ASTM D6546-00

(Test Method)Standard Test Methods for and Suggested Limits for Determining Compatibility of Elastomer Seals for Industrial Hydraulic Fluid Applications

Standard Test Methods for and Suggested Limits for Determining Compatibility of Elastomer Seals for Industrial Hydraulic Fluid Applications

SCOPE

1.1 These test methods cover the procedure for measuring physical properties of elastomer seals in the form of O-rings after exposure to industrial hydraulic fluids and thermal aging. The measured properties are then compared to the physical properties of elastomer seals that have not been exposed to the industrial hydraulic fluids and thermal aging. The changes in these properties form a basis for assessing compatibility when these changes are compared against the suggested limits in .

1.2 While these test methods involve the use of O-rings, they can also be used to evaluate the compatibility of the elastomeric compounds of specialty seals with industrial hydraulic fluids and their resistance to thermal aging. The compounds can be molded into O-rings for evaluation purposes.

1.3 These test methods provide procedures for exposing O-ring test specimens to industrial hydraulic fluids under definite conditions of temperature and time. The resulting deterioration of the O-ring material is determined by comparing the changes in work function, hardness, physical properties, compression set, and seal volume after immersion in the test fluid to the pre-immersion values.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This test method covers the determination of the cure state of elastomers by DSC. It is based on Test Method D 5028. This test method is applicable to elastomers with adequate vulcanizers. The normal operating temperature range is from room temperature to 250C (482F), but not limited to such. All elastomers should be fully cured.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D6546–00

Standard Test Methods for

and Suggested Limits for Determining Compatibility of

Elastomer Seals for Industrial Hydraulic Fluid Applications

This standard is issued under the fixed designation D 6546; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 395 Test Methods for Rubber Property—Compression

Set

1.1 These test methods cover the procedure for measuring

D 412 Test Methods for Vulcanized Rubber and Thermo-

physical properties of elastomer seals in the form of O-rings

plastic Elastomers—Tension

after exposure to industrial hydraulic fluids and thermal aging.

D 471 Test Method for Rubber Property–Effect of Liquids

The measured properties are then compared to the physical

D 1414 Test Methods for Rubber O-Rings

properties of elastomer seals that have not been exposed to the

D 2000 Classification System for Rubber Products inAuto-

industrial hydraulic fluids and thermal aging. The changes in

motive Applications

these properties form a basis for assessing compatibility when

D 2240 Test Method for Rubber Property—Durometer

these changes are compared against the suggested limits in

Hardness

Table 1.

D 3677 Test Methods for Rubber—Identification by Infra-

1.2 While these test methods involve the use of O-rings,

red Spectrophotometry

they can also be used to evaluate the compatibility of the

D 3767 Practice for Rubber—Measurement of Dimensions

elastomeric compounds of specialty seals with industrial hy-

D 5028 Test Method for Curing Properties of Pultrusion

draulic fluids and their resistance to thermal aging. The

Resins by Thermal Analysis

compounds can be molded into O-rings for evaluation pur-

E 1131 Test Method for Compositional Analysis by Ther-

poses.

mogravimetry

1.3 These test methods provide procedures for exposing

2.2 SAE Standard:

O-ring test specimens to industrial hydraulic fluids under

AS568A O-ring Sizes

definite conditions of temperature and time. The resulting

deterioration of the O-ring material is determined by compar-

3. Terminology

ing the changes in work function, hardness, physical proper-

3.1 Definitions:

ties, compression set, and seal volume after immersion in the

3.1.1 batch—all the O-rings molded from the same lot of

test fluid to the pre-immersion values.

material and presented for inspection at one time.

1.4 This standard does not purport to address all of the

3.1.2 compound—a fully formulated elastomer material

safety concerns, if any, associated with its use. It is the

containing all fillers and cross- linking agents.

responsibility of the user of this standard to establish appro-

3.1.3 fluid saturation effect—the absorption of fluid by the

priate safety and health practices and determine the applica-

elastomer until an equilibrium swell value is reached at a

bility of regulatory limitations prior to use.

particular temperature.

1.5 The values stated in SI units are to be regarded as the

3.1.4 O-ring—a rubber seal of homogeneous composition

standard. The values given in parentheses are for information

moldedinonepiecetotheconfigurationofatoruswithcircular

only.

cross section.

