ASTM D4976-12a(2020)

(Specification)Standard Specification for Polyethylene Plastics Molding and Extrusion Materials

Standard Specification for Polyethylene Plastics Molding and Extrusion Materials

ABSTRACT

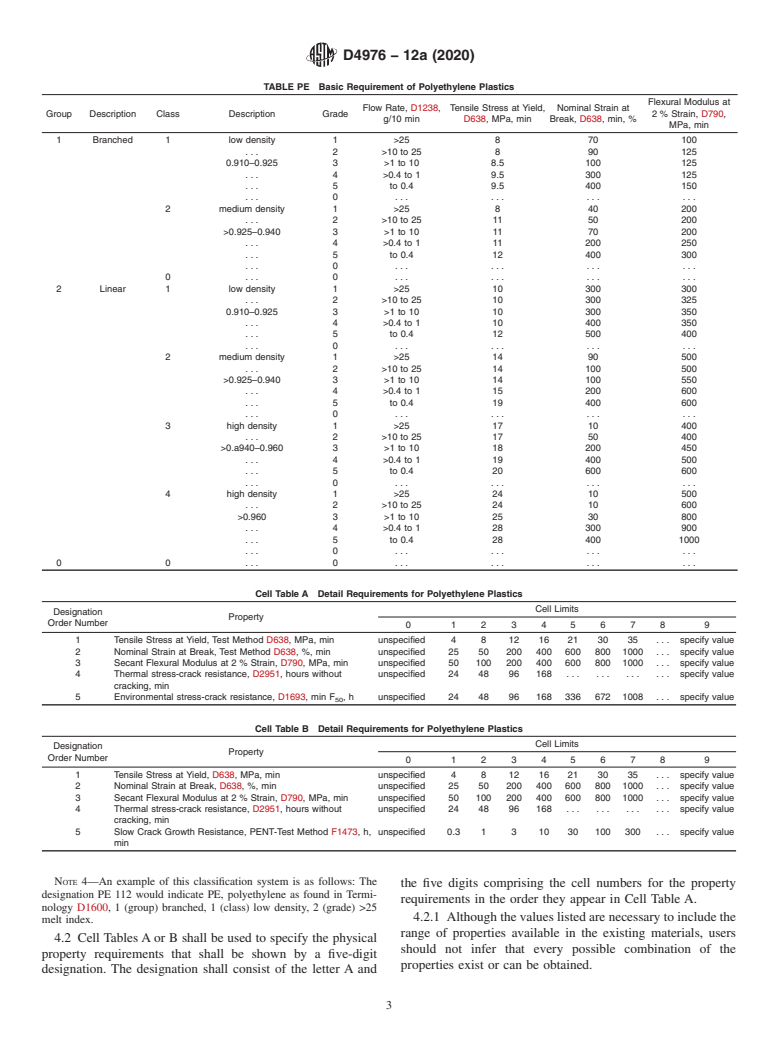

This specification provides the standard requirements for polyethylene plastic molding and extrusion materials. The tests involved in this specification are intended to provide information for identifying materials in accordance with the groups, classes, and grades covered. Polyethylene plastic materials are classified into two groups in accordance with the molecular structure which may be branched or linear. Test specimens shall be compression molded, conditioned in a standard or controlled laboratory atmosphere, and tested to determine the materials' physical and electrical properties. The specimens shall comply with the following requirements: flow rate; density; tensile stress at yield; nominal strain at break; secant flexural modulus; environmental stress-crack resistance; slow crack growth resistance; thermal stress crack resistance; permittivity; dissipation factor; volume resistivity; water immersion stability; flammability; and weatherability.

SCOPE

1.1 This specification provides for the identification of polyethylene plastics molding and extrusion materials in such a manner that the supplier and the user can agree on the acceptability of different commercial lots or shipments. The tests involved in this specification are intended to provide information for identifying materials in accordance with the groups, classes, and grades covered. It is not the function of this specification to provide specific engineering data for design purposes.

