ASTM F2618-09(2014)

(Specification)Standard Specification for Chlorinated Poly (Vinyl Chloride) (CPVC) Pipe and Fittings for Chemical Waste Drainage Systems

Standard Specification for Chlorinated Poly (Vinyl Chloride) (CPVC) Pipe and Fittings for Chemical Waste Drainage Systems

SCOPE

1.1 This specification covers the performance requirements of CPVC pipe, fittings and solvent cements used in chemical waste drainage systems.

1.2 A system is made up of pipe, fittings and solvent cement that meet the requirements of this standard.

Note 1: Consult the manufacturer’s chemical resistance recommendations for chemical waste drainage applications prior to use.

1.3 The text of this specification references notes, footnotes and appendices that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.4 The pressure tests described in this standard are laboratory hydrostatic tests that are intended to verify joint/system integrity. They are not intended for use as field tests of installed systems.

1.5 Due to inherent hazards associated with testing components and systems with compressed air or other compressed gases, no such testing shall be done unless the component manufacturer gives approval in writing.

Note 2: Pressurized (compressed) air or other compressed gases contain large amounts of stored energy, which present serious safety hazards should a system fail for any reason.

1.6 Mechanical joints used for joining pipe and fittings of different materials are provided for in this specification. They include common flanges, couplings, and unions.

1.7 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 3: This specification specifies dimensional, performance, and test requirements for fluid handling applications but does not address venting of combustion gases.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2618 −09(Reapproved 2014)

Standard Specification for

Chlorinated Poly (Vinyl Chloride) (CPVC) Pipe and Fittings

for Chemical Waste Drainage Systems

This standard is issued under the fixed designation F2618; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This specification covers the performance requirements

of CPVC pipe, fittings and solvent cements used in chemical

NOTE 3—This specification specifies dimensional, performance, and

test requirements for fluid handling applications but does not address

waste drainage systems.

venting of combustion gases.

1.2 Asystem is made up of pipe, fittings and solvent cement

that meet the requirements of this standard.

2. Referenced Documents

NOTE 1—Consult the manufacturer’s chemical resistance recommenda-

2.1 ASTM Standards:

tions for chemical waste drainage applications prior to use.

D543 Practices for Evaluating the Resistance of Plastics to

Chemical Reagents

1.3 The text of this specification references notes, footnotes

and appendices that provide explanatory material. These notes D618 Practice for Conditioning Plastics for Testing

D1600 TerminologyforAbbreviatedTermsRelatingtoPlas-

and footnotes (excluding those in tables and figures) shall not

be considered as requirements of the specification. tics

D1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

1.4 The pressure tests described in this standard are labora-

Compounds and Chlorinated Poly(Vinyl Chloride)

tory hydrostatic tests that are intended to verify joint/system

(CPVC) Compounds

integrity.Theyarenotintendedforuseasfieldtestsofinstalled

D2122 Test Method for Determining Dimensions of Ther-

systems.

moplastic Pipe and Fittings

1.5 Due to inherent hazards associated with testing compo-

D2321 PracticeforUndergroundInstallationofThermoplas-

nents and systems with compressed air or other compressed

tic Pipe for Sewers and Other Gravity-Flow Applications

gases, no such testing shall be done unless the component

D2412 Test Method for Determination of External Loading

manufacturer gives approval in writing.

Characteristics of Plastic Pipe by Parallel-Plate Loading

D2444 Test Method for Determination of the Impact Resis-

NOTE 2—Pressurized (compressed) air or other compressed gases

tance of Thermoplastic Pipe and Fittings by Means of a

contain large amounts of stored energy, which present serious safety

hazards should a system fail for any reason. Tup (Falling Weight)

D3311 Specification for Drain, Waste, and Vent (DWV)

1.6 Mechanical joints used for joining pipe and fittings of

Plastic Fittings Patterns

different materials are provided for in this specification. They

F402 Practice for Safe Handling of Solvent Cements,

include common flanges, couplings, and unions.

Primers, and Cleaners Used for Joining Thermoplastic

1.7 The values stated in inch-pound units are to be regarded

Pipe and Fittings

as standard. The values given in parentheses are mathematical

F412 Terminology Relating to Plastic Piping Systems

conversions to SI units that are provided for information only

F493 Specification for Solvent Cements for Chlorinated

and are not considered standard.

