ASTM C592-22a

(Specification)Standard Specification for Mineral Fiber Blanket Insulation and Blanket-Type Pipe Insulation (Metal-Mesh Covered) (Industrial Type)

Standard Specification for Mineral Fiber Blanket Insulation and Blanket-Type Pipe Insulation (Metal-Mesh Covered) (Industrial Type)

ABSTRACT

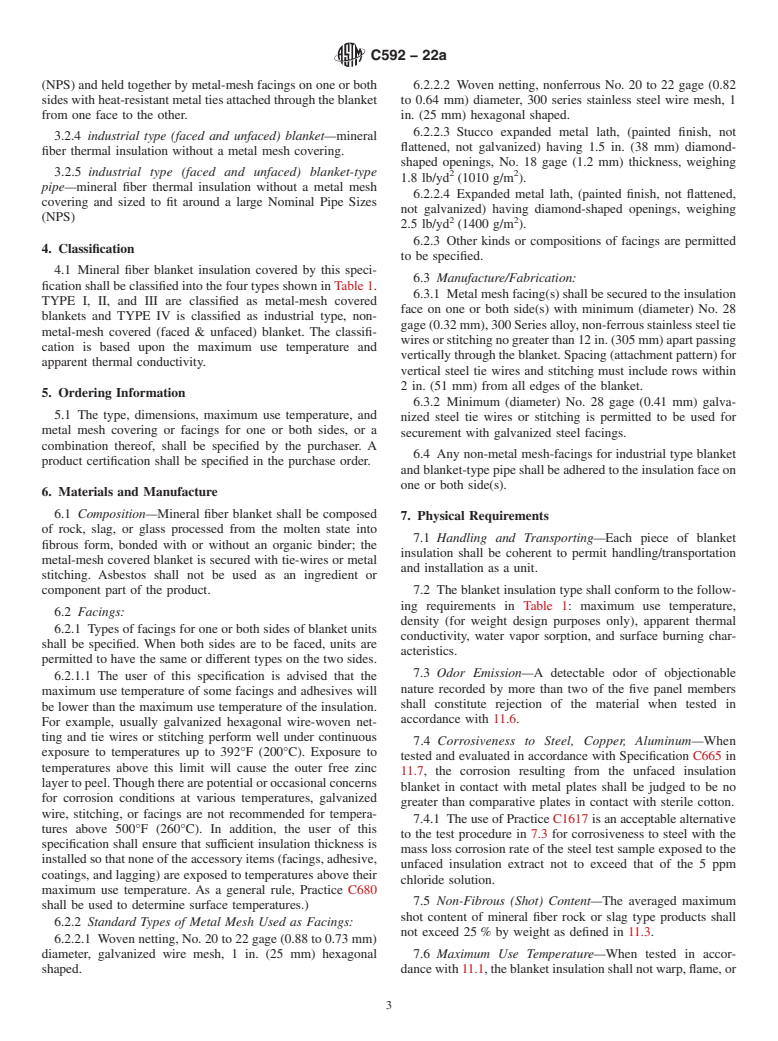

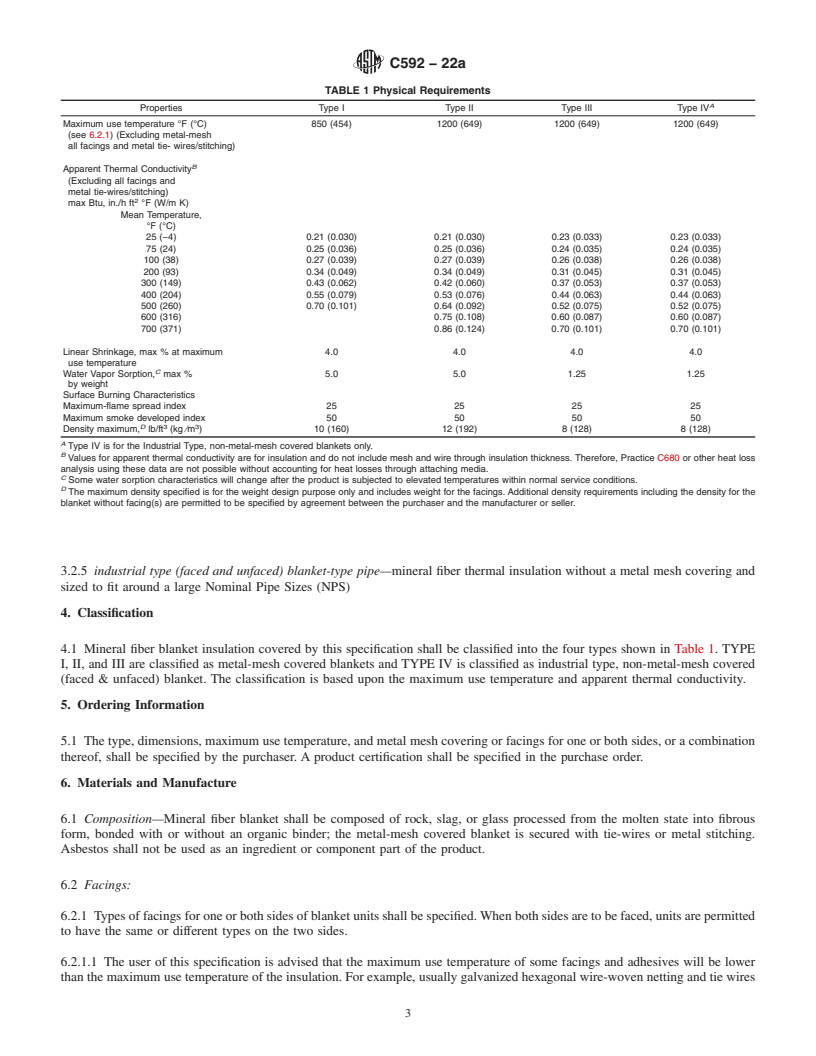

This specification covers mineral fiber blanket insulation and blanket-type pipe insulation (metal-mesh covered) (industrial type). Mineral fiber metal-mesh covered blanket shall be composed of rock, slag, or glass processed from the molten state into fibrous form, bonded with or without an organic binder, and secured with metallic supporting facing(s). Types of facings for one or both sides of blanket units shall be specified. When both sides are to be faced, units are permitted to have the same or different types on the two sides. Each piece of metal-mesh covered insulation shall be coherent to permit handling/transportation and installation as a unit. A detectable odor of objectionable nature recorded by more than two of the five panel members shall constitute rejection of the material. When tested and evaluated, the corrosion resulting from the unfaced insulation blanket in contact with metal plates shall be judged to be no greater than comparative plates in contact with sterile cotton. The averaged maximum shot content of mineral fiber rock or slag type products shall not exceed 30 % by weight. When tested, the blanket insulation shall not warp, flame, or glow during hot surface exposure. When tested, the blanket mid-point temperature shall not at any time exceed the hot surface temperature by more than 100°F (55.5°C). When tested, the blanket insulation shall not exceed the recorded temperature rise more than 54°F (30°C) with no flaming and weight loss exceeding 5 %.

SCOPE

1.1 This specification covers the composition, dimensions, and physical properties of mineral fiber (rock, slag, or glass) metal mesh covered and industrial type blanket and blanket-type pipe insulation (typically on 24 in. (610 mm) diameters or larger)). Its use is for cooled surfaces at temperatures operating below ambient to 0°F (−18°C) and on heated surfaces on expansion joints to large diameter vessels and tanks operating at temperatures up to 1200°F (649°C). Specific applications outside the actual use temperatures shall be agreed upon between the manufacturer and purchaser.

1.2 For satisfactory performance, properly installed protective vapor retarders or barriers shall be used on below ambient temperature applications to reduce movement of moisture/water vapor through or around the insulation towards the colder surface. Failure to use a vapor retarder can lead to insulation and system damage. Refer to Practice C921 to aid material selection. Although vapor retarder properties are not part of this specification, properties required in Specification C1136 are pertinent to applications or performance.

