ASTM D6374-99(2009)

(Test Method)Standard Test Method for Volatile Matter in Green Petroleum Coke Quartz Crucible Procedure

Standard Test Method for Volatile Matter in Green Petroleum Coke Quartz Crucible Procedure

SIGNIFICANCE AND USE

The volatile matter of petroleum coke affects the density of coke particles and can affect artifacts produced from further processing of the coke.

The volatile matter can be used in estimating the calorific value of coke.

SCOPE

1.1 This test method covers the determination of the volatile matter produced by pyrolysis or evolved when petroleum coke is subjected to the specific conditions of the test method.

1.2 The interlaboratory study for precision covered materials with a volatile matter concentration ranging from about 8 to 16 %.

1.3 Samples having a thermal history above 600°C are excluded.

1.4 This test method is empirical and requires the entire test procedure to be closely followed to ensure that results from different laboratories will be comparable.

1.5 This test method is not satisfactory for determining de-dusting material content.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6374–99 (Reapproved 2009)

Standard Test Method for

Volatile Matter in Green Petroleum Coke Quartz Crucible

Procedure

This standard is issued under the fixed designation D6374; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 analysis sample—the reduced and divided representa-

tive portion of the bulk sample, prepared for use in the

1.1 This test method covers the determination of the volatile

laboratory.

matter produced by pyrolysis or evolved when petroleum coke

3.1.2 analysis time—period test samples are placed in the

is subjected to the specific conditions of the test method.

furnace, as determined in Section 9 (5 to 10 min).

1.2 The interlaboratory study for precision covered materi-

3.1.3 bulk sample—the reduced and divided representative

als with a volatile matter concentration ranging from about 8 to

portion of a gross sample as prepared for shipment to and

16 %.

received by a laboratory, to be prepared for analysis.

1.3 Samples having a thermal history above 600°C are

3.1.4 green petroleum coke—same as raw petroleum coke

excluded.

3.1.5 gross sample—the original, uncrushed, representative

1.4 This test method is empirical and requires the entire test

portion taken from a shipment or lot of coke.

procedure to be closely followed to ensure that results from

3.1.6 petroleum coke—a solid, carbonaceous residue pro-

different laboratories will be comparable.

duced by thermal decomposition of heavy petroleum fractions

1.5 This test method is not satisfactory for determining

or cracked stocks, or both.

de-dusting material content.

3.1.7 raw petroleum coke—petroleum coke that has not

1.6 The values stated in SI units are to be regarded as

been calcined.

standard. No other units of measurement are included in this

3.1.8 test sample—the weighed portion of the analysis

standard.

sample actually used in a test.

1.7 This standard does not purport to address all of the

3.1.9 volatile matter—themasslossonheatingexpressedas

safety concerns, if any, associated with its use. It is the

a percent of the moisture free sample used.

responsibility of the user to establish appropriate safety and

health practices and to determine the applicability of regula-

4. Summary of Test Method

tory limitations prior to use.

4.1 Volatile matter of a moisture free petroleum coke is

2. Referenced Documents determined by measuring the mass loss of the coke when

heated under the exact conditions of this test method.

2.1 ASTM Standards:

E11 SpecificationforWovenWireTestSieveClothandTest

5. Significance and Use

Sieves

5.1 The volatile matter of petroleum coke affects the density

E220 Test Method for Calibration of Thermocouples By

of coke particles and can affect artifacts produced from further

Comparison Techniques

processing of the coke.

3. Terminology 5.2 The volatile matter can be used in estimating the

calorific value of coke.

3.1 Definitions of Terms Specific to This Standard:

6. Interferences

This test method is under the jurisdiction of ASTM Committee D02 on

6.1 Moisture has a double effect. The mass loss is increased

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

and the moisture free sample weight is decreased by the

D02.05 on Properties of Fuels, Petroleum Coke and Carbon Material.

amount of moisture actually present in the test sample.

Current edition approved April 15, 2009. Published July 2009. Originally

6.2 Particle Size Effect:

approved in 1999. Last previous edition approved in 2004 as D6374–99(2004).

DOI: 10.1520/D6374-99R09.

6.2.1 The particle size range of the analysis sample affects

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the volatile matter. The coarser the analysis sample, the lower

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the reported volatile matter will be. Crush analysis sample (see

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Annex A1) to pass a 0.250-mm opening (No. 60) sieve but do

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6374–99 (2009)

not overcrush. A 0.125-mm opening (No. 120) sieve should 9.6 Round the recorded elapsed time to the next higher

retain 40 to 55 % of the sample. Do not obtain the analysis minute. This rounded time will be the analysis time for future

sample is by scalping and discarding a portion of the sample. runs (5 min minimum).

6.2.2 Any segregation of particle sizes within the analysis

10. Procedure

sampleshallbecorrectedbyreblendingthesamplejustpriorto

10.1 Ignite the quartz crucible and cover at 950 6 20°C for

weighing the test sample.

5 min periods to constant mass (60.5 mg). Do not cover the

6.3 Thefurnaceshallrecoverto950 620°Cbeforethetime

crucible at this time to allow the carbon to burn off. Cool to

limit is reached. If the furnace does not recover to the starting

ambient temperature in a desiccator before weighing the

temperature within a maximum of 10 min, reduce the number

crucible and cover.

of samples being analyzed until recovery is achieved within 10

min (see Section 9).

