ASTM G71-81(2003)

(Guide)Standard Guide for Conducting and Evaluating Galvanic Corrosion Tests in Electrolytes

Standard Guide for Conducting and Evaluating Galvanic Corrosion Tests in Electrolytes

SIGNIFICANCE AND USE

Use of this guide is intended to provide information on the galvanic corrosion of metals in electrical contact in an electrolyte that does not have a flow velocity sufficient to cause erosion-corrosion or cavitation.

This standard is presented as a guide for conducting galvanic corrosion tests in liquid electrolyte solutions, both in the laboratory and in service environments. Adherence to this guide will aid in avoiding some of the inherent difficulties in such testing.

SCOPE

1.1 This guide covers conducting and evaluating galvanic corrosion tests to characterize the behavior of two dissimilar metals in electrical contact in an electrolyte under low-flow conditions. It can be adapted to wrought or cast metals and alloys.

1.2 This guide covers the selection of materials, specimen preparation, test environment, method of exposure, and method for evaluating the results to characterize the behavior of galvanic couples in an electrolyte. Additional information on galvanic corrosion testing and examples of the conduct and evaluation of galvanic corrosion tests in electrolytes are given in Refs (1) through (7).

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G 71 – 81 (Reapproved 2003)

Standard Guide for

Conducting and Evaluating Galvanic Corrosion Tests in

1

Electrolytes

ThisstandardisissuedunderthefixeddesignationG 71;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Significance and Use

1.1 This guide covers conducting and evaluating galvanic 3.1 Use of this guide is intended to provide information on

corrosion tests to characterize the behavior of two dissimilar the galvanic corrosion of metals in electrical contact in an

metals in electrical contact in an electrolyte under low-flow electrolyte that does not have a flow velocity sufficient to cause

conditions. It can be adapted to wrought or cast metals and erosion-corrosion or cavitation.

alloys. 3.2 This standard is presented as a guide for conducting

1.2 This guide covers the selection of materials, specimen galvanic corrosion tests in liquid electrolyte solutions, both in

preparation,testenvironment,methodofexposure,andmethod the laboratory and in service environments. Adherence to this

for evaluating the results to characterize the behavior of guide will aid in avoiding some of the inherent difficulties in

galvanic couples in an electrolyte. such testing.

NOTE 1—Additional information on galvanic corrosion testing and

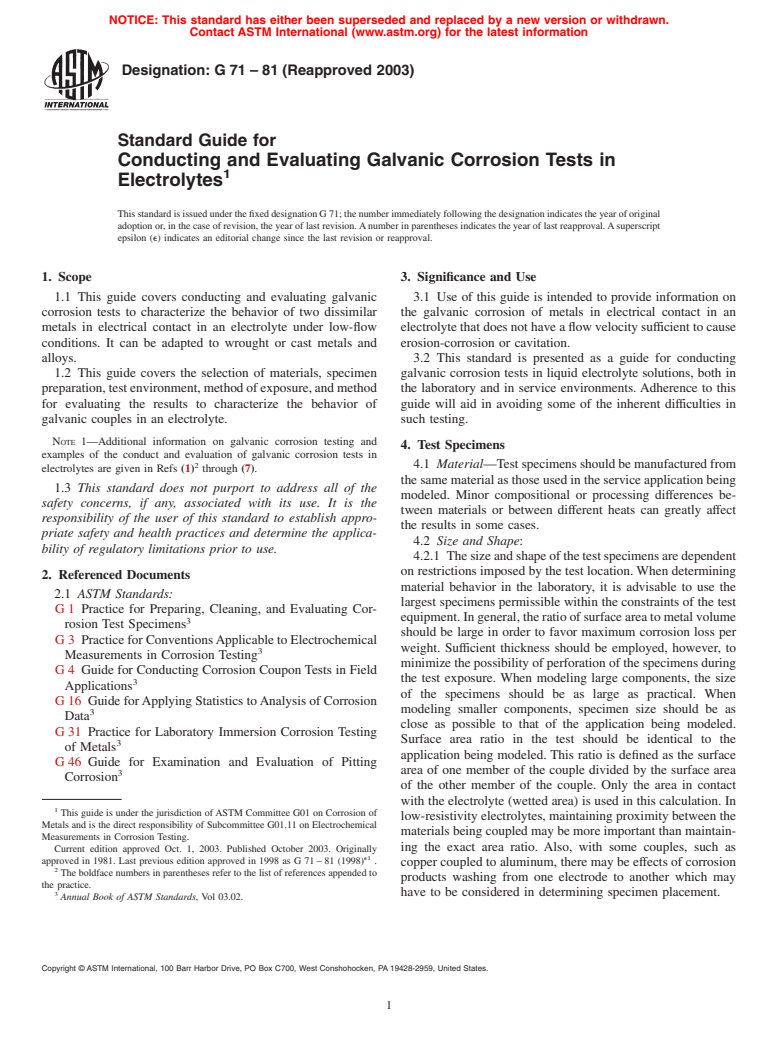

4. Test Specimens

examples of the conduct and evaluation of galvanic corrosion tests in

2 4.1 Material—Testspecimensshouldbemanufacturedfrom

electrolytes are given in Refs (1) through (7).

the same material as those used in the service application being

1.3 This standard does not purport to address all of the

modeled. Minor compositional or processing differences be-

safety concerns, if any, associated with its use. It is the

tween materials or between different heats can greatly affect

responsibility of the user of this standard to establish appro-

the results in some cases.

priate safety and health practices and determine the applica-

4.2 Size and Shape:

bility of regulatory limitations prior to use.