Poly(Vinyl Chloride) (CPVC) Plastic Pipe and Fittings

1.8 This standard does not purport to address all of the F1498 Specification forTaper PipeThreads 60° forThermo-

plastic Pipe and Fittings

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- F2135 Specification for Molded Drain, Waste, and Vent

(DWV) Short-Pattern Plastic Fittings

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.63 on DWV. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2014. Published December 2014. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2009. last previous edition approved in 2009 as F2618–09. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2618-09R14. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2618−09 (2014)

2.2 Other Documents: fittings provided that the final compound, and the pipe and

International Plumbing Code fittings produced, meet the requirements of this specification.

Uniform Plumbing Code 4.2.3 Rework Material—Clean rework material generated

Federal Standard 123 Marking for Shipment (CivilianAgen- from the manufacturer’s own pipe or fittings may be used

cies) providedthepipeorfittingsproducedmeettherequirementsof

Federal Standard 129 Military Marking for Shipment and this specification.

Storage 4.2.4 All thread sealants, gaskets, and seal rings shall be of

a material that meets the chemical resistance for the end use

3. Terminology

application.

3.1 Definitions:

5. General Requirements for Solvent Cement

3.1.1 Definitions used in this specification are in accordance

with the definitions given in Terminology F412, and abbrevia- 5.1 The solvent cement shall meet the general requirements

tions are in accordance with Terminology D1600, unless of standard F493 and be classified as heavy-bodied, having a

otherwise indicated. minimum viscosity of 1600 cP (1600 MPa-s).

3.1.2 The plumbing terminology used in this specification is

5.2 The cement shall not contain any inorganic fillers.

in accordance with the definitions given in the International

5.3 CPVC solvent cement meeting the requirements of this

Plumbing Code and the Uniform Plumbing Code, unless

standard shall be mustard in color to facilitate identification

otherwise indicated.

and minimize unintentional use of other cements that may fail

4. Requirements at elevated service temperatures.

4.1 The requirements in this section are intended only for

NOTE 5—Safe handling of solvent cements: Solvent cements for plastic

pipe are made from flammable liquids. Keep them away from all sources

use as quality control tests, not as simulated service tests.

of ignition. Maintain proper ventilation to reduce fire hazard and to

4.1.1 All pipe and fittings shall be homogeneous throughout

minimize breathing of solvent vapors. Avoid contact of cement with skin

and be free of visible cracks, holes, foreign inclusions, or other

and eyes. Refer to Practice F402 for information on safe handling of

injurious defects. The pipe and fittings shall be as uniform as

solvent cements.

commercially practicable in color, opacity, density and other

6. Dimensions and Tolerances

physical properties.

4.1.2 Pipe and fittings shall be joined by the use of solvent

6.1 The patterns, dimensions, and laying lengths of molded

cement, threading, or mechanical joints meeting the require-

fittings, including adaptors, shall meet the requirements of

ments of this standard and as recommended by the manufac-

Specifications D3311 or F2135 or shall be of a proven design

turer.

and shall allow a smooth transition of flow from one direction

4.1.3 All dimensions shall be determined in accordance

to another. Specialty fittings or fittings with laying lengths not

with Test Method D2122.

meeting the requirements of Specification D3311 or Specifica-

4.1.4 All components within a system shall meet the speci-

tion F2135 shall not be excluded. For these fittings, laying

fications of this standard.

lengths shall be provided by the manufacturer.

4.1.5 CPVC Solvent Cement—The CPVC solvent cement

NOTE 6—ASTM International takes no position respecting the validity

used to join the pipe and fittings covered under this specifica-

ofanypatentrightsassertedinconnectionwithanyitemmentionedinthis

tion shall comply with Section 5 and 9.4. Consult the pipe and

standard. Users of this standard are expressly advised that determination

fitting manufacturer to determine whether or not a primer is

of the validity of any such patent rights, and the risk of infringement of

such rights, are entirely their own responsibility.

required.