2. Referenced Documents 3.1.4.1 Discussion—O-rings are used as both dynamic and

static seals. The size of the O-ring is normally designated by a

2.1 ASTM Standards:

dashnumbercorrespondingtothesizetableslistedinAS568A.

The dimensions for the O-rings used in these test methods are

These test methods are under the jurisdiction of ASTM Committee D02 on

listed in Annex A2.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

3.1.5 ultimate elongation—the amount of stretch that the

D02.NO.09 on Compatibility.

O-ring is exposed to before breaking.

Current edition approved April 10, 2000. Published June 2000.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers, 400 Commonwealth Drive,

the ASTM website. Warrendale, PA 15096.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6546–00

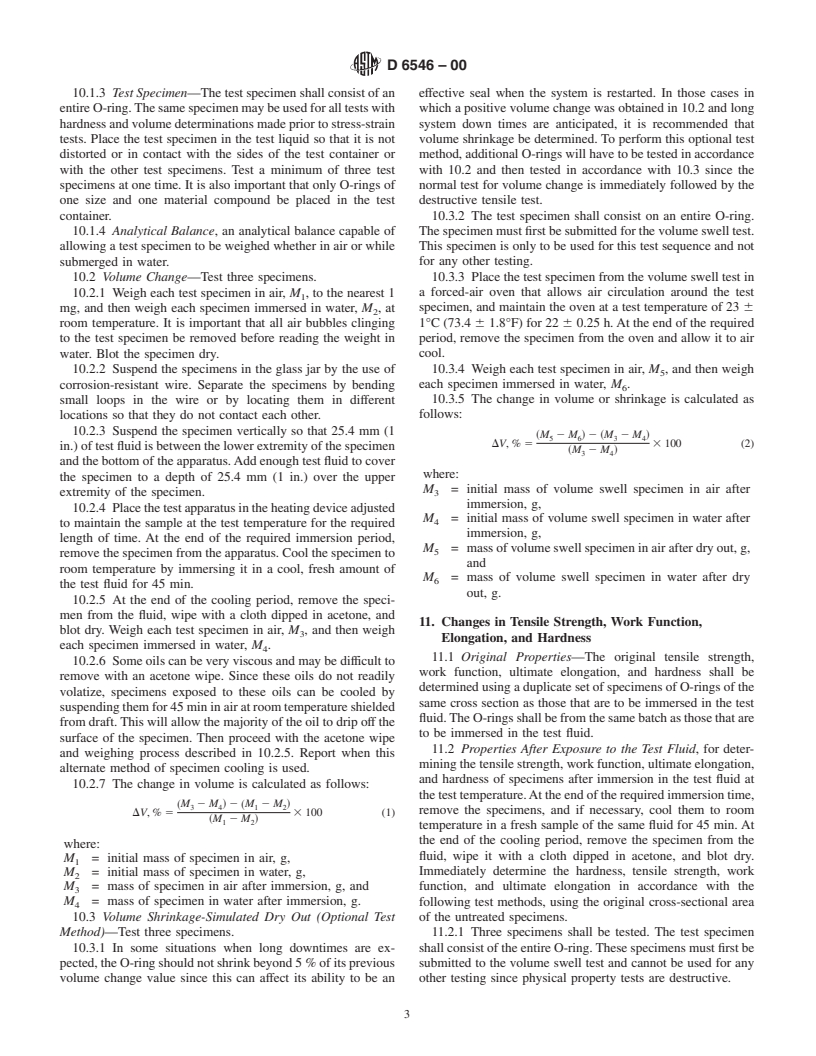

TABLE 1 Property Change Limits

Time, h Maxi- Maxi- Hardness Maxi- Maxi- Maxi- Maxi-

mum mum Change, mum mum mum mum

Volume Volume Shore A Tensile Elongation Work Compres-

Swell, Shrinkage, Points Strength Change, Function sion Set,

% % Change, % Change, %

% %

24 15 −3 67 −20 −20 612 .

70 15 −3 67 −20 −20 612 20

100 15 −3 68 −20 −20 612 20

250 15 −4 68 −20 −20 612 25

500 20 −4 610 −25 −25 617 30

1000 20 −5 610 −30 −30 620 35

3.1.6 work function—workdoneonatestspecimentocause previous immersion period. If the changes in the physical

20 % deformation. properties have deteriorated beyond the suggested limits, then

further testing is not required.The tolerance for any immersion

4. Significance and Use

period shall be 6 1 % of the immersion period.

