ASTM D3798-00

(Test Method)Standard Test Method for Analysis of p-Xylene by Gas Chromatography

Standard Test Method for Analysis of <I>p</I>-Xylene by Gas Chromatography

SCOPE

1.1 This test method covers the determination of known hydrocarbon impurities in, and the purity of -xylene by gas chromatography (GC). It is generally meant for the analysis of -xylene of 99% or greater purity. Impurity concentrations that can be measured range from 0.001 to 1.000 weight %.

1.2 The following applies to all specified limits in this standard: for purposes of determining conformance with this standard, an observed value or a calculated value shall be rounded off `to the nearest unit' in the right-hand digit used in expressing the specification limit, in accordance with the rounding-off method of Practice E29.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement, see Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3798 – 00

Standard Test Method for

Analysis of p-Xylene by Gas Chromatography

This standard is issued under the fixed designation D 3798; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope OSHA Regulations, 29 CFR, paragraphs 1910.1000 and

1910.1200

1.1 This test method covers the determination of known

hydrocarbon impurities in, and the purity of p-xylene by gas

3. Terminology

chromatography (GC). It is generally meant for the analysis of

3.1 Definitions:

p-xylene of 99 % or greater purity. Impurity concentrations that

3.1.1 For definition of terms used in this test method see

can be measured range from 0.001 to 1.000 weight %.

Terminology D 4790.

1.2 The following applies to all specified limits in this test

method: for purposes of determining conformance with this

4. Summary of Test Method

test method, an observed value or a calculated value shall be

4.1 A known amount of an internal standard is added to a

rounded off 8to the nearest unit’ in the right-hand digit used in

specimen of p-xylene. The prepared specimen is mixed and

expressing the specification limit, in accordance with the

analyzed by a gas chromatograph equipped with a flame

rounding-off method of Practice E 29.

ionization detector (FID). The peak area of each impurity and

1.3 This standard does not purport to address all of the

the internal standard is measured. The amount of each impurity

safety concerns, if any, associated with its use. It is the

is calculated from the ratio of the peak area of the internal

responsibility of the user of this standard to establish appro-

standard versus the peak area of the impurity. Purity by GC

priate safety and health practices and determine the applica-

(the p-xylene content) is calculated by subtracting the sum of

bility of regulatory limitations prior to use. For a specific

the impurities found from 100.00. Results are reported in

hazard statement, see Section 9.

weight percent.

2. Referenced Documents

5. Significance and Use

2.1 ASTM Standards:

5.1 This test method is suitable for setting specifications on

D 3437 Practice for Sampling and Handling Liquid Cyclic

2 p-xylene and for use as an internal quality control tool where

Products

p-xylene is produced or is used in a manufacturing process. It

D 4790 Terminology of Aromatic Hydrocarbons and Re-

2 may also be used in development or research work involving

lated Chemicals

2 p-xylene. It is generally applied to determining those com-

D 5136 Specification for High Purity p-Xylene

monly occurring impurities such as nonaromatic hydrocarbons,

E 29 Practice for Using Significant Digits in Test Data to

3 benzene, toluene, ethylbenzene, m-xylene, o-xylene, and

Determine Conformance with Specifications

cumene (isopropylbenzene).

E 260 Practice for Packed Column Gas Chromatography

5.2 Purity is commonly reported by subtracting the deter-

E 355 Practice for Gas Chromatography Terms and Rela-

mined expected impurities from 100.00. However, a gas

tionships

chromatographic analysis cannot determine absolute purity if

E 691 Practice for Conducting an Interlaboratory Study to

unknown components are contained within the material being

Determine the Precision of a Test Method

examined. Refer to Specification D 5136 for determining other

E 1510 Practice for Installing Fused Silica Open Tubular

chemical and physical properties of p-xylene.

Capillary Columns in Gas Chromatographs

2.2 Other Document:

6. Interferences

6.1 The internal standard chosen must be sufficiently re-

solved from any impurity and the p-xylene peak. Refer to 8.4.1.