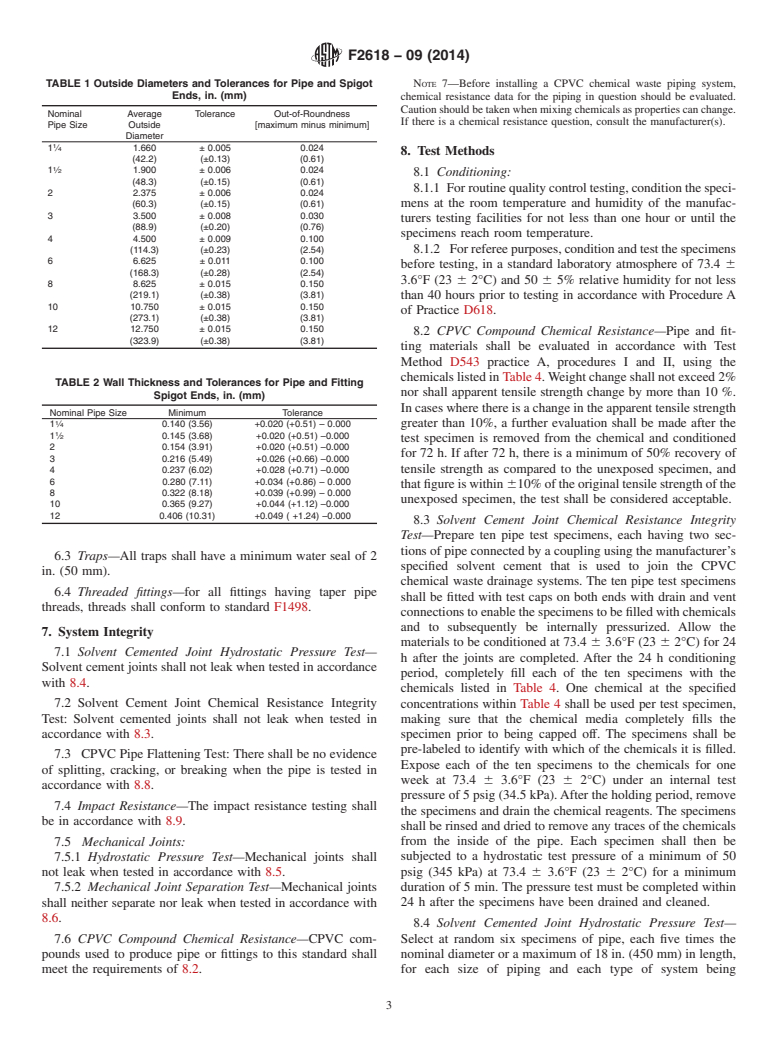

6.1.1 The outside diameter and wall thickness of pipe shall

NOTE 4—At lower temperatures (< 40°F, or < 4°C) and for larger

meet the requirements of Table 1 and Table 2.

diameters of pipe and fittings (>6 in. in diameter), a primer may be

recommended by the manufacturer.

6.1.2 Fitting sockets shall conform to the dimensional

requirements as specified in Table 3.

4.1.6 Mechanical fittings shall meet the requirements of

6.1.3 The spigot dimensions of fittings shall meet the

7.4.

requirements of Table 1 and Table 2.

4.2 Materials:

6.2 Cleanouts—Cleanout plugs, and caps, as commonly

4.2.1 CPVC Material—All pipe and fittings shall be made

used in the manufacturer’s laboratory drainage system, shall

CPVC compounds meeting or exceeding the requirements of

have a thread size and depth sufficient to ensure that the

cell classification 23447 as defined in Specification D1784.

minimum waterway dimensions are maintained. All CPVC

4.2.2 CPVC materials shall be permitted to contain

cleanouts having female threads shall be supplied with CPVC

stabilizers,lubricants,andpigmentsnotdetrimentaltopipeand

plugs.

Available from International Code Council (ICC), 500 New Jersey Ave., NW,

6th Floor, Washington, DC 20001-2070, http://www.iccsafe.org. Molded fittings meeting the requirements of Specification D3311 made from

Available from International Association of Plumbing and Mechanical CPVC and used for piping that handles corrosive waste are covered by a patent.