4.1 When more than one elastomer seal material is tested,

7. Test Fluids

the test methods yield comparative data on which to base

judgementsastoexpectedservicequality.Suggestedin-service 7.1 For reliable compatibility assessments, it is desirable to

property change limits are provided. Property changes beyond use the fluid with which the elastomer will come in contact in

these limits will indicate limited service life of the elastomer actual service. For comparative tests, samples of fluid from the

seal. same drum or shipment shall be used.

4.2 These test methods attempt to simulate service condi-

8. Test Specimen

tions through controlled aging and evaluation of property

changes but may not give any direct correlations with actual 8.1 The test specimens shall be O-rings molded from the

part performance since actual service conditions vary widely. same compound batch from which the actual seals will be

These test methods yield comparative data and indications of molded.The test samples should approximate the cross section

property changes of the elastomeric seal material under ideal of the actual seal to be used so that the fluid saturation effect is

service conditions. These test methods can be used for quality

properly considered. The test samples should be either -021,

control purposes, for engineering assessments, for service -120, -214, or -320 O-rings, in accordance with AS568A.

evaluation, and for manufacturing control. The information

These have an approximate inside diameter of 25.4 mm (1 in.)

from these test methods can be used to anticipate expected and represent the most popular cross sections of seals used in

service quality.

industrial systems. The actual dimensions of each O-ring size

are listed in Annex A2.

5. General Test Methods

8.2 Test specimens shall be wiped clean of external con-

5.1 Except as otherwise specified, the test methods for taminants prior to testing by using a clean dry wipe.

rubber O-rings referred to in 5.1.1-5.1.6, which are applicable

9. Suggested Compatibility Test Limits

in general to vulcanized rubber, shall be complied with as

required and are hereby made a part of these test methods. 9.1 For a critical seal application, property change limits, as

5.1.1 Tension Test—Test Methods D 412 and D 1414. described in Table 1, should be observed.

5.1.2 Compression Set—Test Methods D 395 and D 1414. 9.2 All values are in reference to soak time in the opera-

5.1.3 Fluid Aging—Test Method D 471 and Test Methods tional fluid at the operating temperature of the application.

D 1414. Values reflect changes from the determined pre-immersion

5.1.4 Hardness—Test Method D 2240. original physical property values of the test specimens.

5.1.5 Compositional Analysis—Test Methods D 3677 and

9.3 If the changes are within these limits, the elastomer

Test Method E 1131. should be considered compatible. Once a seal material is found

5.1.6 Degree of Cure—Test Method D 5028. to be compatible, all seals for that system should be ordered by

5.2 In case of conflict between the provisions of theASTM specific compound or specification and not by Classification D

test methods referenced in 5.1.1-5.1.6 and the detailed provi- 200 call out number or generic polymer designation.

sions of the test methods in Test Methods D 6546, the latter

10. Procedure for Change in Volume

shall take precedence.

10.1 Apparatus:

6. Test Conditions

10.1.1 Test Container, a Mason jar (quart size) fitted with a

6.1 Temperature—The test temperature shall be the maxi- lid to prevent liquid and vapor from escaping. The lid shall not

mum sustained temperature anticipated in service. contaminate the test liquid. Cover the lid with aluminum foil.

6.2 Immersion Periods—The following immersion periods 10.1.2 Heating Device, a forced air oven, aluminum block

are recommended: 24 h, 72 h, 100 h, 250 h, 500 h, and 1000 h. heater, or oil bath heater. Maintain the temperature within 6

The final immersion period will depend upon the results of the 1°C (1.8°F).

D6546–00

10.1.3 Test Specimen—The test specimen shall consist of an effective seal when the system is restarted. In those cases in

entireO-ring.Thesamespecimenmaybeusedforalltestswith which a positive volume change was obtained in 10.2 and long

hardnessandvolumedeterminationsmadepriortostress-strain system down times are anticipated, it is recommended that

tests. Place the test specimen in the test liquid so that it is not volume shrinkage be determined. To perform this optional test

distorted or in contact with the sides of the test container or method,additionalO-ringswillhavetobetestedinaccordance

with the other test specimens. Test a minimum of three test with 10.2 and then tested in accordance with 10.3 since the

specimens at one time. It is also important that only O-rings of normal test for volume change is immediately followed by the

one size and one material compound be placed in the test destructive tensile test.

container. 10.3.2 The test specimen shall consist on an entire O-ring.