4.2.1 Thesizeandshapeofthetestspecimensaredependent

on restrictions imposed by the test location. When determining

2. Referenced Documents

material behavior in the laboratory, it is advisable to use the

2.1 ASTM Standards:

largest specimens permissible within the constraints of the test

G1 Practice for Preparing, Cleaning, and Evaluating Cor-

equipment.Ingeneral,theratioofsurfaceareatometalvolume

3

rosion Test Specimens

should be large in order to favor maximum corrosion loss per

G3 PracticeforConventionsApplicabletoElectrochemical

weight. Sufficient thickness should be employed, however, to

3

Measurements in Corrosion Testing

minimize the possibility of perforation of the specimens during

G4 Guide for Conducting Corrosion Coupon Tests in Field

the test exposure. When modeling large components, the size

3

Applications

of the specimens should be as large as practical. When

G16 Guide forApplying Statistics toAnalysis of Corrosion

modeling smaller components, specimen size should be as

3

Data

close as possible to that of the application being modeled.

G31 Practice for Laboratory Immersion Corrosion Testing

Surface area ratio in the test should be identical to the

3

of Metals

application being modeled. This ratio is defined as the surface

G46 Guide for Examination and Evaluation of Pitting

area of one member of the couple divided by the surface area

3

Corrosion

of the other member of the couple. Only the area in contact

with the electrolyte (wetted area) is used in this calculation. In

1

This guide is under the jurisdiction ofASTM Committee G01 on Corrosion of

low-resistivity electrolytes, maintaining proximity between the

Metals and is the direct responsibility of Subcommittee G01.11 on Electrochemical

materials being coupled may be more important than maintain-

Measurements in Corrosion Testing.

ing the exact area ratio. Also, with some couples, such as

Current edition approved Oct. 1, 2003. Published October 2003. Originally

e1

approved in 1981. Last previous edition approved in 1998 as G 71 – 81 (1998) .

copper coupled to aluminum, there may be effects of corrosion

2

The boldface numbers in parentheses refer to the list of references appended to

products washing from one electrode to another which may

the practice.

3 have to be considered in determining specimen placement.

Annual Book of ASTM Standards, Vol 03.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

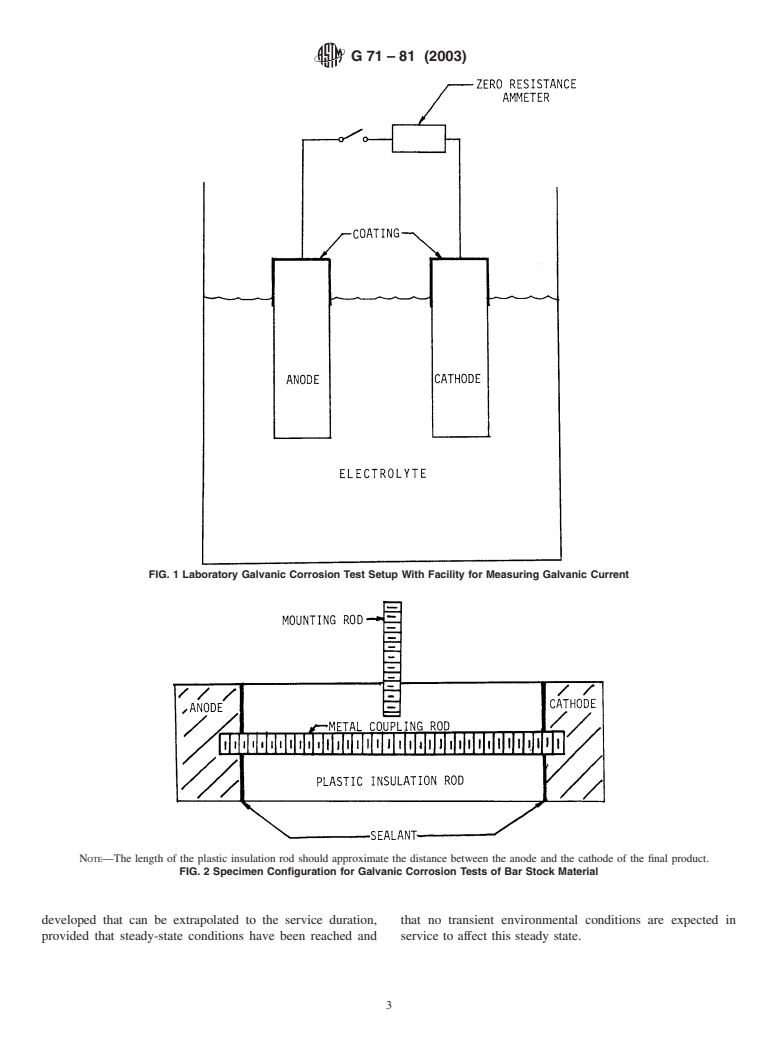

G 71 – 81 (2003)

4.2.2 Laboratory tests are normally performed on rectangu- solution shoul

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.