Officials, 5001 E. Philadelphia St., Ontario, CA 91761, http://www.iapmo.org. Interested parties are invited to submit information regarding the identification of an

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, alternative(s) to this patented item to the ASTM International Headquarters. Your

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http:// comments will receive careful consideration at a meeting of the responsible

www.dodssp.daps.mil. technical committee, which you may attend.

F2618−09 (2014)

TABLE 1 Outside Diameters and Tolerances for Pipe and Spigot NOTE 7—Before installing a CPVC chemical waste piping system,

Ends, in. (mm)

chemical resistance data for the piping in question should be evaluated.

Cautionshouldbetakenwhenmixingchemicalsaspropertiescanchange.

Nominal Average Tolerance Out-of-Roundness

If there is a chemical resistance question, consult the manufacturer(s).

Pipe Size Outside [maximum minus minimum]

Diameter

1 ⁄4 1.660 ± 0.005 0.024

8. Test Methods

(42.2) (±0.13) (0.61)

1 ⁄2 1.900 ± 0.006 0.024

8.1 Conditioning:

(48.3) (±0.15) (0.61)

8.1.1 Forroutinequalitycontroltesting,conditionthespeci-

2 2.375 ± 0.006 0.024

(60.3) (±0.15) (0.61) mens at the room temperature and humidity of the manufac-

3 3.500 ± 0.008 0.030

turers testing facilities for not less than one hour or until the

(88.9) (±0.20) (0.76)

specimens reach room temperature.

4 4.500 ± 0.009 0.100

(114.3) (±0.23) (2.54)

8.1.2 Forrefereepurposes,conditionandtestthespecimens

6 6.625 ±0.011 0.100

before testing, in a standard laboratory atmosphere of 73.4 6

(168.3) (±0.28) (2.54)

3.6°F (23 6 2°C) and 50 6 5% relative humidity for not less

8 8.625 ± 0.015 0.150

(219.1) (±0.38) (3.81) than 40 hours prior to testing in accordance with Procedure A

10 10.750 ± 0.015 0.150

of Practice D618.

(273.1) (±0.38) (3.81)

12 12.750 ± 0.015 0.150

8.2 CPVC Compound Chemical Resistance—Pipe and fit-

(323.9) (±0.38) (3.81)

ting materials shall be evaluated in accordance with Test

Method D543 practice A, procedures I and II, using the

chemicalslistedinTable4.Weightchangeshallnotexceed2%

TABLE 2 Wall Thickness and Tolerances for Pipe and Fitting

nor shall apparent tensile strength change by more than 10 %.

Spigot Ends, in. (mm)

Incaseswherethereisachangeintheapparenttensilestrength

Nominal Pipe Size Minimum Tolerance

greater than 10%, a further evaluation shall be made after the

1 ⁄4 0.140 (3.56) +0.020 (+0.51) – 0.000

1 ⁄2 0.145 (3.68) +0.020 (+0.51) –0.000

test specimen is removed from the chemical and conditioned

2 0.154 (3.91) +0.020 (+0.51) –0.000

for 72 h. If after 72 h, there is a minimum of 50% recovery of

3 0.216 (5.49) +0.026 (+0.66) –0.000

tensile strength as compared to the unexposed specimen, and

4 0.237 (6.02) +0.028 (+0.71) –0.000

6 0.280 (7.11) +0.034 (+0.86) – 0.000

thatfigureiswithin 610%oftheoriginaltensilestrengthofthe

8 0.322 (8.18) +0.039 (+0.99) – 0.000

unexposed specimen, the test shall be considered acceptable.

10 0.365 (9.27) +0.044 (+1.12) –0.000

12 0.406 (10.31) +0.049 ( +1.24) –0.000

8.3 Solvent Cement Joint Chemical Resistance Integrity

Test—Prepare ten pipe test specimens, each having two sec-

tions of pipe connected by a coupling using the manufacturer’s

6.3 Traps—All traps shall have a minimum water seal of 2

specified solvent cement that is used to join the CPVC

in. (50 mm).

chemical waste drainage systems. The ten pipe test specimens

6.4 Threaded fittings—for all fittings having taper pipe

shall be fitted with test caps on both ends with drain and vent

threads, threads shall conform to standard F1498.

