ASTM D635-22

(Test Method)Standard Test Method for Rate of Burning and/or Extent and Time of Burning of Plastics in a Horizontal Position

Standard Test Method for Rate of Burning and/or Extent and Time of Burning of Plastics in a Horizontal Position

SIGNIFICANCE AND USE

5.1 Tests made on a material under conditions herein prescribed are of value in comparing the rate of burning or extent and time of burning characteristics, or both, of different materials, in controlling manufacturing processes, or as a measure of deterioration or change in these burning characteristics prior to or during use. Correlation with flammability under actual use conditions is not implied.

5.2 The rate of burning and other burning phenomena will be affected by such factors as density, pigments, any anisotropy of the material and the thickness of the specimen. Test data shall be compared only for specimens of similar thickness, whether comparisons are being made with the same or different materials. The rate of burning and other burning phenomena will vary with thickness.

5.3 It is feasible that sheet materials that have been stretched during processing will relax during burning and give erratic results unless they are first heated above their deflection temperature, in accordance with Test Method D648, for a time sufficient to permit complete relaxation.

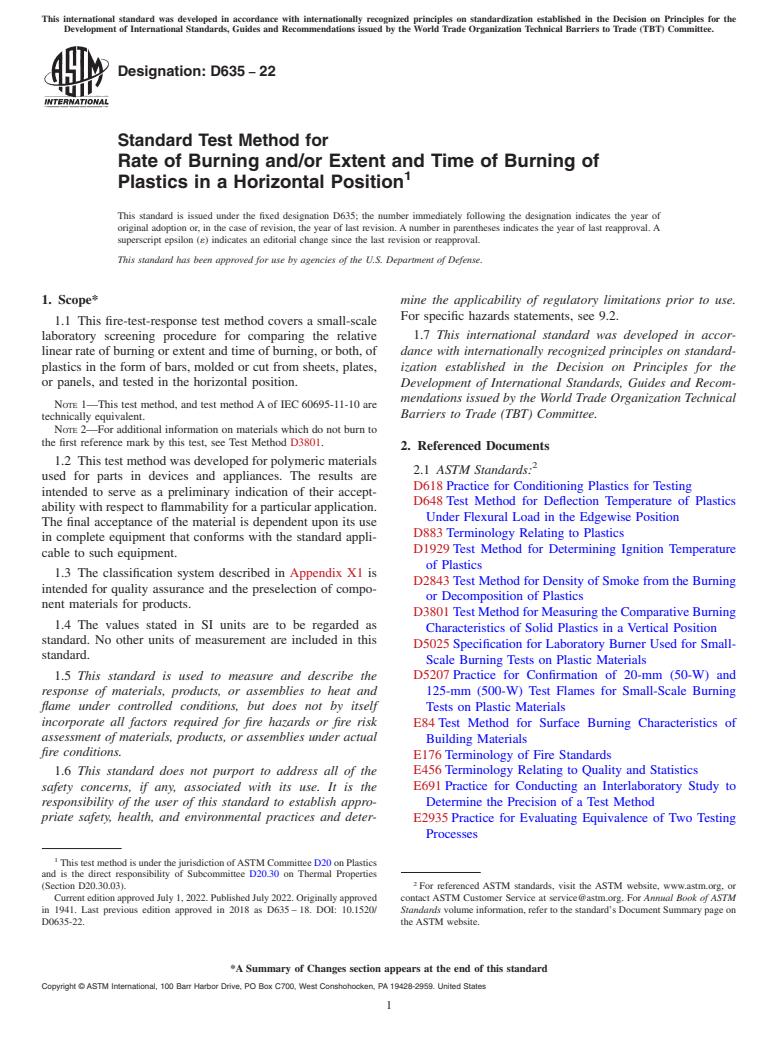

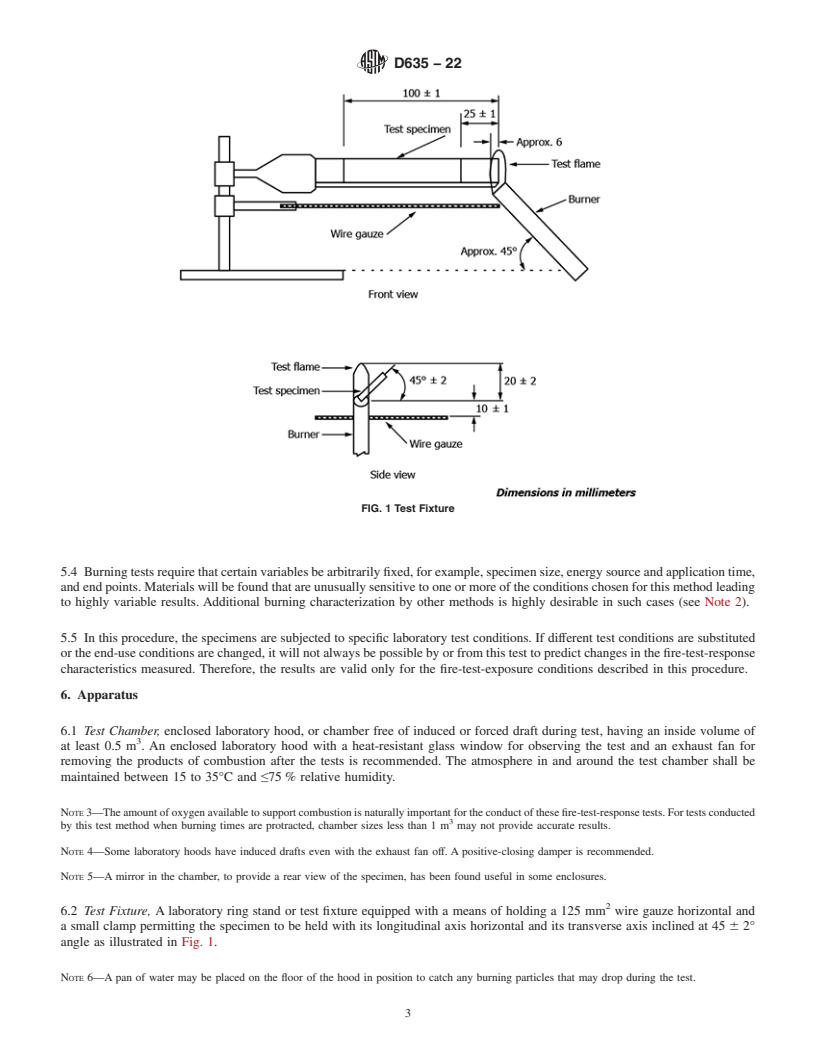

5.4 Burning tests require that certain variables be arbitrarily fixed, for example, specimen size, energy source and application time, and end points. Materials will be found that are unusually sensitive to one or more of the conditions chosen for this method leading to highly variable results. Additional burning characterization by other methods is highly desirable in such cases (see Note 2).

5.5 In this procedure, the specimens are subjected to specific laboratory test conditions. If different test conditions are substituted or the end-use conditions are changed, it will not always be possible by or from this test to predict changes in the fire-test-response characteristics measured. Therefore, the results are valid only for the fire-test-exposure conditions described in this procedure.

SCOPE

1.1 This fire-test-response test method covers a small-scale laboratory screening procedure for comparing the relative linear rate of burning or extent and time of burning, or both, of plastics in the form of bars, molded or cut from sheets, plates, or panels, and tested in the horizontal position.