1.3 The orientation of the fibers within the blanket is primarily parallel to the heated surface. This specification does not cover fabricated pipe and tank wrap insulation where the insulation has been cut and fabricated to provide fiber orientation that is perpendicular to the heated surface.

1.4 This standard does not purport to provide the performance requirements of hourly-rated fire systems. Consult the manufacturer for the appropriate system.

1.5 See Supplementary Requirements for modifications to sections in this standard only when specified by purchaser in the contract or order from the U.S. Military specifications utilized by the U.S. Department of Defense, Department of the Navy, and the Naval Systems Command.

1.6 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internatio...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:C592 −22a

Standard Specification for

Mineral Fiber Blanket Insulation and Blanket-Type Pipe

1

Insulation (Metal-Mesh Covered) (Industrial Type)

This standard is issued under the fixed designation C592; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.6 Thevaluesstatedininch-poundunitsaretoberegarded

as standard. The values given in parentheses are mathematical

1.1 This specification covers the composition, dimensions,

conversions to SI units that are provided for information only

and physical properties of mineral fiber (rock, slag, or glass)

and are not considered standard.

metal mesh covered and industrial type blanket and blanket-

typepipeinsulation(typicallyon24in.(610mm)diametersor 1.7 This standard does not purport to address all of the

larger)).Itsuseisforcooledsurfacesattemperaturesoperating safety concerns, if any, associated with its use. It is the

below ambient to 0°F (−18°C) and on heated surfaces on responsibility of the user of this standard to establish appro-

expansion joints to large diameter vessels and tanks operating priate safety, health, and environmental practices and deter-

at temperatures up to 1200°F (649°C). Specific applications mine the applicability of regulatory limitations prior to use.

outside the actual use temperatures shall be agreed upon

1.8 This international standard was developed in accor-

between the manufacturer and purchaser.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

1.2 For satisfactory performance, properly installed protec-

Development of International Standards, Guides and Recom-

tive vapor retarders or barriers shall be used on below ambient

mendations issued by the World Trade Organization Technical

temperature applications to reduce movement of moisture/

Barriers to Trade (TBT) Committee.

water vapor through or around the insulation towards the

colder surface. Failure to use a vapor retarder can lead to

2. Referenced Documents

insulation and system damage. Refer to Practice C921 to aid

2

material selection. Although vapor retarder properties are not

2.1 ASTM Standards:

part of this specification, properties required in Specification

C167Test Methods forThickness and Density of Blanket or

C1136 are pertinent to applications or performance.

