ASTM D5933-96(2013)

(Specification)Standard Specification for 2 5/8-in. and 4-in. Diameter Metal Shear Plates for Use in Wood Constructions

Standard Specification for 2 5/8-in. and 4-in. Diameter Metal Shear Plates for Use in Wood Constructions

ABSTRACT

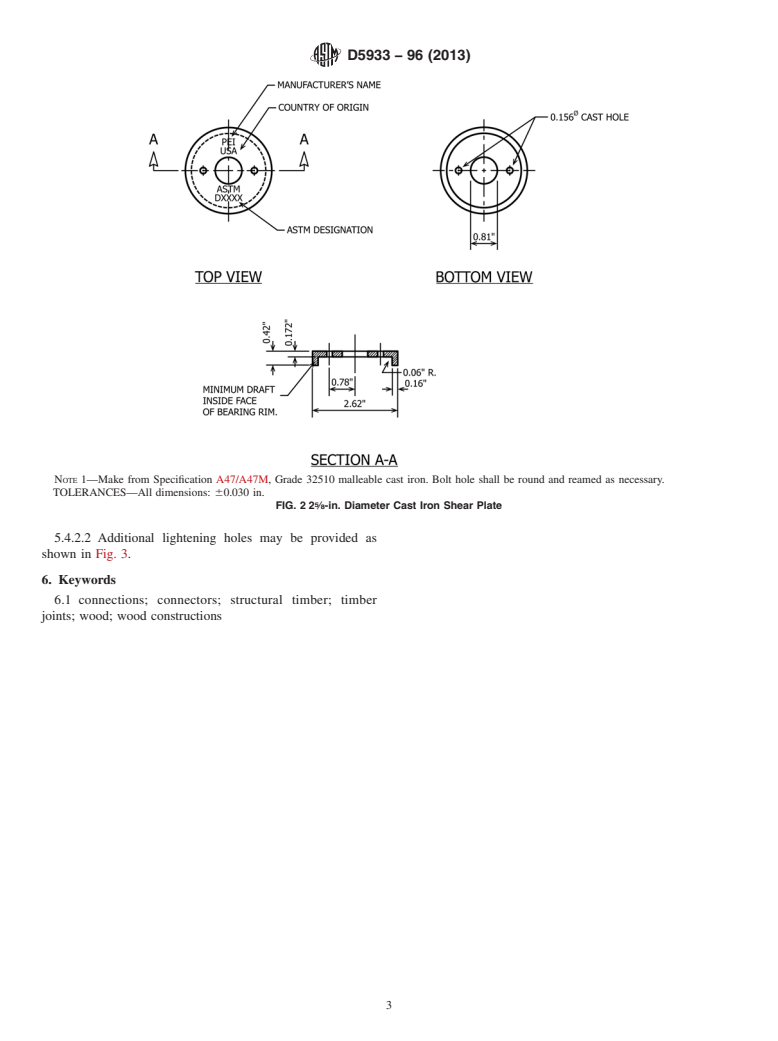

This specification covers standardizing the dimensions and materials for the manufacture of steel or cast iron shear plates used in the fabrication of connections in wood constructions. This specification covers the two basic diameters of metal shear plates commonly used in North American timber construction. Shear plates shall be free from any casting defects that would hinder normal installation and performance. Shear plates shall conform to the specified requirements for the following: (1) marking (2) nail attachment holes, (3) draft casting on the rim and on the hub, (4) central bolt or lag screw holes, (5) furnishing with or without galvanization, and (6) fit and finish. The geometry and dimensional requirements for stamped steel shear plates and cast iron shear plates are specified and illustrated.

SCOPE

1.1 This specification covers standardizing the dimensions and materials for the manufacture of 25/8 and 4-in. diameter steel or cast iron shear plates used in the fabrication of connections in wood constructions. The referencing of this specification in design, construction, and purchase order documents gives the using parties ensurance that the shear plates to be used in an assembly meet minimum materials quality standards and that dimensions for fabrication and finish can be relied on to ensure connection performance. This specification provides regulatory agencies with a set of standards by which to judge the acceptability of shear plates encountered in the field and in fabricators' shops.