connectionstoenablethespecimenstobefilledwithchemicals

and to subsequently be internally pressurized. Allow the

7. System Integrity

materials to be conditioned at 73.4 6 3.6°F (23 6 2°C) for 24

7.1 Solvent Cemented Joint Hydrostatic Pressure Test—

h after the joints are completed. After the 24 h conditioning

Solvent cement joints shall not leak when tested in accordance

period, completely fill each of the ten specimens with the

with 8.4.

chemicals listed in Table 4. One chemical at the specified

7.2 Solvent Cement Joint Chemical Resistance Integrity concentrations within Table 4 shall be used per test specimen,

Test: Solvent cemented joints shall not leak when tested in making sure that the chemical media completely fills the

accordance with 8.3. specimen prior to being capped off. The specimens shall be

pre-labeled to identify with which of the chemicals it is filled.

7.3 CPVC Pipe Flattening Test: There shall be no evidence

Expose each of the ten specimens to the chemicals for one

of splitting, cracking, or breaking when the pipe is tested in

week at 73.4 6 3.6°F (23 6 2°C) under an internal test

accordance with 8.8.

pressure of 5 psig (34.5 kPa).After the holding period, remove

7.4 Impact Resistance—The impact resistance testing shall

the specimens and drain the chemical reagents. The specimens

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2618 − 09 F2618 − 09 (Reapproved 2014) An American National Standard

Standard Specification for

Chlorinated Poly (Vinyl Chloride) (CPVC) Pipe and Fittings

for Chemical Waste Drainage Systems

This standard is issued under the fixed designation F2618; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the performance requirements of CPVC pipe, fittings and solvent cements used in chemical waste

drainage systems.

1.2 A system is made up of pipe, fittings and solvent cement that meet the requirements of this standard.

NOTE 1—Consult the manufacturer’s chemical resistance recommendations for chemical waste drainage applications prior to use.

1.3 The text of this specification references notes, footnotes and appendices that provide explanatory material. These notes and

footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.4 The pressure tests described in this standard are laboratory hydrostatic tests that are intended to verify joint/system integrity.

They are not intended for use as field tests of installed systems.

1.5 Due to inherent hazards associated with testing components and systems with compressed air or other compressed gases,

no such testing shall be done unless the component manufacturer gives approval in writing.

NOTE 2—Pressurized (compressed) air or other compressed gases contain large amounts of stored energy, which present serious safety hazards should

a system fail for any reason.

1.6 Mechanical joints used for joining pipe and fittings of different materials are provided for in this specification. They include

common flanges, couplings, and unions.

1.7 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 3—This specification specifies dimensional, performance, and test requirements for fluid handling applications but does not address venting of

combustion gases.

2. Referenced Documents

2.1 ASTM Standards:

D543 Practices for Evaluating the Resistance of Plastics to Chemical Reagents

D618 Practice for Conditioning Plastics for Testing

D1600 Terminology for Abbreviated Terms Relating to Plastics

D1784 Specification for Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlorinated Poly(Vinyl Chloride) (CPVC)

Compounds

D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

D2321 Practice for Underground Installation of Thermoplastic Pipe for Sewers and Other Gravity-Flow Applications

D2412 Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

D2444 Test Method for Determination of the Impact Resistance of Thermoplastic Pipe and Fittings by Means of a Tup (Falling

Weight)

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.63 on DWV.

Current edition approved April 1, 2009Nov. 1, 2014. Published June 2009December 2014. Originally approved in 2009. last previous edition approved in 2009 as

F2618–09. DOI: 10.1520/F2618-09.10.1520/F2618-09R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2618 − 09 (2014)

D3311 Specification for Drain, Waste, and Vent (DWV) Plastic Fittings Patterns

F402 Practice for Safe Handling of Solvent Cements, Primers, and Cleaners Used for Joining Thermoplastic Pipe and Fittings

F412 Terminology Relating to Plastic Piping Systems

F493 Specification for Solvent Cements for Chlorinated Poly(Vinyl Chloride) (CPVC) Plastic Pipe and Fittings

F1498 Specification for Taper Pipe Threads 60° for Thermoplastic Pipe and Fittings

F2135 Specification for Molded Drain, Waste, and Vent (DWV) Short-Pattern Plastic Fittings

2.2 Other Documents:

International Plumbing Code

Uniform Plumbing Code

Federal Standard 123 Marking for Shipment (Civilian Agencies)

Federal Standard 129 Military Marking for Shipment and Storage

3. Terminology

3.1 Definitions:

3.1.1 Definitions used in this specification are in accordance with the definitions given in Terminology F412, and abbreviations

are in accordance with Terminology D1600, unless otherwise indicated.