Batt Thermal Insulations

C168Terminology Relating to Thermal Insulation

1.3 The orientation of the fibers within the blanket is

C177Test Method for Steady-State Heat Flux Measure-

primarilyparalleltotheheatedsurface.Thisspecificationdoes

ments and Thermal Transmission Properties by Means of

not cover fabricated pipe and tank wrap insulation where the

the Guarded-Hot-Plate Apparatus

insulation has been cut and fabricated to provide fiber orien-

C356Test Method for Linear Shrinkage of Preformed High-

tation that is perpendicular to the heated surface.

Temperature Thermal Insulation Subjected to Soaking

1.4 This standard does not purport to provide the perfor-

Heat

mance requirements of hourly-rated fire systems. Consult the

C390Practice for Sampling and Acceptance of Thermal

manufacturer for the appropriate system.

Insulation Lots

1.5 See Supplementary Requirements for modifications to

C411Test Method for Hot-Surface Performance of High-

sections in this standard only when specified by purchaser in

Temperature Thermal Insulation

the contract or order from the U.S. Military specifications

C447Practice for Estimating the Maximum Use Tempera-

utilizedbytheU.S.DepartmentofDefense,Departmentofthe

ture of Thermal Insulations

Navy, and the Naval Systems Command.

C518Test Method for Steady-State Thermal Transmission

Properties by Means of the Heat Flow Meter Apparatus

1

This specification is under the jurisdiction of ASTM Committee C16 on

Thermal Insulation and is the direct responsibility of Subcommittee C16.23 on

2

Blanket and Loose Fill Insulation. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2022. Published May 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1966. Last previous edition approved in 2022 as C592–22. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C0592-22A. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive,

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C592 − 22 C592 − 22a

Standard Specification for

Mineral Fiber Blanket Insulation and Blanket-Type Pipe

1

Insulation (Metal-Mesh Covered) (Industrial Type)

This standard is issued under the fixed designation C592; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers the composition, dimensions, and physical properties of mineral fiber (rock, slag, or glass) metal

mesh covered and industrial type blanket and blanket-type pipe insulation (typically on 24 in. (610 mm) diameters or larger)). Its

use is for cooled surfaces at temperatures operating below ambient to 0°F (−18°C) and on heated surfaces on expansion joints to

large diameter vessels and tanks operating at temperatures up to 1200°F (649°C). Specific applications outside the actual use

temperatures shall be agreed upon between the manufacturer and purchaser.

1.2 For satisfactory performance, properly installed protective vapor retarders or barriers shall be used on below ambient

temperature applications to reduce movement of moisture/water vapor through or around the insulation towards the colder surface.

Failure to use a vapor retarder can lead to insulation and system damage. Refer to Practice C921 to aid material selection. Although

vapor retarder properties are not part of this specification, properties required in Specification C1136 are pertinent to applications

or performance.

1.3 The orientation of the fibers within the blanket is primarily parallel to the heated surface. This specification does not cover

fabricated pipe and tank wrap insulation where the insulation has been cut and fabricated to provide fiber orientation that is

perpendicular to the heated surface.

1.4 This standard does not purport to provide the performance requirements of hourly-rated fire systems. Consult the manufacturer

for the appropriate system.

1.5 See Supplementary Requirements for modifications to sections in this standard only when specified by purchaser in the

contract or order from the U.S. Military specifications utilized by the U.S. Department of Defense, Department of the Navy, and

the Naval Systems Command.

1.6 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1

This specification is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.23 on Blanket and Loose

Fill Insulation.

Current edition approved March 1, 2022May 1, 2022. Published March 2022May 2022. Originally approved in 1966. Last previous edition approved in 20162022 as

C592 – 16.C592 – 22. DOI: 10.1520/C0592-22.10.1520/C0592-22A.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C592 − 22a

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C167 Test Methods for Thickness and Density of Blanket or Batt Thermal Insulations

C168 Terminology Relating to Thermal Insulation

C177 Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the

Guarded-Hot-Plate Apparatus

C356 Test Method for Linear Shrinkage of Preformed High-Temperature Thermal Insulation Subjected to Soaking Heat

C390 Practice for Sampling and Acceptance of Thermal Insulation Lots

C411 Test Method for Hot-Surface Performance of High-Temperature Thermal Insulation

C447 Practice for Estimating the Maximum Use Temperature of Thermal Insulations

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.