This test method is under the jurisdiction of ASTM Committee D16 on

Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of

7. Apparatus

Subcommittee D16.01 on Benzene, Toluene, Xylenes, Cyclohexane and Their

Derivatives. 7.1 Gas Chromatograph—Any chromatograph having a

Current edition approved June 10, 2000. Published August 2000. Originally

published as D 3798 – 79. Last previous edition D 3798 – 96b.

2 4

Annual Book of ASTM Standards, Vol 06.04. Available from Superintendent of Documents, U.S. Government Printing

Annual Book of ASTM Standards, Vol 14.02. Office, Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 3798

flame ionization detector that can be operated at the conditions where such specifications are available. Other grades may be

given in Table 1. The system should have sufficient sensitivity used, provided it is first ascertained that the reagent is of

to obtain a minimum peak height response for a 0.001 weight sufficiently high purity to permit its use without lessening the

% impurity twice the height of the signal background noise. accuracy of the determination.

8.2 High Purity p-Xylene (99.99 % or greater purity)—Most

7.2 Columns—Different columns have been found satisfac-

p-xylene is available commercially at a purity less than 99.9

tory, depending on the purity of the p-xylene to be analyzed.

weight %, but can be purified by recrystallization. To prepare

7.2.1 p-Xylene Range from 99.0 to 99.8 %—Both capillary

2 qt of high-purity p-xylene, begin with approximately 1 gal of

and packed columns have been found satisfactory. The column

reagent-grade p-xylene and cool in an explosion-proof freezer

must give satisfactory separation of the internal standard from

1 3

at−106 10°C until approximately ⁄2to ⁄4 of the p-xylene has

p-xylene and the impurity peaks. Complete separation of

frozen. This should require about 5 h. Remove the sample and

ethylbenzene and m-xylene from p-xylene is difficult and can

decant the liquid portion. Allow the p-xylene to thaw and

be considered adequate if the distance from the baseline to the

repeat the crystallization step on the remaining sample until the

valley between peaks is not greater than 50 % of the peak

p-xylene is free of contamination as indicated by gas chroma-

height of the impurity. Table 1 contains a description of two

tography.

columns that have been found satisfactory.

8.3 Carrier Gas—Chromatographic-grade nitrogen, helium,

7.2.2 p-Xylene Range 99.8 % and Greater—Only capillary or hydrogen have been found satisfactory for the p-xylene

range from 99.0 to 99.8 %. However, only helium or hydrogen

columns have been found satisfactory. Complete separation of

have been found satisfactory for the p-xylene range of 99.8 %

ethylbenzene and m-xylene from p-xylene is difficult and can

and greater.

be considered adequate if the distance from the baseline to the

8.4 Pure Compounds for Calibration, shall include

valley between peaks is not greater than 50 % of the peak

m-xylene, o-xylene, toluene, ethylbenzene, isopropylbenzene

height of the impurity. It is important that tangential skimming

(cumene), and n-nonane. The purity of all reagents should be

is employed. Table 1 contains a description of one column that

99 % or greater. If the purity is less than 99 %, the concentra-

has been found satisfactory.

tion and identification of impurities must be known so that the

7.3 Recorder—Electronic integration is required. Tangent

composition of the standard can be adjusted for the presence of

skimming capabilities are required because of the difficulty in

the impurities.

fully separating impurities from p-xylene.

8.4.1 Internal Standard— n-Undecane (NC11) is the rec-

7.4 Microsyringe, 100-μL capacity.

ommended internal standard of choice for Conditions A and

n-octane (NC8) for Conditions B in Table 1. However, other

7.5 Volumetric Flask, 100-mL capacity.

compounds may be found acceptable provided they meet the

criteria as defined in Section 6 and 8.4.

8. Reagents

8.1 Purity of Reagent—Reagent grade chemicals shall be

9. Hazards

used in all tests. Unless otherwise indicated, it is intended that

9.1 Consult current OSHA regulations, supplier’s Material

all reagents shall conform to the specifications of the Commit-

Safety Data Sheets, and local regulations for all materials used

tee on Analytical Reagents of the American Chemical Society,

in this test method.