3.1.2 The plumbing terminology used in this specification is in accordance with the definitions given in the International

Plumbing Code and the Uniform Plumbing Code, unless otherwise indicated.

4. Requirements

4.1 The requirements in this section are intended only for use as quality control tests, not as simulated service tests.

4.1.1 All pipe and fittings shall be homogeneous throughout and be free of visible cracks, holes, foreign inclusions, or other

injurious defects. The pipe and fittings shall be as uniform as commercially practicable in color, opacity, density and other physical

properties.

4.1.2 Pipe and fittings shall be joined by the use of solvent cement, threading, or mechanical joints meeting the requirements

of this standard and as recommended by the manufacturer.

4.1.3 All dimensions shall be determined in accordance with Test Method D2122.

4.1.4 All components within a system shall meet the specifications of this standard.

4.1.5 CPVC Solvent Cement—The CPVC solvent cement used to join the pipe and fittings covered under this specification shall

comply with Section 5 and 9.4. Consult the pipe and fitting manufacturer to determine whether or not a primer is required.

NOTE 4—At lower temperatures (< 40°F, or < 4°C) and for larger diameters of pipe and fittings (>6 in. in diameter), a primer may be recommended

by the manufacturer.

4.1.6 Mechanical fittings shall meet the requirements of 7.4.

4.2 Materials:

4.2.1 CPVC Material—All pipe and fittings shall be made CPVC compounds meeting or exceeding the requirements of cell

classification 23447 as defined in Specification D1784.

4.2.2 CPVC materials shall be permitted to contain stabilizers, lubricants, and pigments not detrimental to pipe and fittings

provided that the final compound, and the pipe and fittings produced, meet the requirements of this specification.

4.2.3 Rework Material—Clean rework material generated from the manufacturer’s own pipe or fittings may be used provided

the pipe or fittings produced meet the requirements of this specification.

4.2.4 All thread sealants, gaskets, and seal rings shall be of a material that meets the chemical resistance for the end use

application.

5. General Requirements for Solvent Cement

5.1 The solvent cement shall meet the general requirements of standard F493 and be classified as heavy-bodied, having a

minimum viscosity of 1600 cP (1600 MPa-s).

5.2 The cement shall not contain any inorganic fillers.

5.3 CPVC solvent cement meeting the requirements of this standard shall be mustard in color to facilitate identification and

minimize unintentional use of other cements that may fail at elevated service temperatures.

NOTE 5—Safe handling of solvent cements: Solvent cements for plastic pipe are made from flammable liquids. Keep them away from all sources of

ignition. Maintain proper ventilation to reduce fire hazard and to minimize breathing of solvent vapors. Avoid contact of cement with skin and eyes. Refer

to Practice F402 for information on safe handling of solvent cements.

Available from International Code Council (ICC), 500 New Jersey Ave., NW, 6th Floor, Washington, DC 20001-2070, http://www.iccsafe.org.

Available from International Association of Plumbing and Mechanical Officials, 5001 E. Philadelphia St., Ontario, CA 91761, http://www.iapmo.org.

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://www.dodssp.daps.mil.

F2618 − 09 (2014)