Note 1: This test method, and test method A of IEC 60695-11-10 are technically equivalent.

Note 2: For additional information on materials which do not burn to the first reference mark by this test, see Test Method D3801.

1.2 This test method was developed for polymeric materials used for parts in devices and appliances. The results are intended to serve as a preliminary indication of their acceptability with respect to flammability for a particular application. The final acceptance of the material is dependent upon its use in complete equipment that conforms with the standard applicable to such equipment.

1.3 The classification system described in Appendix X1 is intended for quality assurance and the preselection of component materials for products.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazards or fire risk assessment of materials, products, or assemblies under actual fire conditions.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazards statements, see 9.2.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of Internati...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D635 − 22

Standard Test Method for

Rate of Burning and/or Extent and Time of Burning of

1

Plastics in a Horizontal Position

This standard is issued under the fixed designation D635; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* mine the applicability of regulatory limitations prior to use.

For specific hazards statements, see 9.2.

1.1 This fire-test-response test method covers a small-scale

1.7 This international standard was developed in accor-

laboratory screening procedure for comparing the relative

linearrateofburningorextentandtimeofburning,orboth,of dance with internationally recognized principles on standard-

plastics in the form of bars, molded or cut from sheets, plates, ization established in the Decision on Principles for the

or panels, and tested in the horizontal position.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

NOTE 1—This test method, and test methodAof IEC60695-11-10 are

Barriers to Trade (TBT) Committee.

technically equivalent.

NOTE 2—For additional information on materials which do not burn to

the first reference mark by this test, see Test Method D3801.

2. Referenced Documents

1.2 Thistestmethodwasdevelopedforpolymericmaterials

2

2.1 ASTM Standards:

used for parts in devices and appliances. The results are

D618Practice for Conditioning Plastics for Testing

intended to serve as a preliminary indication of their accept-

D648Test Method for Deflection Temperature of Plastics

abilitywithrespecttoflammabilityforaparticularapplication.

