ASTM D6941-05

(Practice)Standard Practice for Measuring Fluidization Segregation Tendencies of Powders

Standard Practice for Measuring Fluidization Segregation Tendencies of Powders

SCOPE

1.1 This practice covers an apparatus and procedure for simulating the segregation tendencies of powders by means of the fluidization mechanism.

1.2 Powders must be capable of being fluidized in order to be tested by this practice.

1.3 Temperature- and humidity-sensitive powders may need to be tested at different temperatures and moisture contents, as would happen in an industrial environment. Further, the gas supply (type, temperature, and humidity) should also match the industrial conditions.

1.4 This standard is not applicable to all bulk solids and segregation mechanisms: while fluidization is a common segregation mechanism experienced by many fine powders, other segregation mechanisms not evaluated by this standard might induce segregation in practice.

1.5 The extent to which segregation will occur in an industrial situation is not only a function of the powder and its tendency to segregate, but also the handling equipment (for example, bin design), process (for example, transfer rates), and environment.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6941 – 05

Standard Practice for

1

Measuring Fluidization Segregation Tendencies of Powders

This standard is issued under the fixed designation D 6941; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope as Used in Engineering Design and Construction

1.1 This practice covers an apparatus and procedure for

3. Terminology

simulating the segregation tendencies of powders by means of

3.1 Definitions—Definitions of terms used in this test

the fluidization mechanism.

method shall be in accordance with Terminology D 653.

1.2 Powders must be capable of being fluidized in order to

3.1.1 fluidization, n—the state in which a powder exhibits

be tested by this practice.

fluid-like properties.

1.3 Temperature- and humidity-sensitive powders may need

3.1.2 fluidization segregation, n—a mechanism that causes

to be tested at different temperatures and moisture contents, as

vertical segregation, that is, horizontal layering of fine and

would happen in an industrial environment. Further, the gas

coarse particles, as resulting from fluidization of the bulk solid.

supply(type,temperature,andhumidity)shouldalsomatchthe

3.1.3 segregation, n—a process through which blended or

industrial conditions.

uniform powders or bulk solids become non-uniform, with

1.4 This standard is not applicable to all bulk solids and

regions of varying composition, for example, particle size.

segregation mechanisms: while fluidization is a common

3.2 Definitions of Terms Specific to This Standard:

segregation mechanism experienced by many fine powders,

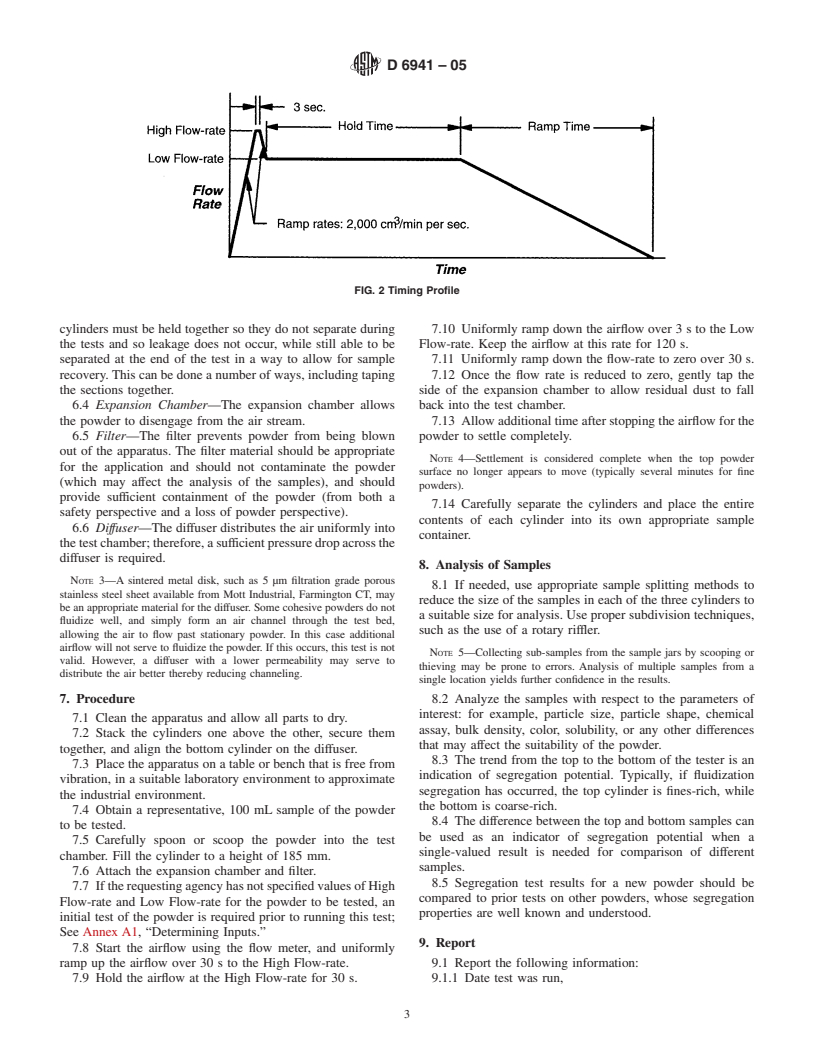

3.2.1 high flow-rate, n—the first stage flow-rate used to

other segregation mechanisms not evaluated by this standard

initiate fluidization.

might induce segregation in practice.

3.2.2 low flow-rate, n—the second stage flow-rate used to

1.5 The extent to which segregation will occur in an

maintain fluidization.

industrial situation is not only a function of the powder and its

3.2.3 representative sample, n—a quantity of the bulk solid

tendency to segregate, but also the handling equipment (for

to be tested that is representative of that solid in an industrial

example, bin design), process (for example, transfer rates), and

application being studied. Parameters of interest that may

environment.

affect whether or not a sample is representative include:

1.6 This standard does not purport to address all of the

moisture, particle size distribution, raw material variation,

safety concerns, if any, associated with its use. It is the

method of production, aging, chemical composition.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Summary of Practice

bility of regulatory limitations prior to use.

4.1 A representative sample of a powder is placed in the

2. Referenced Documents apparatus.

2 4.2 Pressurizedgas(usuallyair)isblownfromthebottomat

2.1 ASTM Standards:

a series of flow-rates for specified times, creating a state of

D 653 Terminology Relating to Soil, Rock, and Contained

fluidization of the powder.

Fluids

4.3 Once the airflow is stopped, the powder in the test

D 3740 Practice for Minimum Requirements for Agencies

chamber is divided into three samples from the bottom, center,

Engaged in the Testing and/or Inspection of Soil and Rock

and top of the column.

4.4 The samples are then available to be tested for differ-

1

This practice is under the jurisdiction of ASTM Committee D18 on Soil and ences relevant to the application, for example, particle size or

Rock and is the direct responsibility of Subcommittee D18.24 on Characterization

chemical assay.

and Handling of Powders and Bulk Solids.

Current edition approved Nov. 1, 2005. Published November 2005. Originally

5. Significance and Use

approved in 2003. Last previous edition approved in 2004 as D 6941–04.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 5.1 Fluidization segregation can cause vertical segregation

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

within bins used to hold and transport powders. This can affect

Standardsvolume information, refer to the standard’s Document Summary page on

final product quality in industrial applications.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6941–05

evaluating the quality of an agency performing this practice. Currently

5.2 By measuring a powder’s segregation tendency, one can

there is no known qualifying national authority tha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.