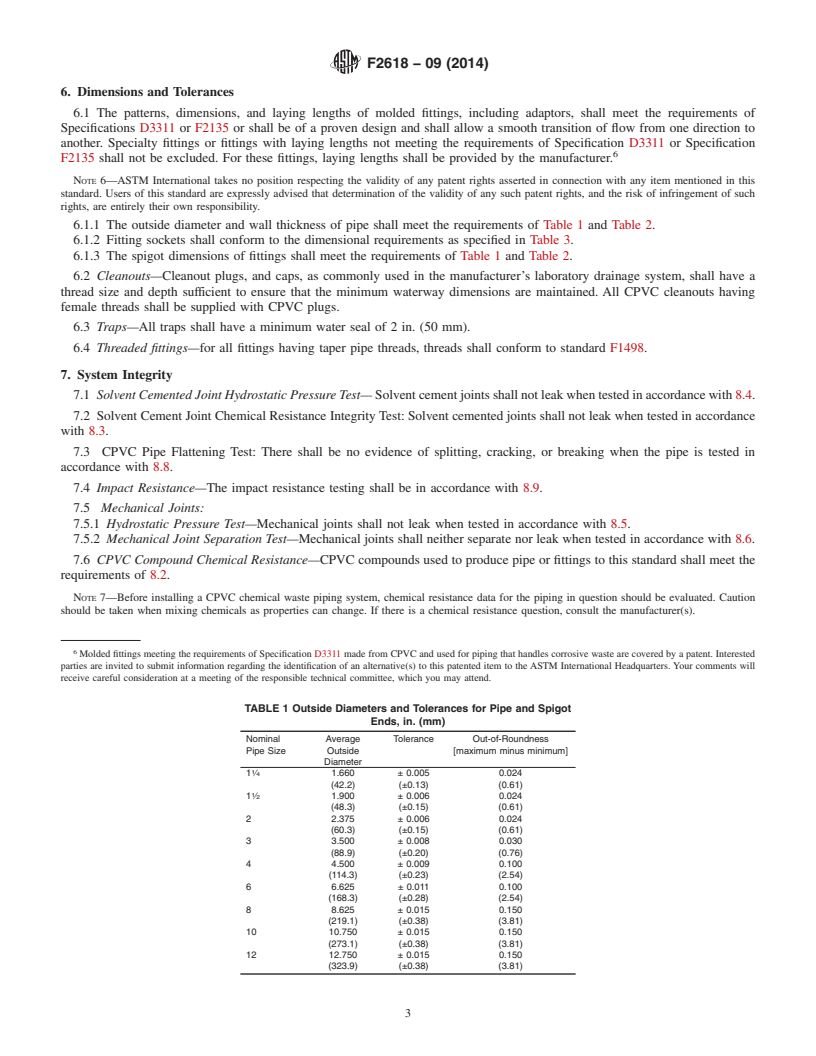

6. Dimensions and Tolerances

6.1 The patterns, dimensions, and laying lengths of molded fittings, including adaptors, shall meet the requirements of

Specifications D3311 or F2135 or shall be of a proven design and shall allow a smooth transition of flow from one direction to

another. Specialty fittings or fittings with laying lengths not meeting the requirements of Specification D3311 or Specification

F2135 shall not be excluded. For these fittings, laying lengths shall be provided by the manufacturer.

NOTE 6—ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned in this

standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk of infringement of such

rights, are entirely their own responsibility.

6.1.1 The outside diameter and wall thickness of pipe shall meet the requirements of Table 1 and Table 2.

6.1.2 Fitting sockets shall conform to the dimensional requirements as specified in Table 3.

6.1.3 The spigot dimensions of fittings shall meet the requirements of Table 1 and Table 2.

6.2 Cleanouts—Cleanout plugs, and caps, as commonly used in the manufacturer’s laboratory drainage system, shall have a

thread size and depth sufficient to ensure that the minimum waterway dimensions are maintained. All CPVC cleanouts having

female threads shall be supplied with CPVC plugs.

6.3 Traps—All traps shall have a minimum water seal of 2 in. (50 mm).

6.4 Threaded fittings—for all fittings having taper pipe threads, threads shall conform to standard F1498.

7. System Integrity

7.1 Solvent Cemented Joint Hydrostatic Pressure Test— Solvent cement joints shall not leak when tested in accordance with 8.4.

7.2 Solvent Cement Joint Chemical Resistance Integrity Test: Solvent cemented joints shall not leak when tested in accordance

with 8.3.

7.3 CPVC Pipe Flattening Test: There shall be no evidence of splitting, cracking, or breaking when the pipe is tested in

accordance with 8.8.

