ASTM D3407-78(1994)e1

(Test Method)Standard Test Methods for Joint Sealants, Hot-Poured, for Concrete and Asphalt Pavements (Withdrawn 1996)

Standard Test Methods for Joint Sealants, Hot-Poured, for Concrete and Asphalt Pavements (Withdrawn 1996)

SCOPE

1.1 These test methods cover the following tests for bituminous hot-poured types of joint sealants for portland cement concrete and asphaltic concrete pavements: cone penetration, flow, bond at low temperatures, resilience, asphalt compatibility, and prolonged heating.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

An American National Standard

[{[b Designation: D 3407 - 78 (Reapproved 1994)''

PMERICAN SOCIETY FOR TESTINGAND MATERIALS

1916 Race St Philadelphia, Pa 19103

Reprinted from the Annual Book of ASTM Standards Copyright ASTM

If not listed in the current combined index, will appear in the nix? edrtion

Standard Test Methods for

Joint Sealants, Hot-Poured, for Concrete and Asphalt

Pavements

This standard is issued under the fixed designation D 3407; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revwon. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (E) indicates an editorial change since the last revision or reapproval.

fi NOTE-Keywords were added editonally in June 1994.

temperature by more than 75'F (42°C) and, in no case, shall

1. Scope

be more than 550°F (288"). Add the remaining 400 g, in

1.1 These test methods cover the following tests for

quantities of approximately 50 g at a time, to the melted

bituminous hot-poured types of joint sealants for portland

material, continuing agitation. Continue the heating and

cement concrete and asphaltic concrete pavements: cone

stimng until the entire sample is at the maximum safe

penetration, now, bond at low temperatures, resilience,

heating temperature.

asphalt compatibility, and prolonged heating.

1.2 This standard does not purport to address all of the

4. Standard Conditions

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 4.1 The laboratory atmospheric conditions, hereinafter

priate safety and health practices and determine the applica-

referred to as standard conditions, shall be: temperature 75 f

bility of regulatory limitations prior to use.

7°F (24 f 4T), and relative humidity 50 k 10 %. The spec-

imens prepared as hereinafter prescribed shall be stored

under standard conditions until needed for testing.

2. Referenced Documents

2.1 ASTM Standards:

5. Penetration

C 33 Specification for Concrete Aggregates'

5.1 Make this test in accordance with Test Method D 5,

C 150 Specification for Portland Cement3

except use a penetration cone in place of the standard

C 192 Practice for Making and Curing Concrete Test

penetration needle. The cone shall conform to the require-

Specimens in the Laboratory2

ments given in Test Methods D 2 17, except that the interior

D5 Test Method for Penetration of Bituminous Mate-

construction may be modified as desired. The total moving

*als4

weight of the cone and attachments shall be 150.0 2 O. 1 g.

D 2 17 Test Method for Cone Penetration of Lubricating

Greases

D 1074 Test Method for Compressive Strength of Bitumi- 6. Flow

nous Mixtures4

6.1 Test Specimens-Pour a portion of the sample pre-

D 1559 Test Method for Resistance to Plastic Flow of

pared in accordance with Section 3 into a suitable (See Note

Bituminous Mixtures Using Marshall Apparatus4

1) mold of 40 mm wide by 60 mm long by 3.2 mm deep,

D 156 1 Practice for Preparation of Bituminous Mixture

placed on a bright tin panel. Fill the mold with an excess of

Test Specimens by Means of California Kneading

material, Allow the test specimen to cool at room tempera-

Compactor"

ture for at least '12 h; then trim the specimen flush with the

face of the mold with a heated metal knife or spatula.

3. Sample Preparation

NOTE I-A release agent should be used where it is necessary to

3.1 Select a sample of the fresh material, weighing approx-

separate the material being tested from the metai. A nontoxic, water-

imately 600 g, in such a manner as to avoid inclusion of the washable, release agent recommended for this purpose is prepared by