10.1.4 Analytical Balance, an analytical balance capable of Thespecimenmustfirstbesubmittedforthevolumeswelltest.

allowing a test specimen to be weighed whether in air or while This specimen is only to be used for this test sequence and not

submerged in water. for any other testing.

10.2 Volume Change—Test three specimens. 10.3.3 Place the test specimen from the volume swell test in

10.2.1 Weigh each test specimen in air, M , to the nearest 1 a forced-air oven that allows air circulation around the test

mg, and then weigh each specimen immersed in water, M,at specimen, and maintain the oven at a test temperature of 23 6

1°C (73.4 6 1.8°F) for 22 6 0.25 h.At the end of the required

room temperature. It is important that all air bubbles clinging

to the test specimen be removed before reading the weight in period, remove the specimen from the oven and allow it to air

cool.

water. Blot the specimen dry.

10.2.2 Suspend the specimens in the glass jar by the use of 10.3.4 Weigh each test specimen in air, M , and then weigh

each specimen immersed in water, M .

corrosion-resistant wire. Separate the specimens by bending

small loops in the wire or by locating them in different 10.3.5 The change in volume or shrinkage is calculated as

follows:

locations so that they do not contact each other.

10.2.3 Suspend the specimen vertically so that 25.4 mm (1

~M 2 M ! 2 ~M 2 M !

5 6 3 4

DV,% 5 3 100 (2)

in.) of test fluid is between the lower extremity of the specimen

~M 2 M !

3 4

and the bottom of the apparatus.Add enough test fluid to cover

where:

the specimen to a depth of 25.4 mm (1 in.) over the upper

M = initial mass of volume swell specimen in air after

extremity of the specimen. 3

immersion, g,

10.2.4 Placethetestapparatusintheheatingdeviceadjusted

M = initial mass of volume swell specimen in water after

to maintain the sample at the test temperature for the required

immersion, g,

length of time. At the end of the required immersion period,

M = massofvolumeswellspecimeninairafterdryout,g,

remove the specimen from the apparatus. Cool the specimen to

and

room temperature by immersing it in a cool, fresh amount of

M = mass of volume swell specimen in water after dry

the test fluid for 45 min.

out, g.

10.2.5 At the end of the cooling period, remove the speci-

men from the fluid, wipe with a cloth dipped in acetone, and

11. Changes in Tensile Strength, Work Function,

blot dry. Weigh each test specimen in air, M , and then weigh

Elongation, and Hardness

each specimen immersed in water, M .

11.1 Original Properties—The original tensile strength,

10.2.6 Some oils can be very viscous and may be difficult to

work function, ultimate elongation, and hardness shall be

remove with an acetone wipe. Since these oils do not readily

determined using a duplicate set of specimens of O-rings of the

volatize, specimens exposed to these oils can be cooled by

same cross section as those that are to be immersed in the test

suspendingthemfor45mininairatroomtemperatureshielded

fluid.TheO-ringsshallbefromthesamebatchasthosethatare

from draft.This will allow the majority of the oil to drip off the

to be immersed in the test fluid.

surface of the specimen. Then proceed with the acetone wipe

11.2 Properties After Exposure to the Test Fluid, for deter-

and weighing process described in 10.2.5. Report when this

mining the tensile strength, work function, ultimate elongation,

alternate method of specimen cooling is used.

and hardness of specimens after immersion in the test fluid at

10.2.7 The change in volume is calculated as follows:

thetesttemperature.Attheendoftherequiredimmersiontime,

~M 2 M ! 2 ~M 2 M !

3 4 1 2

remove the specimens, and if necessary, cool them to room

DV,% 5 3 100 (1)

~M 2 M !

1 2

temperature in a fresh sample of the same fluid for 45 min. At

the end of the cooling period, remove the specimen from the

where:

fluid, wipe it with a cloth dipped in acetone, and blot dry.

M = initial mass of specimen in air, g,

Immediately determine the hardness, tensile strength, work

M = initial mass of specimen in water, g,

M = mass of specimen in air after immersion, g, and function, and ultimate elongation in accordance with the

M = mass of specimen in water after immersion, g.

following test methods, using the original cross-sectional area

10.3 Volume Shrinkage-Simulated Dry Out (Optional Test of the untreated specimens.

Method)—Test three specimens.

11.2.1 Three specimens shall be tested. The test specimen

10.3.1 In some situations

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.