7.4 Impact Resistance—The impact resistance testing shall be in accordance with 8.9.

7.5 Mechanical Joints:

7.5.1 Hydrostatic Pressure Test—Mechanical joints shall not leak when tested in accordance with 8.5.

7.5.2 Mechanical Joint Separation Test—Mechanical joints shall neither separate nor leak when tested in accordance with 8.6.

7.6 CPVC Compound Chemical Resistance—CPVC compounds used to produce pipe or fittings to this standard shall meet the

requirements of 8.2.

NOTE 7—Before installing a CPVC chemical waste piping system, chemical resistance data for the piping in question should be evaluated. Caution

should be taken when mixing chemicals as properties can change. If there is a chemical resistance question, consult the manufacturer(s).

Molded fittings meeting the requirements of Specification D3311 made from CPVC and used for piping that handles corrosive waste are covered by a patent. Interested

parties are invited to submit information regarding the identification of an alternative(s) to this patented item to the ASTM International Headquarters. Your comments will

receive careful consideration at a meeting of the responsible technical committee, which you may attend.

TABLE 1 Outside Diameters and Tolerances for Pipe and Spigot

Ends, in. (mm)

Nominal Average Tolerance Out-of-Roundness

Pipe Size Outside [maximum minus minimum]

Diameter

1 ⁄4 1.660 ± 0.005 0.024

(42.2) (±0.13) (0.61)

1 ⁄2 1.900 ± 0.006 0.024

(48.3) (±0.15) (0.61)

2 2.375 ± 0.006 0.024

(60.3) (±0.15) (0.61)

3 3.500 ± 0.008 0.030

(88.9) (±0.20) (0.76)

4 4.500 ± 0.009 0.100

(114.3) (±0.23) (2.54)

6 6.625 ± 0.011 0.100

(168.3) (±0.28) (2.54)

8 8.625 ± 0.015 0.150

(219.1) (±0.38) (3.81)

10 10.750 ± 0.015 0.150

(273.1) (±0.38) (3.81)

12 12.750 ± 0.015 0.150

(323.9) (±0.38) (3.81)

F2618 − 09 (2014)

TABLE 2 Wall Thickness and Tolerances for Pipe and Fitting

Spigot Ends, in. (mm)

Nominal Pipe Size Minimum Tolerance

1 ⁄4 0.140 (3.56) +0.020 (+0.51) – 0.000

1 ⁄2 0.145 (3.68) +0.020 (+0.51) –0.000

2 0.154 (3.91) +0.020 (+0.51) –0.000

3 0.216 (5.49) +0.026 (+0.66) –0.000

4 0.237 (6.02) +0.028 (+0.71) –0.000

6 0.280 (7.11) +0.034 (+0.86) – 0.000

8 0.322 (8.18) +0.039 (+0.99) – 0.000

10 0.365 (9.27) +0.044 (+1.12) –0.000

12 0.406 (10.31) +0.049 ( +1.24) –0.000

8. Test Methods

8.1 Conditioning:

8.1.1 For routine quality control testing, condition the specimens at the room temperature and humidity of the manufacturers

testing facilities for not less than one hour or until the specimens reach room temperature.

8.1.2 For referee purposes, condition and test the specimens before testing, in a standard laboratory atmosphere of 73.4 6 3.6°F

(23 6 2°C) and 50 6 5% relative humidity for not less than 40 hours prior to testing in accordance with Procedure A of Practice

D618.

8.2 CPVC Compound Chemical Resistance—Pipe and fitting materials shall be evaluated in accordance with Test Method D543

practice A, procedures I and II, using the chemicals listed in Table 4. Weight change shall not exceed 2% nor shall apparent tensile

strength change by more than 10 %. In cases where there is a change in the apparent tensile strength greater than 10%, a further

evaluation shall be made after the test specimen is removed from the chemical and conditioned for 72 h. If after 72 h, there is a

minimum of 50% recovery of tensile strength as compared to the unexposed specimen, and that figure is within 610% of the

original tensile strength of the unexposed specimen, the test shall be considered acceptable.

8.3 Solvent Cement Joint Chemical Resistance Integrity Test—Prepare ten pipe test specimens, each having two sections of pipe

connected by a coupling using the manufacturer’s specified solvent cement that is used to join the CPVC chemical waste drainage

sys

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.