grinding into a smooth paste a mixture of approximately 50 % talc,

surface layer or any container liner. Heat 200 g of the sample

35 X glycerin and IS % by weight of a water-soluble medical lubricant.6

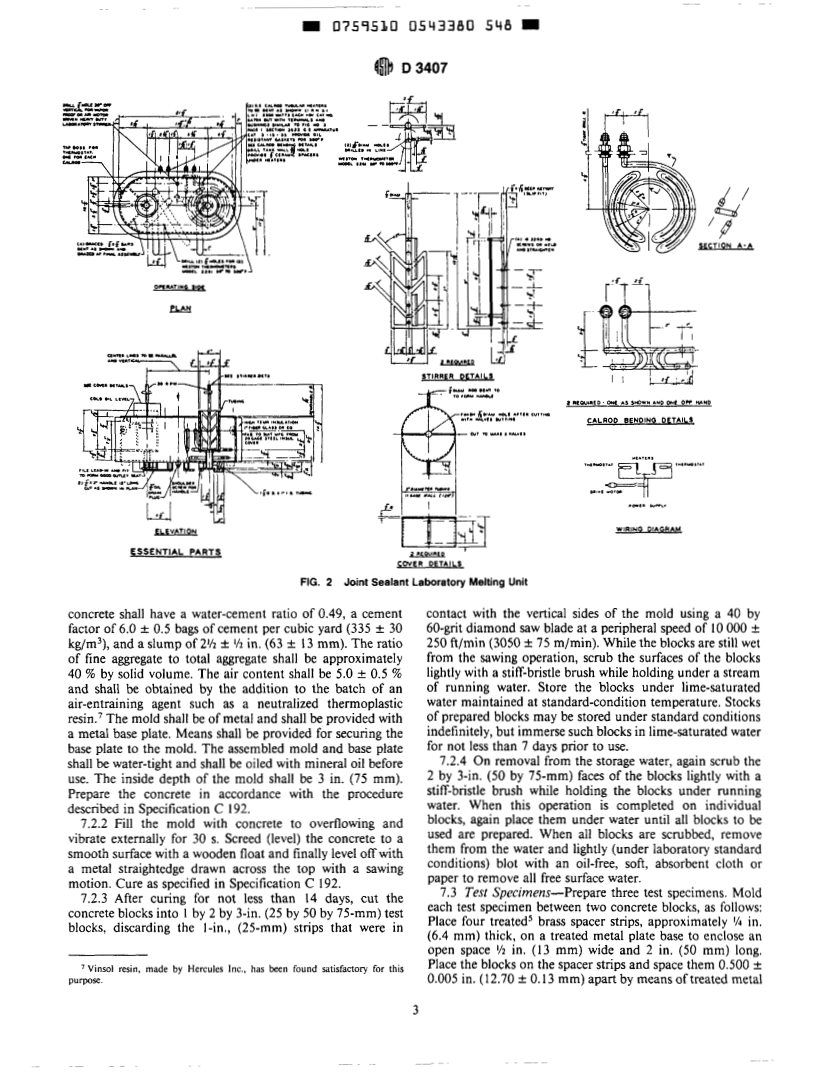

in a clean oil-jacketed melter equipped with mechanical

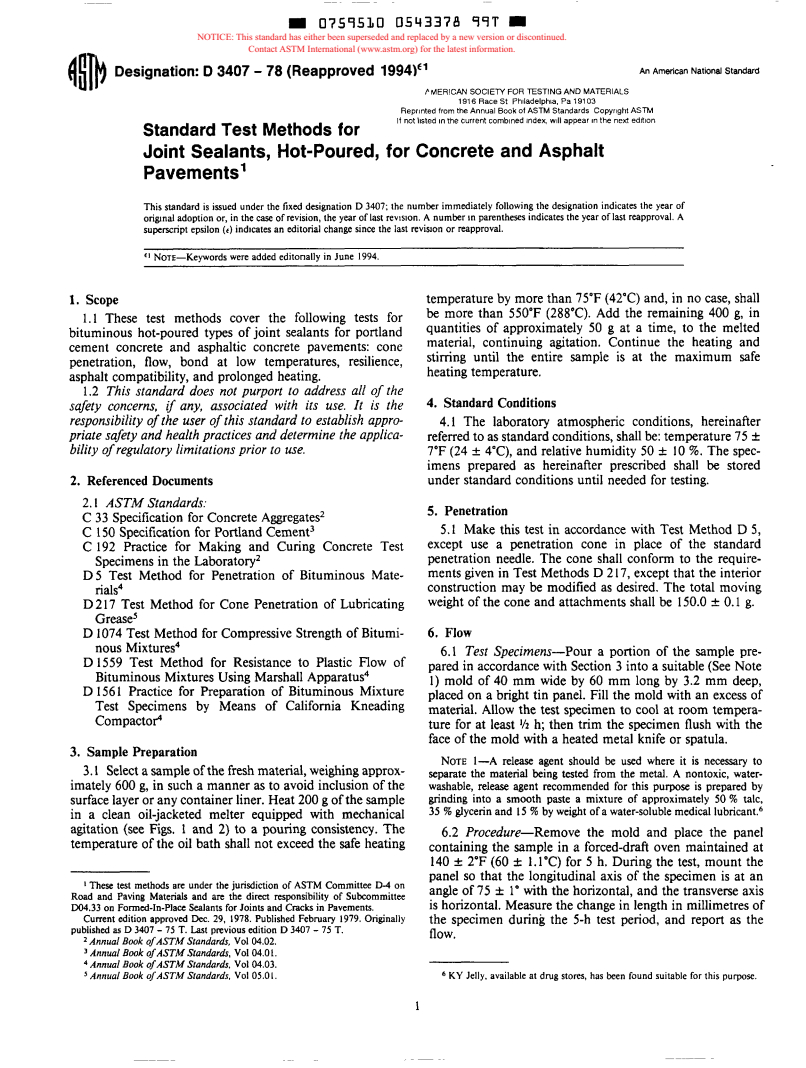

agitation (see Figs. 1 and 2) to a pouring consistency. The

6.2 Procedure-Remove the mold and place the panel

temperature of the oil bath shall not exceed the safe heating

containing the sample in a forced-draft oven maintained at

140 k 2'F (60 ii 1.1"C) for 5 h. During the test, mount the

panel so that the longitudinal axis of the specimen is at an

1 These test methods an under the jurisdiction of ASTM Committee D-I on

angle of 75 f 1" with the horizontal, and the transverse axis

Road and Paving Materials and are the direct responsibility of Subcommittee

is horizontal. Measure the change in length in millimetres of

w4.33 on Formed-In-Place Sealants for Joints and Cracks in Pavements.

Current edition approved Dec. 29, 1978. Published February 1979. Originally

the specimen during the 5-h test period, and report as the

published as D 3407 - 75 T. Last PreviOüS edition D 3407 - 75 T.

flow.

Annual Book of ASTM Standards, Vol 04.02.

Annual Book oJASTM Standards, Vol 04.0 l.

Annual Book of ASTM Standards, Vol 04.03.

5 Annual Book oJASTM Standards, Vol 05.0 I. KY Jelly, available at drug stores, has been found suitable for this purpose

= 0759530 0543379 82b m

OPER&TING SIM

PLAN

-

END VIEW

ELEVATION

DRIVE AND FRAME

FIG. 1 Joint Sealant Laboratory Melting Unit

7. Bond

neously is shown in Fig. 3.

7.2 Concrete-Block Preparation:

7.1 Extension Machine-The extension machine used in

7.2.1 The aggregate shall conform to Specification C 33,

the bond test shall be so designed that the specimen can be

except as specified herein. The aggregate grading shall be as

expanded 0.50 in. (12.7 mm) at a uniform rate of approxi-

shown in Table 1. The coarse aggregate shall consist of

mately Ya in. (3.2 mm)/h. It shall consist essentially of one or

crushed limestone (plus 95 96 Caco,) having a water absorp-

more screws rotated by an electric motor through suitable

tion of not more than 1.5 %. The fine aggregate shall consist

gear reductions. Self-aligning plates or grips, one fixed and

of crushed limestone and shall be manufactured from the

be

the other camed by the rotating screw or screws, shall

same parent rock as the coarse aggregate. The portland