10. Sampling

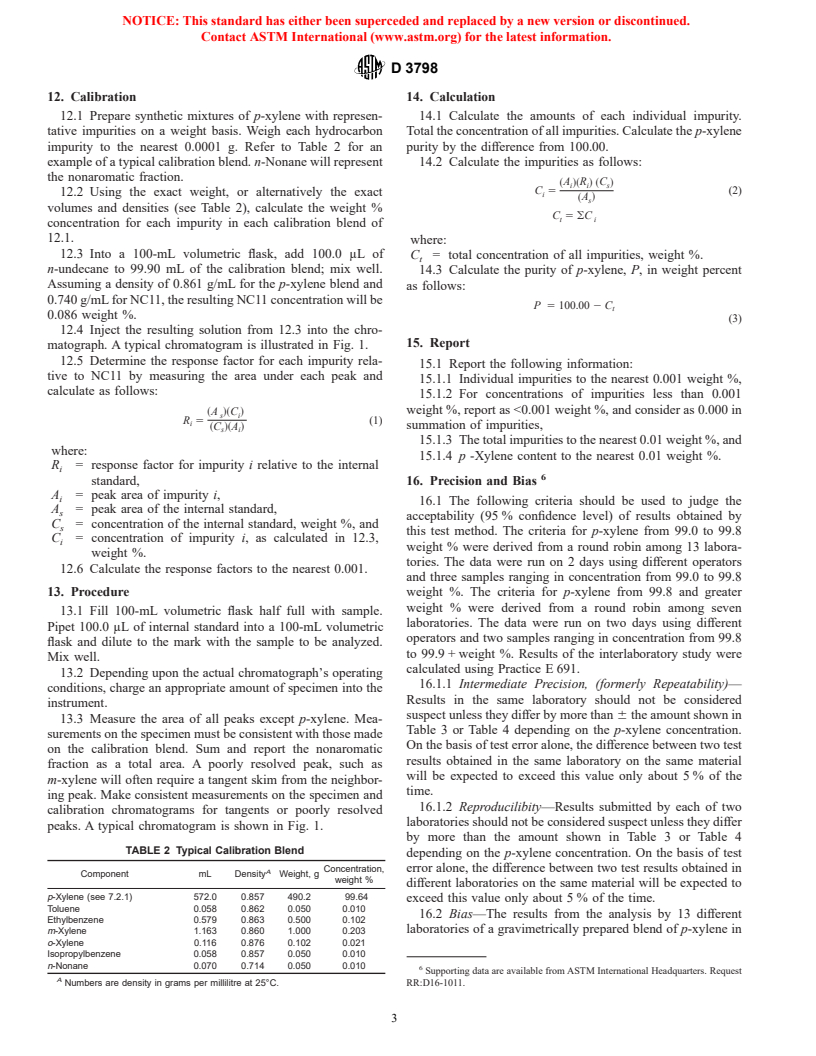

TABLE 1 Instrument Conditions for p -Xylene Analysis

10.1 Sample the material in accordance with Practice

AB D 3437.

Column:

11. Preparation of Apparatus

Tubing fused silica stainless steel

Stationary phase crosslinked diisodecylphthalate

11.1 The method used to prepare packed columns is not

A

Bentone 34

critical provided that the finished column produces the desired

Concentration, weight % polyethylene glycol 3.5 %/3.5 %

B

Solid support not applicable flux-calcined diatomite

separation.

Mesh size not applicable 60 to 80

11.2 Follow the manufacturer’s instructions for mounting

Film thickness, μ 0.25 not applicable

Length, m 50 6.1 and conditioning the column into the chromatograph and

Inside diameter, mm 0.32 3.2

adjusting the instrument to the conditions described in Table 1.

Carrier gas: helium helium

Allow sufficient time for the equipment to reach equilibrium.

Flow rate, mL/min 1.0 30

Split ratio 100:1 not applicable See Practices E 26

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.