1.2 The values stated in inch-pound units are to be regarded as standard. The values in parentheses are for information only.

1.3 Safety Hazards—There are no known hazards with the use of this specification. The products manufactured to this specification should not be brittle or difficult to install with proper tools.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5933 −96 (Reapproved 2013)

Standard Specification for

5

2 ⁄8-in. and 4-in. Diameter Metal Shear Plates for Use in

1

Wood Constructions

This standard is issued under the fixed designation D5933; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A924/A924M Specification for General Requirements for

Steel Sheet, Metallic-Coated by the Hot-Dip Process

1.1 This specification covers standardizing the dimensions

5

2.2 Other Document:

and materials for the manufacture of 2 ⁄8 and 4-in. diameter

AISI/SAE No. 1010 Carbon Steel, Steel Products Manual,

steel or cast iron shear plates used in the fabrication of

Plates, Iron and Steel Society

connections in wood constructions. The referencing of this

specification in design, construction, and purchase order docu-

3. Terminology

ments gives the using parties ensurance that the shear plates to

be used in an assembly meet minimum materials quality

3.1 Definitions:

standards and that dimensions for fabrication and finish can be

3.1.1 shear plate—A round, cast, or stamped disk-like

relied on to ensure connection performance. This specification

load-transfer device having a flat base and a perimeter bearing

provides regulatory agencies with a set of standards by which

rim protruding in one direction normal to the base, with a hole

to judge the acceptability of shear plates encountered in the

passing through the center of the disk to accommodate an

field and in fabricators’ shops.

attachment bolt or lag screw.

3.1.1.1 Discussion—The fastener hole at the center may

1.2 The values stated in inch-pound units are to be regarded

have an additional bearing hub. If a bearing hub is present it

as standard.The values in parentheses are for information only.

projects in the same direction as the bearing rim.Ashear plate

1.3 Safety Hazards—There are no known hazards with the

isinstalledintooneormorefacesofapieceofwoodtotransfer

use of this specification. The products manufactured to this

shear forces between the member containing the shear plate or

specification should not be brittle or difficult to install with

plates and adjacent members which may be of wood or steel.

proper tools.

This shear transfer is accomplished through the bolt or lag

screw.

2. Referenced Documents

2

2.1 ASTM Standards:

4. Classification

A47/A47M Specification for Ferritic Malleable Iron Cast-

4.1 This specification covers the two basic diameters of

ings

metal shear plates commonly used in North American timber

A153/A153M Specification for Zinc Coating (Hot-Dip) on

5

construction—2 ⁄8 in. (66.7-mm) diameter stamped steel or

Iron and Steel Hardware

malleable cast iron, and 4-in. (102.1-mm) diameter malleable

A570/A570M Specification for Structural Steel, Sheet and

cast iron. The use of these shear plates is covered in the

3

Strip, Carbon, Hot-Rolled (Withdrawn 2000)

4

National Design Specification for Wood Construction and

A653/A653M Specification for Steel Sheet, Zinc-Coated

other wood design documents.

(Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed)

by the Hot-Dip Process

5. Materials and Manufacture

5.1 General:

1

This specification is under the jurisdiction ofASTM Committee D07 on Wood 5.1.1 Cast iron shear plates shall be free from any casting

and is the direct responsibility of Subcommittee D07.05 on Wood Assemblies.

defects such as voids, irregular holes or sharp burrs greater

Current edition approved April 1, 2013. Published April 2013. Originally

than 0.03 in. (0.8 mm), or any other casting defect that would

approved in 1997. LAst previous edition approved in 2007 as D5933 – 96 (2007).

hinder normal installation and performance.All residual metal

DOI: 10.1520/D5933-96R13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

at casting gate locations and any other protrusions that would

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

The last approved version of this historical standard is referenced on Available from theAmerican Forest and PaperAssociation, 1111 19th St., NW,

www.astm.org. Suite 800, Washington, DC 20036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5933−96 (2013)

prevent the proper installation and fit of the plates shall be 5.1.7 Since slight variations in some dimensions are

ground smooth or otherwise removed. permitted, each shear plate manufacturer shall have available

5.1.2 Shear plates shall

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.