1.2 Other requirements necessary to identify particular characteristics important to specialized applications shall be agreed upon between the user and the supplier, by using the suffixes given in Section 1.3.

1.3 Ethylene plastic materials, being thermoplastic, are reprocessable and recyclable (see Note 1). This specification allows for the use of those ethylene plastic materials, provided that any specific requirements as governed by the producer and the end user are met.

Note 1: See Guide D7209 for information and definitions related to recycled plastics.

1.4 The values stated in SI units are regarded as standard.

1.5 The following precautionary caveat pertains to the test method portion only, Section 12, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 For information regarding plastic pipe materials see Specification D3350. For information regarding wire and cable materials, see Specification D1248.

Note 2: There is no known ISO equivalent to this standard.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D4976 −12a (Reapproved 2020)

Standard Specification for

1

Polyethylene Plastics Molding and Extrusion Materials

This standard is issued under the fixed designation D4976; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

INTRODUCTION

This specification is not intended for the selection of materials, but only as a means to call out

plastic materials to be used for the manufacture of parts.The selection of these materials is to be made

by personnel with expertise in the plastics field where the environment, inherent properties of the

materials, performance of the parts, part design, manufacturing process, and economics are

considered. This specification does not specify the source of the resin to be used for the fabrication

of any given article.

1. Scope* of this standard to establish appropriate safety, health, and

environmental practices and determine the applicability of

1.1 This specification provides for the identification of

regulatory limitations prior to use.

polyethylene plastics molding and extrusion materials in such

1.6 For information regarding plastic pipe materials see

a manner that the supplier and the user can agree on the

Specification D3350. For information regarding wire and cable

acceptability of different commercial lots or shipments. The

materials, see Specification D1248.

tests involved in this specification are intended to provide

NOTE 2—There is no known ISO equivalent to this standard.

information for identifying materials in accordance with the

1.7 This international standard was developed in accor-

groups, classes, and grades covered. It is not the function of

dance with internationally recognized principles on standard-

this specification to provide specific engineering data for

ization established in the Decision on Principles for the

design purposes.

Development of International Standards, Guides and Recom-

1.2 Otherrequirementsnecessarytoidentifyparticularchar-

mendations issued by the World Trade Organization Technical

acteristics important to specialized applications shall be agreed

Barriers to Trade (TBT) Committee.

upon between the user and the supplier, by using the suffixes

given in Section 1.3. 2. Referenced Documents

2

1.3 Ethylene plastic materials, being thermoplastic, are 2.1 ASTM Standards:

reprocessable and recyclable (see Note 1). This specification D257 Test Methods for DC Resistance or Conductance of

allows for the use of those ethylene plastic materials, provided Insulating Materials

D568 Method ofTest for Burning and/or Extent andTime of

that any specific requirements as governed by the producer and

the end user are met. Burning of Flexible Plastics in a Vertical Position (With-

3

drawn 1991)

NOTE 1—See Guide D7209 for information and definitions related to

D618 Practice for Conditioning Plastics for Testing

recycled plastics.

D635 Test Method for Rate of Burning and/or Extent and

1.4 The values stated in SI units are regarded as standard.

Time of Burning of Plastics in a Horizontal Position

1.5 The following precautionary caveat pertains to the test

D638 Test Method for Tensile Properties of Plastics

method portion only, Section 12, of this specification. This

D790 Test Methods for Flexural Properties of Unreinforced

standard does not purport to address all of the safety concerns,

and Reinforced Plastics and Electrical Insulating Materi-

if any, associated with its use. It is the responsibility of the user

als

1 2

This specification is under the jurisdiction of ASTM Committee D20 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Materials. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Dec. 1, 2020. Published December 2020. Originally the ASTM website.

3

approved in 1995. Last previous edition approved in 2012 as D4976 - 12a. DOI: The last approved version of this historical standard is referenced on

10.1520/D4976-12AR20. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4976−12

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.