provided for holding the test specimen in position during the

cement shall conform to Specification C 150, Type II. The

test. A machine suitable for testing three specimens simulta-

~~

-~ ~

m 0759510 0543380 548 m

WIRINO DIAGRAM

,&kVATION

ESSENTIAL PARTS

SOVLR DETAILS

FIG. 2 Joint Sealant Laboratory Melting Unit

concrete shall have a water-cement ratio of 0.49, a cement contact with the vertical sides of the mold using a 40 by

60-grit diamond saw blade at a peripheral speed of 10 O00 k

factor of 6.0 k 0.5 bags of cement per cubic yard (335 i 30

250 ft/min (3050 f 75 m/min). While the blocks are still wet

kg/m3), and a slump of 2% f Vi in. (63 f I3 mm). The ratio

from the sawing operation, scrub the surfaces of the blocks

of fine aggregate to total aggregate shall be approximately

lightly with a stiff-bristle brush while holding under a stream

40 % by solid volume. The air content shall be 5.0 f 0.5 96

of running water. Store the blocks under lime-saturated

and shall be obtained by the addition to the batch of an

water maintained at standard-condition temperature. Stocks

air-entraining agent such as a neutralized thermoplastic

of prepared blocks may be stored under standard conditions

resin.' The mold shall be of metal and shall be provided with

indefinitely, but immerse such blocks in lime-saturated water

a metal base plate. Means shall be provided for securing the

for not less than 7 days prior to use.

base plate to the mold. The assembled mold and base plate

7.2.4 On removal from the storage water, again scrub the

shall be water-tight and shall be oiled with mineral oil before

2 by 3-in. (50 by 75-mm) faces of the blocks lightly with a

use. The inside depth of the mold shall be 3 in. (75 mm).

stiff-bristle brush while holding the blocks under running

Prepare the concrete in accordance with the procedure

water. When this operation is completed on individual

described in Specification C 192.

blocks, again place them under water until all blocks to be

7.2.2 Fill the mold with concrete to overflowing and

used are prepared. When all blocks are scrubbed, remove

vibrate externally for 30 s. Screed (level) the concrete to a

them from the water and lightly (under laboratory standard

off with

smooth surface with a wooden float and finally level

or

conditions) blot with an oil-free, soft, absorbent cloth

a metal straightedge drawn across the top with a sawing

paper to remove all free surface water.

motion. Cure as specified in Specification C 192.

7.3 Tes

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.