixture, weighing not less than

4.12 Butcher Knife—A butcher knife approximately 10 in.

100 g, weigh immediately, and dry in an oven at 230 6 9°F

(250 mm) in length for trimming the top of the specimens.

(110 6 5°C) for at least 12 h or to constant weight. Calculate

4.13 Scarifier—A six-pronged ice pick or similar apparatus

the water content as prescribed in Test Methods D 558 to check

to remove the smooth compaction plane at the top of the first

against design water content.

and second layers of the specimen.

5.2.3 Weigh the compacted specimen and mold, remove the

4.14 Container—A flat, round pan for moisture absorption

specimen from the mold, and calculate the oven-dry weight of

3 3

by soil-cement mixtures, about 12 in. (305 mm) in diameter

each specimen in lb/ft (g/cm ) to check against design density.

and 2 in. (50 mm) deep.

5.2.4 Identify the specimen on a metal tag (or other suitable

4.15 Measuring Device—A measuring device suitable for device) as No. 1 (Note 2) together with other needed identifi-

accurately measuring the heights and diameters of test speci- cation marks and use to obtain data on moisture and volume

mens to the nearest 0.01 in. (0.2 mm). changes during the test.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D559–96

5.2.5 Form a second specimen as rapidly as possible and 6. Test Method B—Using Soil Material Passing a ⁄4-in.

determine the percentage of moisture and oven-dry weight as (19.0-mm) Sieve

described in 5.2.1-5.2.3. Identify this specimen as No. 2,

6.1 Preparation of Material for Molding Specimens:

together with other needed identification marks and use to

6.1.1 Prepare the soil sample in accordance with Test

obtain data on soil-cement losses during the test.

Method B of Test Methods D 558.

5.2.6 Determine the average diameter and height of the No.

6.1.2 Select and maintain separate representative samples of

1 specimen and calculate its volume.

soil passing the No. 4 (4.75-mm) sieve and of saturated,

5.2.7 Place the specimens on suitable carriers in the moist surface-dry aggregate passing the ⁄4-in. (19.0-mm) sieve and

room and protect them from free water for a period of 7 days.

retained on the No. 4 (4.75-mm) sieve so that the total sample

will be enough to provide two (Note 1) compacted specimens

5.2.8 Weigh and measure the No. 1 specimen at the end of

the 7-day storage period to provide data for calculating its and required moisture samples. The percentage, by oven-dry

weight, of aggregate passing the ⁄4-in. (19.0-mm) sieve and

water content and volume.

retained on the No. 4 (4.75-mm) sieve shall be the same as the

NOTE 3—It is important that all height and diameter measurements be

percentage passing the 3-in. (75-mm) sieve and retained on the

accurate to within 0.01 in. (0.2 mm) and be taken at the same points on the

No. 4 (4.75-mm) sieve in the original sample.

specimen at all time

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.