Under Flexural Load in the Edgewise Position

The final acceptance of the material is dependent upon its use

D883Terminology Relating to Plastics

in complete equipment that conforms with the standard appli-

D1929Test Method for Determining Ignition Temperature

cable to such equipment.

of Plastics

1.3 The classification system described in Appendix X1 is

D2843Test Method for Density of Smoke from the Burning

intended for quality assurance and the preselection of compo-

or Decomposition of Plastics

nent materials for products.

D3801TestMethodforMeasuringtheComparativeBurning

1.4 The values stated in SI units are to be regarded as

Characteristics of Solid Plastics in a Vertical Position

standard. No other units of measurement are included in this

D5025Specification for Laboratory Burner Used for Small-

standard.

Scale Burning Tests on Plastic Materials

1.5 This standard is used to measure and describe the D5207Practice for Confirmation of 20-mm (50-W) and

response of materials, products, or assemblies to heat and

125-mm (500-W) Test Flames for Small-Scale Burning

flame under controlled conditions, but does not by itself Tests on Plastic Materials

incorporate all factors required for fire hazards or fire risk

E84Test Method for Surface Burning Characteristics of

assessment of materials, products, or assemblies under actual

Building Materials

fire conditions.

E176Terminology of Fire Standards

E456Terminology Relating to Quality and Statistics

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the E691Practice for Conducting an Interlaboratory Study to

responsibility of the user of this standard to establish appro- Determine the Precision of a Test Method

priate safety, health, and environmental practices and deter-

E2935Practice for Evaluating Equivalence of Two Testing

Processes

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

and is the direct responsibility of Subcommittee D20.30 on Thermal Properties

2

(Section D20.30.03). For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedJuly1,2022.PublishedJuly2022.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 1941. Last previous edition approved in 2018 as D635–18. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

D0635-22. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D635 − 22

3

2.2 IEC Standards: burning characterization by other methods is highly desirable

IEC 60695-1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D635 − 18 D635 − 22

Standard Test Method for

Rate of Burning and/or Extent and Time of Burning of

1

Plastics in a Horizontal Position

This standard is issued under the fixed designation D635; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This fire-test-response test method covers a small-scale laboratory screening procedure for comparing the relative linear rate

of burning or extent and time of burning, or both, of plastics in the form of bars, molded or cut from sheets, plates, or panels, and

tested in the horizontal position.

NOTE 1—This test method, and test method A of IEC 60695-11-10 are technically equivalent.

NOTE 2—For additional information on materials which do not burn to the first reference mark by this test, see Test Method D3801.

1.2 This test method was developed for polymeric materials used for parts in devices and appliances. The results are intended to

serve as a preliminary indication of their acceptability with respect to flammability for a particular application. The final acceptance

of the material is dependent upon its use in complete equipment that conforms with the standard applicable to such equipment.

1.3 The classification system described in Appendix X1 is intended for quality assurance and the preselection of component

materials for products.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under

controlled conditions, but does not by itself incorporate all factors required for fire hazards or fire risk assessment of materials,

products, or assemblies under actual fire conditions.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. For specific hazards statements, see 9.2.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.30 on Thermal Properties (Section

D20.30.03).

Current edition approved Nov. 1, 2018July 1, 2022. Published November 2018July 2022. Originally approved in 1941. Last previous edition approved in 20142018 as

D635 – 14.D635 – 18. DOI: 10.1520/D0635-18.10.1520/D0635-22.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D635 − 22

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D648 Test Method for Deflection Temperature of Plastics Under Flexural Load in the Edgewise Position

D883 Terminology Relating to Plastics

D1929 Test Method for Determining Ignition Temperature of Plastics

D2843 Test Method for Density of Smoke from the Burning or Decomposition of Plastics

D3801 Test Method for Measuring the Comparative Burning Characteristics of Solid Plastics in a Vertical Position

D5025 Specification for Laboratory Burner Used for Small-Scale Burning Tests on Plastic Materials

D5207 Practice for Confirmation of 20-mm (50-W) and 125-mm (500-W) Test Flames for Small-Scale Burning Tests on Plastic

Materials

E84 Test Method for Surface Burning Characteristics of Building Materials

E176 Terminology of Fire Standards

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E2935 Practice for Evaluating Equivalence of Two Testing Processes

3

2.2 IEC Standards:

IEC 60695-11-10 Fire Hazard Testing—Part 11-10 Test Flames—50W Horizontal

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.