NOTE 1—Placing the empty crucibles in the inverted cover when

igniting will reduce breakage and chipping.

7. Apparatus

10.2 Avoiding segregation of particles, transfer 1 g 610 mg

7.1 Electric Muffle Furnace—Calibrated (Test Method

of the analysis sample (see Annex A1) to the crucible, weigh

E220) and regulated to maintain a temperature of 950 6 20°C

the crucible with its contents, and cover to the nearest 0.1 mg.

(1742°F), as measured by a thermocouple mounted inside the

Place the cover on the crucible, and place in sample rack.

furnace. Its heat capacity shall be such that the initial tempera-

10.3 Set the timer for the analysis time (5 to 10 min). Place

ture is regained after the introduction of a cold rack of samples

the rack in the furnace. Start the timer.

within 10 min.

7.2 Quartz Crucibles, self-sealing, 10 mL capacity with NOTE 2—Place the rack in the center of the furnace. Do not allow the

rack to touch the walls of the furnace.

covers.

7.3 Rack,stainlesssteel,designedtoholdupto20crucibles.

10.4 After the analysis time (65 s), remove the rack from

7.4 Rifflers, with hoppers and closures.

the furnace and immediately place on a heat sink.

7.5 Jaw Crusher and Roll Crusher—Other style crushers

10.5 Weigh the crucible after it has cooled to room tem-

that allow control over particle size without contamination are

perature and before it has been at room temperature for longer

acceptable (see Annex A1).

than 20 min.

7.6 Balance, capable of weighing to 0.1 mg.

NOTE 3—If cool down is not in a humidity controlled area, desiccation

7.7 Dessicator.

is required.

7.8 Sieves, meeting Specification E11.

7.9 Timers, stopwatch or second timer.

11. Calculation

7.10 Heat Sink, 1/2 in. plate steel or other heat resistant

11.1 Calculate the volatile matter of the moisture free

material large enough to hold the crucible rack.

prepared coke as follows:

8. Precautions Volatile matter, mass % 5 ~~A2B!!/C! 3 100 (1)

8.1 Effusionofgaseousproducts,includingsootandvarious

where:

hydrocarbons, and the increase of heat associated with the test

A = weight of crucible and prepared sample prior to analy-

can make the use of a hood desirable.

sis, g,

B = weight of crucible and prepared sample after analysis,

9. Furnace Calibration

g, and

9.1 Avoiding segregation of particles, transfer1g(6 0.05

C = weight of prepared sample, g.

g) of an analysis sample (seeAnnexA1) to each crucible in the

12. Report

rack, weigh each crucible with its contents, and cover to the

nearest 0.1 mg. Pl

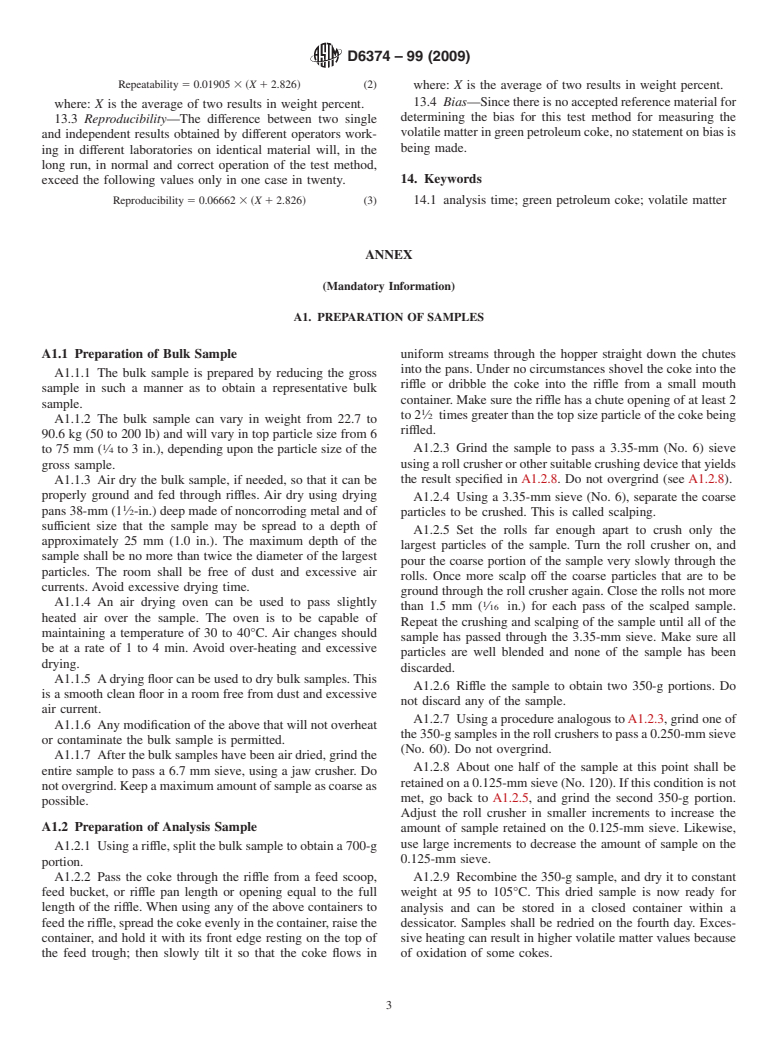

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.